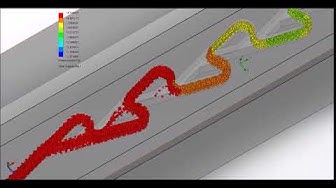

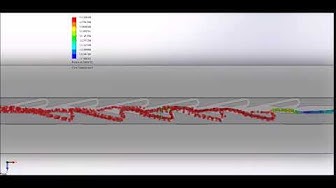

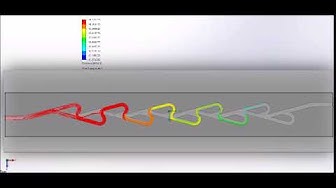

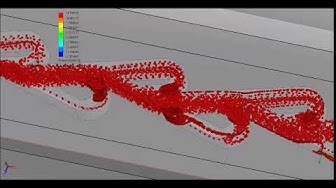

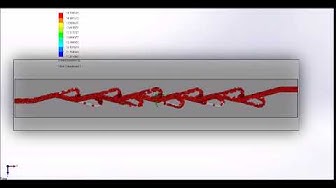

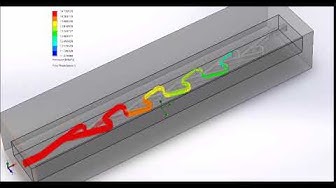

Infinity Turbine: Tesla One Way Valve Valvular Conduit (reverse 4) CFD Computational Fluid Dynamics

Originally designed by Nikola Tesla, the one way valve (or valvular conduit) and was patented in 1916 under US patent US1329559A. From the patent: The high elliciency of the device, irrespective of the character of the pulses, is due to two causes: first, rapid reversal of direction of flow and second great relative. velocity of the colliding fluid columns. As will be readily seen each bucket causes a deviation through an angle of 180, and another change of 180 occurs in each of the spaces between two adjacent buckets. That is to say, from the time the fluid enters or leaves one of the recesses to its passage into, or exit from, the one following a complete cycle, or deflection through 360, is effected. Observe now that the velocity is but slightly reduced in the reversal so that the incoming and deflected fluid columns meet with a relative speed, twice that of the flow, and the energy of their impact is four times greater than with a deflection of only 90, as might be obtained with pockets such as have been employed in asymmetrical conduits for various purposes. The fact is, however, that in these such deflection is not secured, the pockets remaining filled with comparatively quiescent fluid and the latter following a winding path of least resistance between the obstacles interposed. In such conduits the action cannot be characterized as valvular because some of the fluid can pass almost unimpeded in a direction opposite to the normal flow. In my construction, as above indicated, the resistance in the reverse may be 200 times that in the normal direction. Owing to this a comparatively very small number of buckets or elements is required for checking the fluid. To give a concrete idea, suppose that the leak from the first element is represented by the fraction then after the-nth bucket is traversed, only a quantity will escape and it is evident that X need not be a large number to secure a nearly perfect valvular action.