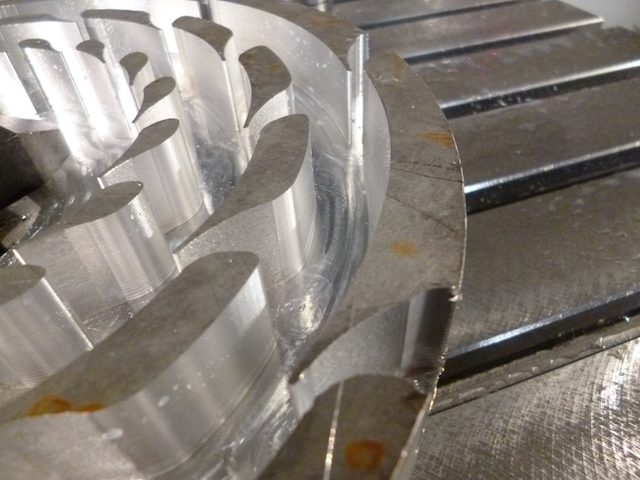

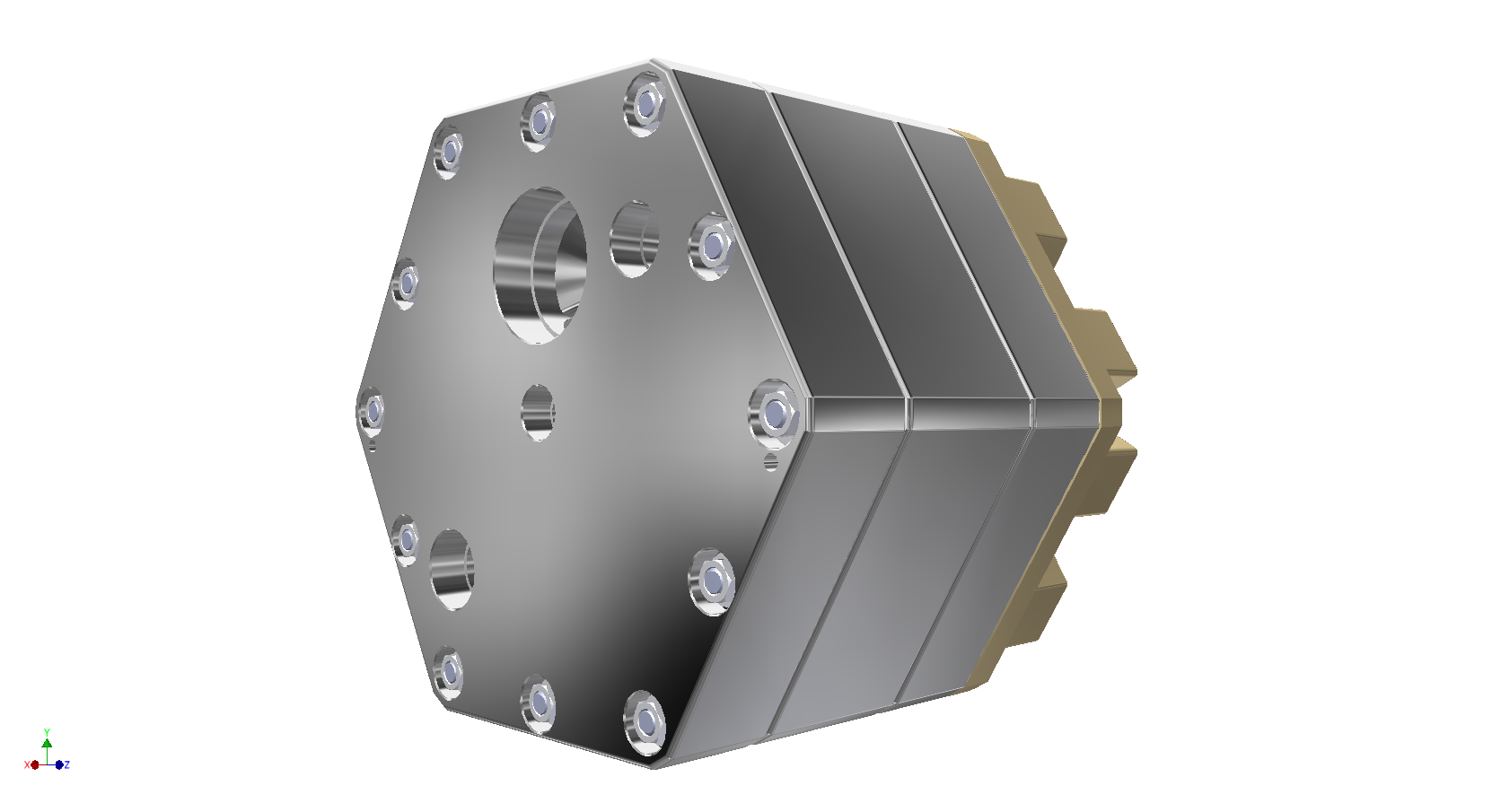

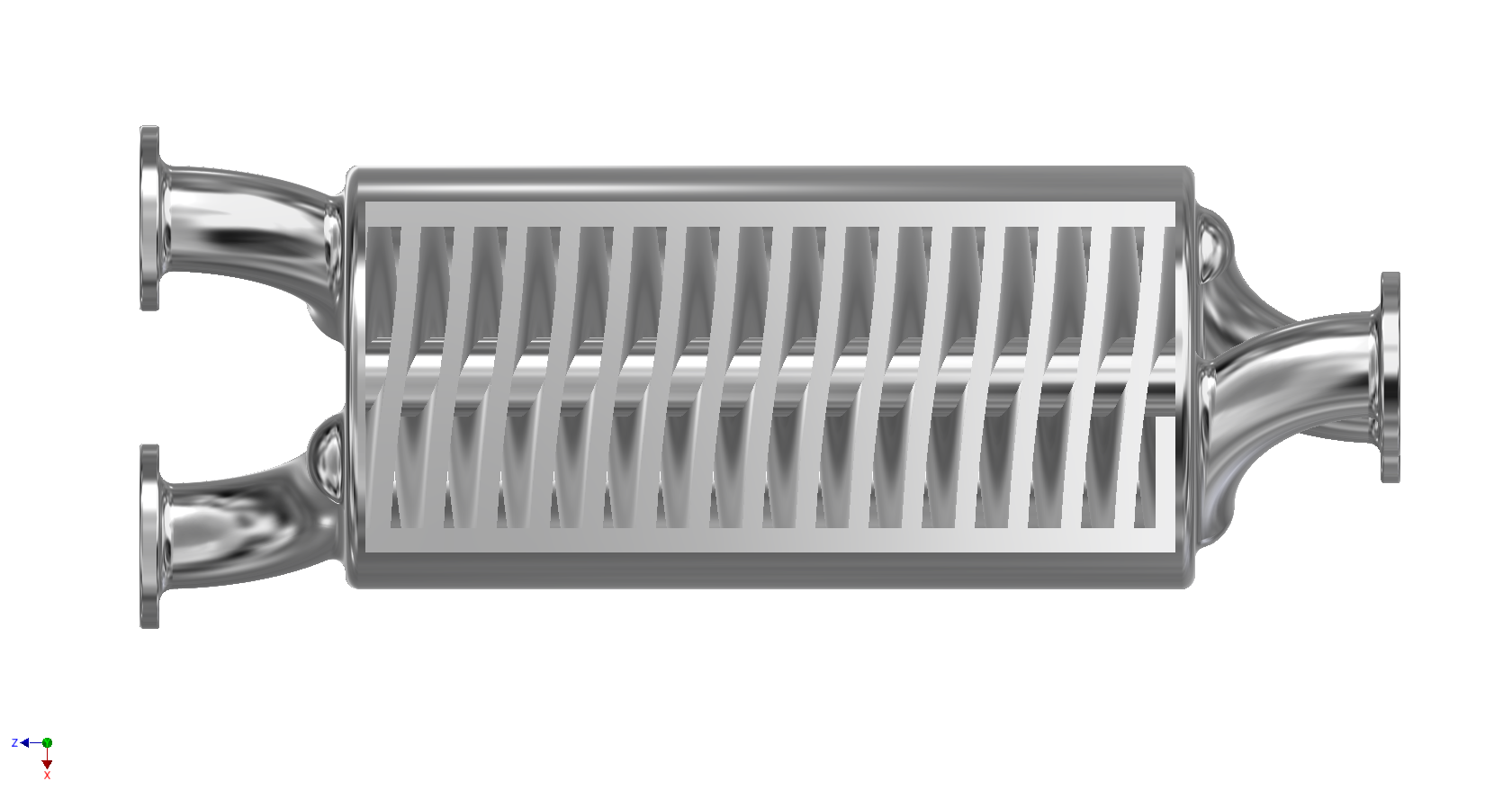

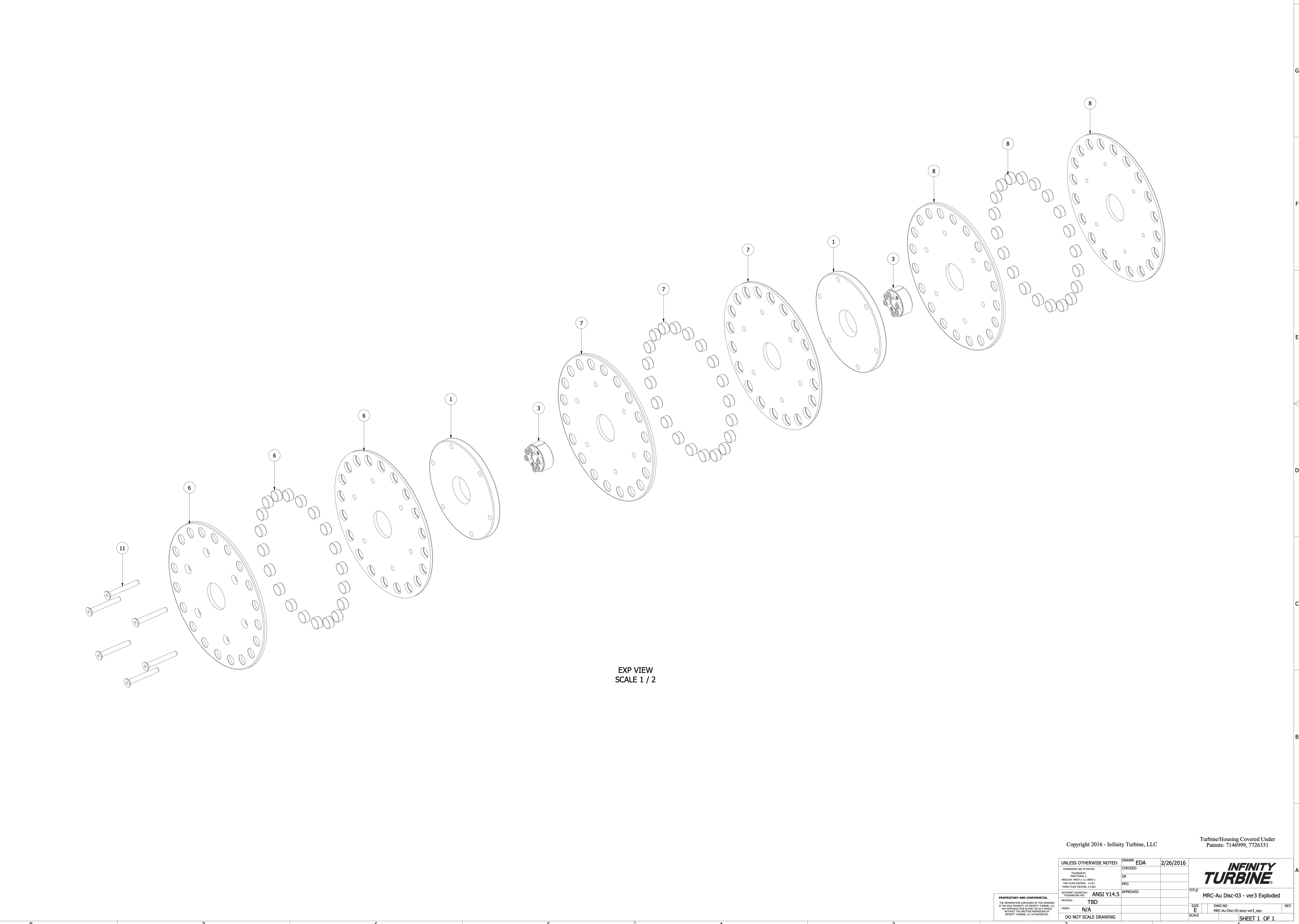

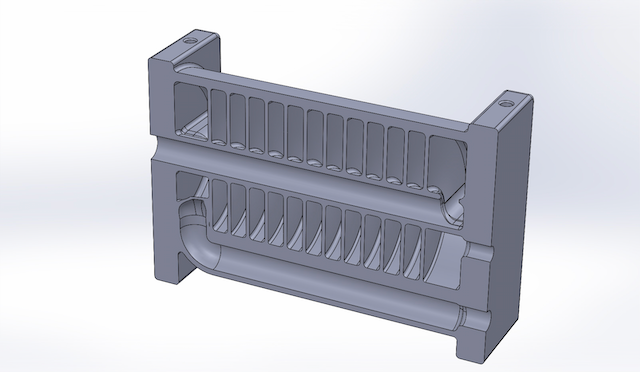

ROT24 Turbine Assembly

ROT24 Radial Outflow Turbine AC Induction Generator Plans and Blueprints

ROT 24 can be used for IT50 and IT250. With dual configuration can be used for 600 kW or larger. ROT 24 Information

We develop technology. You license | Build | Sell to your Customers. We can get you customers, even build your website. You build the technology... More Info

The Micro Robots are Coming: Our newest project making miniature robots for working and making electrodes for our new Saltwater Battery... More Info

Saltwater Battery: Our Salgenx Saltwater Battery and Desalination... More Info

Heat Pump Turbine: High COP heat pump that drives a turboshaft for AI cooling and hydraulic power... More Info

Coming Soon: The Filemaker AI Assistant does the work of 5 people... More Info

ROT24 Turbine Assembly |

ROT24 Radial Outflow Turbine AC Induction Generator Plans and Blueprints ROT 24 can be used for IT50 and IT250. With dual configuration can be used for 600 kW or larger. ROT 24 Information |

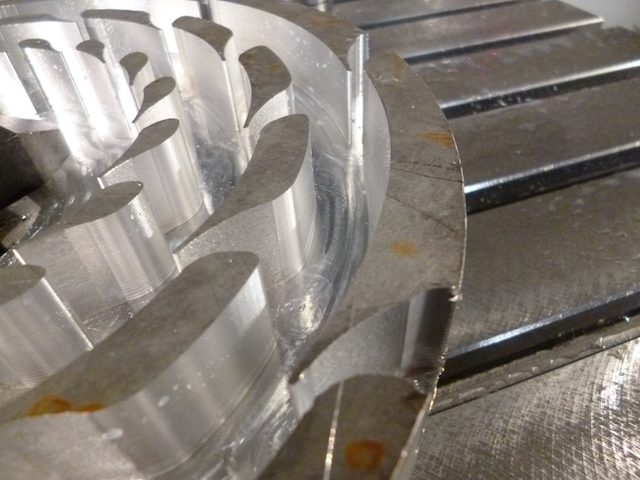

IT50 System Performance |

IT50 System Plans Infinity offers both the ROT turbine plans and the IT50 system plans as a separate package.We recommend the ROT24 for the IT50, even if it is derated.Design Heat Exchangers ASME Rated Pressure - Evaporator R-245fa: 450 psi at 300 F shell side, and 150 psi 300 F on tube side. Welding procedures included. Condenser R-245fa: 450 psi at 250 F shell side, and 150 psi 250F on tube side. Turbine may be used most efficiently at 50 kW, but may also be used for a range of turbines from 30 kW to over 100 kW.IT50 Revenue based on gross sales or savings, not including cost of acquiring waste heat flow or pumps.Revenue from IT50 (24 hours x 365 days per year x 50 kWh = 438,000 kWh per year):at $.20 per kWh = $87,600 USD per yearat $.50 per kWh = $219,000 USD per yearat $1.00 per kWh = $438,000 USD per year Plans Option for IT50 System |

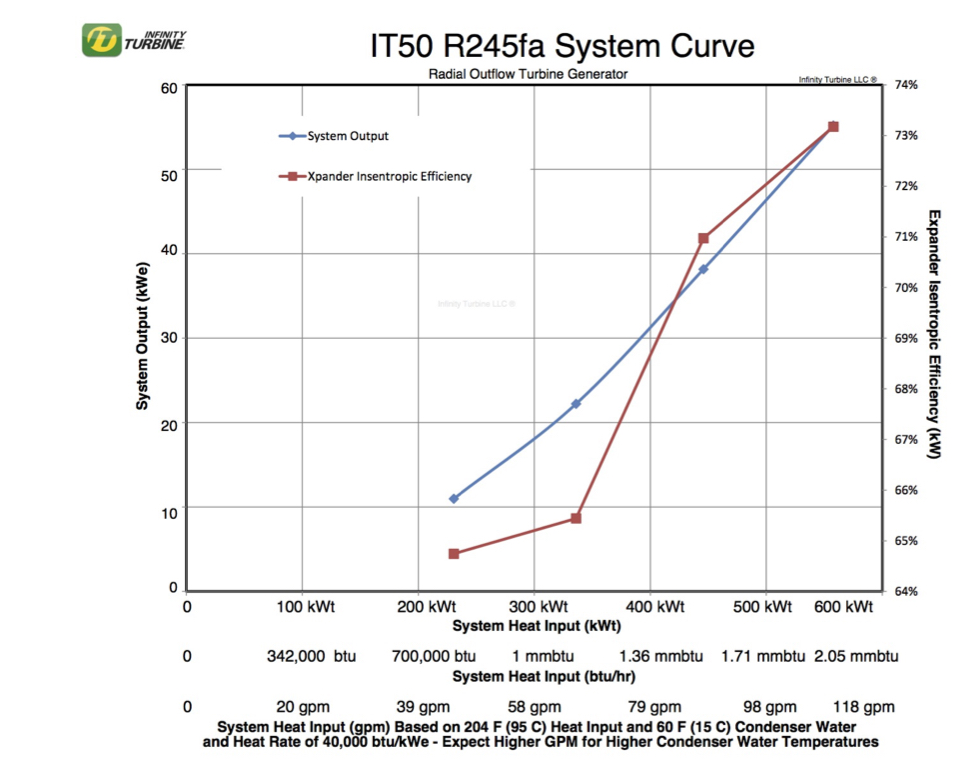

IT50 System |

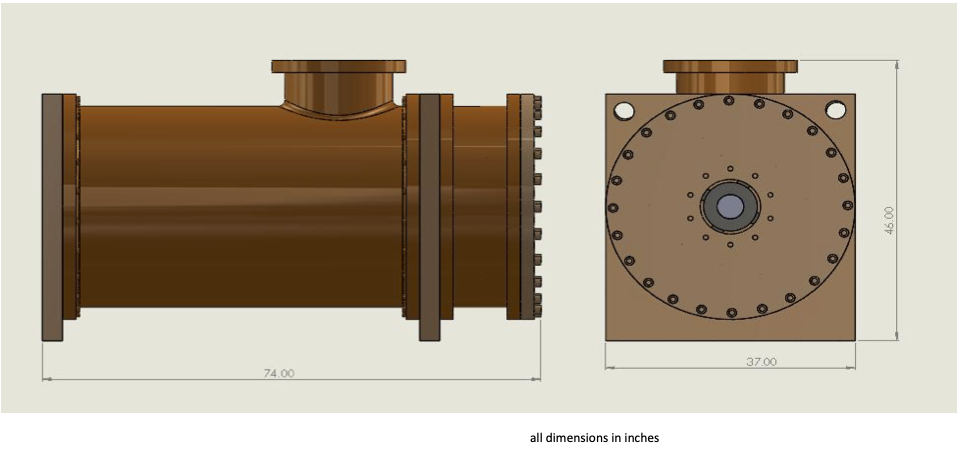

Infinity Turbine IT50 System for AC Power from Waste Heat The IT50 is designed to produce 50 kW of AC power (typically configured for a Grid-Tie connection). We have produced several IT50 systems in the past few years. They take about 6 months to complete, and can be shipped in a standard 20 ft. shipping container.Currently we can complete this build through our sub-contractor who builds ASME certified pressure tested heat exchangers in Toronto, Canada, and ship anywhere in the world. Design Heat Exchangers ASME Rated Pressure - Evaporator R-245fa: 450 psi at 300 F shell side, and 150 psi 300 F on tube side. Welding procedures included. Condenser R-245fa: 450 psi at 250 F shell side, and 150 psi 250F on tube side. Turbine may be used most efficiently at 50 kW, but may also be used for a range of turbines from 30 kW to over 100 kW.IT50 Revenue based on gross sales or savings, not including cost of acquiring waste heat flow or pumps.Revenue from IT50 (24 hours x 365 days per year x 50 kWh = 438,000 kWh per year):at $.20 per kWh = $87,600 USD per yearat $.50 per kWh = $219,000 USD per yearat $1.00 per kWh = $438,000 USD per year IT50 Information |

|

IT250 System Plans Infinity offers both the ROT turbine plans and the IT250 system plans as a separate package.We recommend the ROT24 for the IT250.Design Heat Exchangers ASME Rated Pressure - Evaporator R-245fa: 450 psi at 300 F shell side, and 150 psi 300 F on tube side. Welding procedures included. Condenser R-245fa: 450 psi at 250 F shell side, and 150 psi 250F on tube side. IT250 Revenue based on gross sales or savings, not including cost of acquiring waste heat flow or pumps.Revenue from IT250 (24 hours x 365 days per year x 250 kWh = 2,190,000 kWh per year):at $.20 per kWh = $438,000 USD per yearat $.40 per kWh = $876,000 USD per yearat $.80 per kWh = $1,752,000 USD per year IT250 System Information |

IT250 System |

IT250 250-300 kW Waste Heat to Energy System The IT250 is designed to produce 250 kW net AC power (typically configured for a Grid-Tie connection). We have produced one IT250 system in the. They take about 6-12 months to complete, and can be shipped in a open top 20 ft. shipping container.Currently we can complete this build through our sub-contractor who builds ASME certified pressure tested heat exchangers in Toronto, Canada, and ship anywhere in the world. IT250 Revenue based on gross sales or savings, not including cost of acquiring waste heat flow or pumps.Revenue from IT250 (24 hours x 365 days per year x 250 kWh = 2,190,000 kWh per year):at $.20 per kWh = $438,000 USD per yearat $.40 per kWh = $876,000 USD per yearat $.80 per kWh = $1,752,000 USD per year IT250 Information |

rot 06 turbine |

ROT06 Turbine Generator Plans and Blueprints Pricing: Please refer to price list or email. ROT06 Information |

ROT15 Turbine Assembly |

ROT15 Radial Outflow Turbine AC Induction Generator Plans and Blueprints Perfect for IT10 and higher. ROT15 Information |

Infinity Turbine axial turbine |

Axial Turbine Plans Download:The plans include images of each component in (jpg/png) and .pdf views.The machine ready files include dwg, dxf, xt and we can provide other files on request from our AutoDesk suite of Cad/Cam software.The files are provided by download.The license is for the turbine blueprints only, and does not include any support (optional).If you would like system blueprints (bill of materials, heat exchangers, pump/motor, frame, piping, etc.) for our Supercritical CO2 or standard R245fa, or R134a, please contact Infinity. Axial Turbine Information |

IT10 kW System |

IT10 kW ORC System Waste Heat Power: For years we’ve been hearing requests from customers who would like to use their waste heat to generate power, both on land and marine applications. To meet that demand, we formed Infinity Turbine LLC in 2008 and developed the IT10, the worlds first production 10 kw ORC (Organic Rankine Cycle) waste heat to power generator. New developments in CO2 Brayton Cycle may allow efficiencies to reach 30-50 percent, but only for high grade heat (way above 300 F). This is a huge increase from the legacy ORC process which has a system efficiency (bottoming cycle) of 5-15 percent). We now offer a CO2 Turbine Development Platform for educators and energy developers.Revenue based on gross sales or grid savings, not including cost of acquiring waste heat flow or pumps.Revenue from IT10 (24 hours x 365 days per year x 10 kWh = 87,600 kWh per year):at $.20 per kWh = $17,520 USD per yearat $.40 per kWh = $35,040 USD per yearat $.80 per kWh = $70,080 USD per year IT10 Information |

IT10 System Plans |

IT10 System Plans IT10 ORC Plans • System Blueprints (combine with turbine generator)The plans include images of each component in (jpg/png) and .pdf views.The machine ready files include dwg, dxf, xt and we can provide other files on request from our AutoDesk suite of Cad/Cam software. The files are provided by a FTP download.The license is for the system blueprints only, and does not include any support (optional).Revenue based on gross sales or grid savings, not including cost of acquiring waste heat flow or pumps.Revenue from IT10 (24 hours x 365 days per year x 10 kWh = 87,600 kWh per year):at $.20 per kWh = $17,520 USD per yearat $.40 per kWh = $35,040 USD per yearat $.80 per kWh = $70,080 USD per year IT10 System Information |

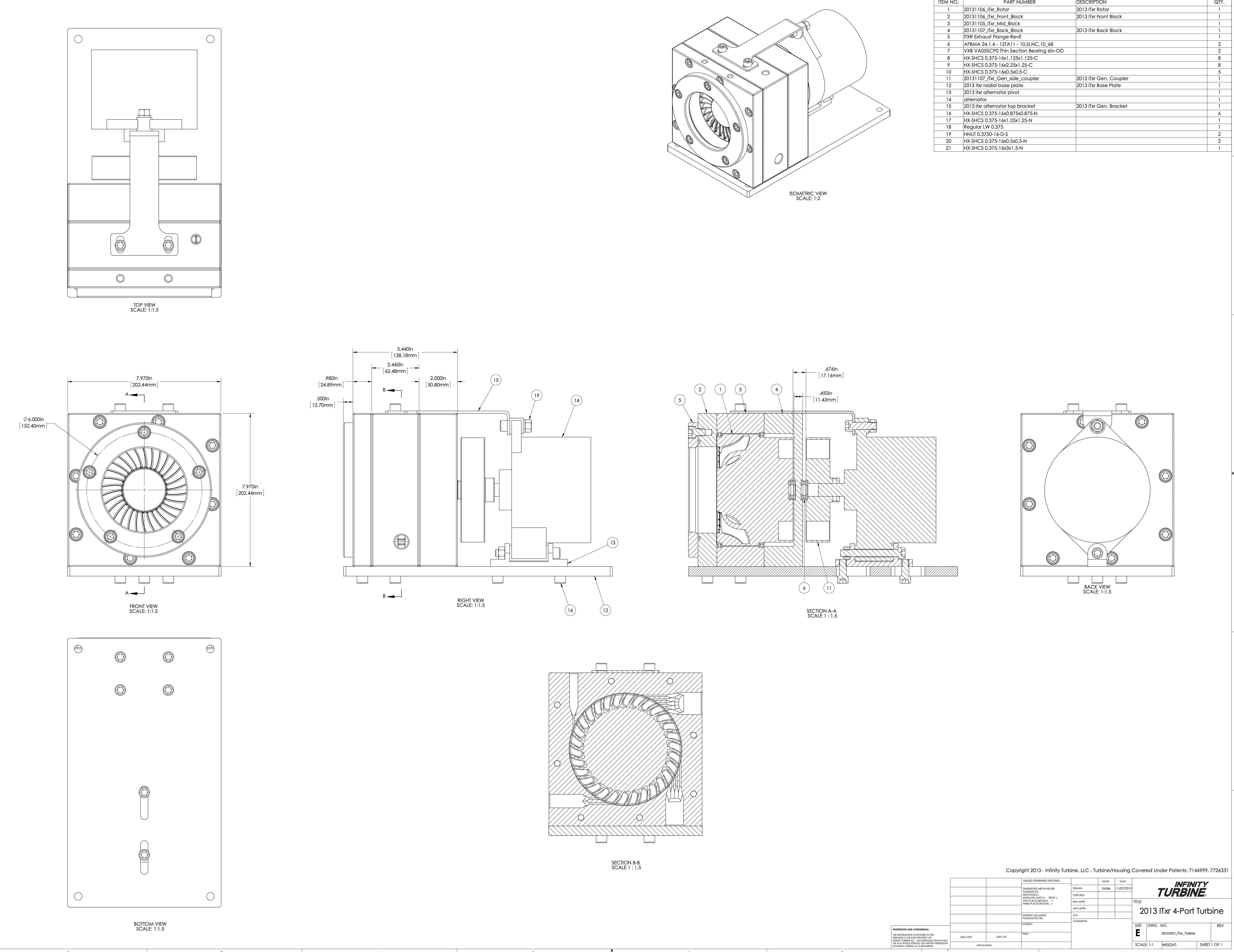

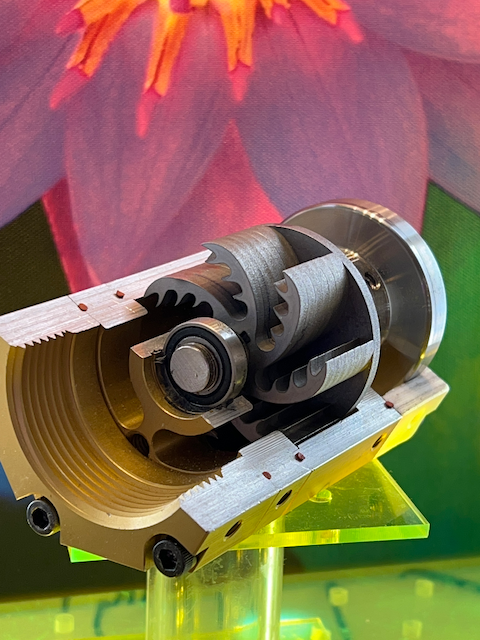

ROT12 Turbine Assembly installed in a IT10 System |

ROT12 Radial Outflow Turbine DC Generator The ROT12 Radial Outflow Turbine with DC Generator was designed for the IT10 system. IT10 Revenue based on gross sales or grid savings, not including cost of acquiring waste heat flow or pumps.Revenue from IT10 (24 hours x 365 days per year x 10 kWh = 87,600 kWh per year):at $.20 per kWh = $17,520 USD per yearat $.40 per kWh = $35,040 USD per yearat $.80 per kWh = $70,080 USD per year ROT12 Performance Chart (pdf) |

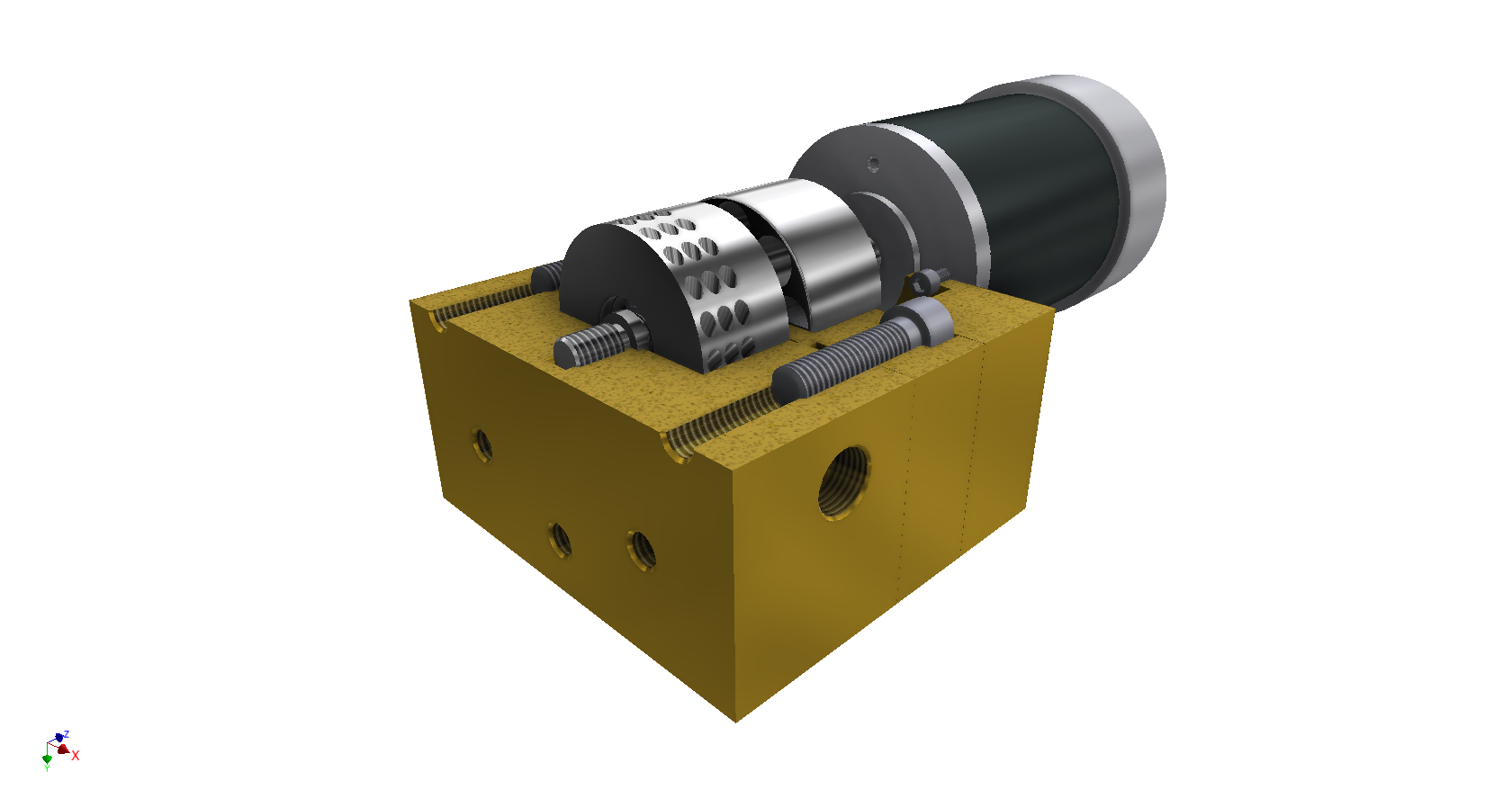

IT 10 Project Redstone Turbine with Integral Pump in One Rotating Element |

IT 10 Redstone Turbine The IT 10 Redstone Turbine is an experimental turbine designed for small scale power production for the home or low power applications (IT10 1-10 kW).Project Goals: Integrate a liquid pump into one rotating element. Instead of a common shaft driven feedpump, make the turbine counter-rotating in one piece.Working Fluid: R-245fa, R-134, Compressed Air, pressurized water, and a Stainless Steel version with CO2.Modular Block Assembly: Used since 2008, our Modular Block concept has been used in hundreds of turbine prototypes and production assemblies. This version uses square blocks with 3/8 fasteners and threaded bores.Purpose: Small power production without the need for a external feed pump.Rapid-Configuration: This assembly allows you to quickly configure turbines and test various working fluids and heat sources. The basic design is for 300 psi or less, which is determinant on the back magnetic coupling block which is made from HDPE. If you can make from nonmagnetic metal or composite fiber for a thicker (stronger) back, then you can use flows with greater pressure.Magnetic Coupling: The design has a basic 6 inch diameter magnetic coupling and follower, which allows you to have a generator or drive unit mounted exterior.IT10 Revenue based on gross sales or grid savings, not including cost of acquiring waste heat flow or pumps.Revenue from IT10 (24 hours x 365 days per year x 10 kWh = 87,600 kWh per year):at $.20 per kWh = $17,520 USD per yearat $.40 per kWh = $35,040 USD per yearat $.80 per kWh = $70,080 USD per year IT 10 Project Redstone Turbine with Integral Pump in One Rotating Element (pdf) |

Infinity Turbine 1 MW ROT Turbine with Two Stages |

Radial Outflow 1MW Turbine AC Induction Generator Plans and Blueprints Infinity Turbine now has available blueprints for a 1 megawatt ORC radial outflow turbine.IT1000 (2 MW) Revenue based on gross sales or savings, not including cost of acquiring waste heat flow or pumps.Revenue from IT250 (24 hours x 365 days per year x 1000 kWh = 8,760,000 kWh per year):at $.20 per kWh = $1,752,000 USD per yearat $.40 per kWh = $3,504,000 USD per yearat $.80 per kWh = $7,008,000 USD per year 1 MW Information |

12 Inch Radial Inflow Turbine |

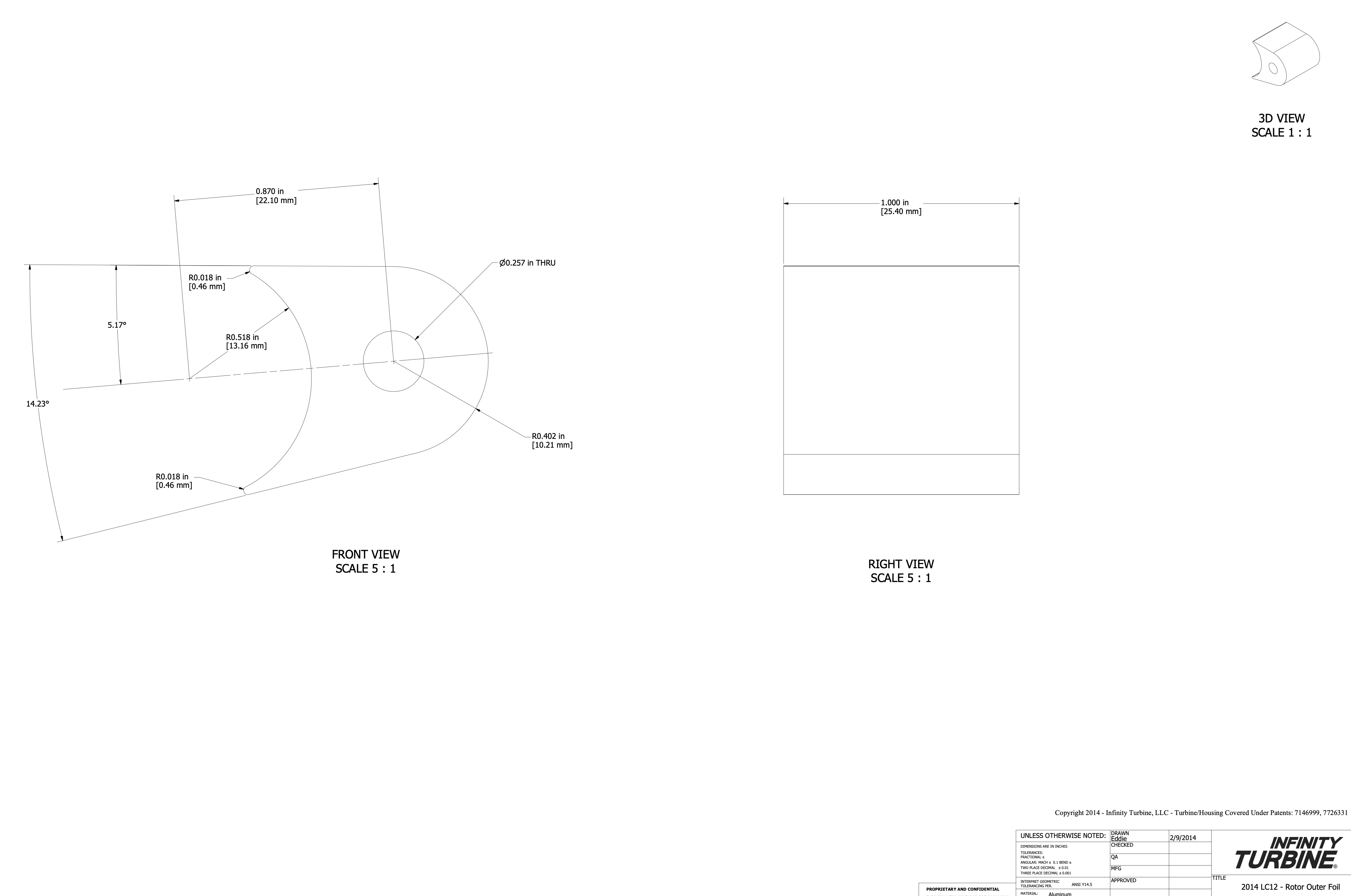

Radial Inflow 12 Inch Turbine The IT 10 Redstone Turbine is an experimental turbine designed for small scale power production for the home or low power applications (IT10 1-10 kW).Project Goals: Make turbine fabrication simple by cutting 2D parts via waterjet or laser, then bolt to plates to form a complete assembly.Working Fluid: R-245fa, R-134, Compressed Air, pressurized water, and a Stainless Steel version with CO2.Rapid-Configuration: This assembly allows you to quickly configure turbines and test various working fluids and heat sources. The basic design is for 300 psi or less.Magnetic Coupling or Large Diameter Gruvlok Pipe Housing Assembly: The unique design has a basic 12 inch diameter which allows for direct-to-motor generator mounting or magnetic coupling and follower, which allows you to have a generator or drive unit mounted exterior.IT10 Revenue based on gross sales or grid savings, not including cost of acquiring waste heat flow or pumps.Revenue from IT10 (24 hours x 365 days per year x 10 kWh = 87,600 kWh per year):at $.20 per kWh = $17,520 USD per yearat $.40 per kWh = $35,040 USD per yearat $.80 per kWh = $70,080 USD per year 12 Inch Radial Inflow Turbine Outer Rotor Foil (pdf) |

6 inch diameter IT XR Turbine |

IT XR Turbine The IT XR 6 inch diameter turbine is an experimental turbine designed for small scale power production for the home or low power applications (IT10 1-10 kW).Project Goals: Make turbine fabrication simple by 3D printing a one part turbine with perimeter bearings and back mounted magnetic coupling for generator coil or exterior shaft drive or motor generator.Common Shaft Drive: The magnetic coupler is bored into the rotor assembly, which allows coil power generation, or a magnetic follower disc for touchless shaft drive, or exterior motor generator options.Working Fluid: R-245fa, R-134, Compressed Air, pressurized water, and a Stainless Steel version with CO2.Rapid-Configuration: This assembly allows you to quickly configure turbines and test various working fluids and heat sources. The basic design is for 300 psi or less.Magnetic Coupling or Large Diameter Gruvlok Pipe Housing Assembly: The unique design has a basic 6 inch diameter which allows for direct-to-motor generator mounting or magnetic coupling and follower, which allows you to have a generator or drive unit mounted exterior.IT10 Revenue based on gross sales or grid savings, not including cost of acquiring waste heat flow or pumps.Revenue from IT10 (24 hours x 365 days per year x 10 kWh = 87,600 kWh per year):at $.20 per kWh = $17,520 USD per yearat $.40 per kWh = $35,040 USD per yearat $.80 per kWh = $70,080 USD per year 6 Inch IT XR Turbine (pdf) |

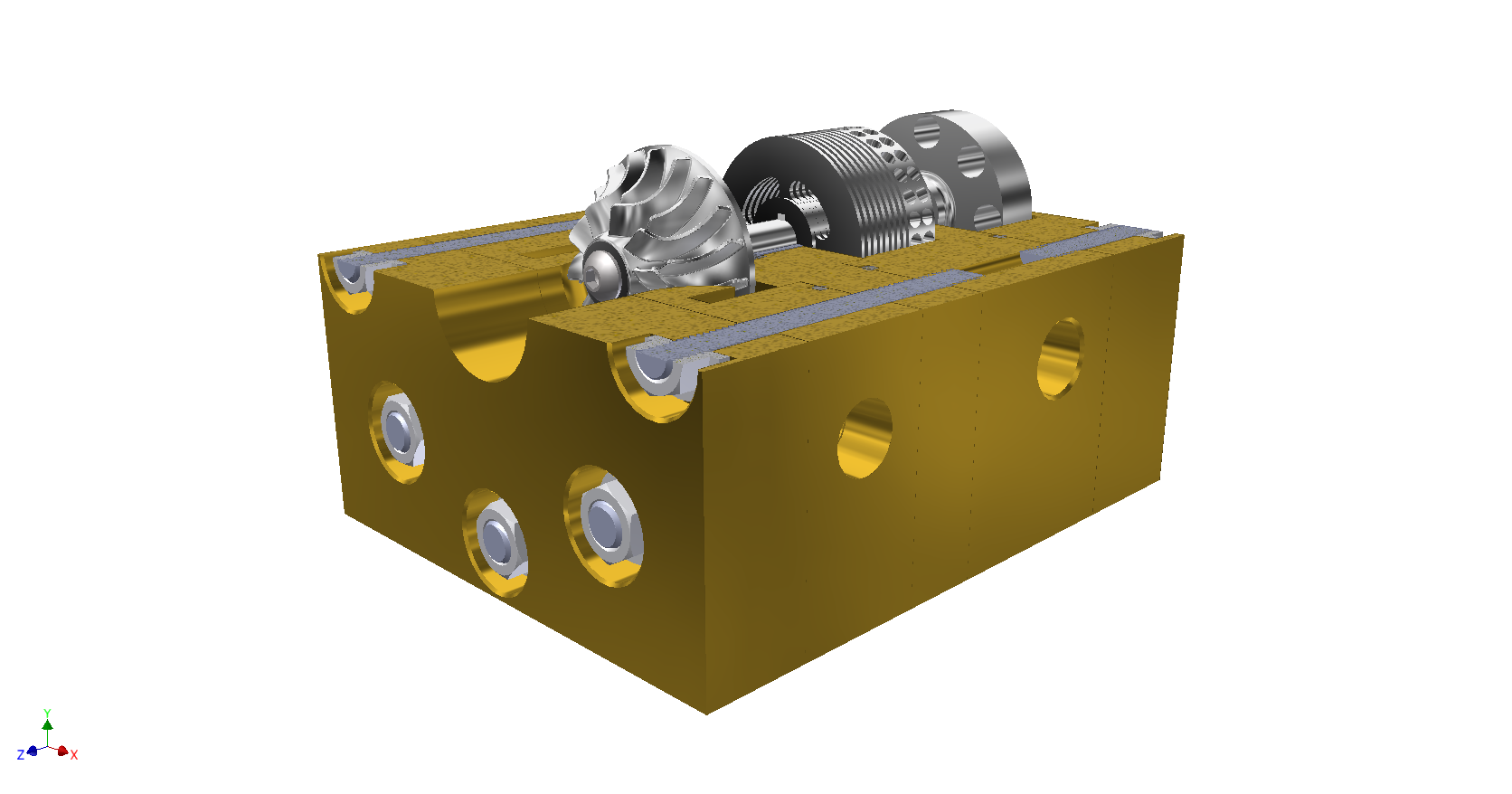

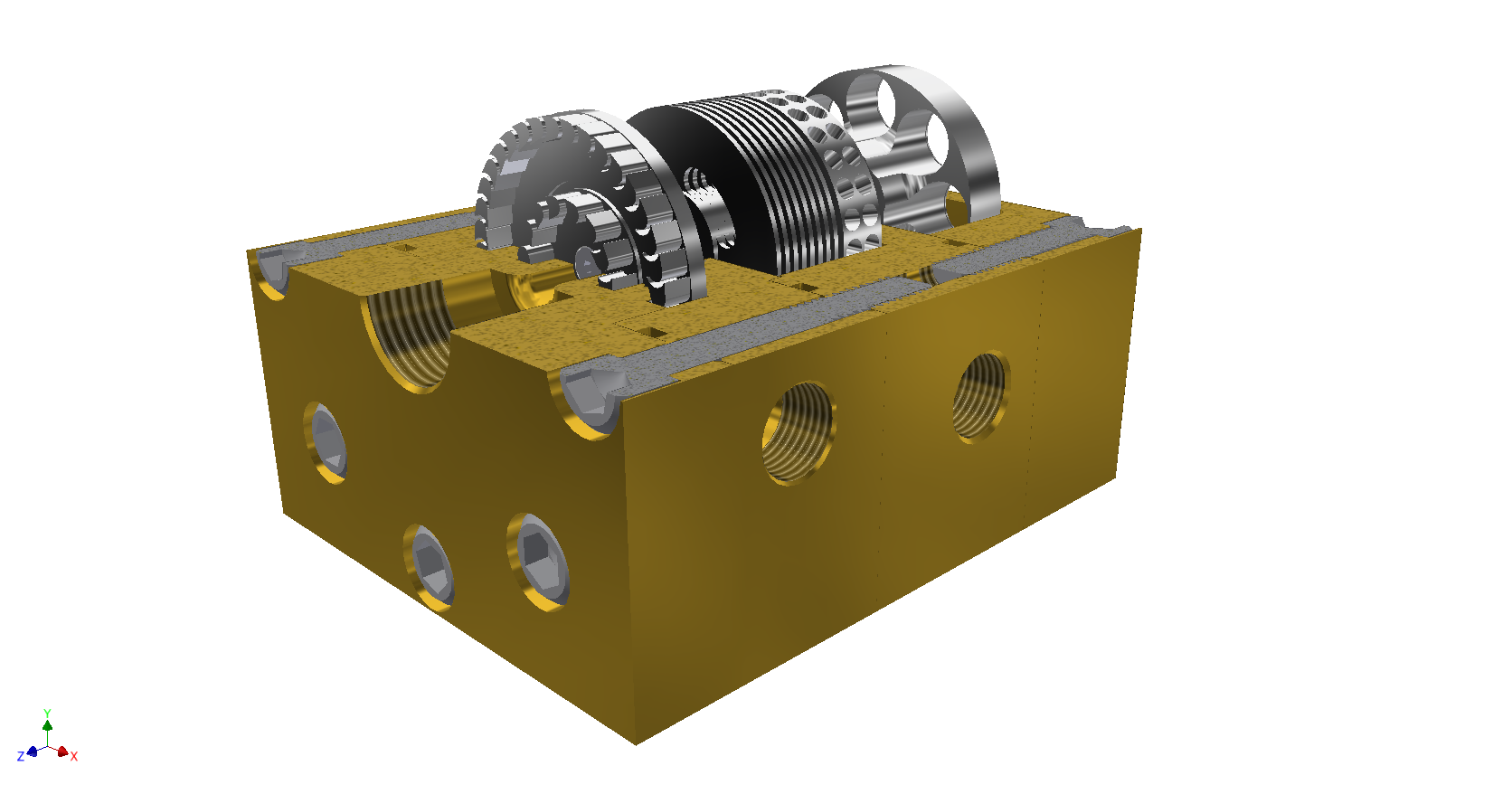

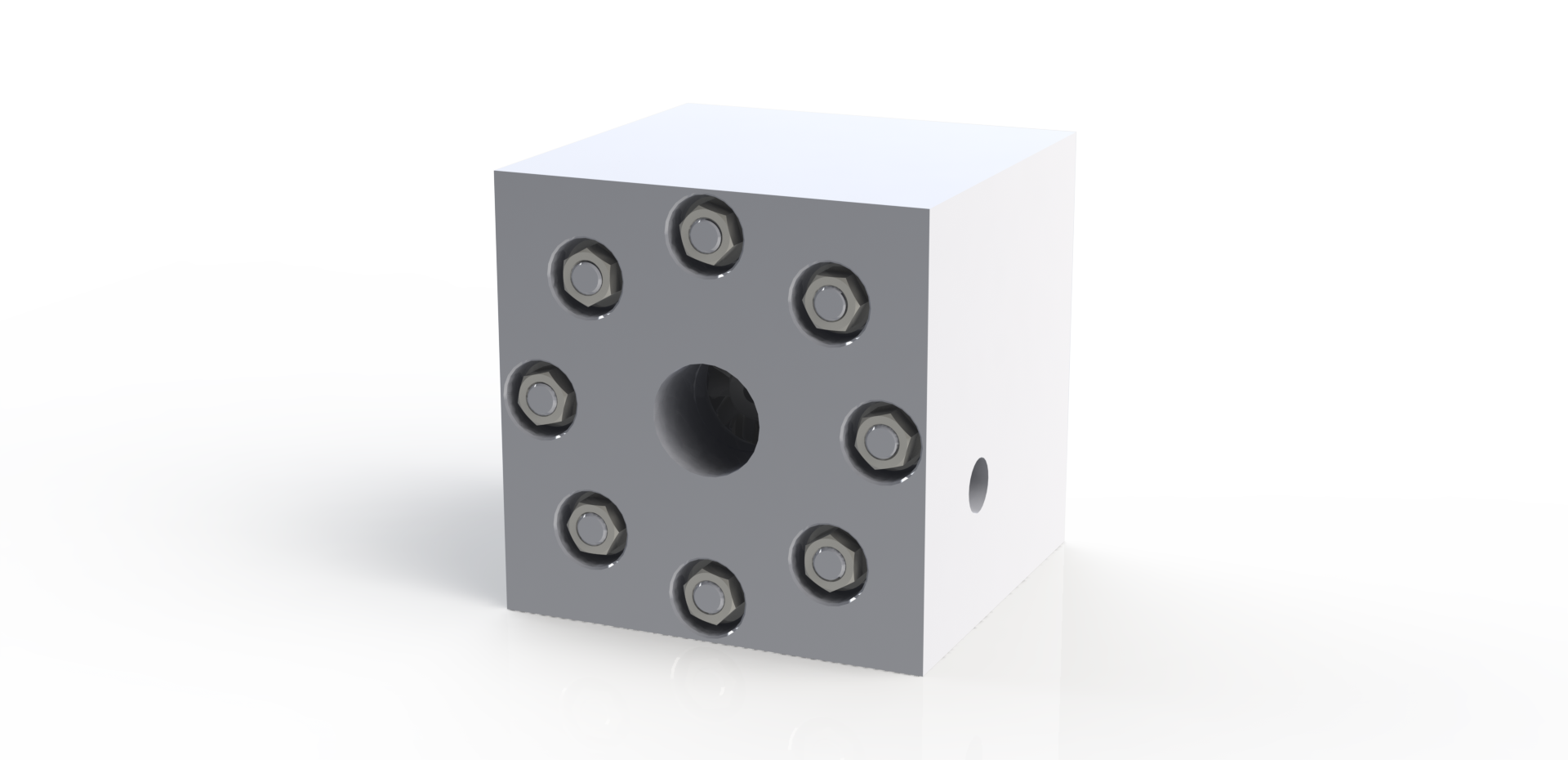

Example of Modular Block Turbine Housing |

Modular Block The modular fluid handling device has a central bore with fluid passages that extend between block faces, both horizontally and vertically. The blocks can be stacked horizontally, vertically, or both. Rotating elements can be configured in any of the passages for the purpose of pumping, extraction, or power production. Purpose: The functionality of the blocks is to perform rapid prototyping by deploying modular construction of systems using bolts.Standard Blocks: 3 inch size with 10/32 inch fasteners. 1 inch center bore and 1/4 and 1/2 inch horizontal bores.Larger Blocks: 6 inch size with 3/8 inch fasteners. 3 inch center bore and 1/4, 3/8, and 1/2 inch horizontal bores.Patents (I and II) cover all sizes and most applications. Modular Block Information |

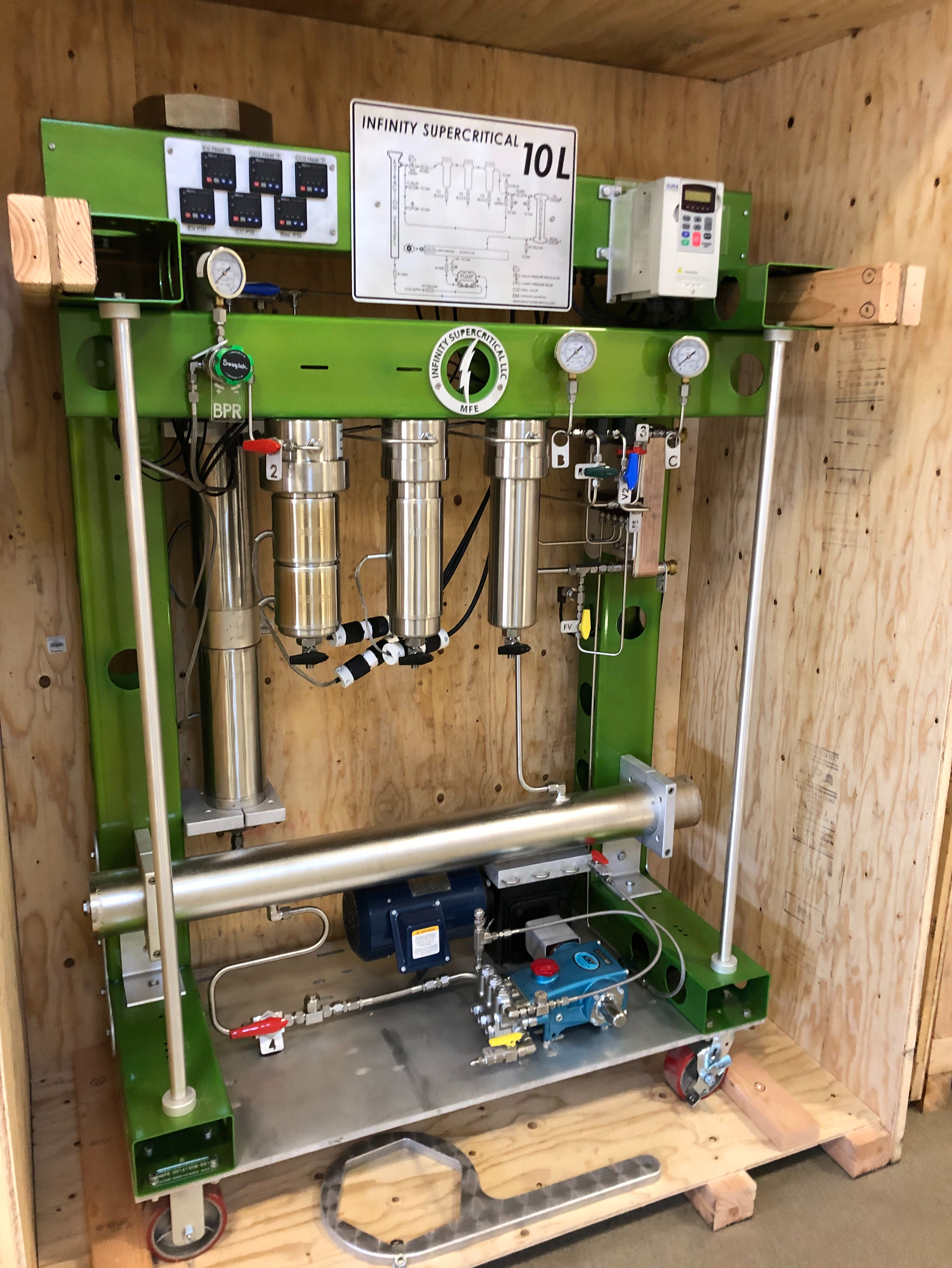

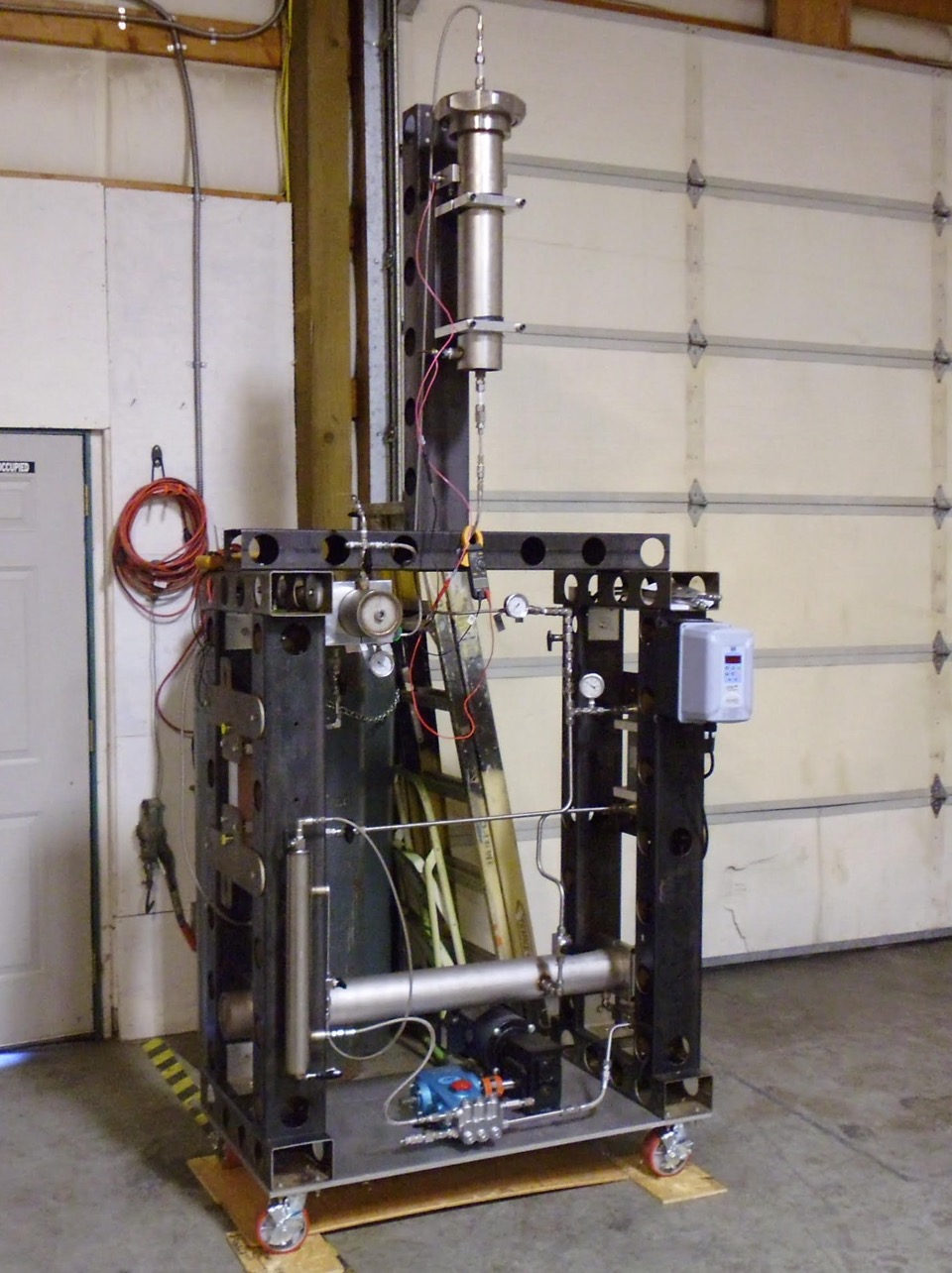

supercritical CO2 extraction |

Supercritical CO2 10L Extractor System Licensing Supercritical CO2 Extractor 10L system for botanical oil extraction.This system is built like a tank. Powder coated caster beams with 5 inch heavy duty casters for easy movement. This system is compact and will fit through any standard door, hallway, or elevator. System operation is manually set parameters, with automatic feedback PID to maintain temperature and pressure. Set it and watch the extraction.System is designed for maximum 2,000 psi operation. Most processors use 1,400 psi or less. Terpene extraction can be done running cold prior to turning on the heat for FSO extraction. This system is great for lavender, vanilla, pinene, and other valuable terp extractions. |

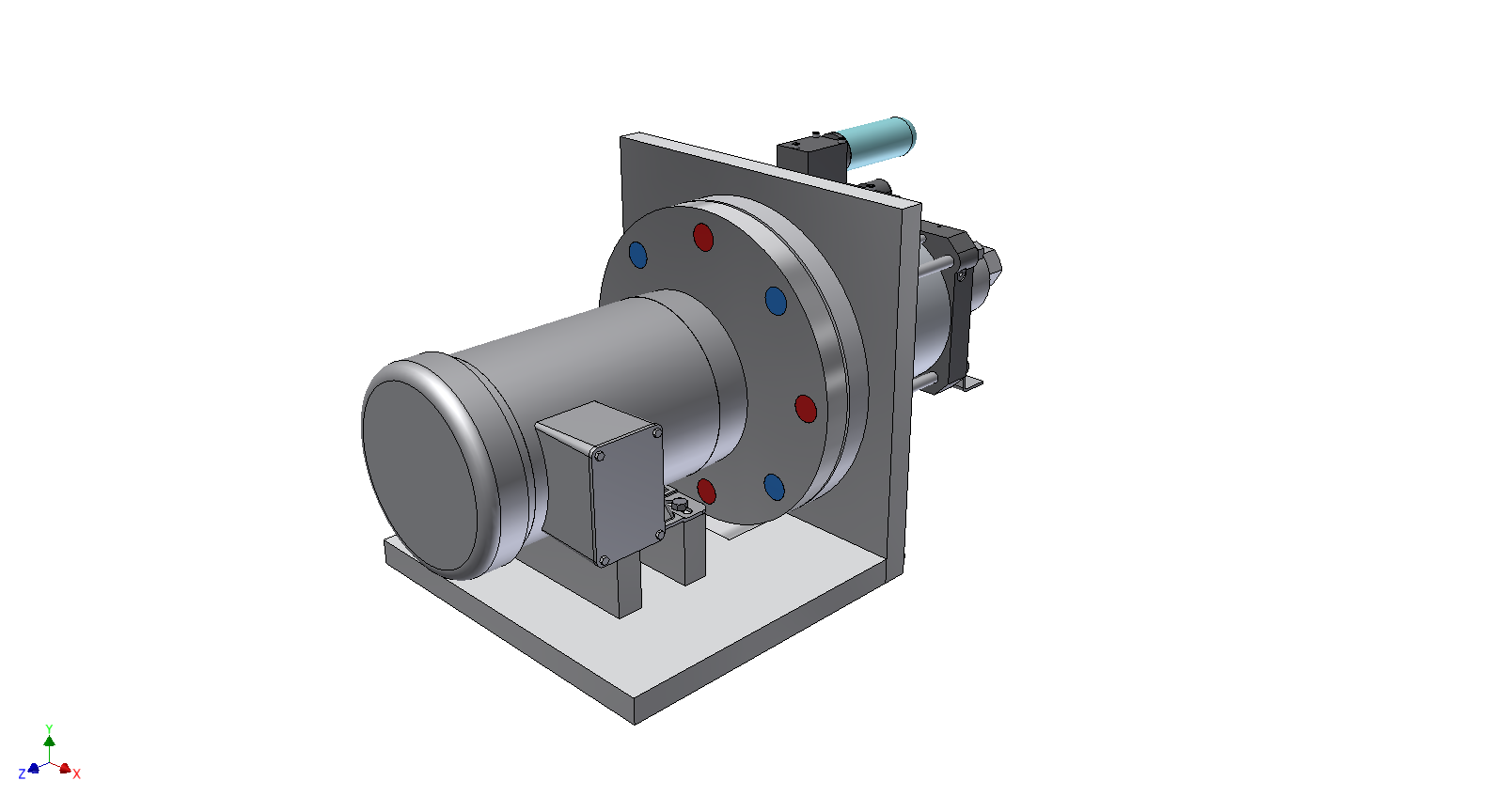

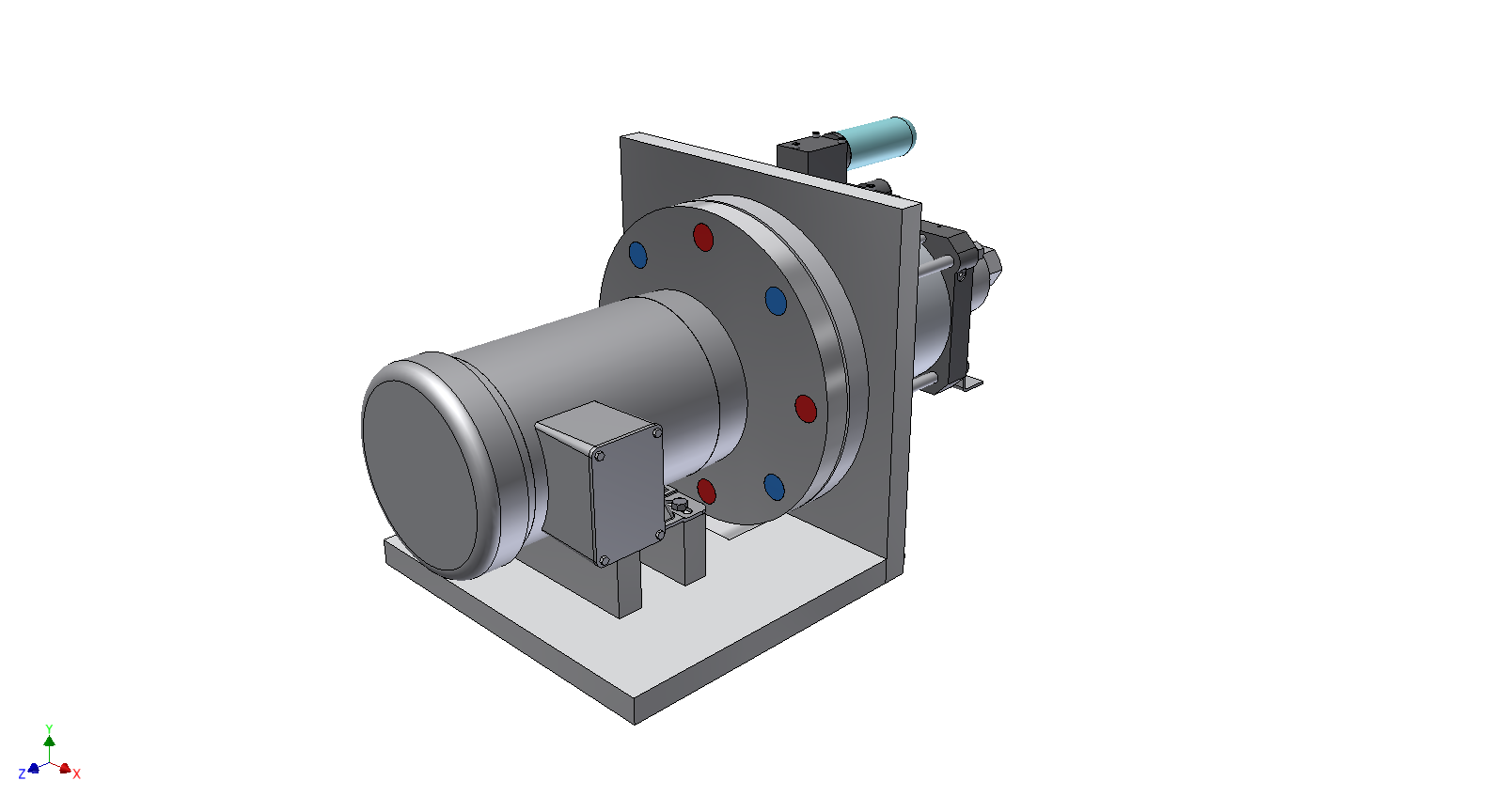

Infinity Magnetic Coupling |

Magnetic Coupling High torque contactless magnetic coupling for shaft drive applications.Plans and licensing available. Magnetic Coupling (pdf) |

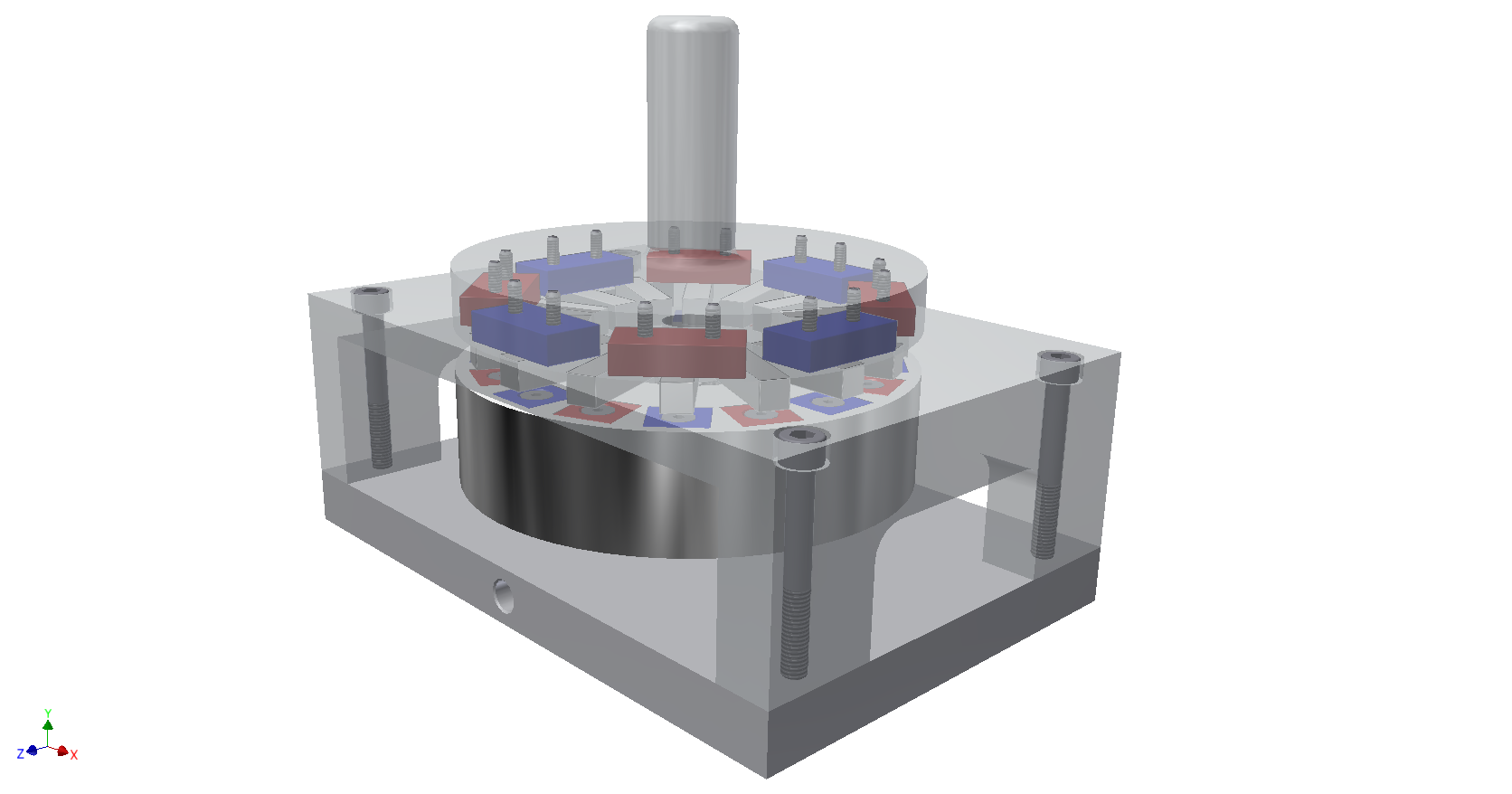

Infinity Magnetic Gear |

Magnetic Gear High torque contactless magnetic coupling for shaft drive applications. Built and tested working (2:1 gear ratio). Video available.Plans and licensing available. Magnetic Gear (pdf) |

Infinity Heat Exchanger 3D Metal Printed |

Heat Exchanger 3D Metal Printed High torque contactless magnetic coupling for shaft drive applications. Built and tested working (2:1 gear ratio). Video available.Plans and licensing available. Heat Exchanger 3D Metal Printed (pdf) |

Infinity Magnetic Coupling |

Magnetic Coupling High torque contactless magnetic coupling for shaft drive applications.Plans and licensing available. Magnetic Coupling (pdf) |

IT Micro Turbine with Integral Liquid Pump for Turbine and Compressor Applications |

IT Micro Turbine with Integral Liquid Pump Micro common shaft turbine with integral liquid pump and cavitation heater. Endless applications for ORC and water and liquid CO2 working fluid uses. Expander (turbine): ORC, Organic Rankine Cycle, Steam, Refrigerants, CO2, compressed airCompressor (pump): water, CO2, airCommon Shaft: Allows spool up of Tesla disc pump and cavitation applications.Built and tested working. IT Micro Turbine with Integral Liquid Pump (pdf) |

IT Mini Turbine with Integral Liquid Pump for Turbine and Compressor Applications |

IT Mini CO2 Turbine with Integral Liquid Pump Mini turbine assembly with common shaft turbine for integral liquid pump and cavitation heater. Endless applications for ORC and water and liquid CO2 working fluid uses. Expander (turbine): CO2, ORC, Rankine Cycle, Steam, Refrigerants, CO2, compressed airCompressor (pump): water, CO2, airCommon Shaft: Allows spool up of Tesla disc pump and cavitation applications.Cavitation Disc: Can be used for making fluids go supercritical (ex. CO2), or can be plugged with magnets to produce induction heating.Built and tested working. IT Mini Turbine with Integral Liquid Pump (pdf) |

IT Micro Redstone 3D Metal Turbine with Counter-rotating Pump |

IT Micro Redstone 3D Metal Turbine with Counter-rotating Pump The goal of the Redstone project was to incorporate all moving and rotating functions into one component. This is done by using a layered up rotating assembly, or 3D printed in metal or cast carbon fiber.Expander (turbine): CO2, ORC, Rankine Cycle, refrigerants, CO2, compressed air, waterCompressor (pump): water, CO2, air, refrigerantsShaft Free: Turbine assembly is the shaft (magnetic bearings or perimeter bearings).Cavitation Disc: Can be used for making fluids go supercritical (ex. CO2), or can be plugged with magnets to produce induction heating.History: The Redstone project was made into 3D printed metal (sintered) steel. What we found was that larger parts tended to lose tolerance as the parts grew in size, so the turbine was designed at 2 inches or less in diameter and turned to true for high speed rotational tolerance. The housing castings needed to be machined to tolerance on the inside and trued for surface mounting.Final Project: The project was printed by X-One when the larger housing tolerance problems were found. We received boxes of these castings, which were ultimately thrown away. A few surviving parts remain (which are solid metal and extremely heavy). There are a total of three parts, which reduces build time and has a huge time savings from standard metal machining. Ultimately, the best method we found (most cost effective and fast) was cutting basic parts with a waterjet, then layering up for 3D effect, and to achieve the internal chamber structure (complex counter-rotating screws). IT Micro Redstone (pdf) |

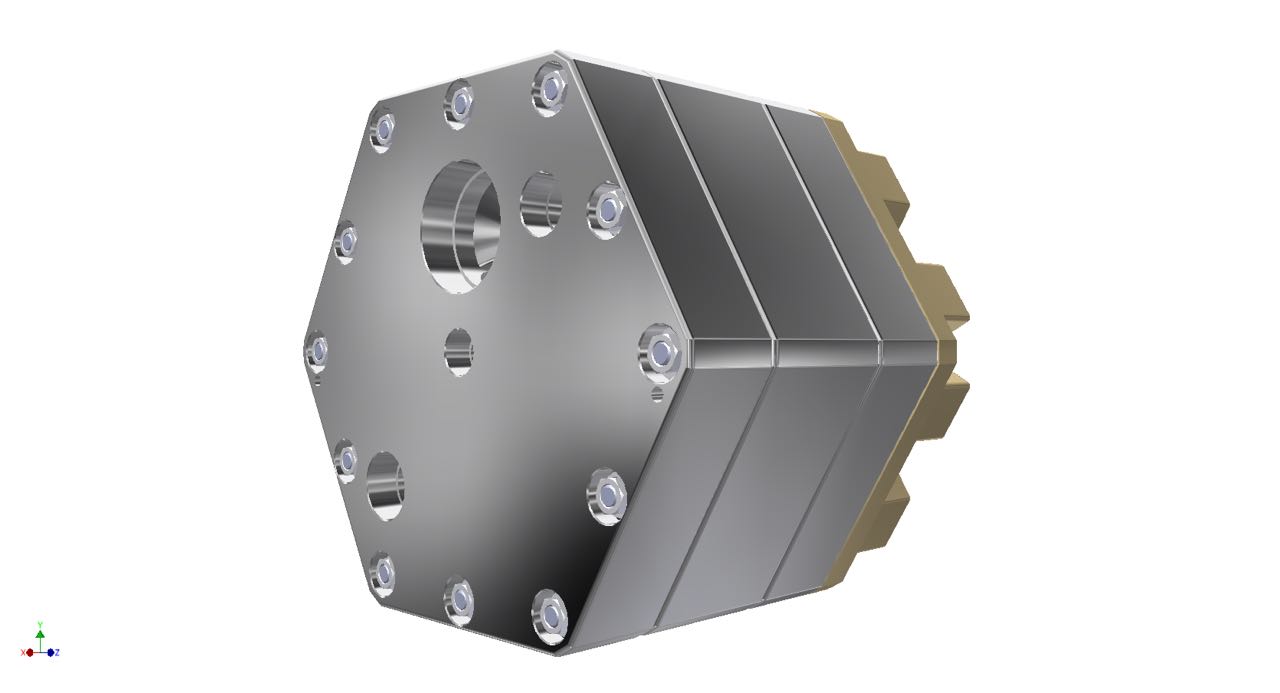

IT Mini Experimenters Turbine Kit |

IT Mini Experimenters Kit The IT Mini Experimenters Kit is designed for modular block rapid prototyping of turbine (expander) blades. We have all the parts for this kit for purchase, or you may purchase the plans and build yourself. We have these in aluminum and HDPE, but you can use any material determinant on the working pressure needed. We have successfully used these using R-245fa, R-134, Compressed Air, pressurized water, and a Stainless Steel version with CO2. See our YouTube videos for examples.Modular Block Assembly: Used since 2008, our Modular Block concept has been used in hundreds of turbine prototypes and production assemblies. These 2.5 inch hexagonal blocks (3 inch overall width) have a interior bore for expanders which measures 2 inches. 10/32 standardized threaded bores and passthrough bores for 10/32 bolts.Purpose: The purpose of the kit is to allow rapid prototyping and experimentation of your turbine or expander design in a bolt-together format.Rapid-Configuration: This strategy allows you to quickly assemble turbines and test various expanders on air and water. The basic design is for 300 psi or less, which is determinant on the back magnetic coupling block which is made from HDPE. If you can make from nonmagnetic metal or composite fiber for a thicker (stronger) back, then you can use fluids with greater pressure.Magnetic Coupling: The design has a basic 2 inch diameter magnetic coupling and follower, which allows you to have a generator or drive unit mounted exterior.Plans and licensing available. IT Mini Experimenters Kit (pdf) |

IT Micro Radial Turbine for low power applications |

IT Micro Radial Turbine The IT Micro Radial Turbine is designed for small scale power production for the home or low power applications (less than 5 kW). Working Fluid: R-245fa, R-134, Compressed Air, pressurized water, and a Stainless Steel version with CO2.Modular Block Assembly: Used since 2008, our Modular Block concept has been used in hundreds of turbine prototypes and production assemblies. This version uses square blocks with 3/8 fasteners and threaded bores.Purpose: Small power production.Rapid-Configuration: This assembly allows you to quickly configure turbines and test various working fluids and heat sources. The basic design is for 300 psi or less, which is determinant on the back magnetic coupling block which is made from HDPE. If you can make from nonmagnetic metal or composite fiber for a thicker (stronger) back, then you can use flows with greater pressure.Magnetic Coupling: The design has a basic 2 inch diameter magnetic coupling and follower, which allows you to have a generator or drive unit mounted exterior. IT Micro Radial Turbine (pdf) |

Infinity Magnetic Coupling Au Version which allows multiple discs and drives |

Magnetic Coupling Au Version High torque contactless magnetic coupling for shaft drive applications. Au allows multiple discs and drive configurations.Plans and licensing available. Magnetic Coupling (pdf) |

Haas Tooling Jig for Large Diameter Parts such as Gruvlok End Plates and Pipe Grooves |

Haas Tooling Jig For cutting grooves into metal for large diameter parts, like Gruvlok or other uses.We use this jib for cutting Gruvlok grooves into end plates of metal and large diameter pipe for our turbine housings.Plans and design available for purchase. Haas Tooling Jig Jaws (pdf) |

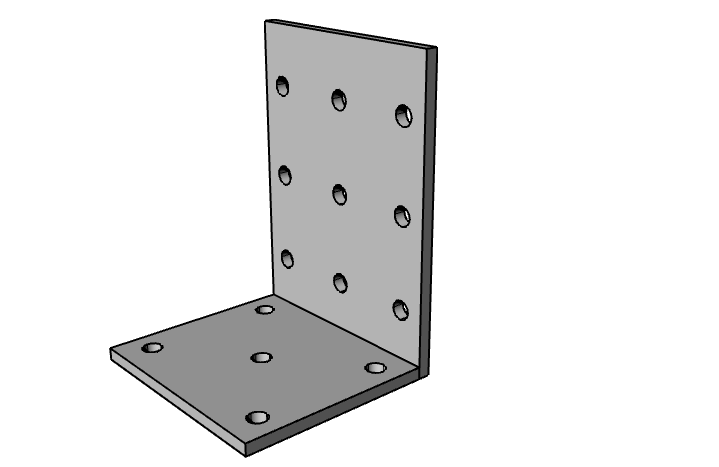

Caster Bracket with pre drilled bores for 3/8 inch fasteners to attached casters to a structure |

Caster Bracket The caster bracket allows quick attachment of 5 inch diameter casters via a standard right angle bracket in both short and long (preferred) versions.License: Free download to build one copy. Production licenses available. Caster Bracket Download (1.3 MB .zip) |

Evaporator and Condenser Heat Exchanger 3D Printed in Plastic and Metal |

Helical 3D Evaporator and Condenser Heat Exchanger Basic helical heat exchanger design for experimental non-pressure applications transfer of heat between two separate liquids.Designed for STL 3D printing in plastic then in metal.Plans and design available for purchase. Evaporator Heat Exchanger 3D (pdf) |

Coni Turbine by Infinity Turbine |

Coni Turbine The Coni Turbine is a disc with angled bores for basic low efficiency expansion of water, compressed air, and Organic Rankine Cycle working fluids. It can be run in reverse for cavitation of water or CO2, for many applications including oil extraction from cells, production of silver nanoparticles, and more.License: Free download to build one copy. Production licenses available. Coni Turbine Free Download (32 MB .zip) |

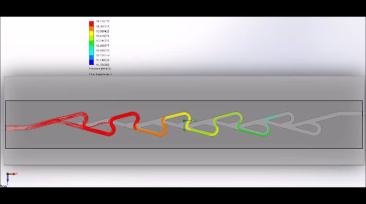

tesla one-way valve |

Tesla One Way Valve The Nikola Tesla one way valve is an invention from over one hundred years ago, which was a fluidic valve. It was presented in multiple US Patents including US1061206, US1329559, US5876187, and US6227809. We have drawn up the basic valve, and provide these drawings for non- commercial use, and to build one actual assembly. For production licensing, please contact Infinity Turbine. We do not grant permission to reprint, store on a remote server or drive or media, or distribute these files. Tesla Valve Drawings Download (13.1 MB .zip) |

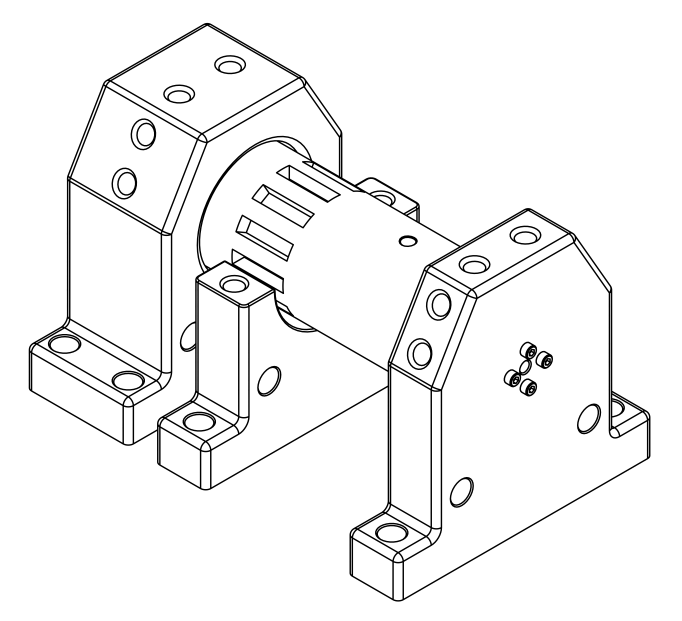

Electric Motor | Rotor Design | Coil Development Kit |

Electric Motor | Rotor Design | Coil Development Kit This concept kit is to help develop magnetic motors, rotors, and coils. The entire assembly can be 3D printed. Magnets can be installed into the rotor and bearings and shafts into the end blocks.We have drawn up the basic device and provide these drawings for non- commerical use, and to build one actual assembly. For production licensing, please contact Infinity Turbine. We do not grant permission to reprint, store on a remote server or drive or media, or distribute these files. Coil Developers Kit Plans Download (3.5 MB .zip) |

Fast Vacuum Table |

Fast Vacuum Table The Infinity Turbine vacuum table is designed for vacuum bagging materials and evacuating air. This process can be used for drying small wood parts, clamping (for glueing), hold-down, vacuum bagging for fiberglass or carbon fiber, removing excess glue or moisture, and even hooked up to a rigid chamber for vacuum drying small quantities of lumber. Infinity Vacuum Table (pdf) |

Infinity Fast Filter System for Dewaxing |

Fast Filter Process for Dewaxing Winterized Liquid If you currently use Buchner flasks, consider a Infinity Fast Filter System for dewaxing your winterized solution for more than 10 times faster than conventional filtering. This is the perfect compliment to your botanical extraction system, whether it be hydrocarbons, ethanol, or supercritical CO2.We offer two sized systems which will handle any production from 5L pours, to over 10L pours in a few minutes.The modular system includes everything you need to get started, including a vacuum pump, paper filters, and a fast filter system mounted in a cart frame with industrial casters, that can be easily moved by one person. The 5L system runs off of 110V and can be solar powered with an inverter for off-grid use. The 10L system is 110V but can be ordered as 220V 50 hz or 60 hz.The Fast Filter System allows you to process more product, in less time, saving you valuable labor and giving you access to more profits.- Industrial Cart with Casters (USA)- Starter Kit Paper Filters (20 inch or 50 cm)- Small Footprint 24x24x48 inches- Self-contained System- Plug and Play Infinity Fast Filter System Cart (pdf) |

Infinity GPU Ground Power Unit for Portable Lithium Power up to 2 kW |

The GPU Ground Power Unit for Stand Alone Portable Power Infinity Turbine is developing a home based GPU (ground power unit) that is based on lithium batteries. This cart mounted system is easy to move around to the jobsite, home, mobile, or marine. Hook up your PV panels, wind generator, backup generator, or grid power to charge. GPU Information |

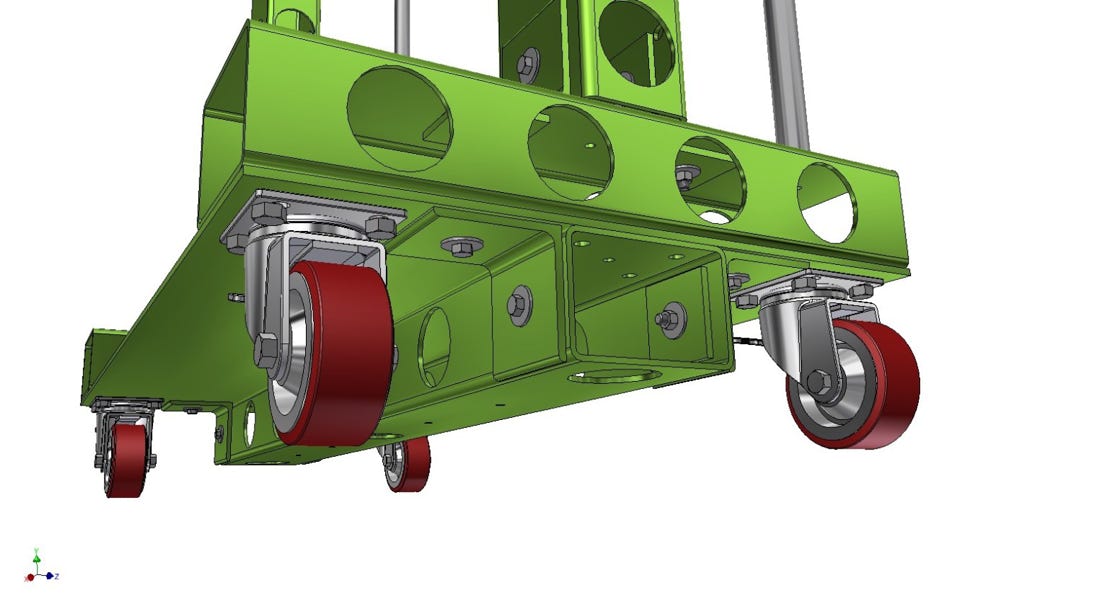

Caster beam modular bolt together structure |

Caster Beam Modular Pre Fabricated Structure Since 2008 Infinity has been building hundreds of turbine and extraction systems all with metal frames. Instead of relying on welded one-use structures, Infinity devised a system to use bolt together beams which had pre drilled 3 inch access ports and 3/8 inch holes for a bolt together system. Beams also have pre drilled 3/8 bolt patterns for standard 5 inch diameter casters which all fast prototyping carts that hold processing equipment, tables, workbenches, and other structures.Plans and licensing available. Caster Beam Information |

Infinity Turbine Tribogen solid state power from waste heat |

Static Electricity Using CO2 With No Moving Parts Since 2008 Infinity Turbine has been experimenting with all forms of waste heat to power generation. All modern day expanders have moving parts, which necessitates bearings and complicated seal technology and maintenance. The holy grail of energy production is no moving parts (solid state). To that end, after 10 years of trying to reduce a rotating expander to one part (successfully done), we finally achieved the ultimate waste heat to power device, the solid state turbine generator. This is done using CO2 which goes supercritical (phase change from liquid to high pressure vapor) at 88F or 31C.Under development. Tribogen Information |

Infinity Turbine Vacuum Pump |

Vacuum Kiln for Fast Drying Fresh Cut Lumber in 3 Days Infinity Turbine with Global Energy are developing DIY plans and kits for kiln vacuum drying lumber. I invented the Global Container Kiln back in 1990 by converting standard shipping containers into dry kilns for the small sawmills. Infinity Turbine has specialized in developing simple pressure vessels and systems with it's renewable waste heat turbine generators back in 2008, and has extensive experience in pressure vessels. It's a natural fit.Why a vacuum kiln ? Lumber prices are crazy. Homebuilders cannot find quality lumber (supplies are limited), and have turned to buying a port)able sawmill, which produces green lumber. For building, that lumber needs to be dried. This is also true for cabinet makers, and other wood craft business. Our container kiln was a standard dry kiln and could KD (kiln dry) hardwoods in 30 days. That's too long for most.A vacuum kiln is the answer. Smaller chambers can dry in 3 days or less. Vacuum Dry Kiln Information |

Modular Block Heat Pump Turbine Kit |

Infinity Heat Pump Turbine Experimenters Kit Infinity has developed a modular block kit for those who wish to experiment with using a heat pump as a turbine to produce power while simultaneously producing heating or cooling. Can also be used in conjunction with a heat pump CO2 flow battery. |

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP | PDF | IG | X.com | Free Tesla Supercharger Miles |