PDF Publication Title:

Text from PDF Page: 004

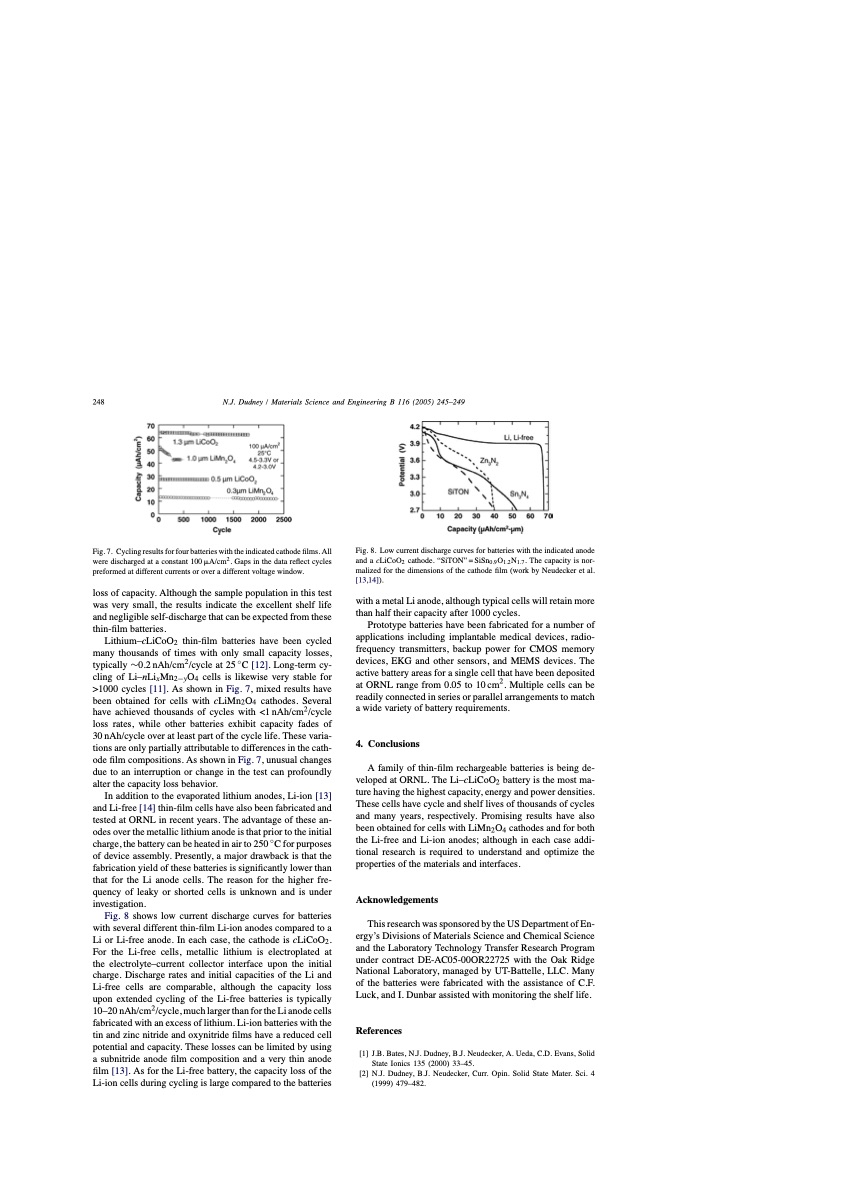

248 N.J. Dudney / Materials Science and Engineering B 116 (2005) 245–249 Fig. 7. Cycling results for four batteries with the indicated cathode films. All were discharged at a constant 100A/cm2. Gaps in the data reflect cycles preformed at different currents or over a different voltage window. loss of capacity. Although the sample population in this test was very small, the results indicate the excellent shelf life and negligible self-discharge that can be expected from these thin-film batteries. Lithium–cLiCoO2 thin-film batteries have been cycled many thousands of times with only small capacity losses, typically ∼0.2 nAh/cm2/cycle at 25 ◦C [12]. Long-term cy- cling of Li–nLixMn2−yO4 cells is likewise very stable for >1000 cycles [11]. As shown in Fig. 7, mixed results have been obtained for cells with cLiMn2O4 cathodes. Several have achieved thousands of cycles with <1nAh/cm2/cycle loss rates, while other batteries exhibit capacity fades of 30 nAh/cycle over at least part of the cycle life. These varia- tions are only partially attributable to differences in the cath- ode film compositions. As shown in Fig. 7, unusual changes due to an interruption or change in the test can profoundly alter the capacity loss behavior. In addition to the evaporated lithium anodes, Li-ion [13] and Li-free [14] thin-film cells have also been fabricated and tested at ORNL in recent years. The advantage of these an- odes over the metallic lithium anode is that prior to the initial charge, the battery can be heated in air to 250 ◦C for purposes of device assembly. Presently, a major drawback is that the fabrication yield of these batteries is significantly lower than that for the Li anode cells. The reason for the higher fre- quency of leaky or shorted cells is unknown and is under investigation. Fig. 8 shows low current discharge curves for batteries with several different thin-film Li-ion anodes compared to a Li or Li-free anode. In each case, the cathode is cLiCoO2. For the Li-free cells, metallic lithium is electroplated at the electrolyte–current collector interface upon the initial charge. Discharge rates and initial capacities of the Li and Li-free cells are comparable, although the capacity loss upon extended cycling of the Li-free batteries is typically 10–20 nAh/cm2/cycle, much larger than for the Li anode cells fabricated with an excess of lithium. Li-ion batteries with the tin and zinc nitride and oxynitride films have a reduced cell potential and capacity. These losses can be limited by using a subnitride anode film composition and a very thin anode film [13]. As for the Li-free battery, the capacity loss of the Li-ion cells during cycling is large compared to the batteries Fig. 8. Low current discharge curves for batteries with the indicated anode and a cLiCoO2 cathode. “SiTON” = SiSn0.9 O1.2 N1.7 . The capacity is nor- malized for the dimensions of the cathode film (work by Neudecker et al. [13,14]). with a metal Li anode, although typical cells will retain more than half their capacity after 1000 cycles. Prototype batteries have been fabricated for a number of applications including implantable medical devices, radio- frequency transmitters, backup power for CMOS memory devices, EKG and other sensors, and MEMS devices. The active battery areas for a single cell that have been deposited at ORNL range from 0.05 to 10cm2. Multiple cells can be readily connected in series or parallel arrangements to match a wide variety of battery requirements. 4. Conclusions A family of thin-film rechargeable batteries is being de- veloped at ORNL. The Li–cLiCoO2 battery is the most ma- ture having the highest capacity, energy and power densities. These cells have cycle and shelf lives of thousands of cycles and many years, respectively. Promising results have also been obtained for cells with LiMn2O4 cathodes and for both the Li-free and Li-ion anodes; although in each case addi- tional research is required to understand and optimize the properties of the materials and interfaces. Acknowledgements This research was sponsored by the US Department of En- ergy’s Divisions of Materials Science and Chemical Science and the Laboratory Technology Transfer Research Program under contract DE-AC05-00OR22725 with the Oak Ridge National Laboratory, managed by UT-Battelle, LLC. Many of the batteries were fabricated with the assistance of C.F. Luck, and I. Dunbar assisted with monitoring the shelf life. References [1] J.B. Bates, N.J. Dudney, B.J. Neudecker, A. Ueda, C.D. Evans, Solid State Ionics 135 (2000) 33–45. [2] N.J. Dudney, B.J. Neudecker, Curr. Opin. Solid State Mater. Sci. 4 (1999) 479–482.PDF Image | Solid-state thin-film rechargeable batteries

PDF Search Title:

Solid-state thin-film rechargeable batteriesOriginal File Name Searched:

120311.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |