PDF Publication Title:

Text from PDF Page: 346

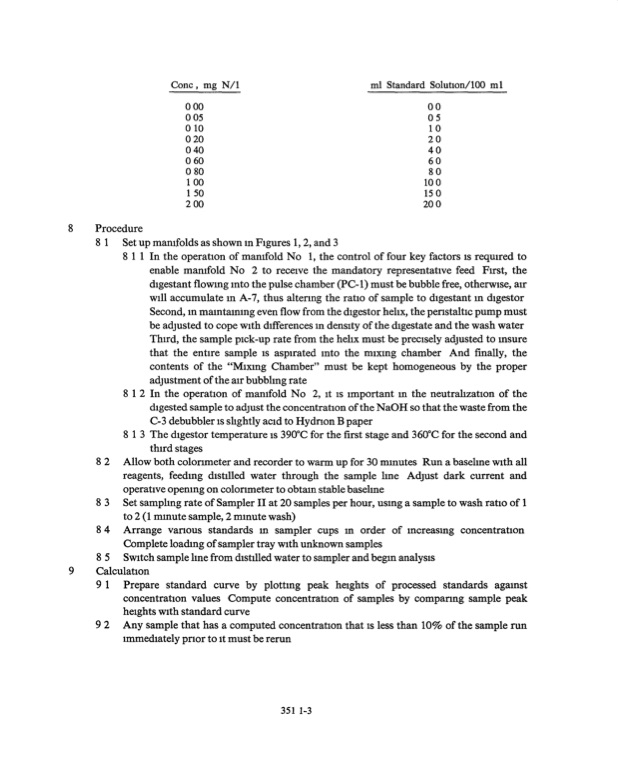

8 Procedure 9 82 83 84 85 CalculatlOn 8 1 Set up mamfolds as shown m FIgures 1, 2, and 3 8 1 1 In the operatlOn of mamfold No 1, the control of four key factors IS reqUlred to enable mamfold No 2 to receIve the mandatory representatIve feed FIrst, the dIgestant flowmg mto the pulse chamber (PC-1) must be bubble free, otherWIse, aIr WIll accumulate m A-7, thus altenng the ratlO of sample to dIgestant m dlgestor Second, m mamtammg even flow from the dlgestor hehx, the penstaltlc pump must be adjusted to cope WIth dIfferences m denSIty of the dlgestate and the wash water ThIrd, the sample pIck-up rate from the hehx must be precIsely adjusted to msure that the entIre sample IS aspIrated mto the mlxmg chamber And finally, the contents of the "Mlxmg Chamber" must be kept homogeneous by the proper adjustment of the atr bubbhng rate 8 12 In the operatlOn of mamfold No 2, It IS Important m the neutrahzatlOn of the dIgested sample to adjust the concentratlOn ofthe NaOH so that the waste from the C-3 debubbler IS shghtly aCId to Hydnon B paper 8 1 3 The dlgestor temperature IS 390°C for the first stage and 360°C for the second and thIrd stages Allow both colonmeter and recorder to warm up for 30 mmutes Run a baselme WIth all reagents, feedmg dIstIlled water through the sample hne Adjust dark current and operatIve openmg on colonmeter to obtam stable basehne Set samphng rate of Sampler II at 20 samples per hour, usmg a sample to wash ratIO of 1 to 2 (1 mmute sample, 2 mmute wash) Arrange vanous standards m sampler cups tn order of mcreasmg concentratlOn Complete loadmg ofsampler tray WIth unknown samples SWItch sample hne from dIstIlled water to sampler and begm analySIS Prepare standard curve by plottmg peak heIghts of processed standards agamst concentratlOn values Compute concentratIon of samples by comparmg sample peak heIghts WIth standard curve Any sample that has a computed concentratIon that IS less than 10% of the sample run ImmedIately pnor to It must be rerun 9 1 92 Cone, mg N/l 000 005 010 020 040 060 080 100 150 200 ml Standard Solutl0n/100 ml 00 05 10 20 40 60 80 100 150 200 351 1-3PDF Image | Methods for Chemical Analysis of Water and Wastes

PDF Search Title:

Methods for Chemical Analysis of Water and WastesOriginal File Name Searched:

epa600_4_79_020.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |