PDF Publication Title:

Text from PDF Page: 013

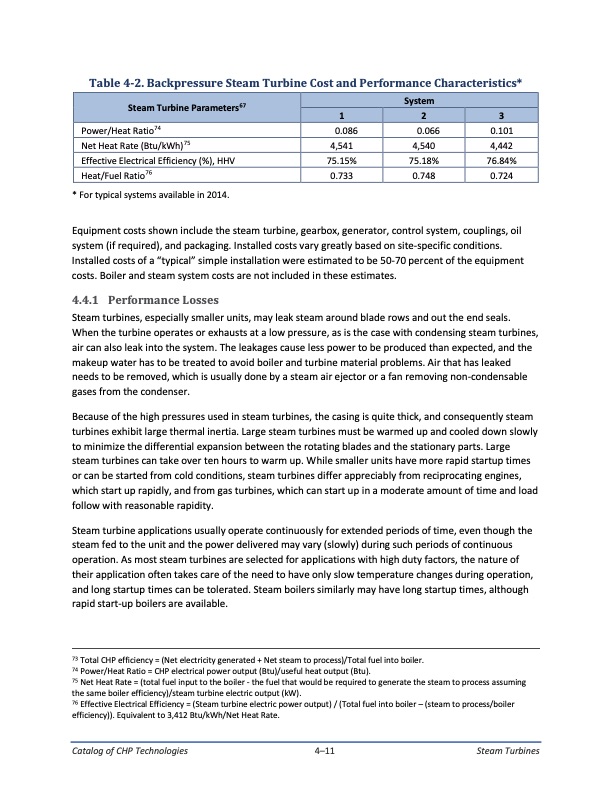

Table 4-2. Backpressure Steam Turbine Cost and Performance Characteristics* Steam Turbine Parameters67 System 1 2 3 Power/Heat Ratio74 Net Heat Rate (Btu/kWh)75 Effective Electrical Efficiency (%), HHV Heat/Fuel Ratio76 * For typical systems available in 2014. 0.086 4,541 75.15% 0.733 0.066 4,540 75.18% 0.748 0.101 4,442 76.84% 0.724 Equipment costs shown include the steam turbine, gearbox, generator, control system, couplings, oil system (if required), and packaging. Installed costs vary greatly based on site-specific conditions. Installed costs of a “typical” simple installation were estimated to be 50-70 percent of the equipment costs. Boiler and steam system costs are not included in these estimates. 4.4.1 Performance Losses Steam turbines, especially smaller units, may leak steam around blade rows and out the end seals. When the turbine operates or exhausts at a low pressure, as is the case with condensing steam turbines, air can also leak into the system. The leakages cause less power to be produced than expected, and the makeup water has to be treated to avoid boiler and turbine material problems. Air that has leaked needs to be removed, which is usually done by a steam air ejector or a fan removing non-condensable gases from the condenser. Because of the high pressures used in steam turbines, the casing is quite thick, and consequently steam turbines exhibit large thermal inertia. Large steam turbines must be warmed up and cooled down slowly to minimize the differential expansion between the rotating blades and the stationary parts. Large steam turbines can take over ten hours to warm up. While smaller units have more rapid startup times or can be started from cold conditions, steam turbines differ appreciably from reciprocating engines, which start up rapidly, and from gas turbines, which can start up in a moderate amount of time and load follow with reasonable rapidity. Steam turbine applications usually operate continuously for extended periods of time, even though the steam fed to the unit and the power delivered may vary (slowly) during such periods of continuous operation. As most steam turbines are selected for applications with high duty factors, the nature of their application often takes care of the need to have only slow temperature changes during operation, and long startup times can be tolerated. Steam boilers similarly may have long startup times, although rapid start-up boilers are available. 73 Total CHP efficiency = (Net electricity generated + Net steam to process)/Total fuel into boiler. 74 Power/Heat Ratio = CHP electrical power output (Btu)/useful heat output (Btu). 75 Net Heat Rate = (total fuel input to the boiler - the fuel that would be required to generate the steam to process assuming the same boiler efficiency)/steam turbine electric output (kW). 76 Effective Electrical Efficiency = (Steam turbine electric power output) / (Total fuel into boiler – (steam to process/boiler efficiency)). Equivalent to 3,412 Btu/kWh/Net Heat Rate. Catalog of CHP Technologies 4–11 Steam TurbinesPDF Image | EPA CHP Technologies Combustion Turbines Section 4

PDF Search Title:

EPA CHP Technologies Combustion Turbines Section 4Original File Name Searched:

catalog_of_chp_technologies_section_4._technology_characterization_-_steam_turbines.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |