Need Strategy? Use our Consulting and analyst services

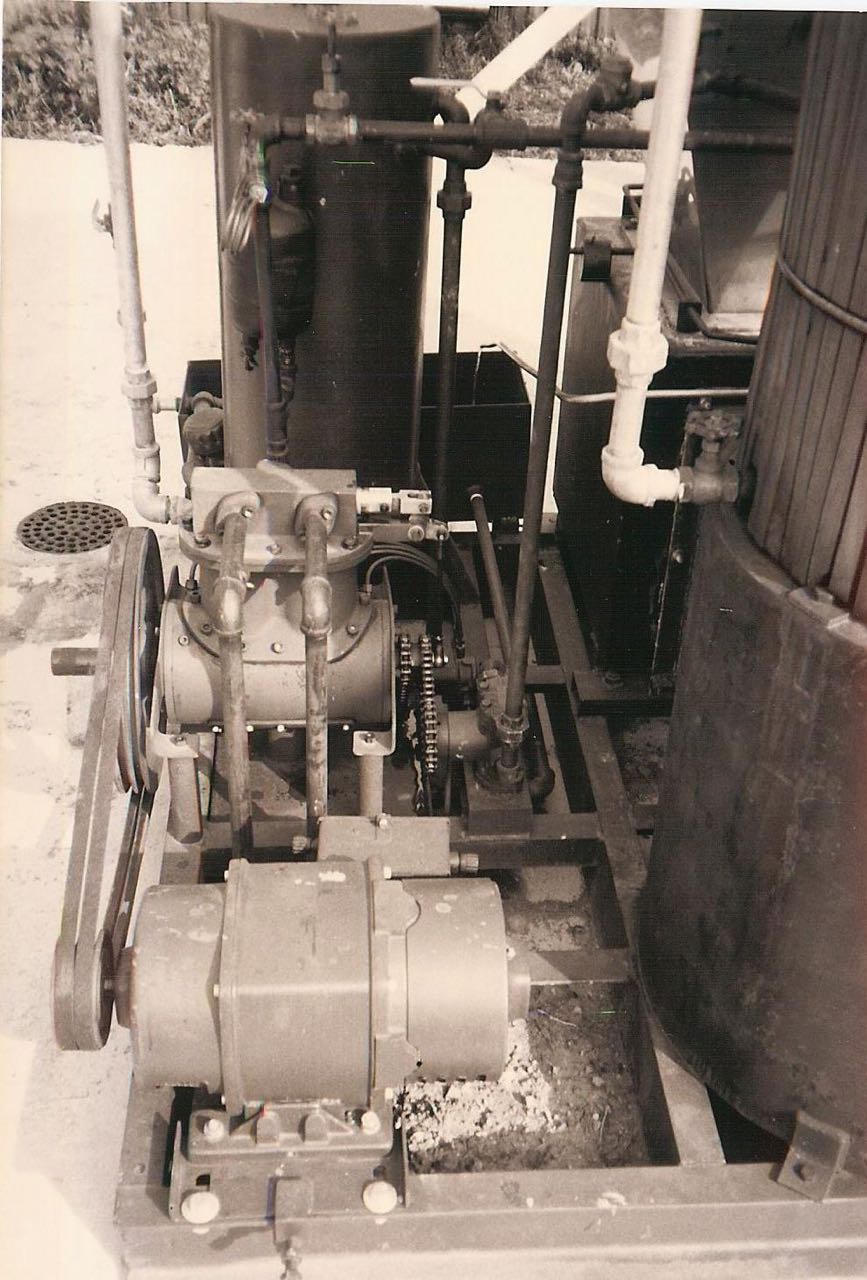

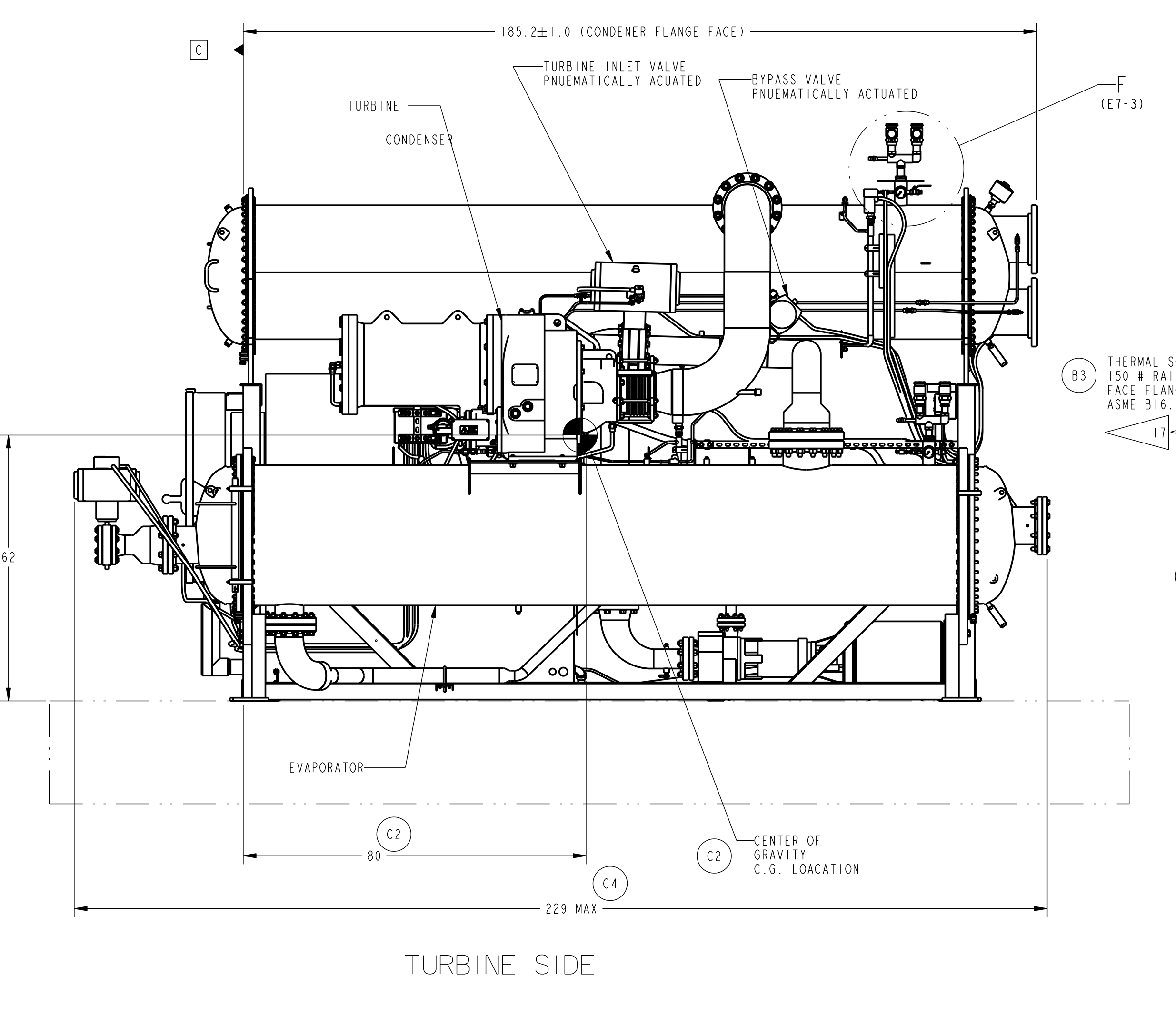

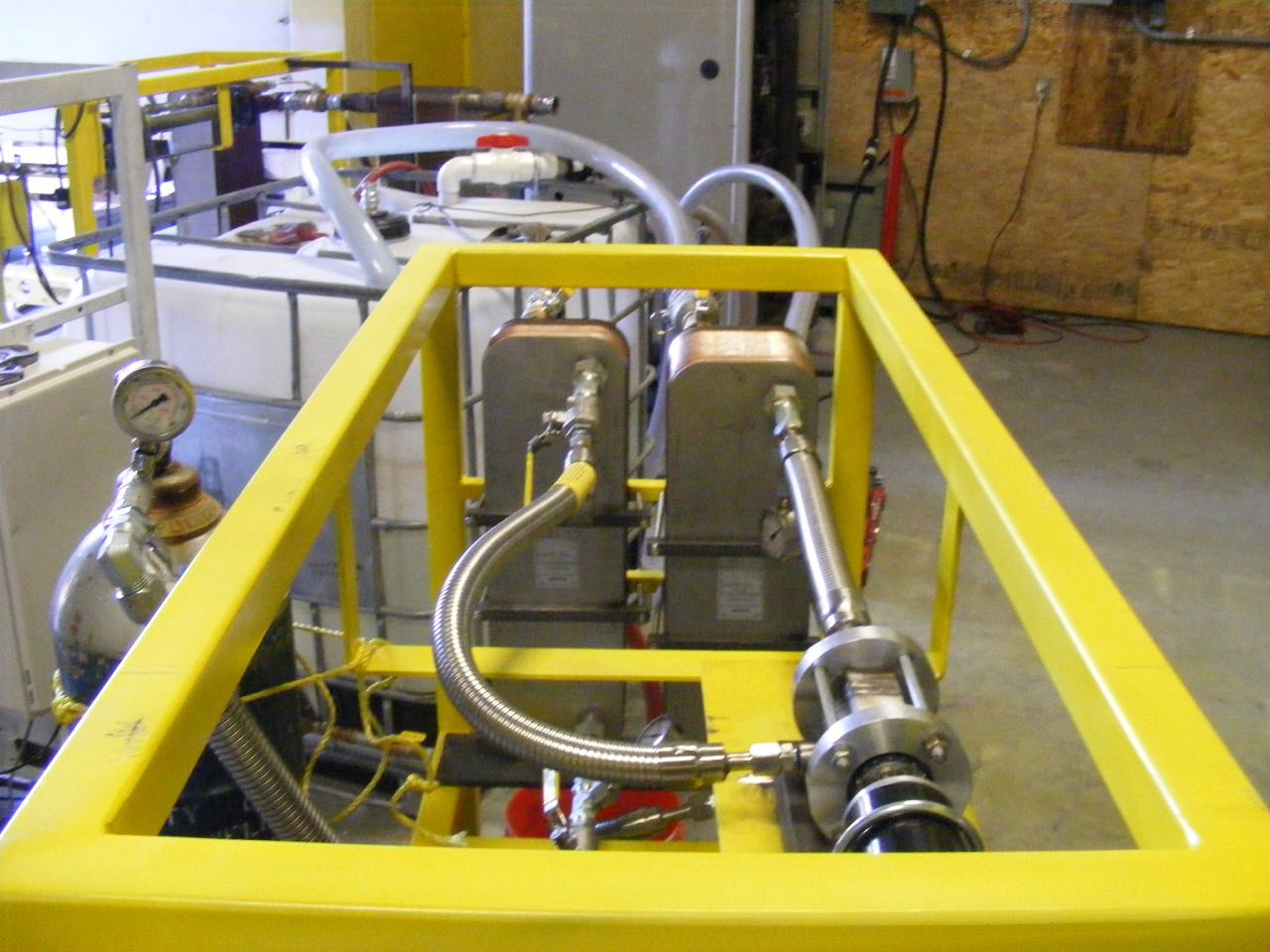

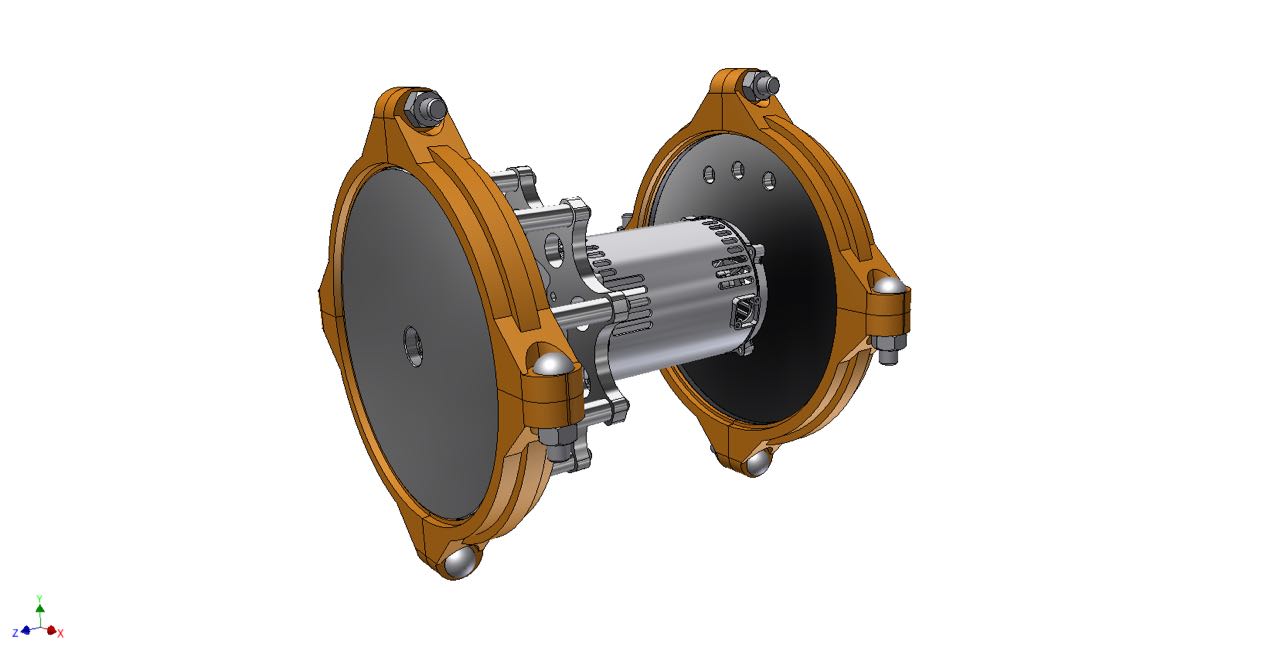

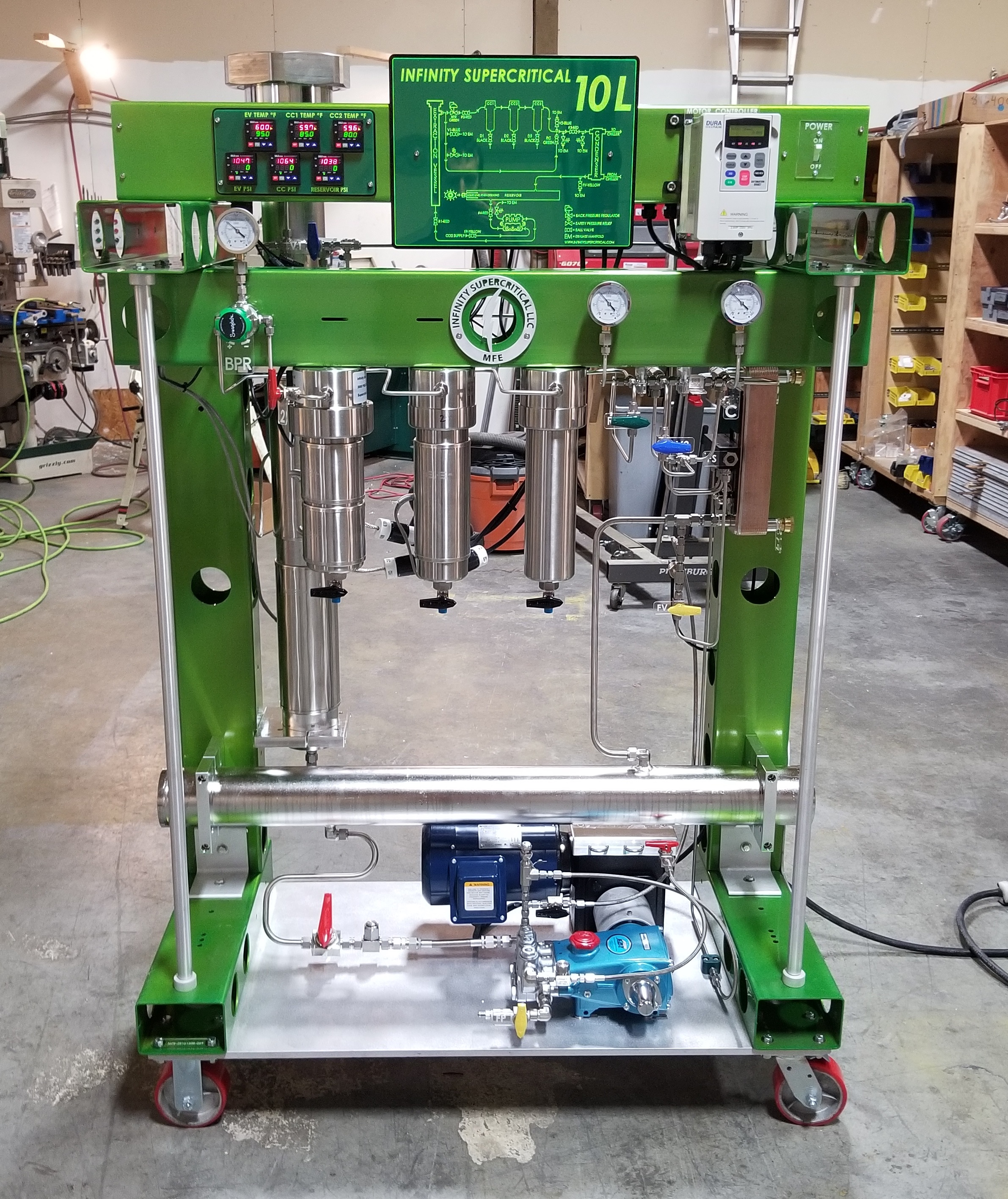

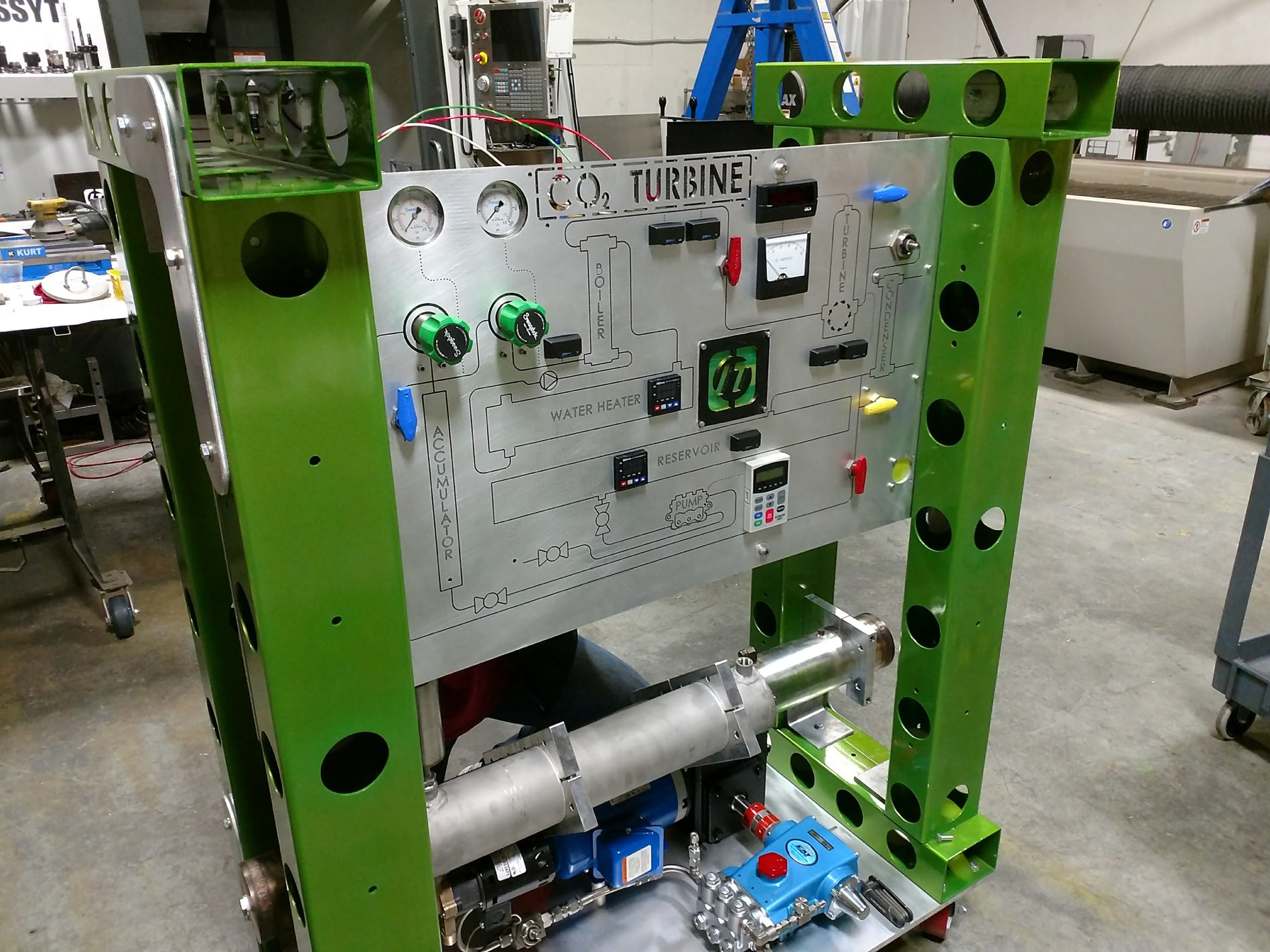

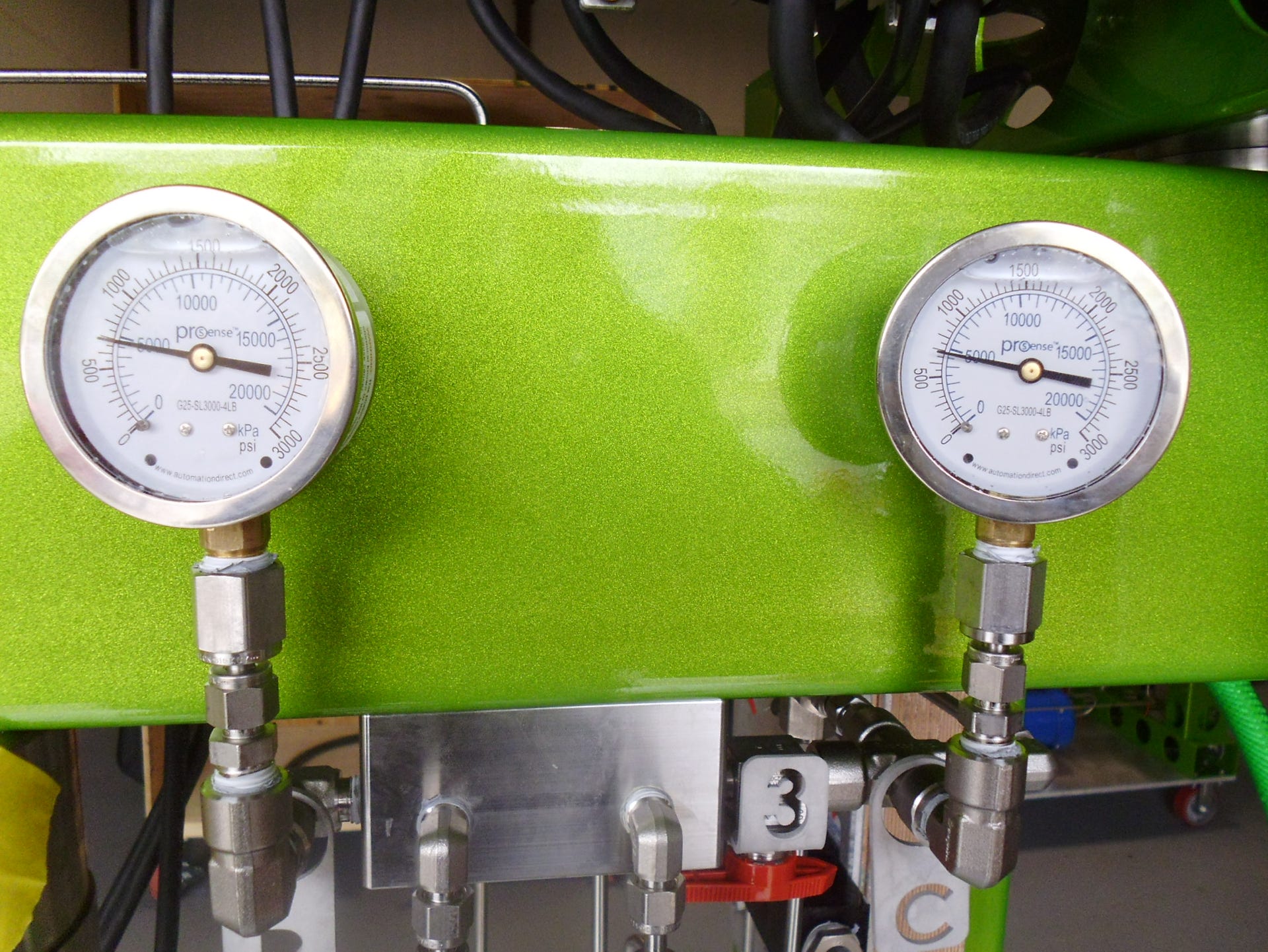

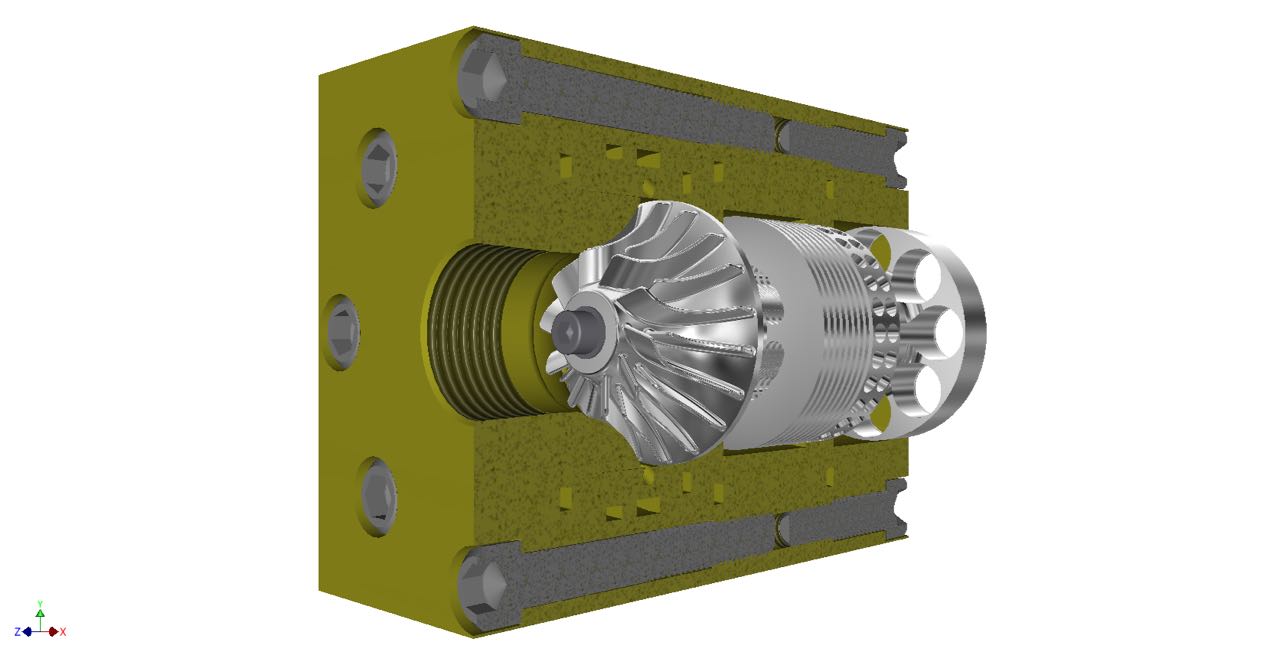

Infinity Turbine LLC is pleased to announce its consulting and analyst services. We present data in logical, easy to understand format with links for additional research or verification of data.Energy: Since 1985, I have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. A wide breadth of subjects and project development includes some of the following subjects.All time is documented and a summary log will be provided when requested. Consulting is provided via telephone, email, or other media as agreed to in writing (email). Our consulting services are available on a best efforts basis and are delivered with our utmost dedication. We strive to provide the best possible service and ensure that all time spent is meticulously documented. Upon request, we can furnish a summary log of our activities. We offer project assessment, engineering studies, turbine design, battery design, supercritical CO2 process strategies, and more.We've worked on steam engines to supercritical CO2 turbines, to tribo-effect no-moving-part energy generation systems.