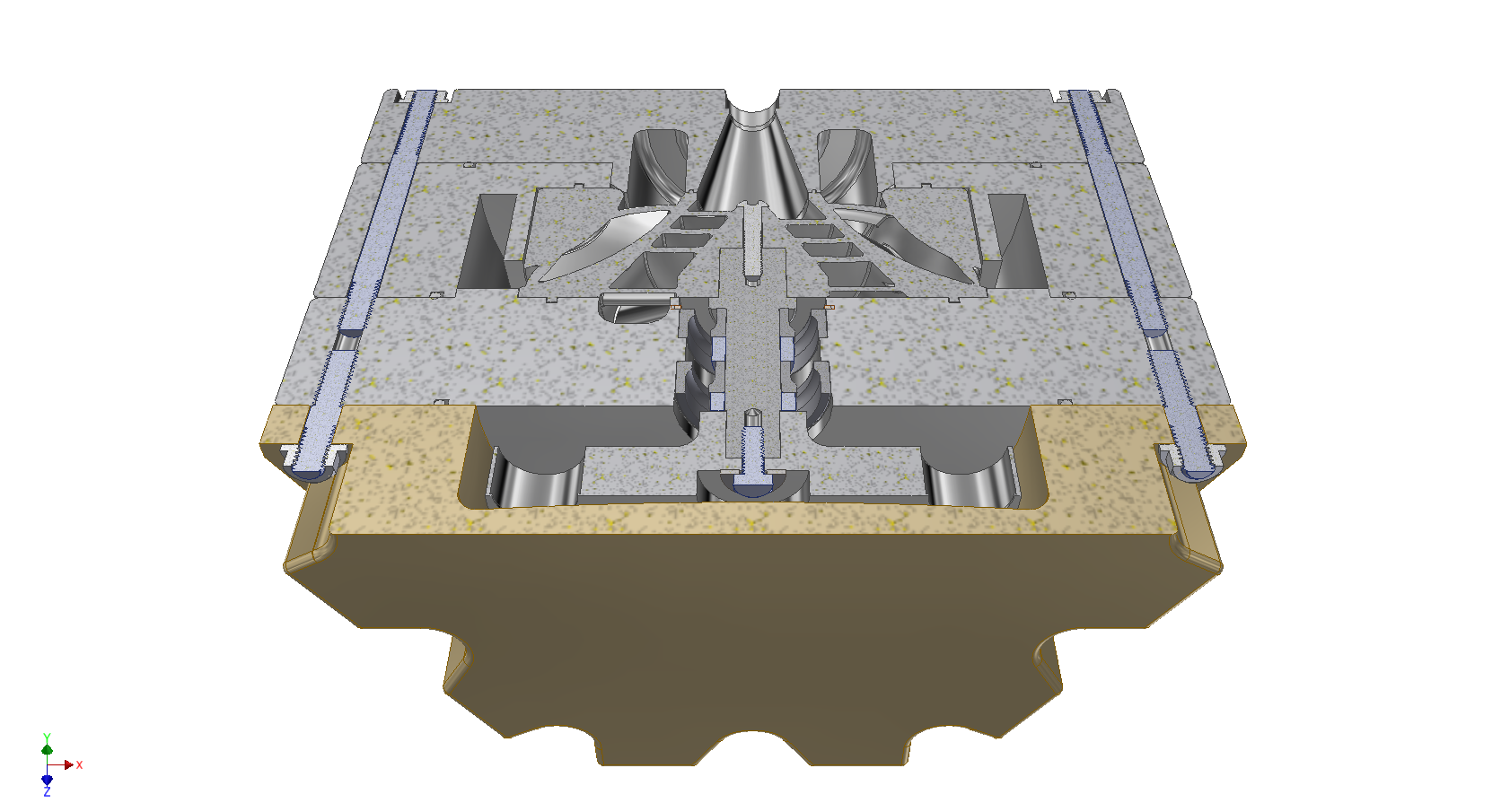

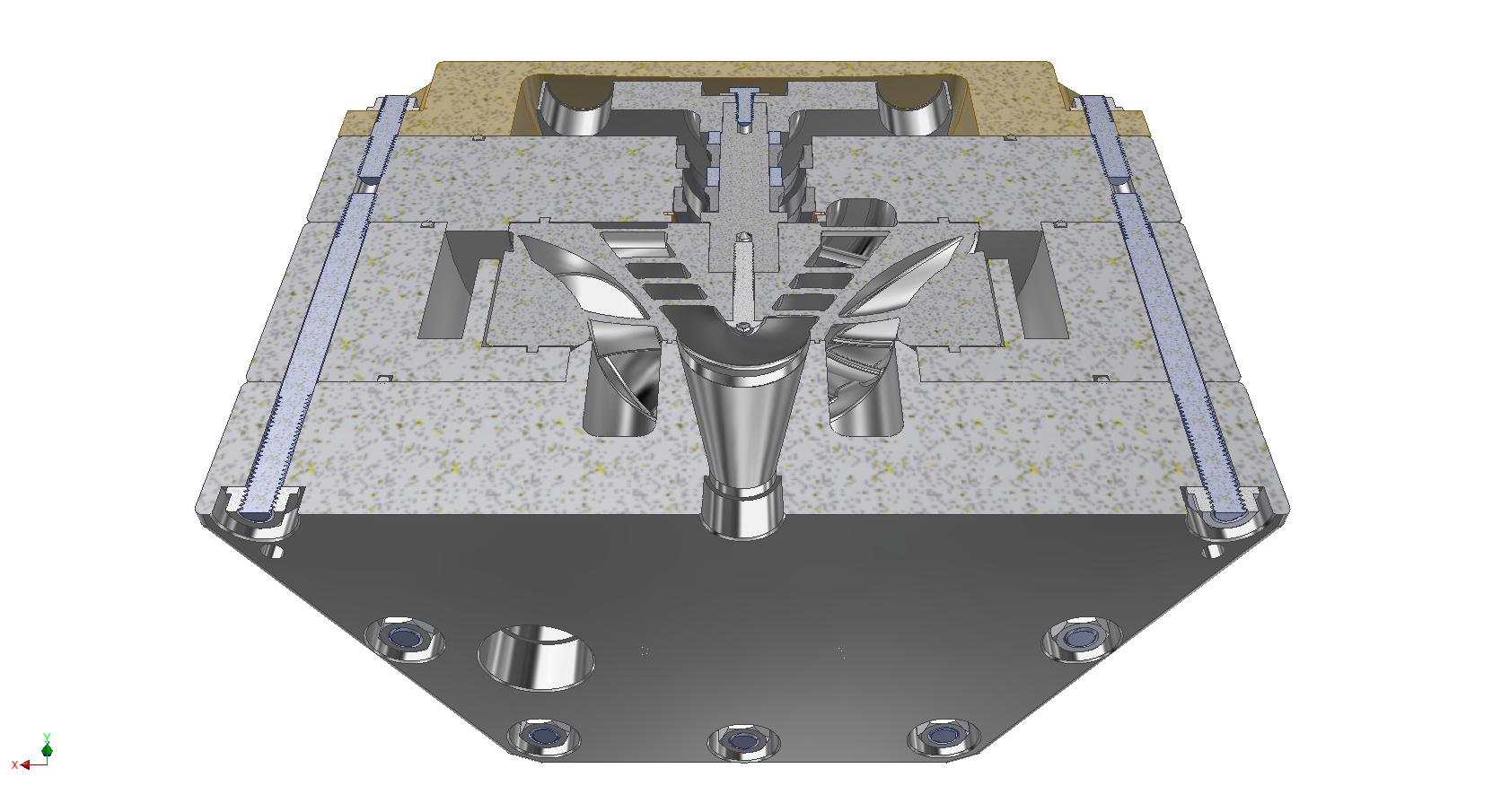

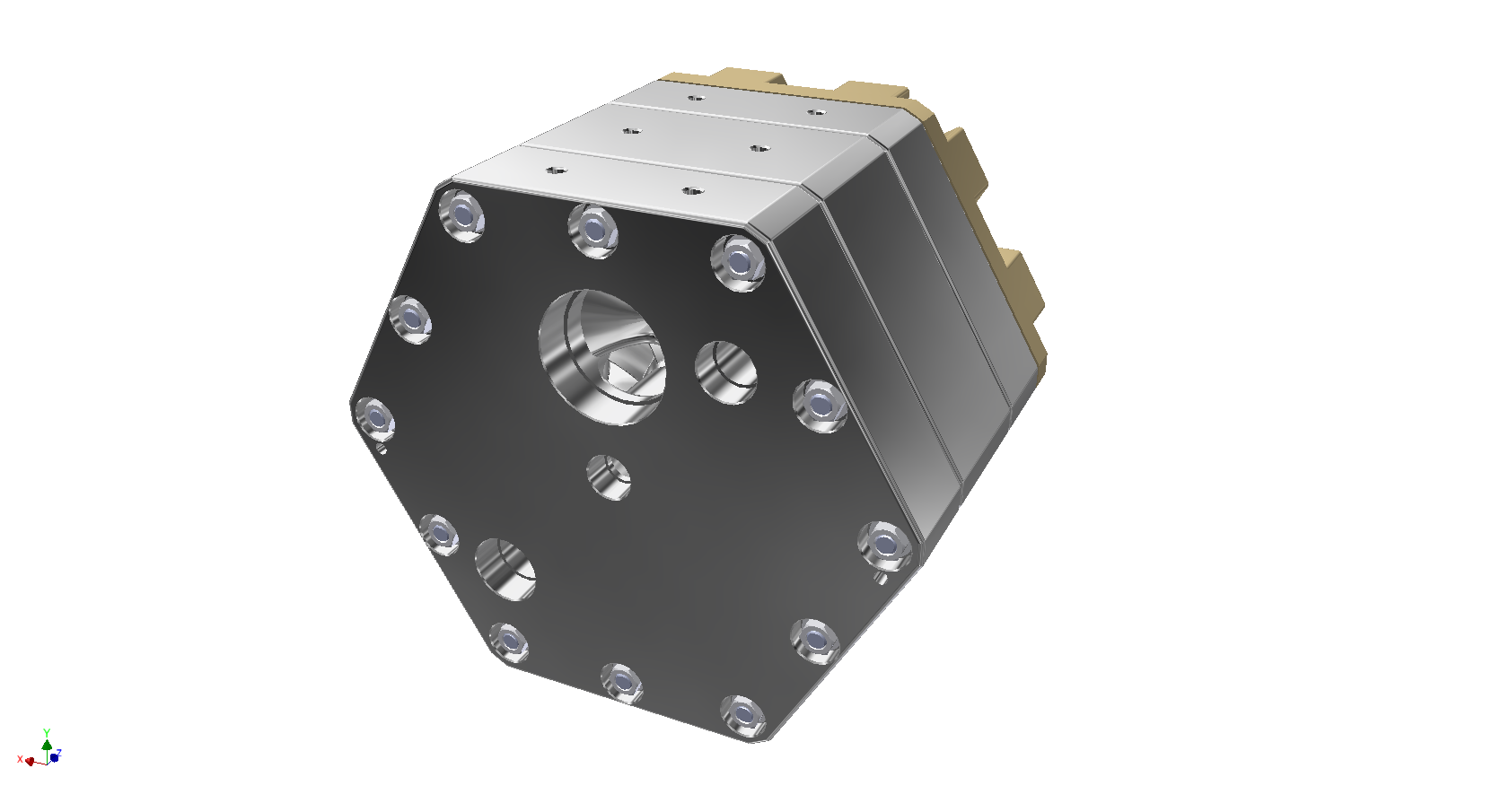

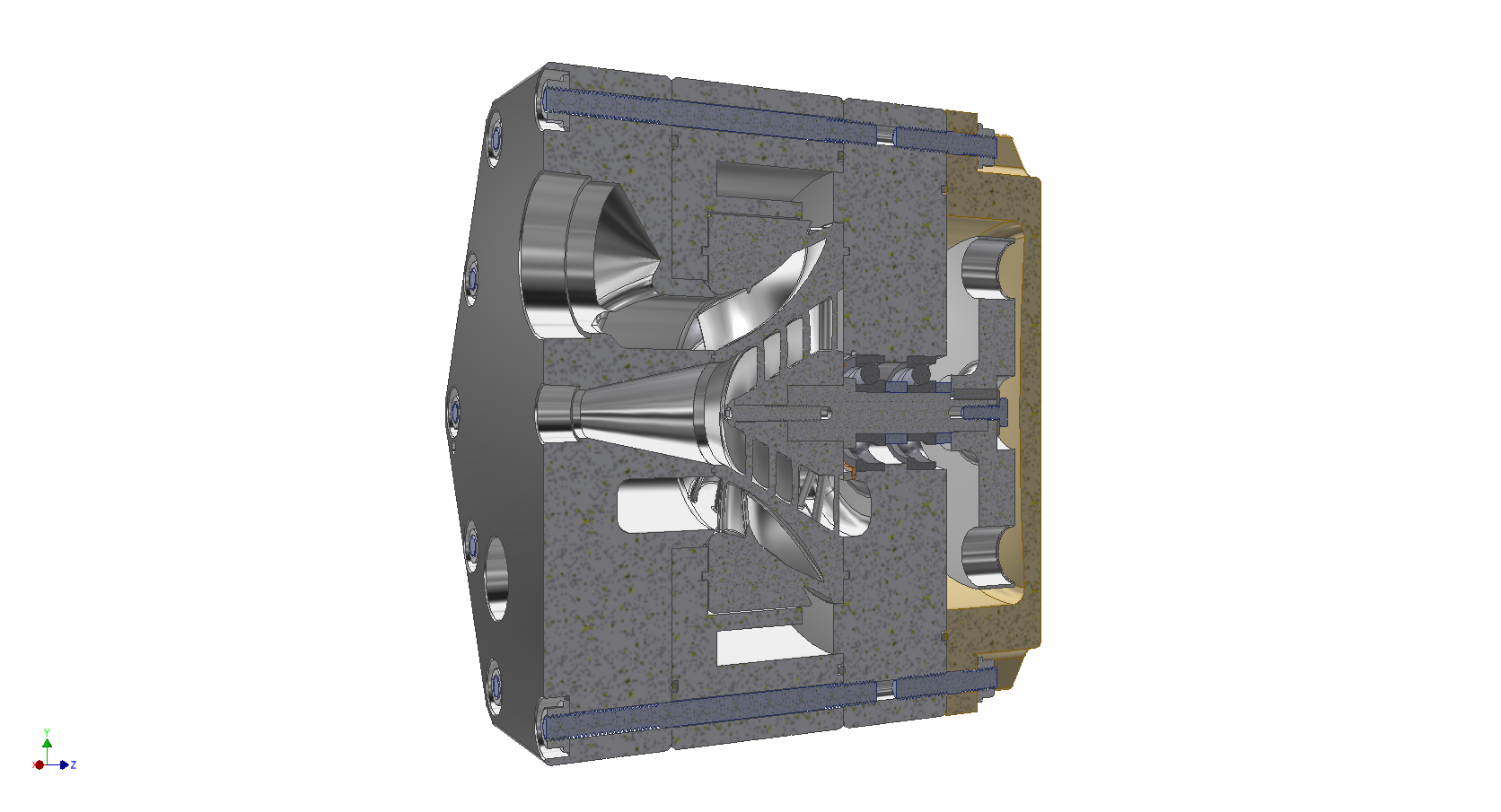

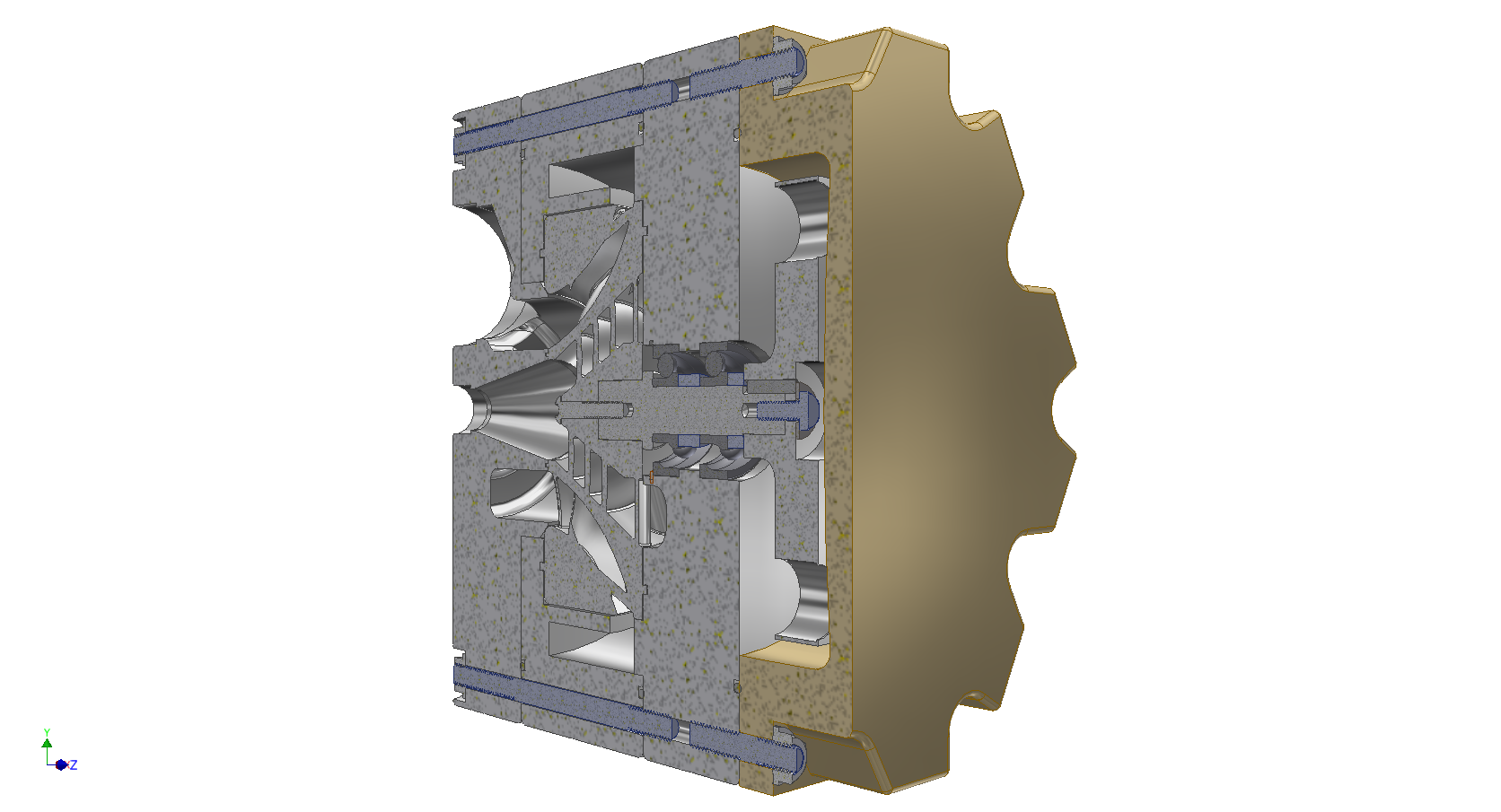

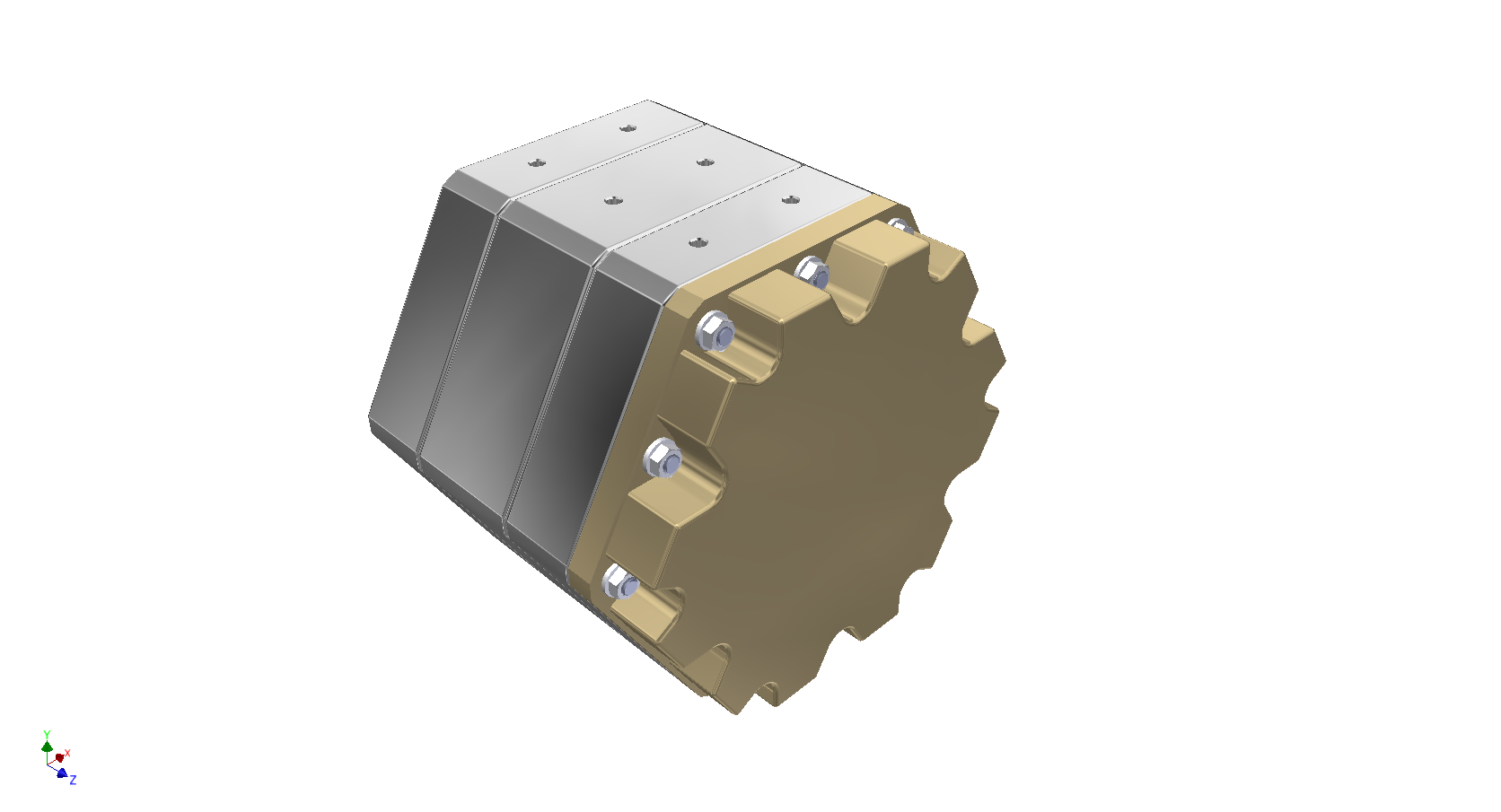

IT 10 Project Redstone Turbine with Integral Pump in One Rotating Element

IT 10 Redstone Turbine

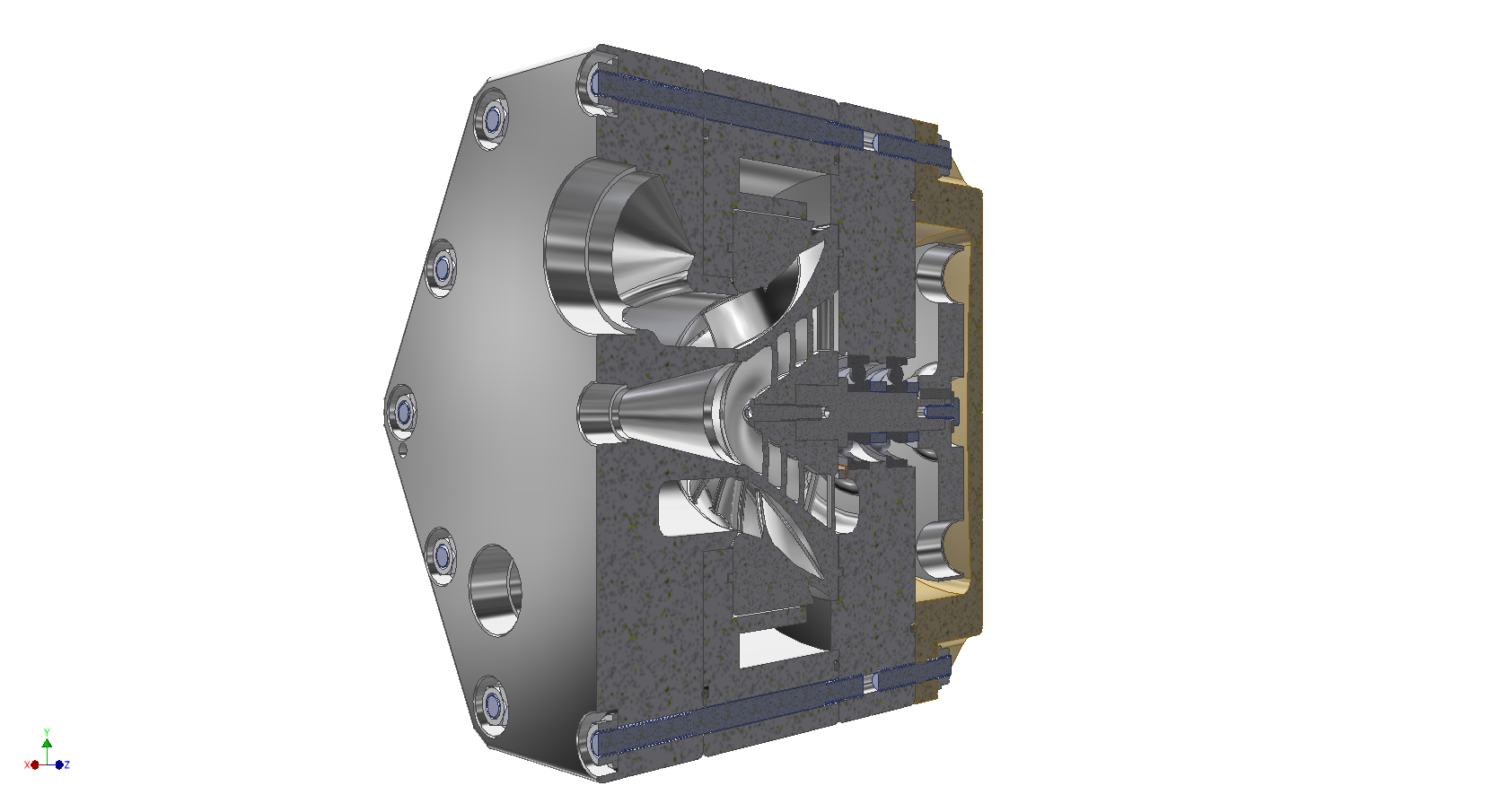

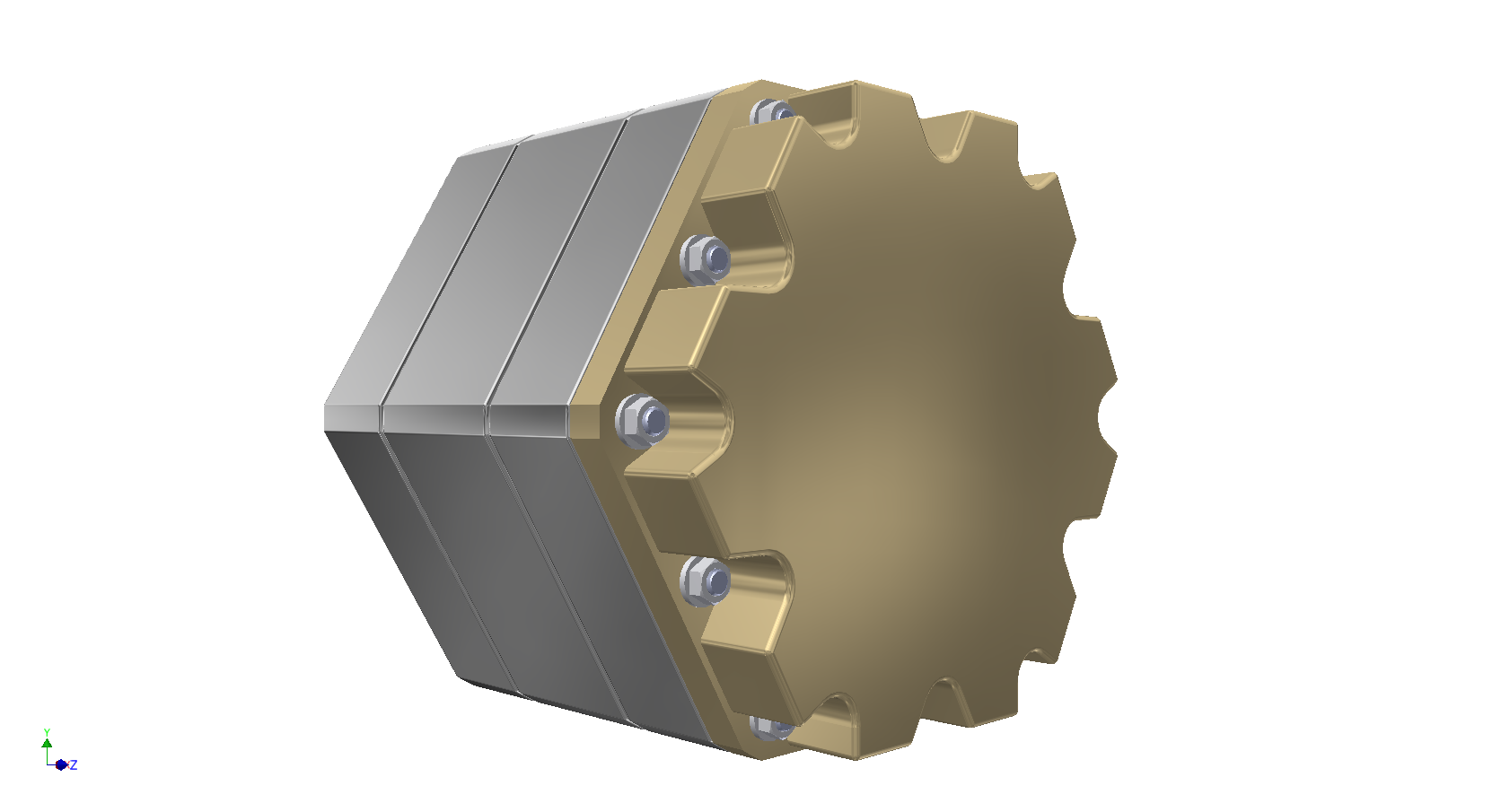

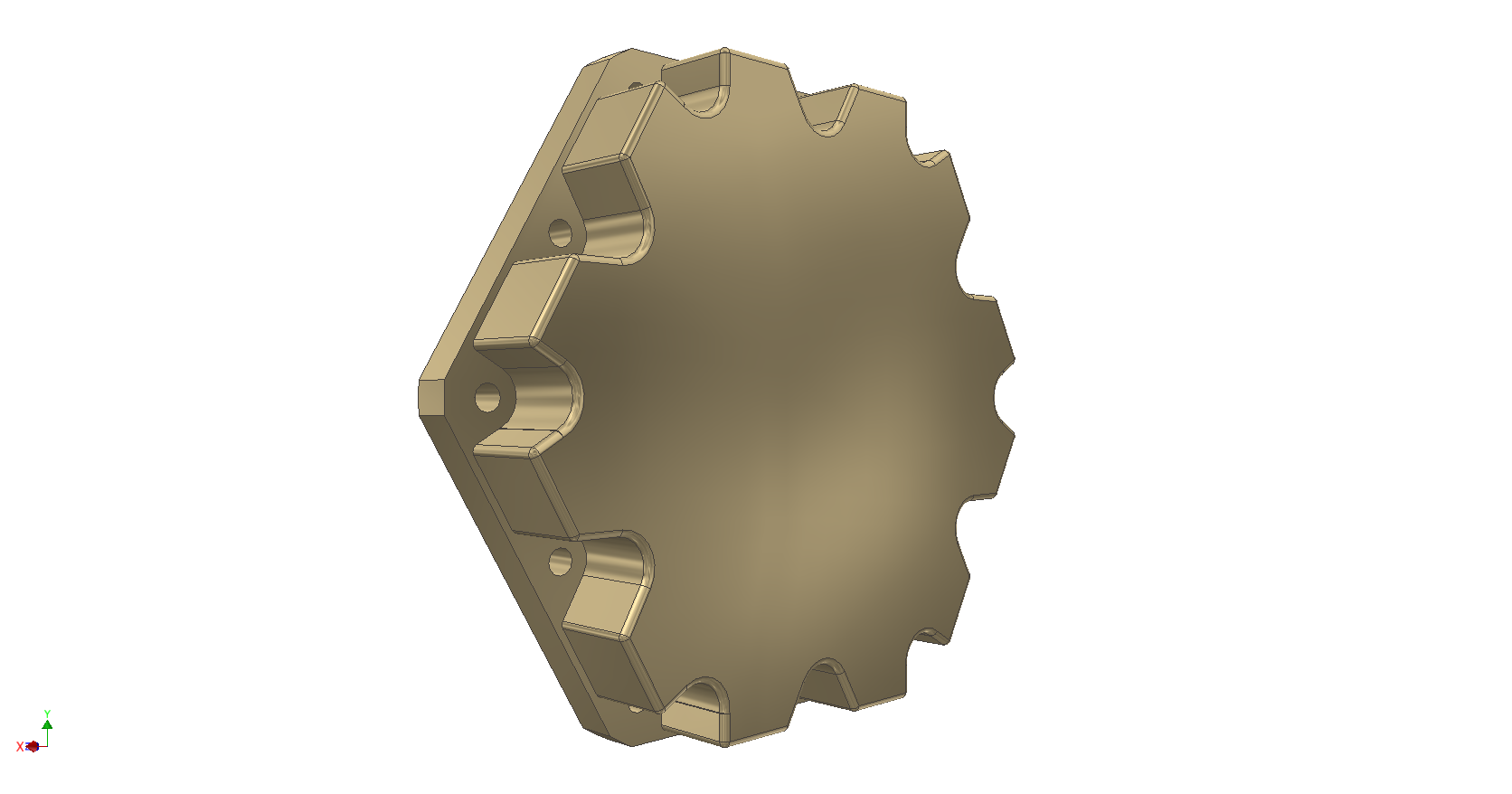

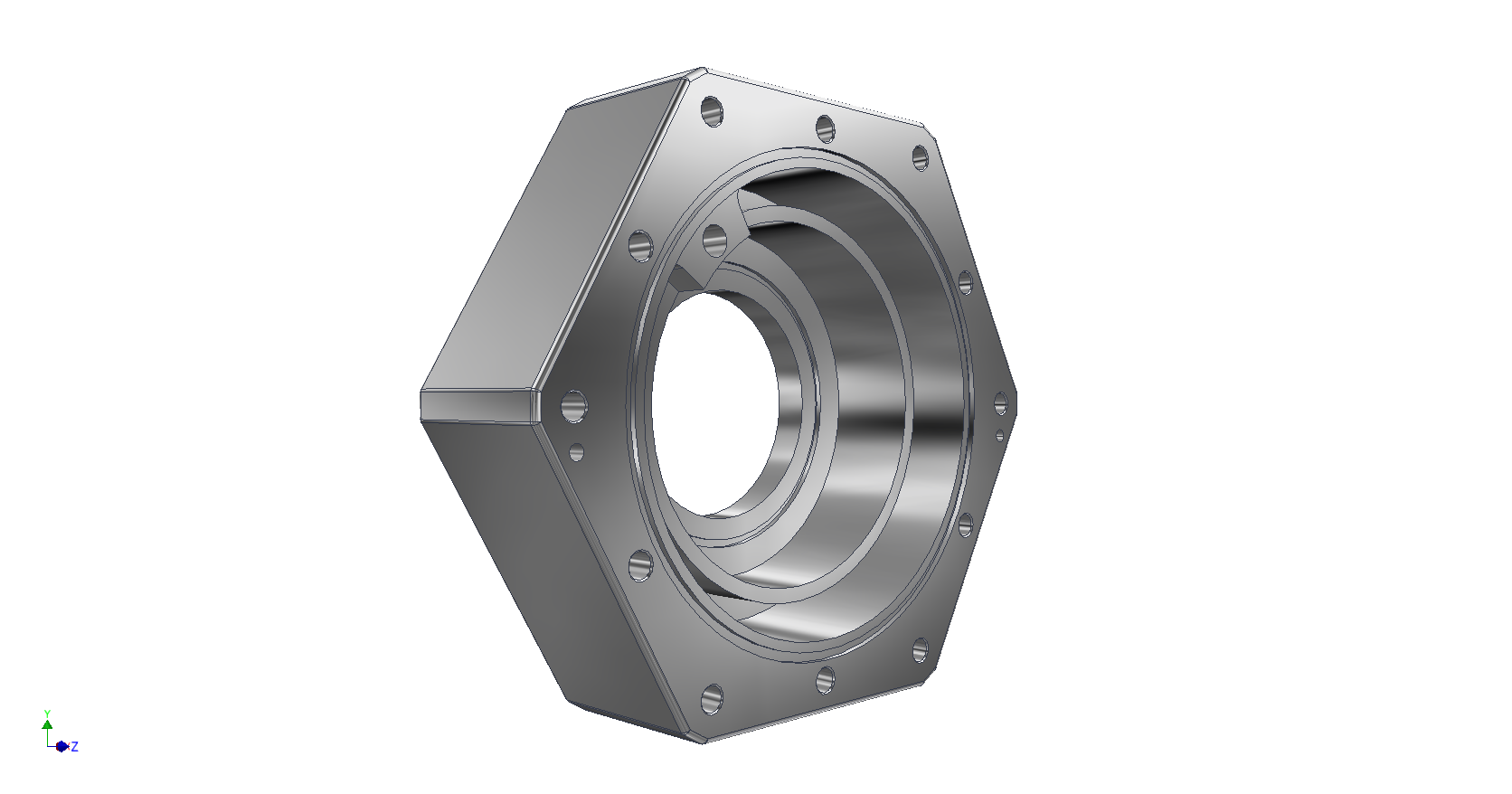

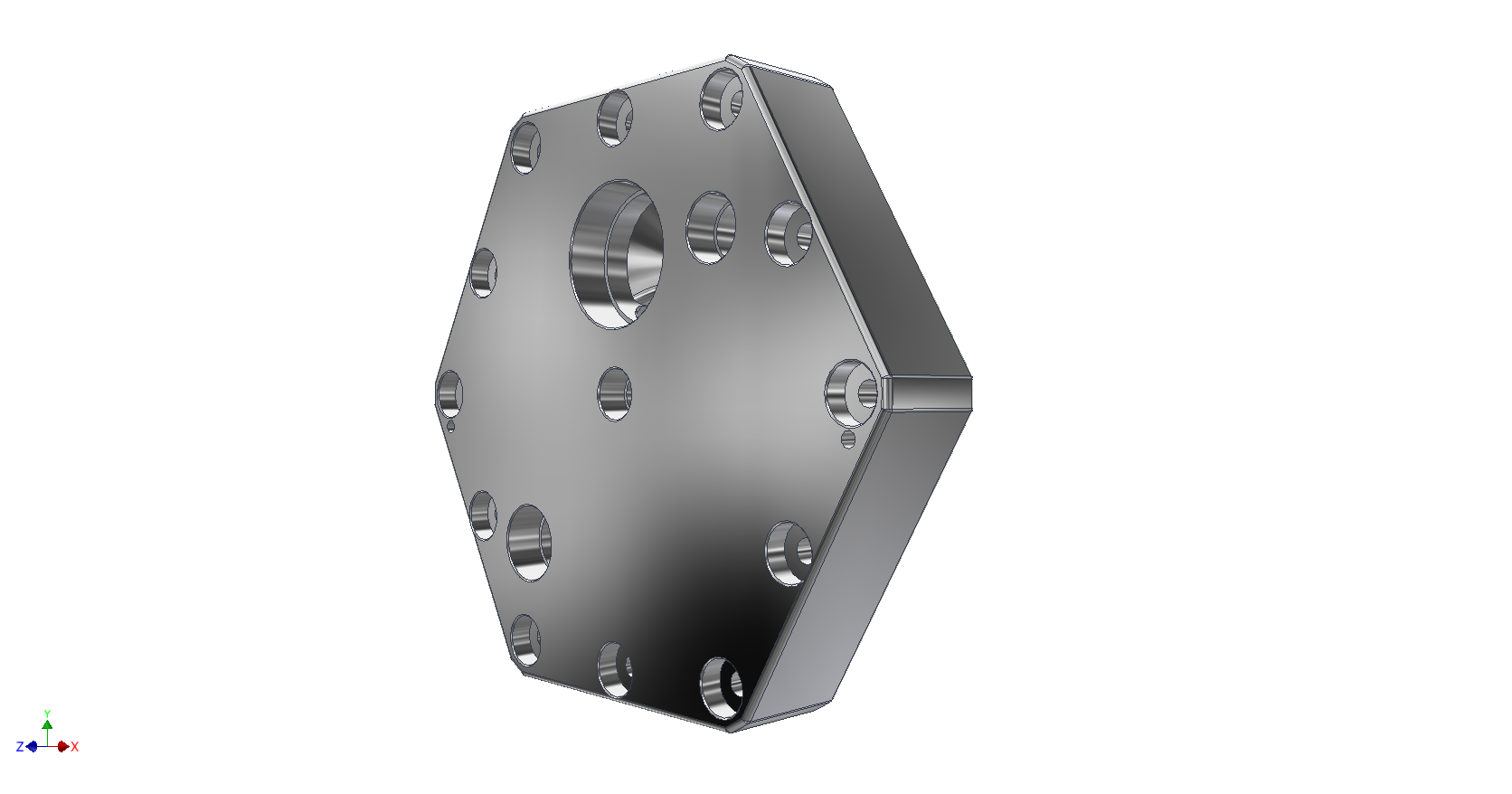

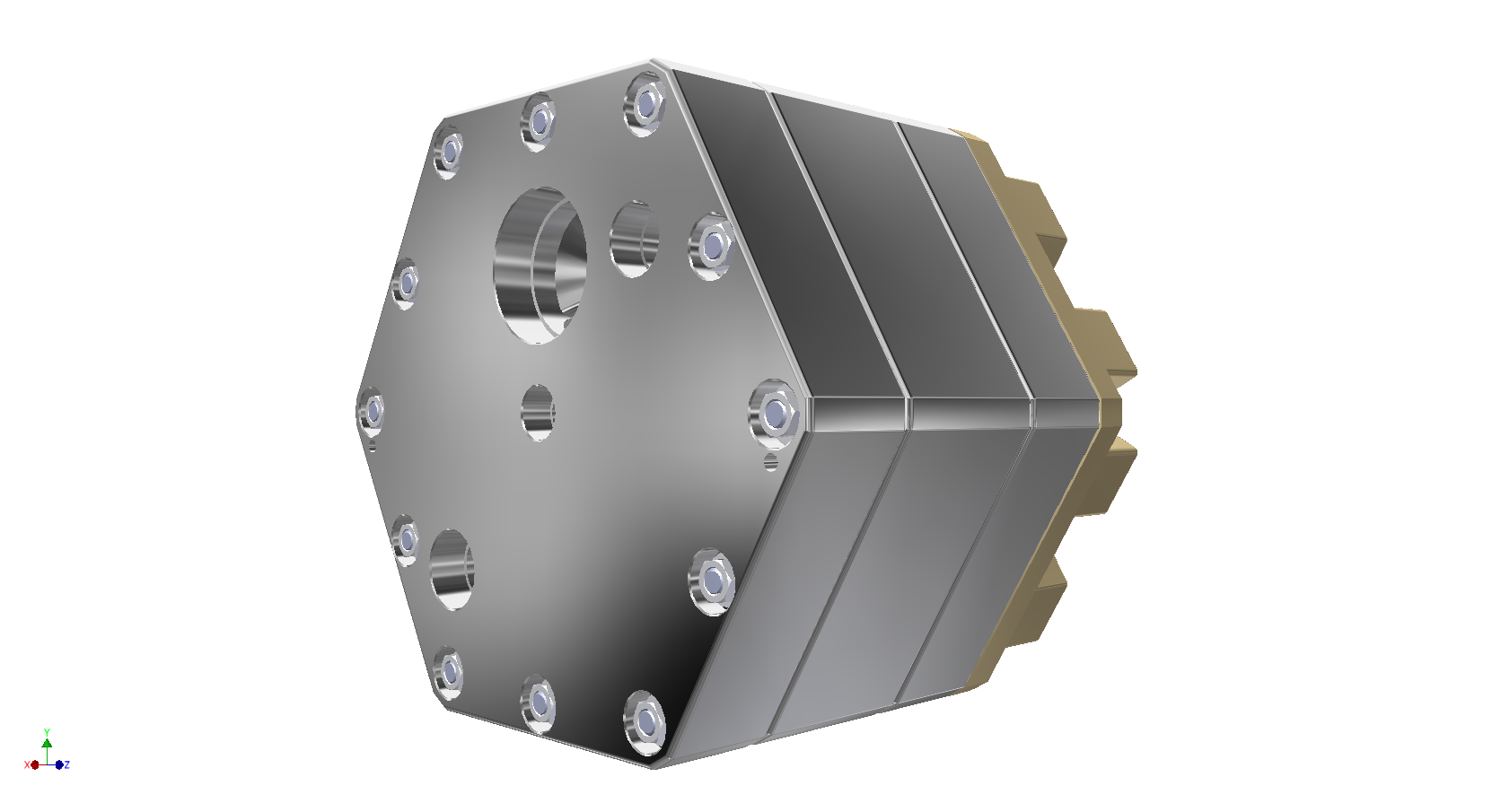

The IT 10 Redstone Turbine is an experimental 6-inch diameter turbine designed for small-scale power production, suitable for residential use or low-power applications (IT10: 1-10 kW).Project Goals: Integrate a liquid pump into a single rotating component. Instead of using a traditional shaft-driven feed pump, the turbine is designed to be counter-rotating as a single unit.Working Fluid: Compatible with R-245fa, R-134, compressed air, pressurized water, and available in a stainless steel version for use with CO2.Modular Block Assembly: Since 2008, our Modular Block concept has been used in hundreds of turbine prototypes and production assemblies. This version features square blocks with 3/8 fasteners and threaded bores.Purpose: Enable small-scale power production without the need for an external feed pump.Rapid Configuration: The modular assembly allows for quick turbine reconfiguration and testing with various working fluids and heat sources. The basic design supports pressures up to 300 psi, which is dependent on the back magnetic coupling block made from HDPE. By using a non-magnetic metal or composite fiber for a stronger backplate, higher pressures can be accommodated.Magnetic Coupling: The design includes a 6-inch diameter magnetic coupling and follower, allowing for an external generator or drive unit to be mounted.Plans and licensing are available.IT10 Revenue Model: Revenue is based on gross sales or grid savings, excluding the cost of acquiring waste heat or pumps.Annual Revenue Projections for IT10 (operating 24 hours/day, 365 days/year, producing 10 kWh/day = 87,600 kWh/year):• At $0.20 per kWh: $17,520 USD per year• At $0.40 per kWh: $35,040 USD per year• At $0.80 per kWh: $70,080 USD per yearIT 10 Project Redstone Turbine with Integral Pump in One Rotating Element (pdf)