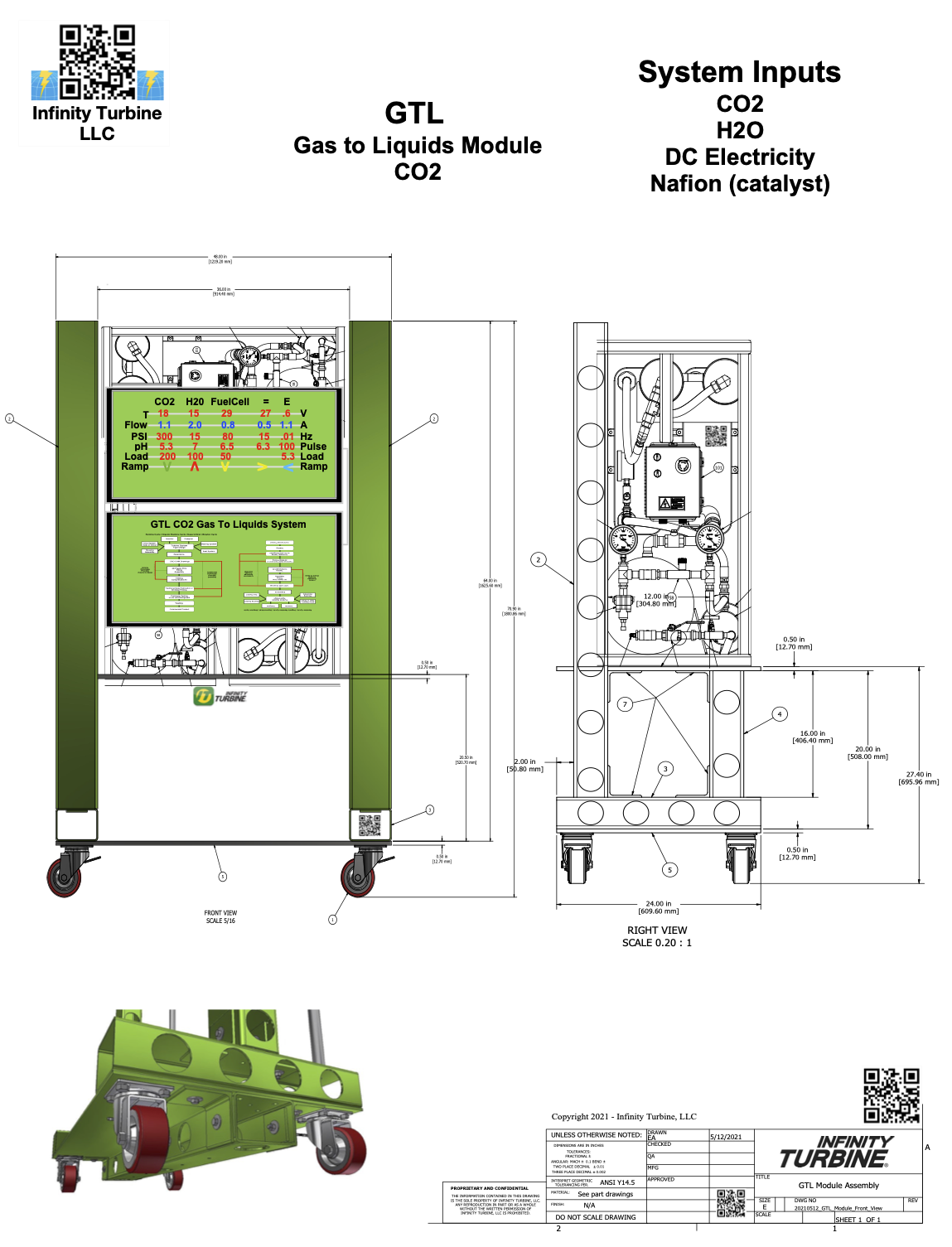

Infinity Turbine GTL Gas to Liquids Experimental Platform Using Reverse Fuel Cell (electrolizer)

Infinity Turbine Sales | Design | Develop | Analysis TEL: 1-608-238-6001 Email: greg@infinityturbine.com

Gold and Silver Precious Metals Recovery Turbine Disc Pump and Supercritical CO2 E Waste Silver Processors

IT1000 Supercritical CO2 Gas Turbine Generator Silent Prime Power $3M 1 MW (natural gas, solar thermal, thermal battery heat) ... More Info

ORC and Products Index Infinity Turbine ORC Index... More Info

Infinity Turbine GTL Gas to Liquids Experimental Platform Using Reverse Fuel Cell (electrolizer) |

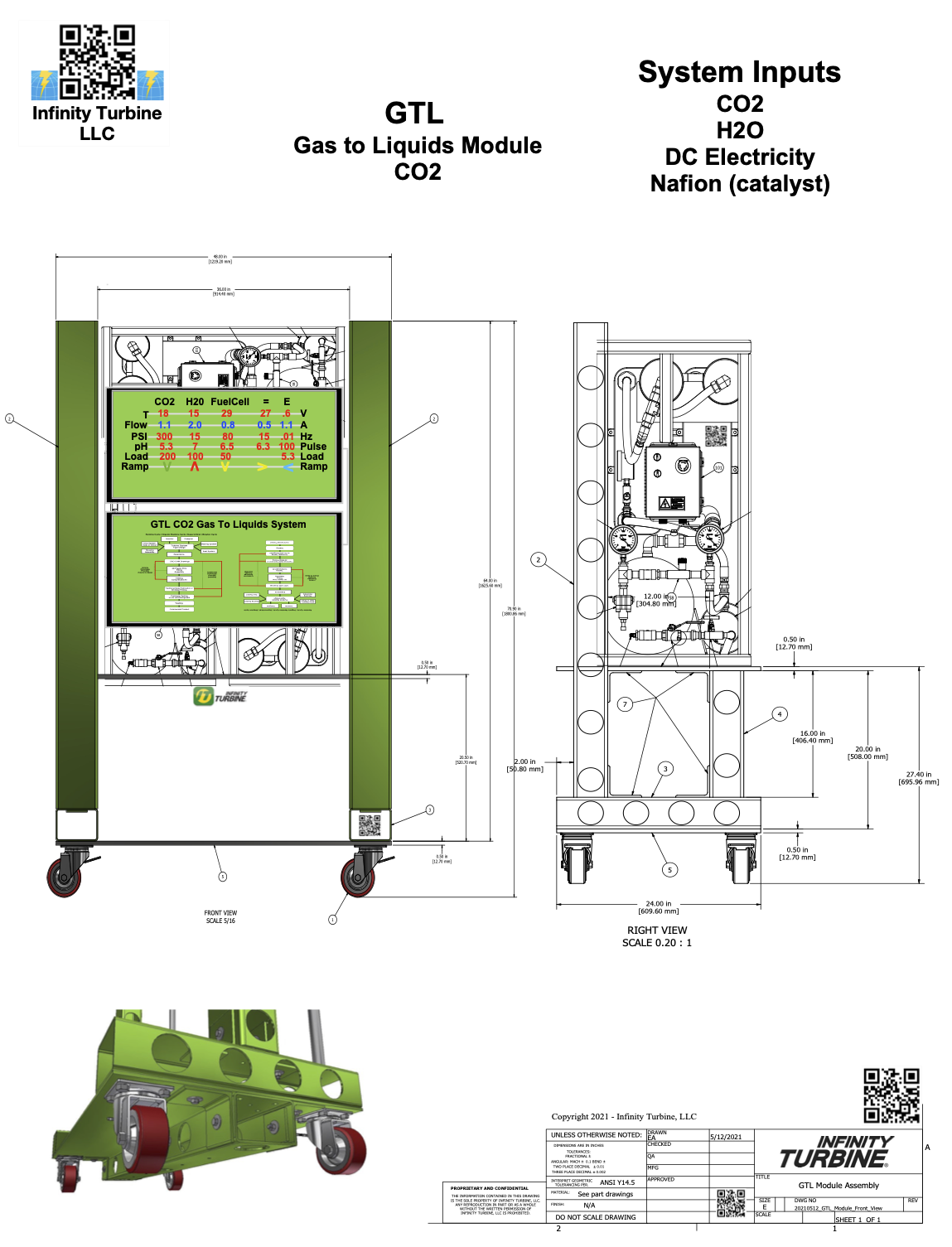

Infinity Turbine GTL Gas to Liquids Module for converting CO2 to fuels and plastics |

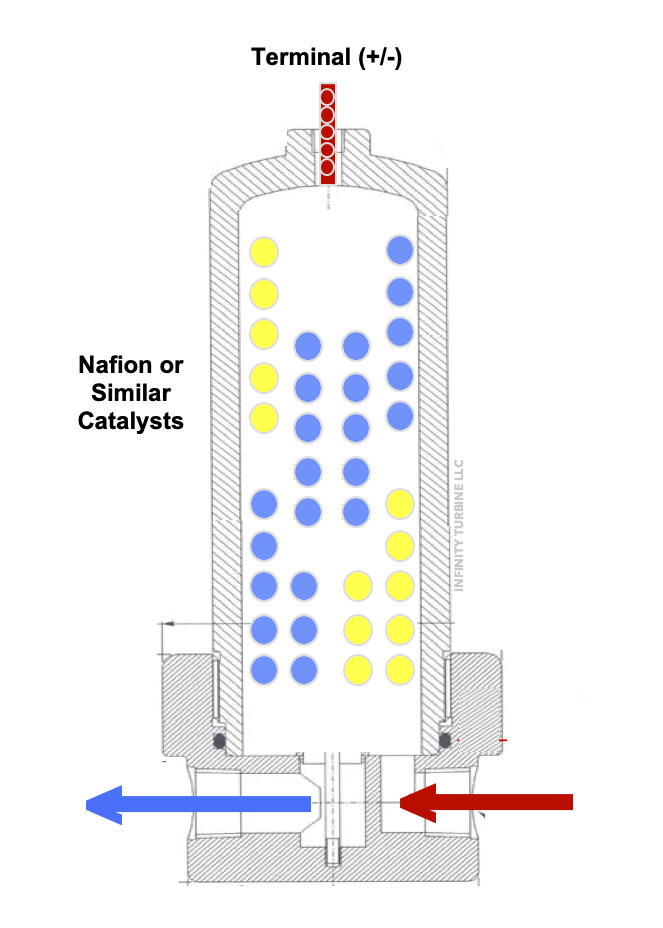

Rocket Fuel GTL Module Experimenters Platform Inputs: CO2, H20, DC electricity, and Nafion or other membrane catalysts. |

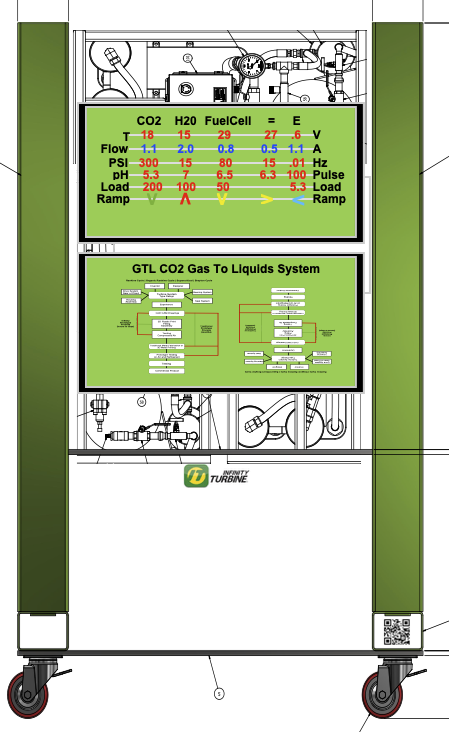

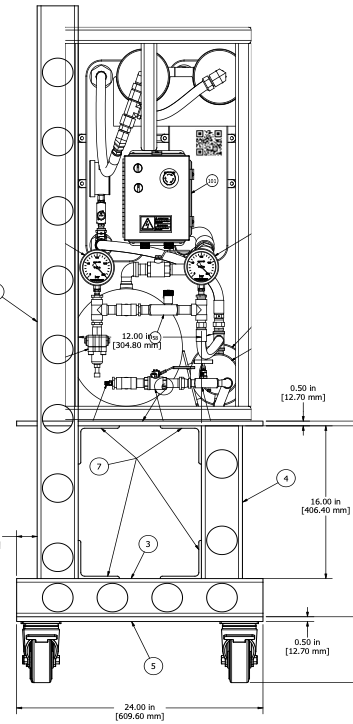

Side View of Infinity Turbine GTL Gas to Liquids Experimental Platform Using Reverse Fuel Cell (electrolizer) |

GTL gas to liquids processor module taking CO2, water and electricity to make fuels |

CO2 to Fuels Experimental Developer Platform Processor The purpose of this platform is to provide experimentation and development of novel gas to liquids (GTL) technologies for the utilization and mitigation of carbon dioxide.Infinity is now providing experimental platforms for developing modular cart mounted GTL (gas to liquids) fuel processing from CO2. Using Nafion or similar catalysts (available in sheets, tubes, pellets, and more), the inputs are CO2, water, and electricity to make alcohol (ethanol, methanol, and butanol). The selectivity of the output will depend on your formula for the inputs and catalyst.The Infinity GTL Processor allows you to adjust the flow of CO2, water, and electricity. The platform also allows you to incorporate and modulate in-situ power production, static electricity generation (SEG), and other unique functions.The processor platform is available in a completed cart or parts in kit form for developers who want to configure their own system. |

GTL gas to liquids modular processor taking CO2, water and electricity to make fuels |

CO2 gas to liquids processor |

CO2 to Rocket Fuel Experimental Developer Platform Processor The purpose of this platform is to provide experimentation and development of novel gas to liquids (GTL) technologies for the utilization and mitigation of carbon dioxide.Infinity is now providing experimental platforms for developing modular cart mounted GTL (gas to liquids) fuel processing from CO2. Using Nafion or similar catalysts (available in sheets, tubes, pellets, and more), the inputs are CO2, water, and electricity to make alcohol (ethanol, methanol, and butanol). The selectivity of the output will depend on your formula for the inputs and catalyst.The Infinity GTL Processor allows you to adjust the flow of CO2, water, and electricity. The platform also allows you to incorporate and modulate in-situ power production, static electricity generation (SEG), and other unique functions.The processor platform is available in a completed cart, or parts (kit form) for developers who want to configure their own system.ConceptThe concept of a modular GTL processor is to provide a rapid configurable platform to perform experiments and development to advance gas to liquids processing.This is accomplished by providing a standard catalyst module which can be easily adjusted (mechanically and flow).The functionality is further enhanced by optional add-ons to incorporate in-situ power production and catalyst tuning using static electricity.The platform is bolted together with standardized fasteners and can easily be modified.ParametersCatalyst: Nafion and other catalysts can be tested or developed for best output.Electricity: Volts, amps, and frequency can be adjusted for production tuning.CO2 and Water: Flow, pressure, and temperature can be adjusted.Rotational Device: Cavitation and other devices can be incorporated into the system.Instrumentation: Sensors allow real-time processor monitoring and data capture.AdvantagesThe biggest advantage of a modular processor platform is time savings from a standardized configuration which allows the user to implement rapid changes on the fly.Components are accessible and the stainless steel tubing can easily be cleaned.Instumentation can be extended to wireless monitoring using a smartphone or tablet. The system can be configured to run remotely.The caster mounted cart is made from heavy duty powder coated beam construction. |

Supercritical CO2 can treat Nafion for Direct Methanol Fuel Cells |

Supercritical CO2 to treat Nafion for Direct Methanol Fuel Cells Supercritical carbon dioxide treatment was used to enhance performance of NR212. The microstructure of NR212 membranes was reorganized after the Sc-CO2 treatment. The treated NR212 membranes showed higher proton conductivity than Nafion 117. The treated NR212 membranes showed lower methanol permeability than Nafion 117. Direct Methanol Fuel Cell (DMFC) performance of the treated NR212 membranes was better than Nafion 117 (2012). The Nafion-grafted-polystyrene sulfonic acid (N-g-pssa) exhibits higher ion conductivity and lower methanol permeability than that of Nafion 115. The N-g-pssa membranes are tested as electrolytes in a direct methanol fuel cell. Compared with the as-received NR212 membranes, all the Sc-CO2 treated NR212 membranes show higher proton conductivity and better capacity of barrier to methanol crossover. From Fenton test, it can be found that the Sc-CO2 treated NR212 membranes have better chemical stability than that of NR212 membranes. Therefore, NR212 membranes treated by the Sc-CO2 method may be promising candidate electrolytes for DMFC applications (2020). |

| CONTACT TEL: 1-608-238-6001 Email: greg@infinityturbine.com | AMP | PDF |