|

What are the various methods to make graphene

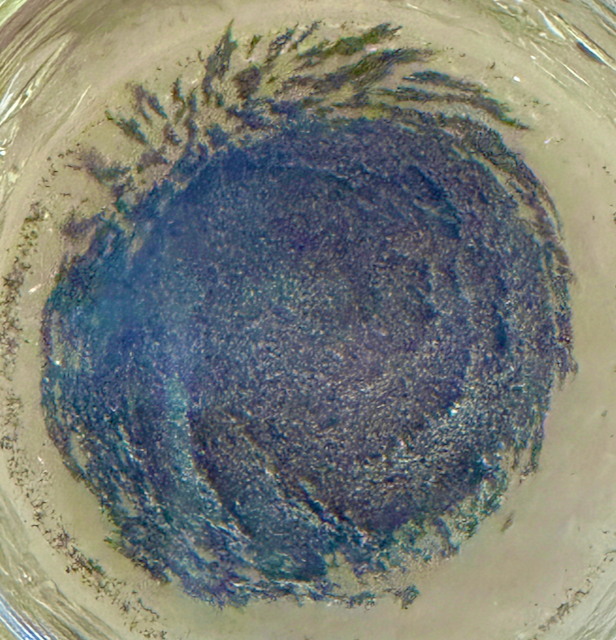

Graphene is a highly versatile and exciting material that has been found to have numerous applications in fields such as electronics, energy, and medicine. It is a thin layer of carbon atoms arranged in a hexagonal lattice, with unique mechanical, electrical, and optical properties. The methods for making graphene have evolved over time and are continually improving.One of the earliest methods for producing graphene was the mechanical exfoliation method, also known as the Scotch tape method. This method involves using adhesive tape to peel off layers of graphite until a single layer of graphene is obtained. While this method is simple and easy to perform, it is also time-consuming and produces small quantities of graphene.Chemical vapor deposition (CVD) is another method used to produce graphene. In this method, a thin film of metal, typically copper, is used as a substrate. A hydrocarbon gas, such as methane or ethylene, is then introduced into a chamber where the metal substrate is heated to high temperatures. The carbon atoms from the gas then settle onto the substrate, forming a layer of graphene. This method is highly scalable and can produce large quantities of high-quality graphene.Another method for producing graphene is the reduction of graphene oxide. Graphene oxide is a derivative of graphene that contains oxygen groups attached to its surface. The reduction process involves removing these oxygen groups, resulting in the formation of graphene. This method is relatively simple and can be performed using a variety of reducing agents, including hydrazine and sodium borohydride.Liquid-phase exfoliation is another method used to produce graphene. In this method, graphite is suspended in a liquid, typically a solvent or surfactant, and then subjected to high-intensity sonication or shearing. The shear forces acting on the graphite cause it to exfoliate into individual layers of graphene. This method is highly scalable and can produce large quantities of graphene in solution.In conclusion, the various methods for producing graphene have different advantages and disadvantages depending on the application and desired outcome. Mechanical exfoliation is simple but time-consuming and produces small quantities of graphene. CVD is highly scalable and produces high-quality graphene, but requires specialized equipment. Reduction of graphene oxide is relatively simple and versatile, while liquid-phase exfoliation can produce large quantities of graphene in solution. The continued development of these methods will further expand the applications of graphene in various industries.

Graphene Search Engine Topics

|