PDF Publication Title:

Text from PDF Page: 004

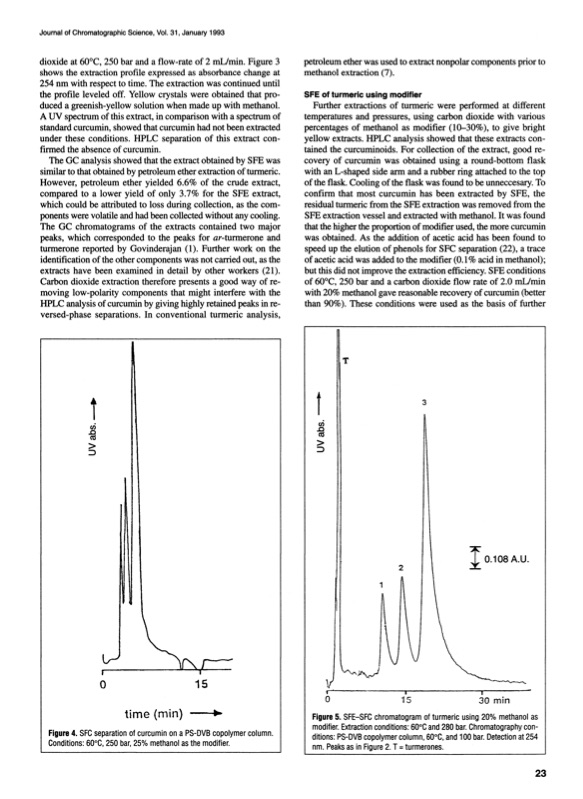

Journal of Chromatographic Science, Vol. 31, January 1993 dioxide at 60°C, 250 bar and a flow-rate of 2 mL/min. Figure 3 shows the extraction profile expressed as absorbance change at 254 n m with respect to time. The extraction was continued until the profile leveled off. Yellow crystals were obtained that pro duced a greenish-yellow solution when made up with methanol. A U V spectrum of this extract, in comparison with a spectrum of standard curcumin, showed that curcumin had not been extracted under these conditions. HPLC separation of this extract con firmed the absence of curcumin. The G C analysis showed that the extract obtained by SFE was similar to that obtained by petroleum ether extraction of turmeric. However, petroleum ether yielded 6.6% of the crude extract, compared to a lower yield of only 3.7% for the SFE extract, which could be attributed to loss during collection, as the com ponents were volatile and had been collected without any cooling. The GC chromatograms of the extracts contained two major peaks, which corresponded to the peaks for ar-turmerone and turmerone reported by Govinderajan (1). Further work on the identification of the other components was not carried out, as the extracts have been examined in detail by other workers (21). Carbon dioxide extraction therefore presents a good way of re moving low-polarity components that might interfere with the HPLC analysis of curcumin by giving highly retained peaks in re versed-phase separations. In conventional turmeric analysis, petroleum ether was used to extract nonpolar components prior to methanol extraction (7). SFE of turmeric using modifier Further extractions of turmeric were performed at different temperatures and pressures, using carbon dioxide with various percentages of methanol as modifier (10-30%), to give bright yellow extracts. HPLC analysis showed that these extracts con tained the curcuminoids. For collection of the extract, good re covery of curcumin was obtained using a round-bottom flask with an L-shaped side arm and a rubber ring attached to the top of the flask. Cooling ofthe flask was found tobeunneccesary. To confirm that most curcumin has been extracted by SFE, the residual turmeric from the SFE extraction was removed from the SFE extraction vessel and extracted with methanol. It was found that the higher the proportion of modifier used, the more curcumin was obtained. A s the addition of acetic acid has been found to speed up the elution of phenols for SFC separation (22), a trace of acetic acid was added to the modifier (0.1% acid in methanol); but this did not improve the extraction efficiency. SFE conditions of 60°C, 250 bar and a carbon dioxide flow rate of 2.0 mL/min with 20% methanol gave reasonable recovery of curcumin (better than 90%). These conditions were used as the basis of further Figure 4. SFC separation of curcumin on a PS-DVB copolymer column. Conditions: 60°C, 250 bar, 25% methanol as the modifier. Figure 5. SFE-SFC chromatogram of turmeric using 20% methanol as modifier. Extraction conditions: 60°C and 280 bar. Chromatography con ditions: PS-DVB copolymer column, 60°C, and 100 bar. Detection at 254 nm. Peaks as in Figure 2. Τ = turmerones. 23PDF Image | Supercritical Fluid Extraction Turmeric

PDF Search Title:

Supercritical Fluid Extraction TurmericOriginal File Name Searched:

turmeric-supercritical-co2-extraction.pdfDIY PDF Search: Google It | Yahoo | Bing

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

Heat Pumps CO2 ORC Heat Pump System Platform More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |