IT Micro Redstone 3D Metal Turbine with Counter-rotating Pump

IT Micro Redstone 3D Metal Turbine with Counter-rotating Pump

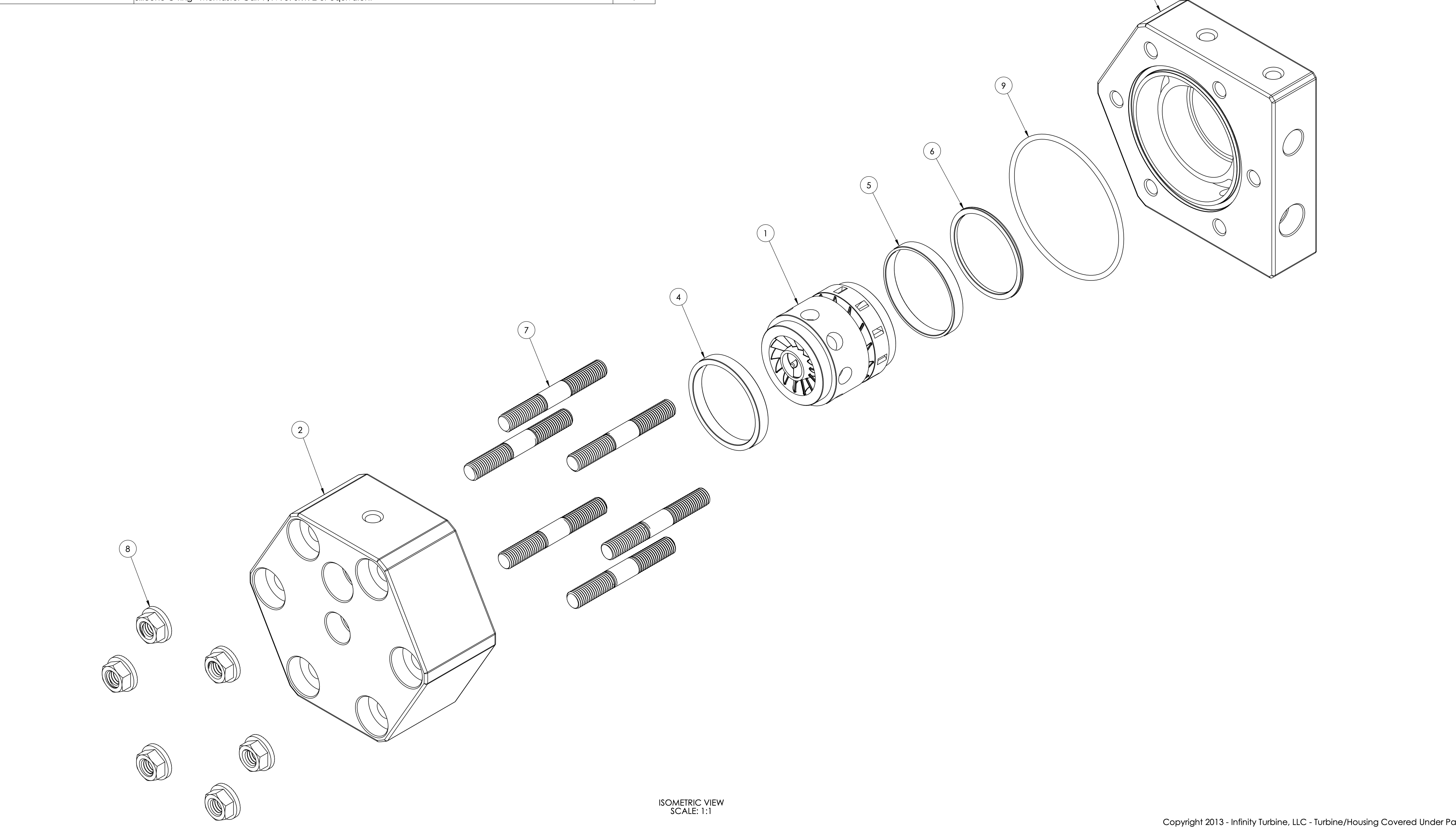

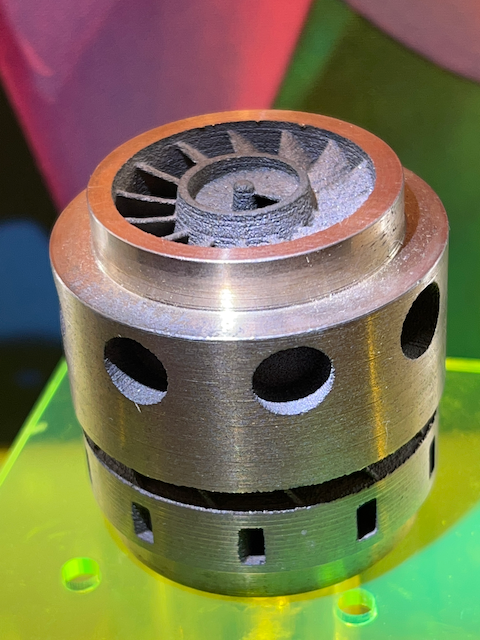

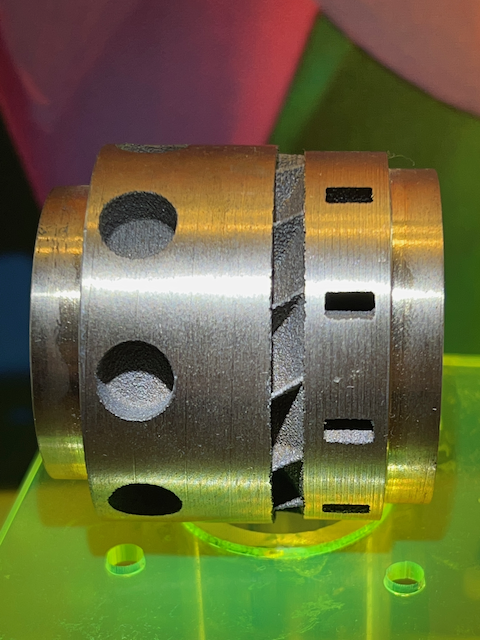

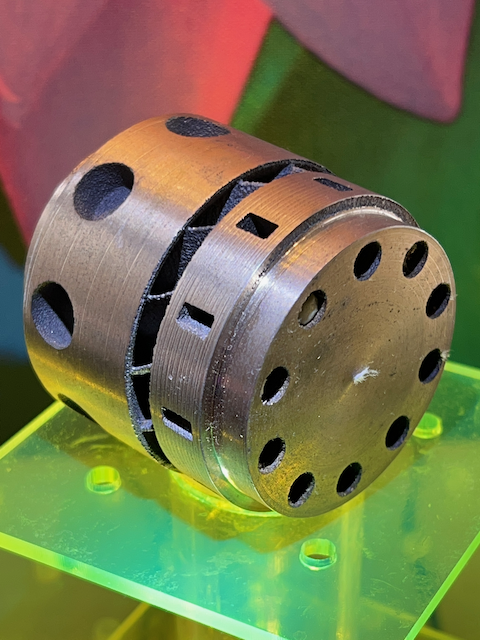

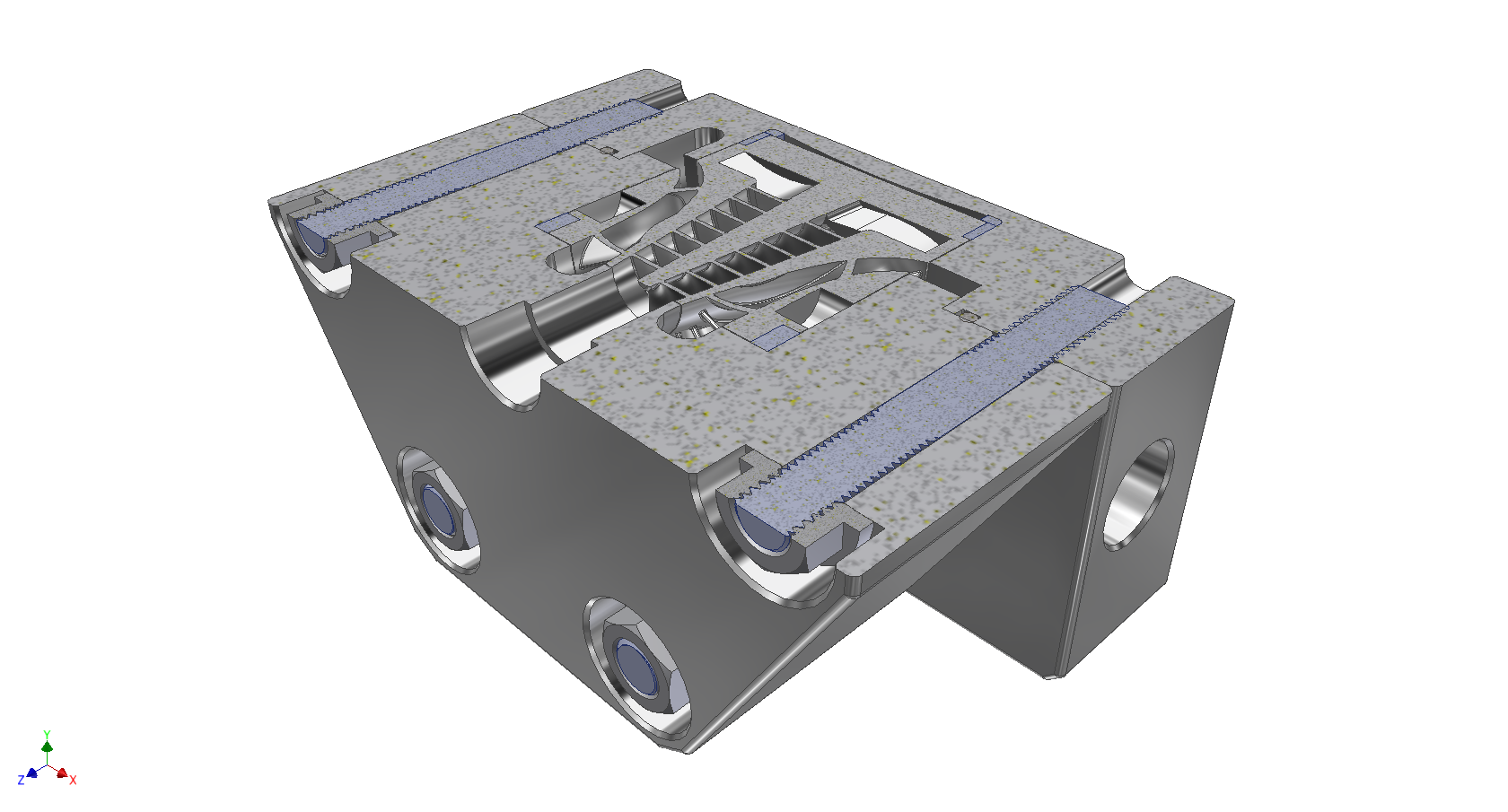

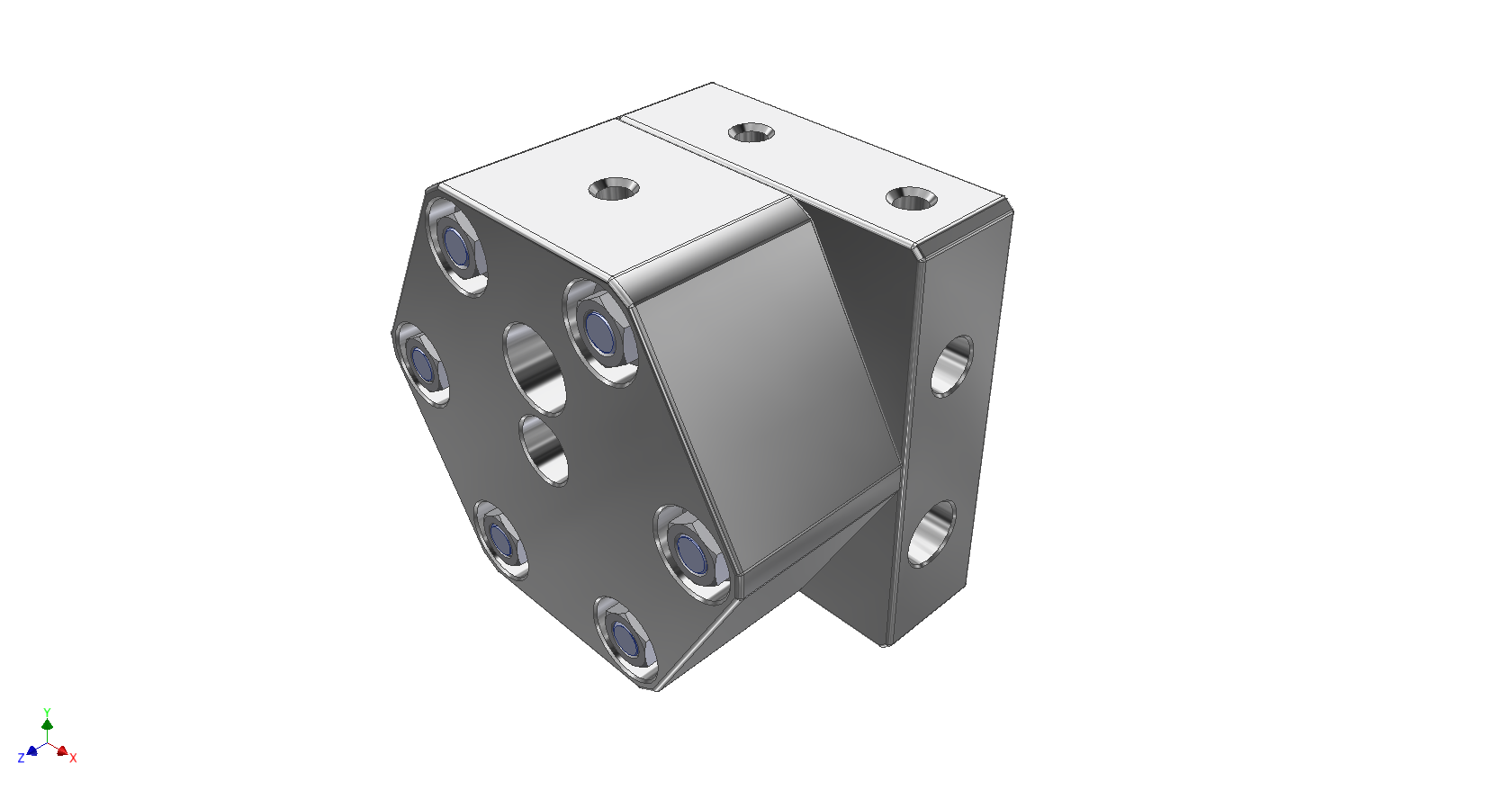

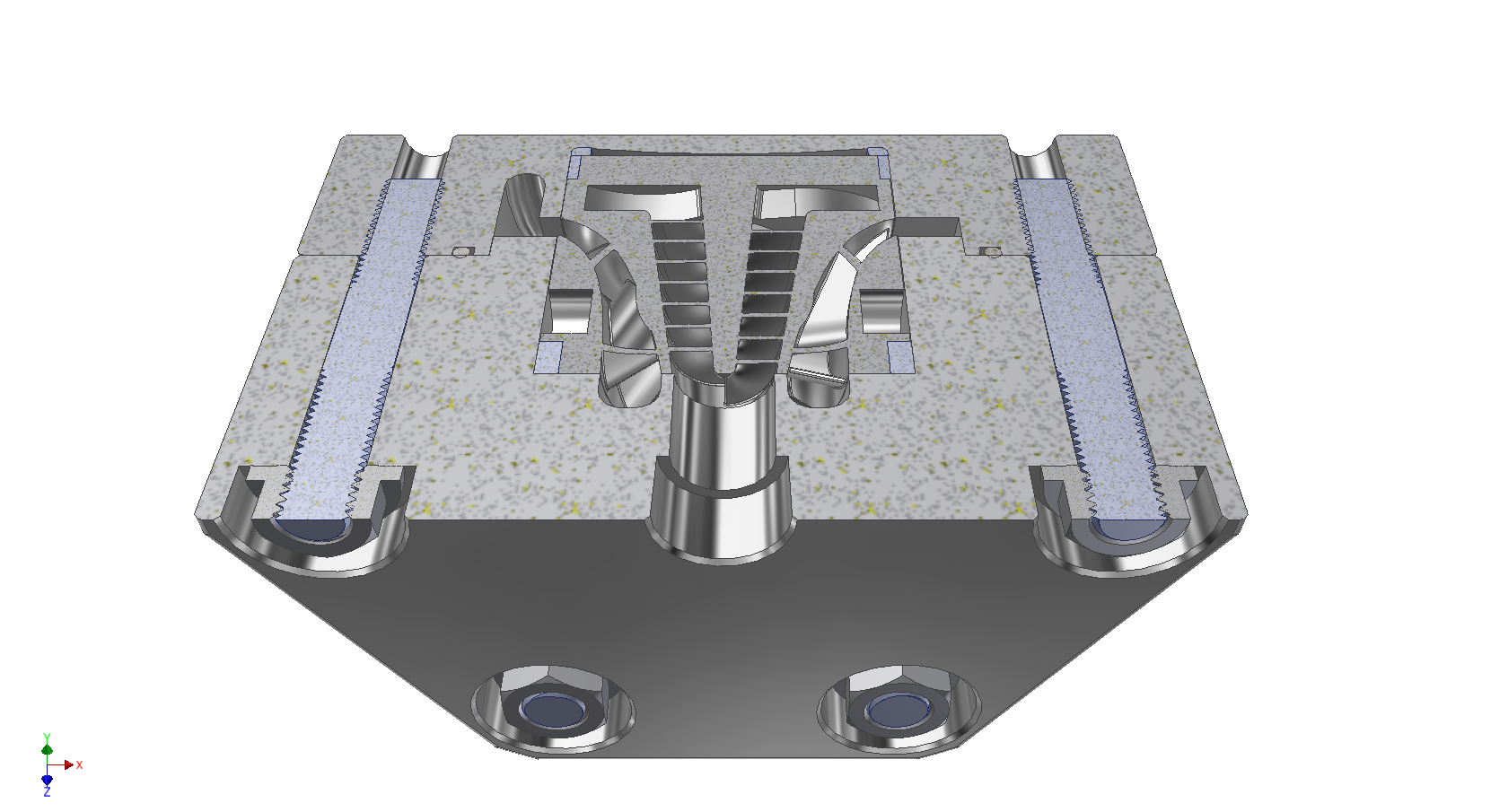

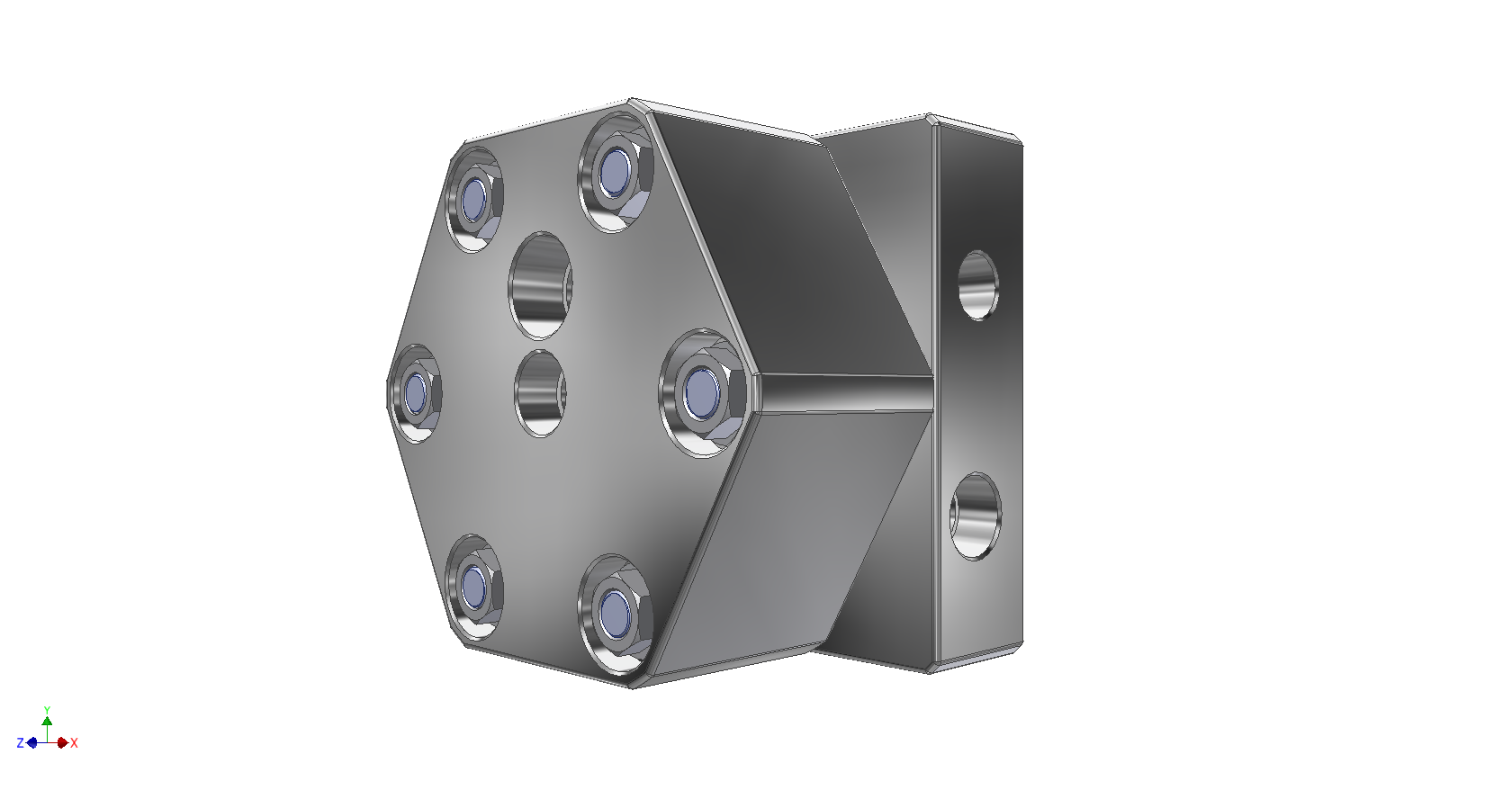

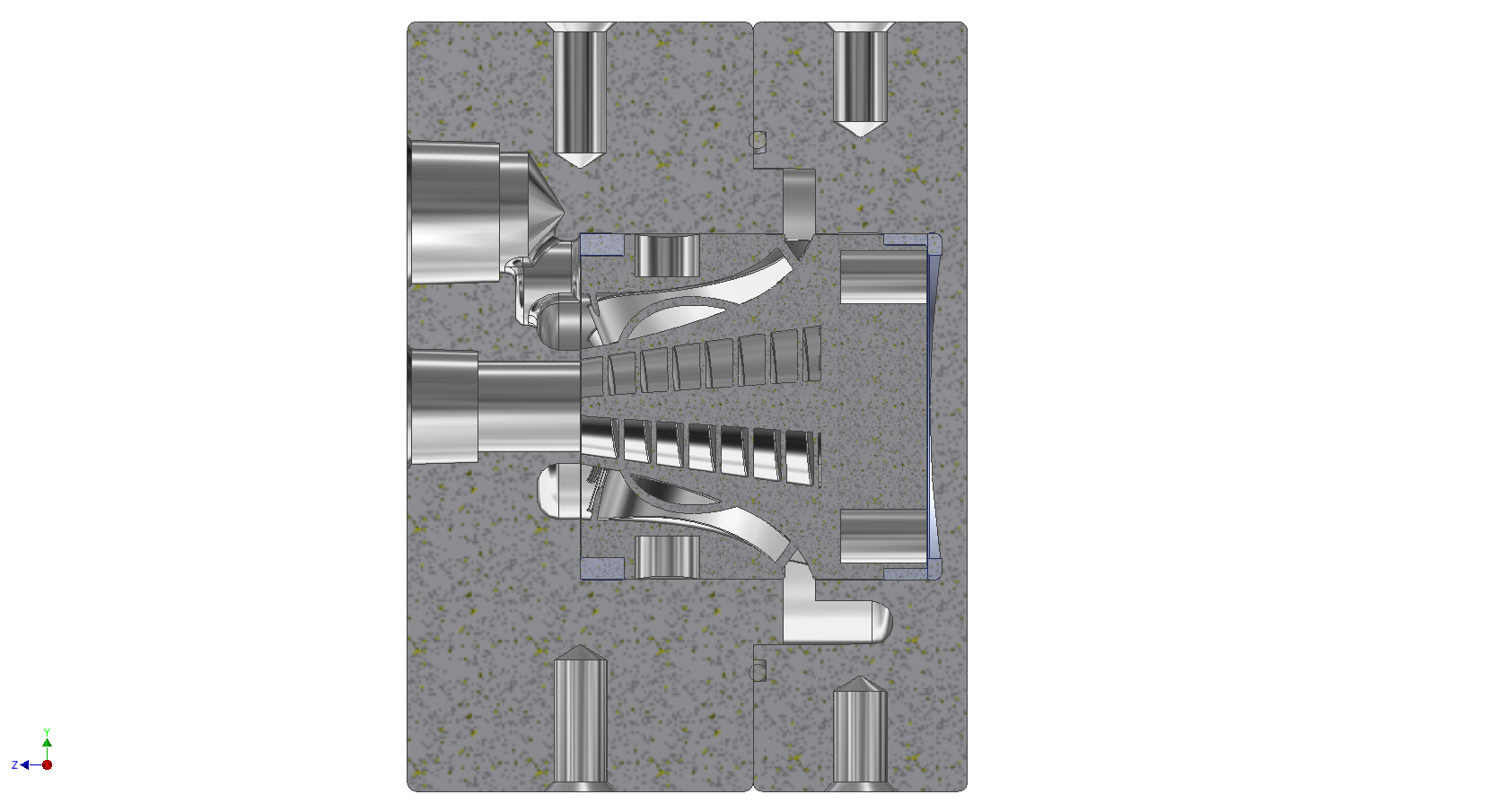

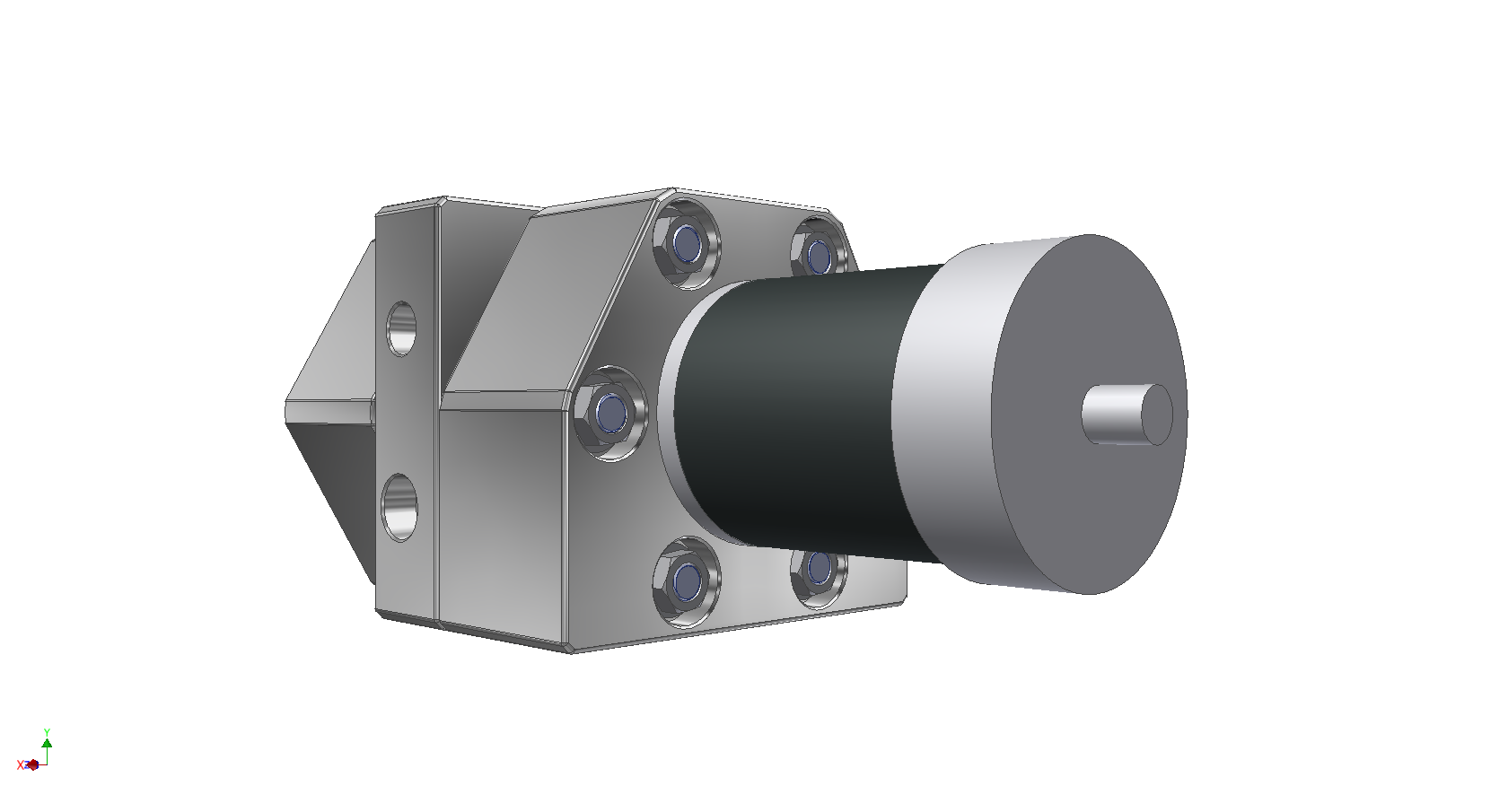

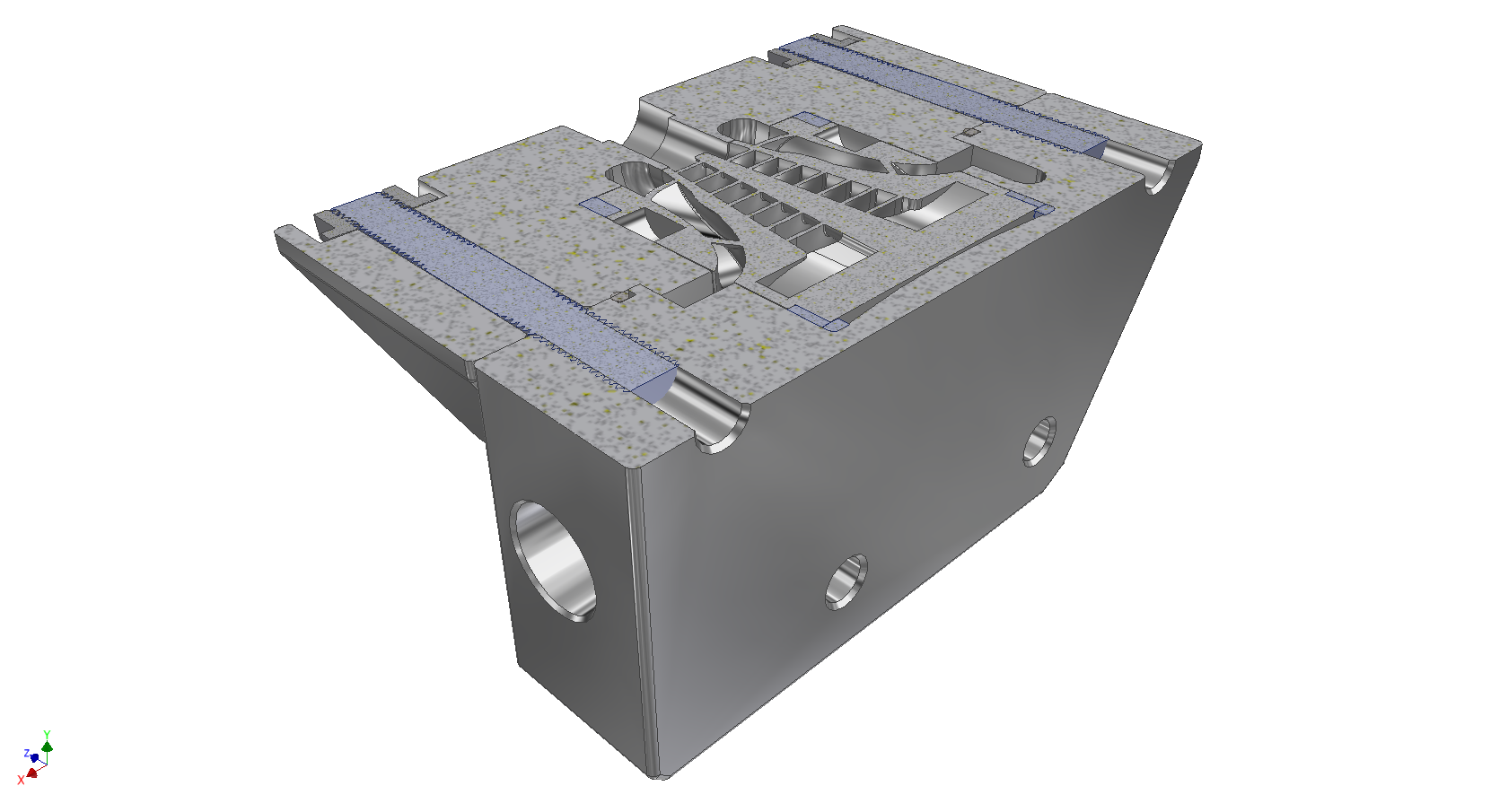

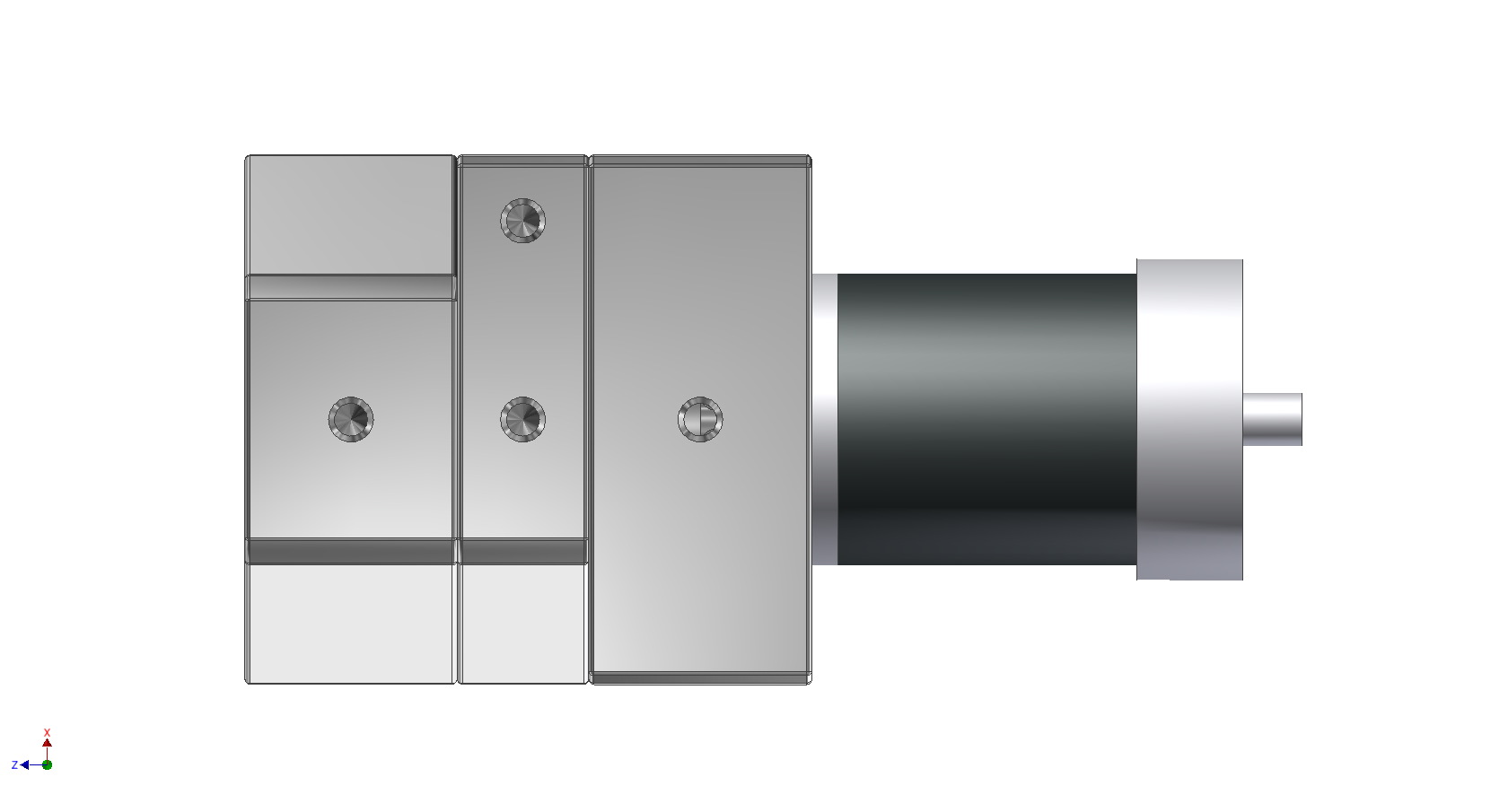

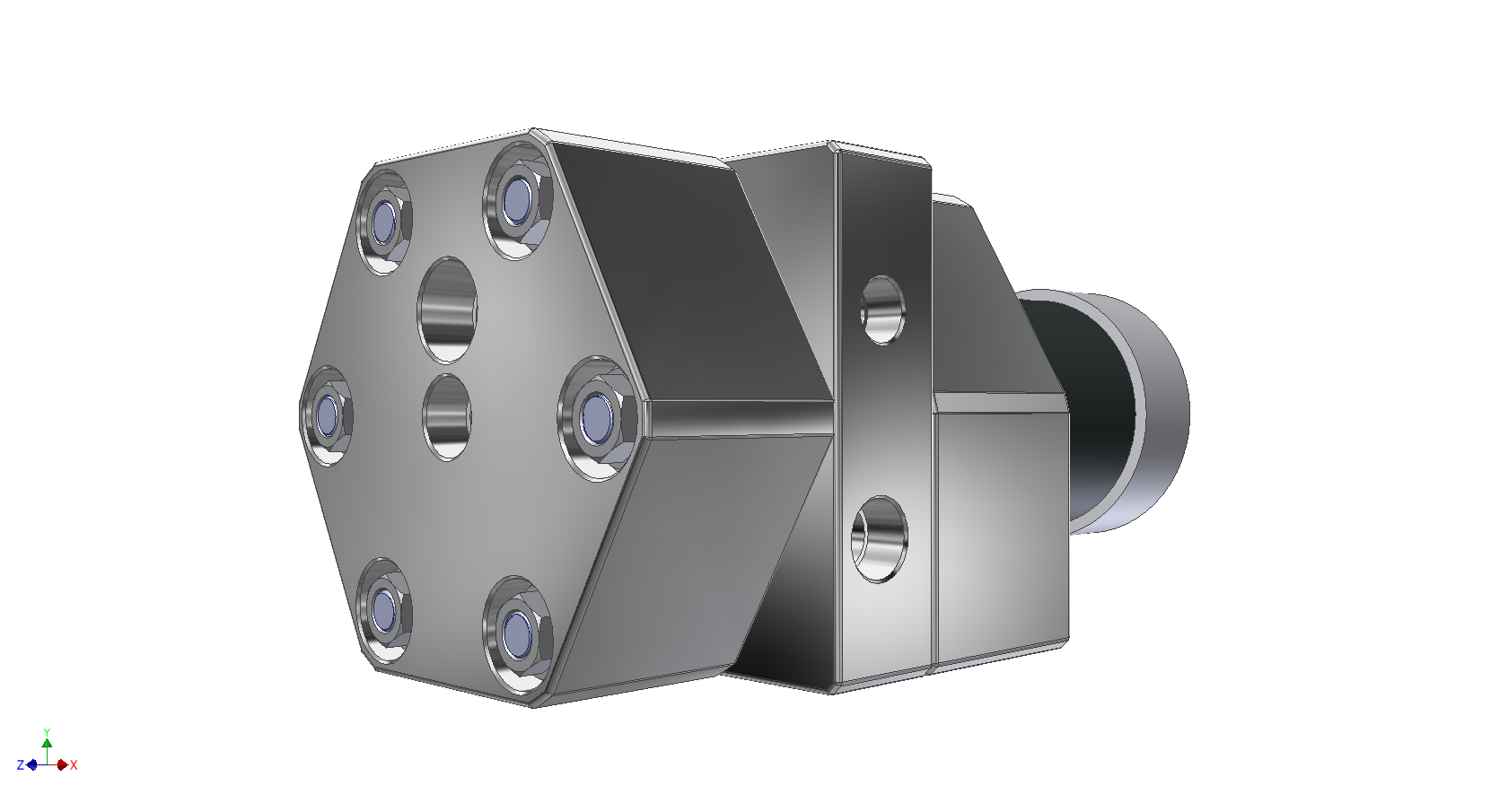

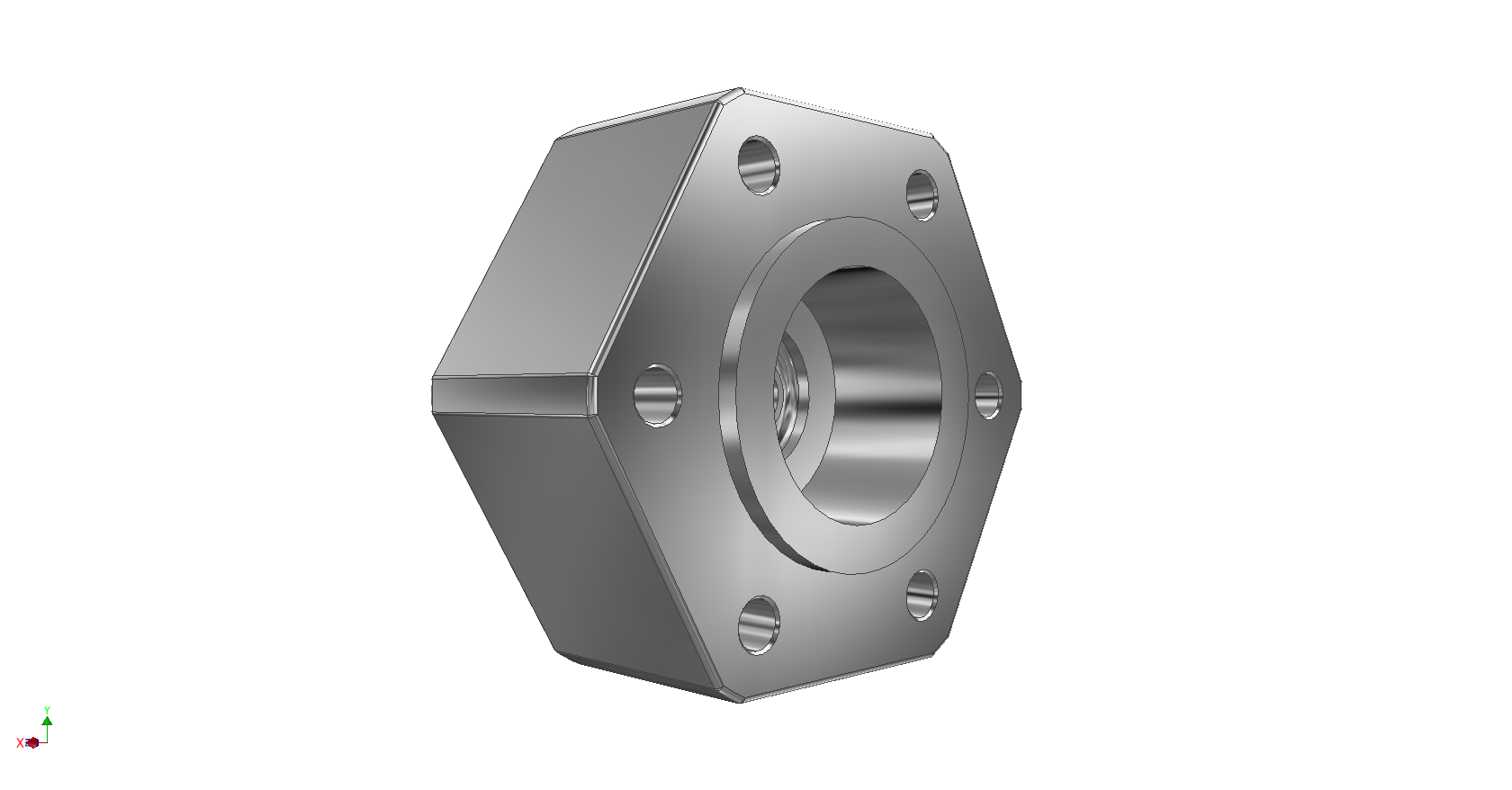

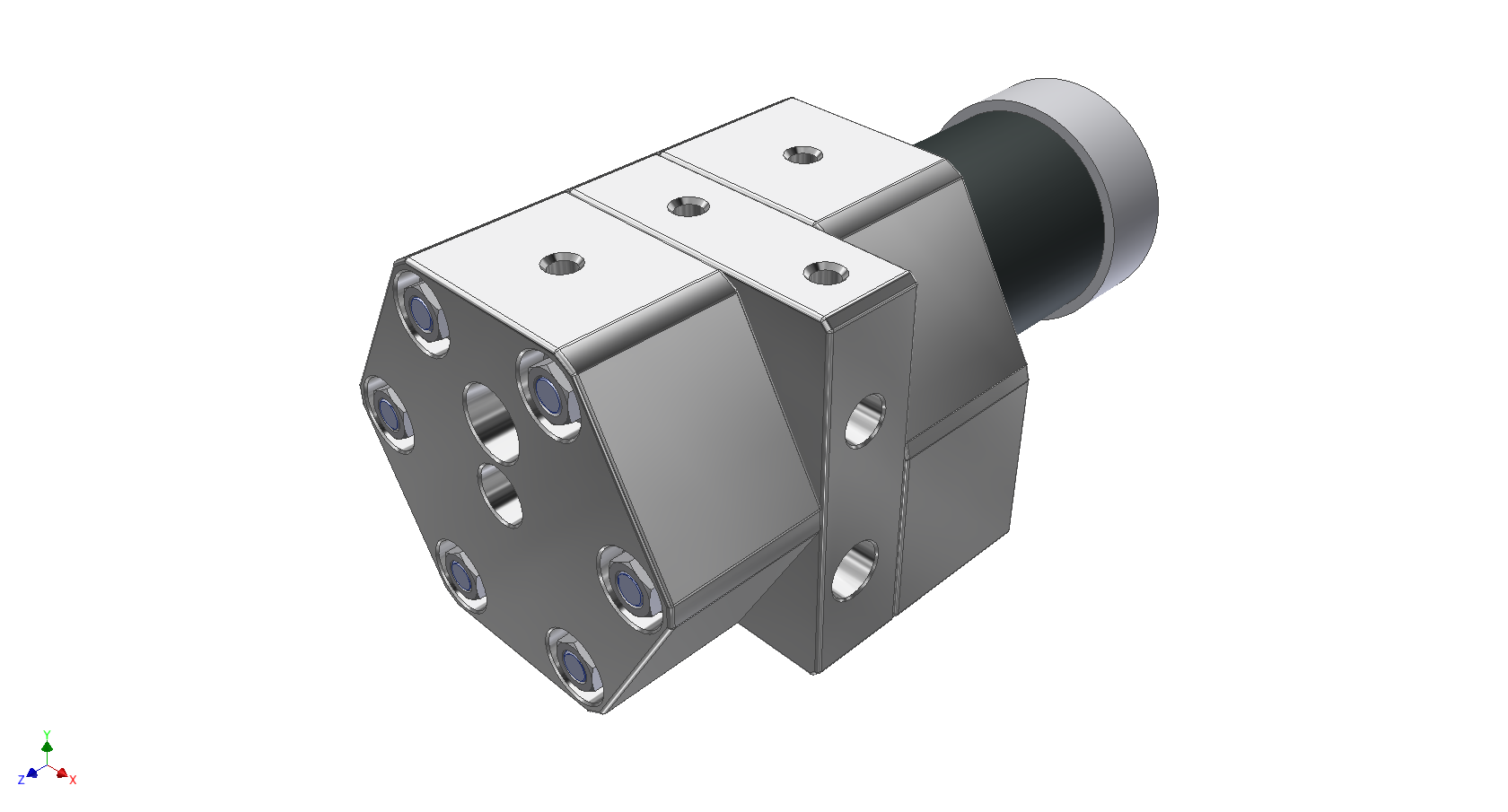

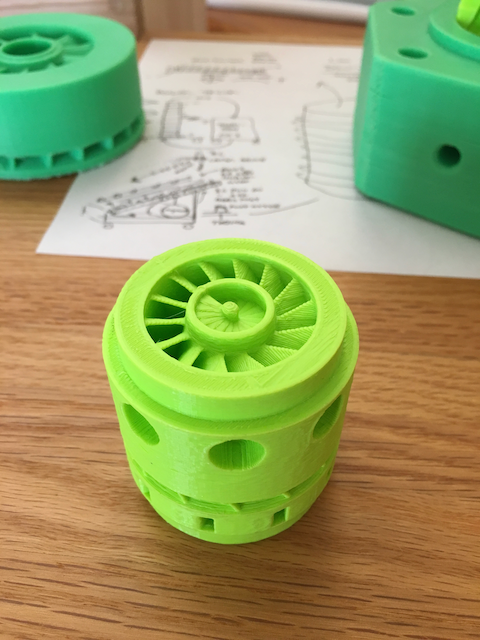

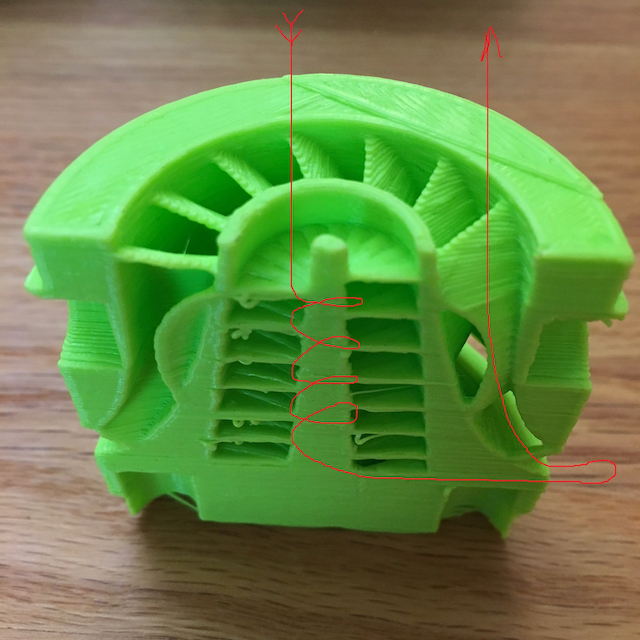

The goal of the Redstone project was to incorporate all moving and rotating functions into one component. This is done by using a layered up rotating assembly, or 3D printed in metal or cast carbon fiber.Expander (turbine): CO2, ORC, Rankine Cycle, refrigerants, CO2, compressed air, waterCompressor (pump): water, CO2, air, refrigerantsShaft Free: Turbine assembly is the shaft (magnetic bearings or perimeter bearings).Cavitation Disc: Can be used for making fluids go supercritical (ex. CO2), or can be plugged with magnets to produce induction heating.History: The Redstone project was made into 3D printed metal (sintered) steel. What we found was that larger parts tended to lose tolerance as the parts grew in size, so the turbine was designed at 2 inches or less in diameter and turned to true for high speed rotational tolerance. The housing castings needed to be machined to tolerance on the inside and trued for surface mounting.Final Project: The project was printed by X-One when the larger housing tolerance problems were found. We received boxes of these castings, which were ultimately thrown away. A few surviving parts remain (which are solid metal and extremely heavy). There are a total of three parts, which reduces build time and has a huge time savings from standard metal machining. Ultimately, the best method we found (most cost effective and fast) was cutting basic parts with a waterjet, then layering up for 3D effect, and to achieve the internal chamber structure (complex counter-rotating screws).Plans and licensing available.