Supercritical CO2 One Inch Turbine

INFINITY TURBINE | SALES | DESIGN | DEVELOPMENT | ANALYSIS CONSULTING

TEL: +1-608-238-6001 (Chicago Time Zone ) Email: greg@infinityturbine.com

GE Vernova Alternative: Supercritical CO2 Turbine Generator Multiple Modular Power Block MMPB Generators for Data Centers More Info

IT1000 Supercritical CO2 Gas Turbine Generator Silent Prime Power $3M 1 MW (natural gas, solar thermal, thermal battery heat) ... More Info

ORC and Products Index Infinity Turbine ORC Index... More Info

Supercritical CO2 One Inch Turbine |

IT50 kW System Loaded into a 20 ft. Shipping Container |

|

The Power of Waste Heat: Why ORC Systems Outperform Solar PV in 24-7 Industrial Applications In the clean energy landscape, solar PV panels often take the spotlight for renewable electricity generation. However, in industrial and data center settings where waste heat is abundant, the Organic Rankine Cycle (ORC) system delivers a compelling alternative. While the upfront cost per kilowatt for ORC is higher, its ability to generate power continuously from waste heat makes it an exceptional technology for 24/7 operations.Solar PV panels remain an excellent option for renewable power generation, especially in distributed applications. However, for industries or facilities already producing significant waste heat, ORC systems unlock a hidden source of clean, continuous energy. The higher initial cost is offset by 24-hour operation, faster payback, and greater environmental impact.Every BTU Deserves a Second Life - Solar PV to ORC Comparison |

IT10 ORC system for hot water geothermal, solar thermal, waterstove, or outdoor wood furnace |

Cart Mounted Supercritical CO2 System with Evaporator and Condenser for 1-5 kW Turbine Only and 1-14 kW with Common Shaft Compressor Cycle System |

Sand Salt Thermal Battery for Chiller, Hydraulic, and Power Applications Converting Hydraulic Pumps into Supercritical CO2 Expanders for Energy Recovery |

|

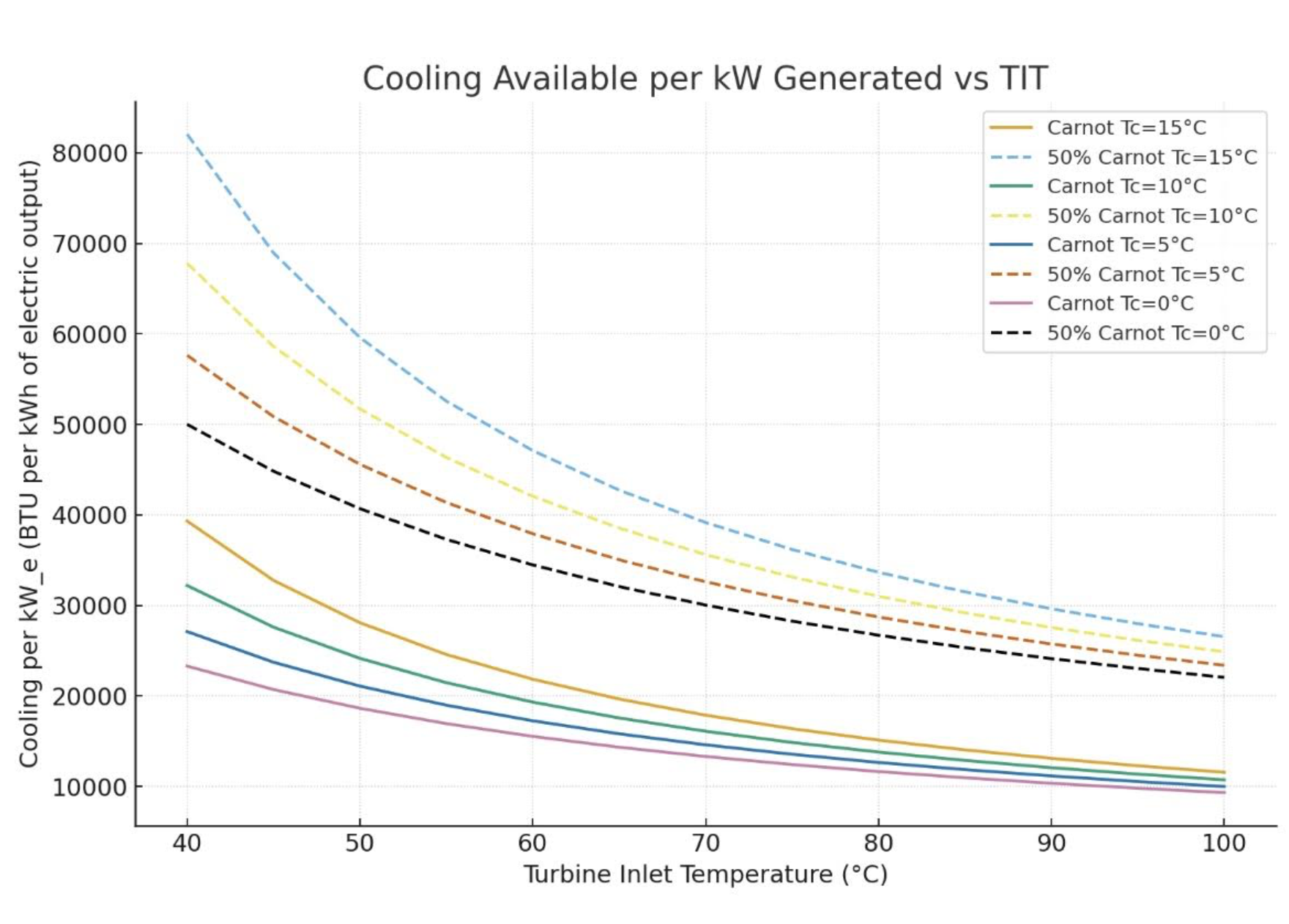

Cooling Potential of Micro Supercritical CO2 Turbines per Kilowatt of Electricity Generated Micro sCO2 turbines provide significant cooling per kilowatt of electricity generated, particularly when operating from low temperature heat sources. Although higher turbine inlet temperatures and lower condenser temperatures improve electrical efficiency, the rejected heat remains substantial. By capturing this cooling capacity, operators can enhance system performance and deliver dual benefits of power generation and refrigeration from the same thermal resource.Cooling Potential of Micro Supercritical CO2 Turbines per Kilowatt of Electricity Generated |

|

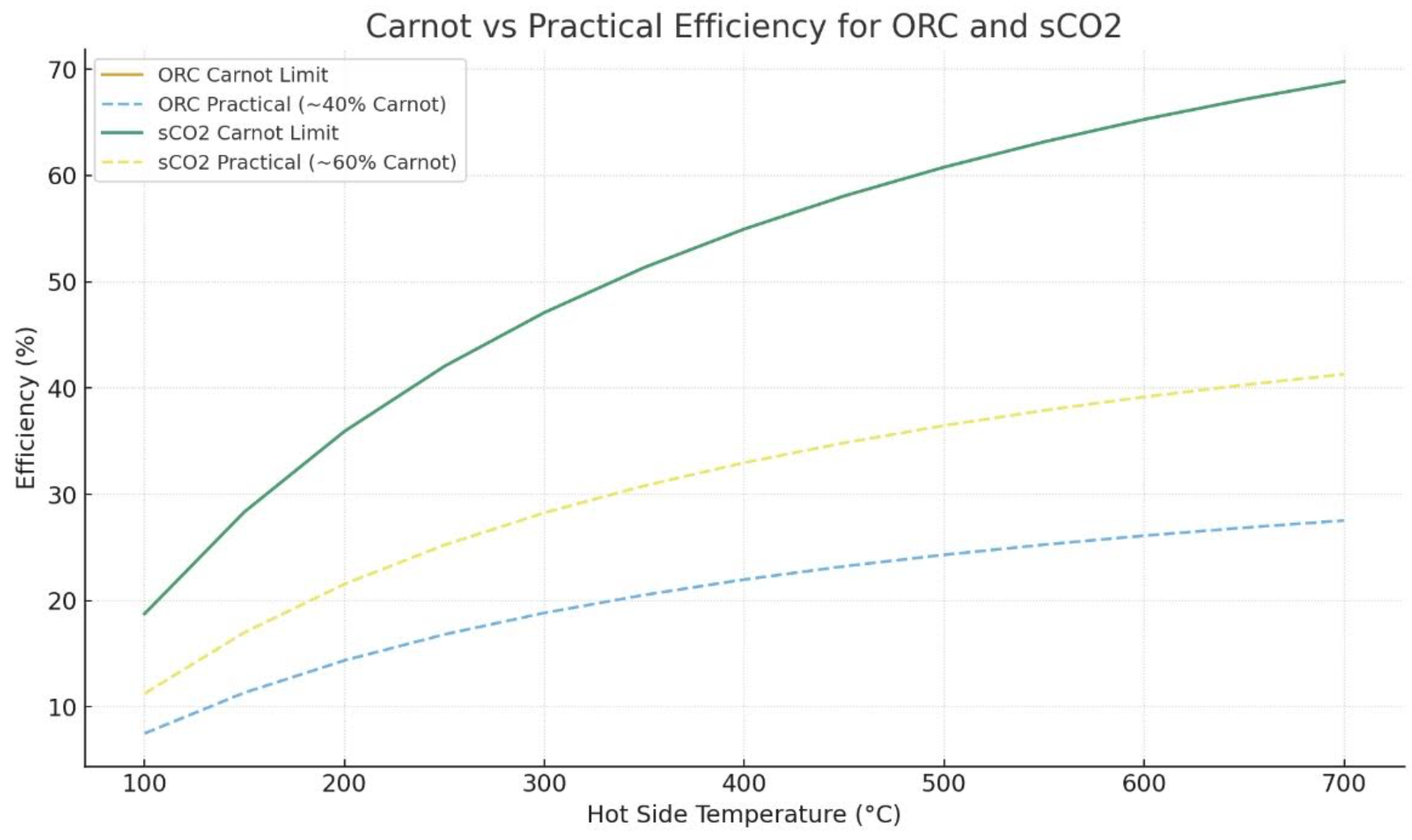

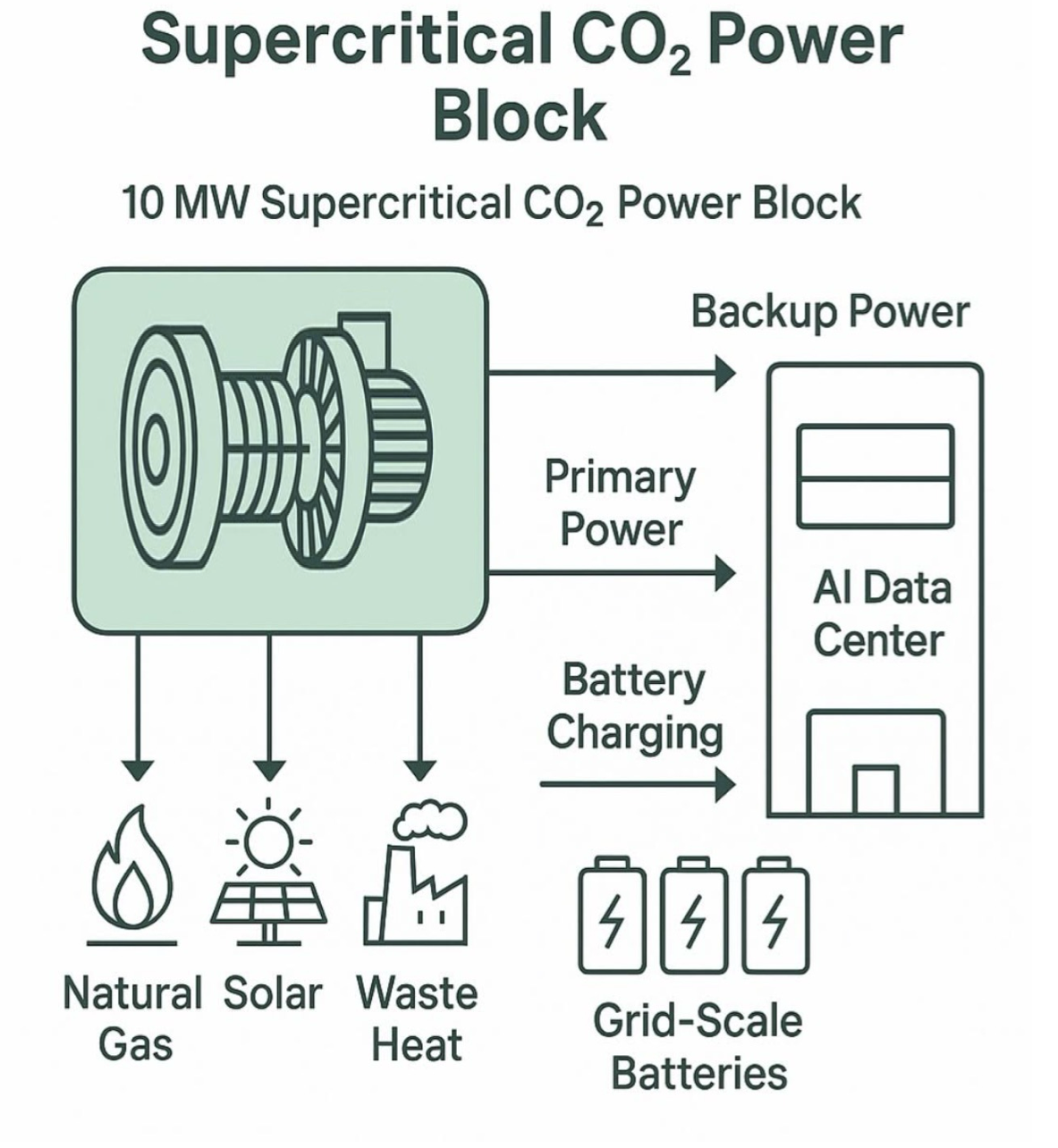

Comparing Carnot Efficiency in Organic Rankine Cycle and Supercritical CO2 Turbomachinery IntroductionAll heat engines are bound by the same thermodynamic law: the Carnot efficiency. Whether the working fluid is an organic compound in an Organic Rankine Cycle (ORC) or supercritical carbon dioxide (sCO2) in a Brayton cycle, the maximum efficiency achievable depends only on the hot side and cold side temperatures. This article examines how Carnot efficiency applies to both systems and what real world performance looks like.Organic Rankine Cycle (ORC)ORC systems are often used for low to medium temperature heat sources such as geothermal, biomass, and industrial waste heat.Typical hot side: 100 to 350 °CTypical cold side: 20 to 40 °CExample: With T= 200 °C and c = 30 °C, Carnot efficiency is 36 percent.Practical efficiency: ORC systems typically achieve 8 to 20 percent. This corresponds to about 30 to 50 percent of Carnot, limited by pump losses, turbine design, and heat exchanger effectiveness.Supercritical CO2 TurbomachinerysCO2 cycles are well suited for higher temperature heat sources, including concentrated solar power, nuclear reactors, and high grade industrial waste heat.Typical hot side: 400 to 700 °C or higherTypical cold side: 20 to 40 °CExample: With h = 600 °C and c = 35 °C Carnot efficiency is 65 percent.Practical efficiency: Modern sCO2 turbomachinery can reach 35 to 50 percent. These systems often achieve 55 to 70 percent of the Carnot limit due to high fluid density, compact turbines, and excellent recuperation.Comparison and Key Differences• ORC excels at capturing low grade heat where sCO2 is inefficient, but suffers from low Carnot limits and reduced practical efficiencies.• sCO2 achieves much higher efficiencies at elevated temperatures and can approach a much larger fraction of Carnot compared to ORC.• Both systems are ultimately constrained by Carnot efficiency, but the choice of working fluid determines how closely real world designs can approach that theoretical limit.ConclusionCarnot efficiency provides a common framework for comparing heat engine technologies. In low temperature applications, ORC offers a viable solution despite modest efficiencies. At higher temperatures, supercritical CO2 turbomachinery demonstrates significant advantages, achieving both higher theoretical and practical performance. Selecting the right working fluid is therefore a matter of matching source temperature with the technology that can best exploit it.Comparing Carnot Efficiency in Organic Rankine Cycle and Supercritical CO2 Turbomachinery |

|

|

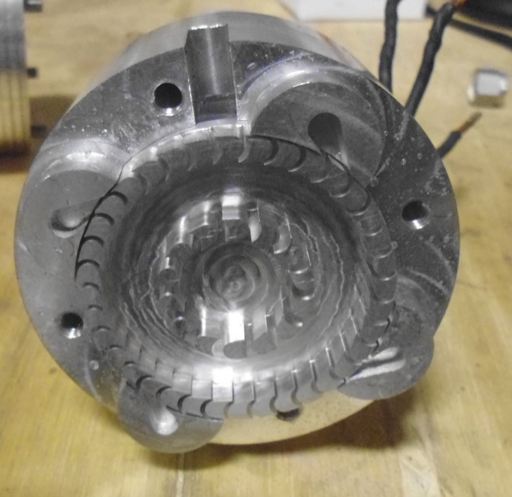

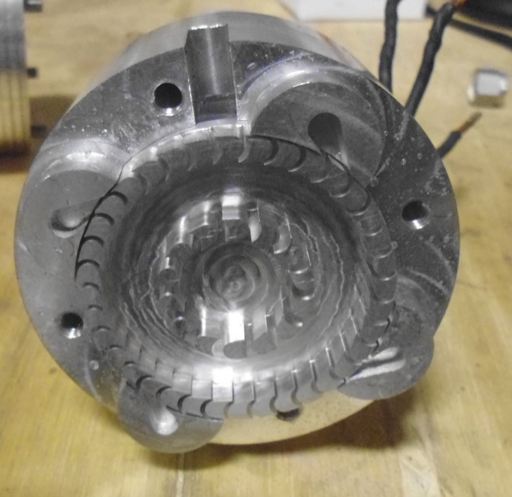

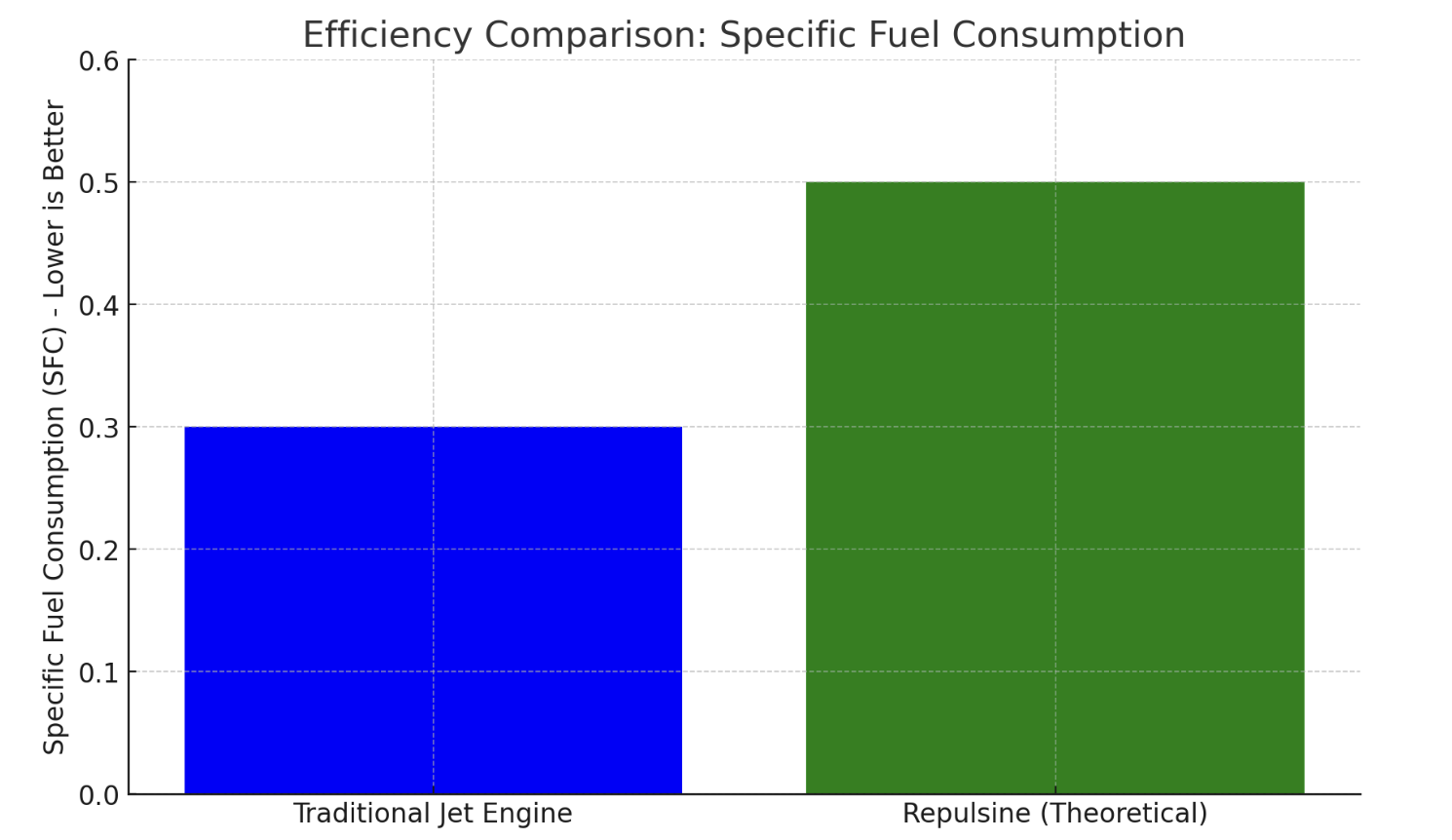

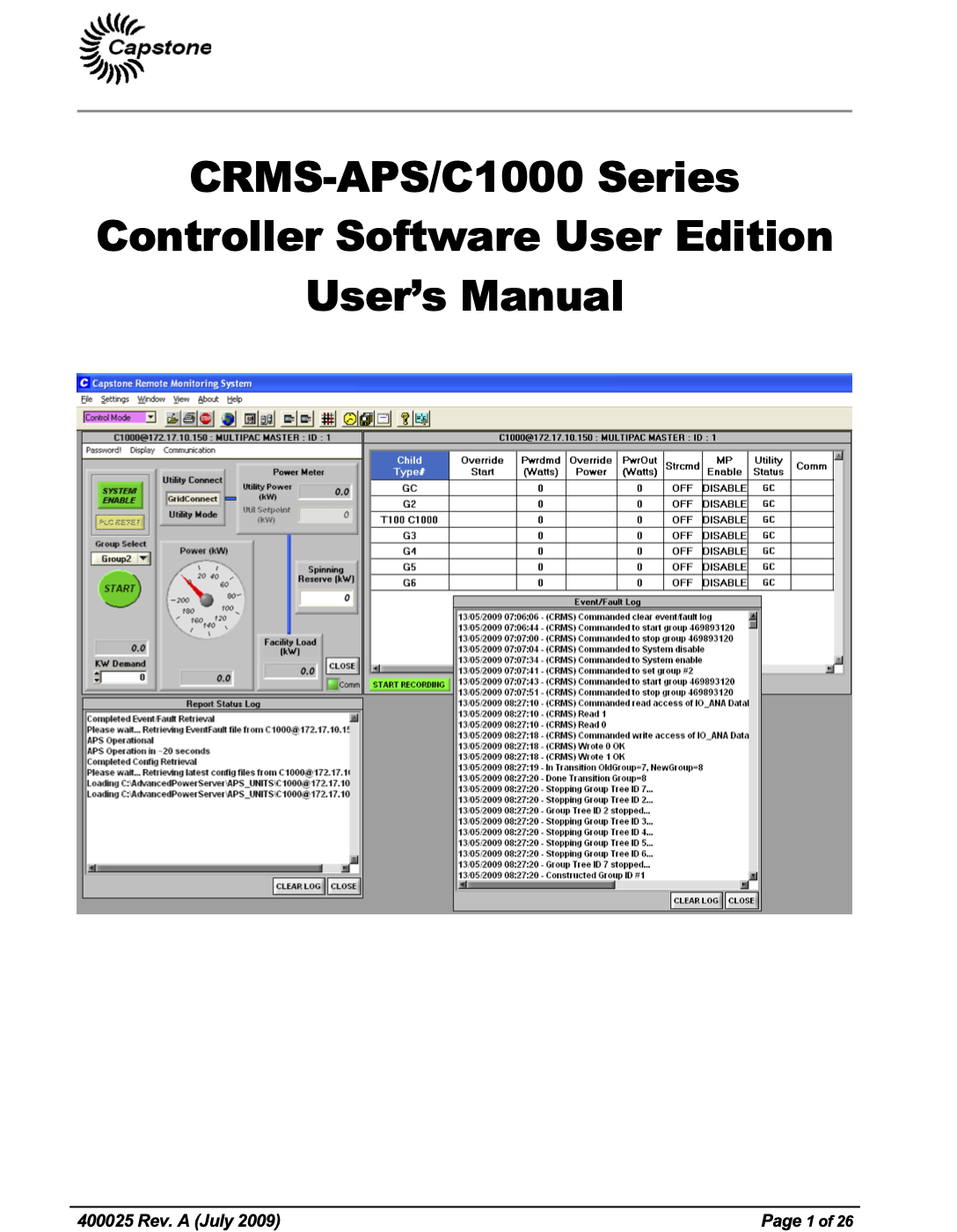

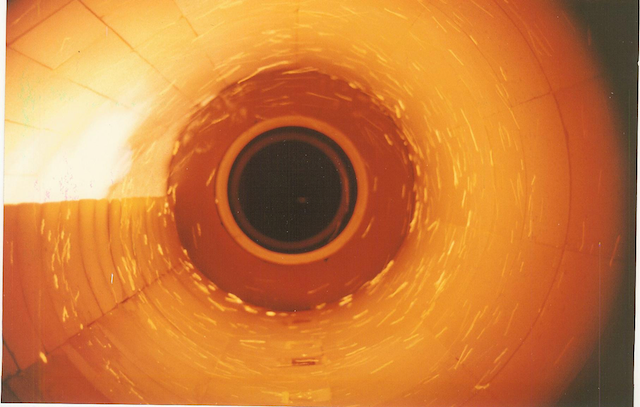

Comparing Thrust in Aviation: Traditional Turbines vs. Viktor Schauberger's Repulsine The evolution of aviation has seen numerous innovations, from the Wright brothers' first flight to the advent of jet engines that revolutionized air travel. Among these innovations, Viktor Schauberger's Repulsine stands out for its unique approach to generating lift and thrust. This article compares traditional thrust aviation turbines with Schauberger's Repulsine, exploring their principles, efficiency, and potential applications.Traditional Turbines vs. the Viktor Schauberger Repulsine Viktor Schauberger Repulsine Design Flying Disk Repulsine Turbine with Viktor Schauberger Technology and Discoveries |

|

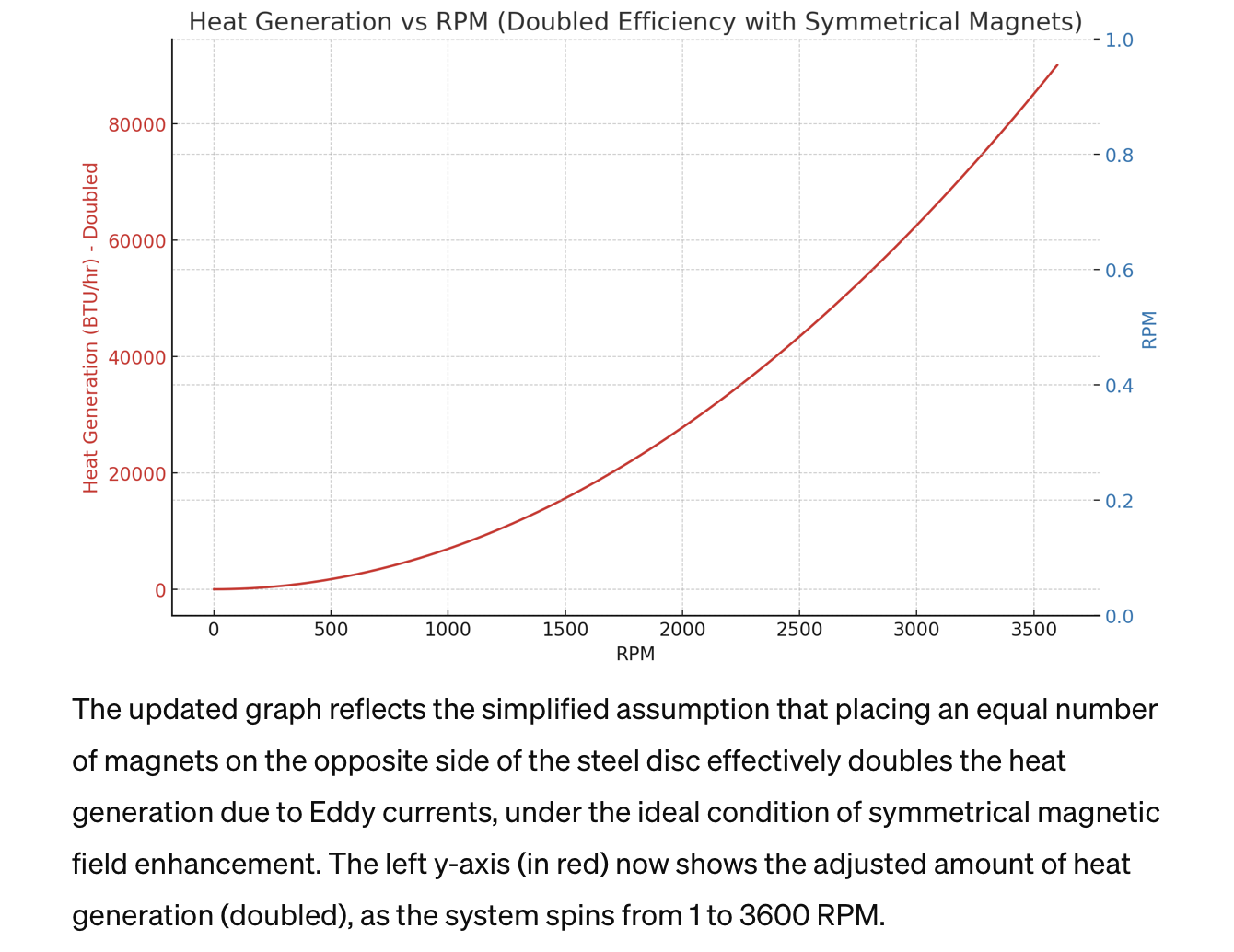

BTU Generated Using Two Sides Balanced Magnetic Force Using Eddy current to boost the efficiency of a ORC turbine from 5-30 percent. Symmetry and Field Enhancement: The symmetric placement of magnets could enhance the magnetic field's uniformity across the steel disc, potentially increasing the Eddy current generation. This might lead to a higher heat generation rate, but the exact increase would depend on the specifics of the magnetic field interactions, which are complex and not necessarily linear.Efficiency of Heat Generation: The efficiency of converting kinetic energy from spinning into heat through Eddy currents might not scale linearly with the number of magnets. While more magnets increase the magnetic field, the relationship between the field strength, speed of rotation, and heat generation is complex. |

|

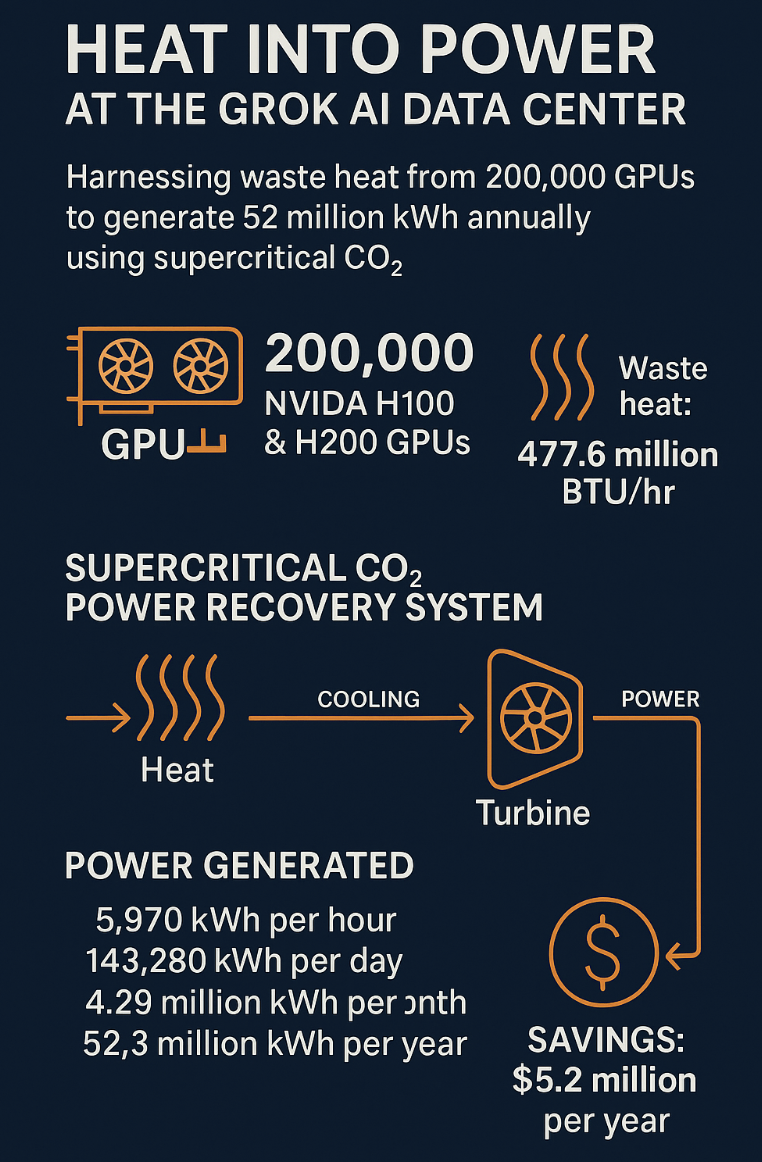

Generate Power from Waste Heat Cooling using sCO2 for AI Data Centers like Grok, Amazon, Google, and ChatGPT Discover how supercritical carbon dioxide is turning waste heat into a powerful resource—providing on-demand cooling and generating electricity from the very servers it keeps running. The future of sustainable data infrastructure starts here. |

|

Infinity Turbine Software Using Filemaker Database Application Solutions Infinity Turbine is now launching SAS software as a service, based on the database application Filemaker. We have been using Filemaker since 1992 and have developed many applications which we use on a daily basis.Applications will include:• PID• Brayton Cycle Calculator• Heat Rate Calculator• ORC Design• Accounting• ChatGPT Prompt Generator• ChatGPT LLM in house use with Filemaker• Your suggestions |

|

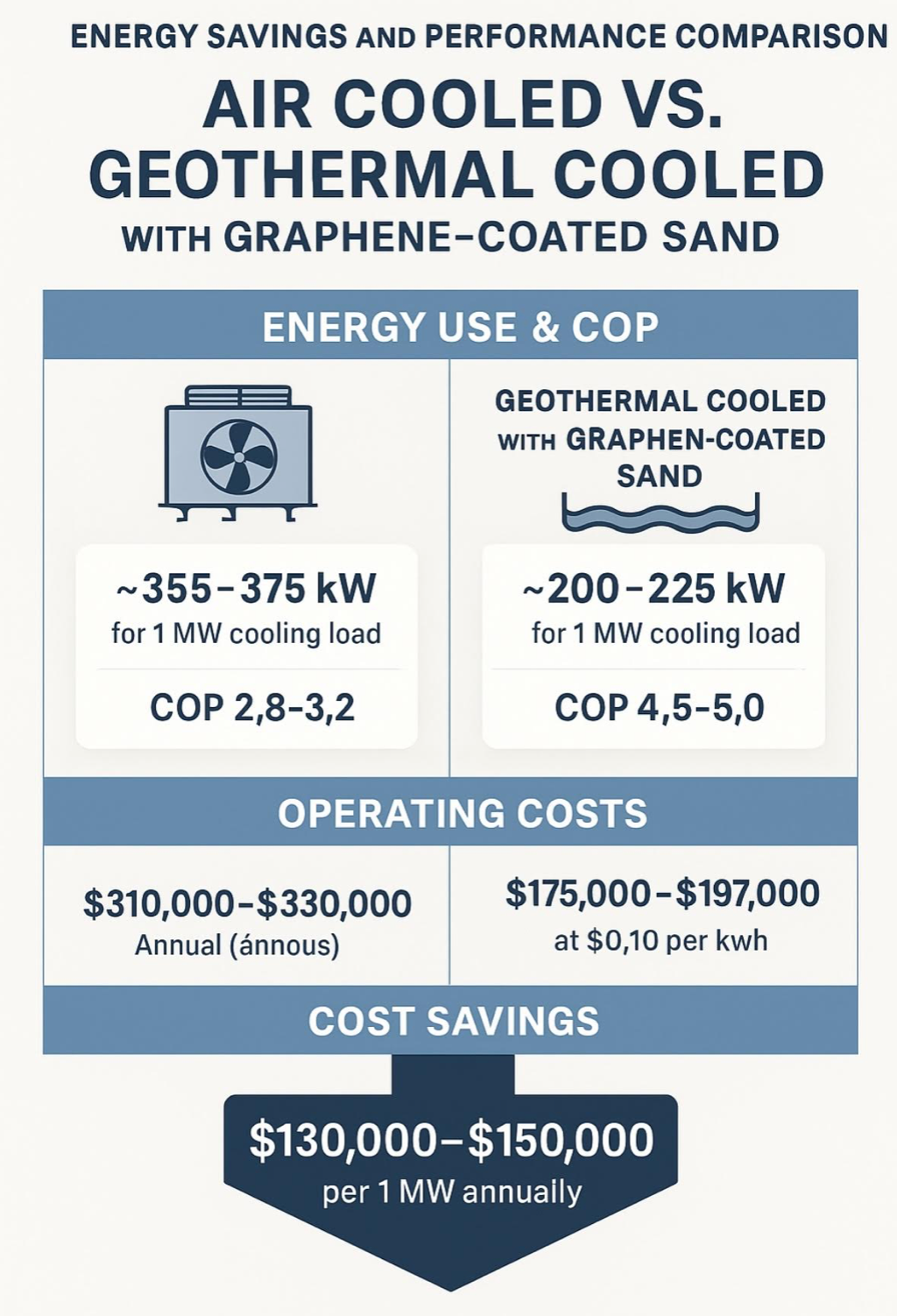

Geothermal vs. Air Cooled Chillers for Texas Data Centers: Cost and Efficiency Analysis A comparison of air cooled chillers versus geothermal cooled chillers using graphene-coated sand for heat transfer in Texas data centers. Analysis includes energy efficiency, operating cost savings at \$0.10 per kWh, and benefits under high temperature and humidity.Geothermal vs. Air Cooled Chillers for Texas Data Centers: Cost and Efficiency Analysis |

|

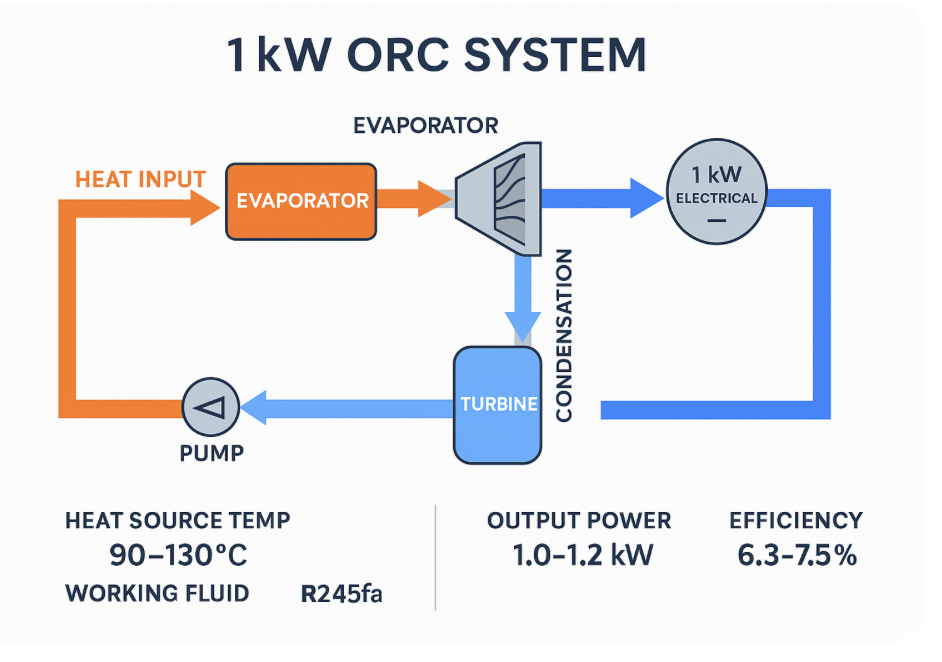

1 kW Organic Rankine Cycle (ORC) Power Generator Overview A detailed summary of a 1.5 kW Organic Rankine Cycle (ORC) power generator that efficiently converts low-grade heat (90–130°C) into 28V DC electricity. This compact system demonstrates the feasibility of small-scale waste heat recovery, featuring direct DC output, fast startup, and oil-free operation for off-grid and industrial use.The 1 kW ORC system represents a breakthrough in compact thermal-to-electric power conversion. Designed to produce 28 volts DC from waste heat sources, it enables direct battery charging or microgrid integration. The system is ideal for small-scale or remote applications where efficiency, reliability, and autonomy are essential.1.5 kW Organic Rankine Cycle (ORC) Power Generator – Compact 28V System for Waste Heat Recovery |

|

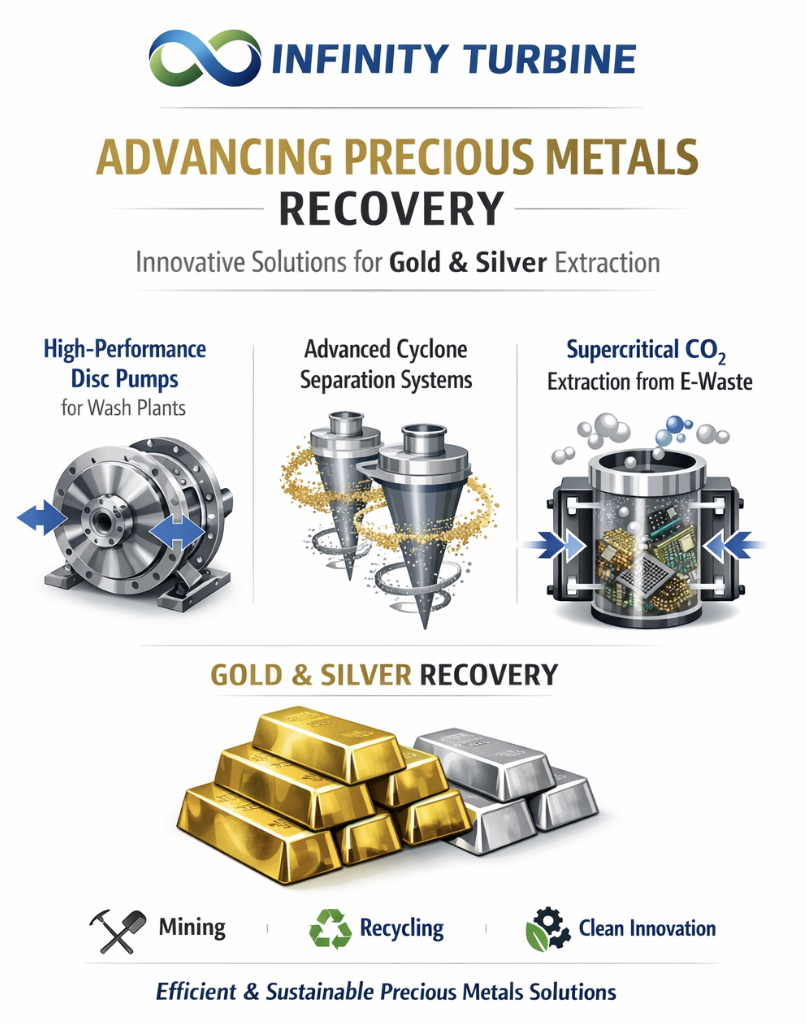

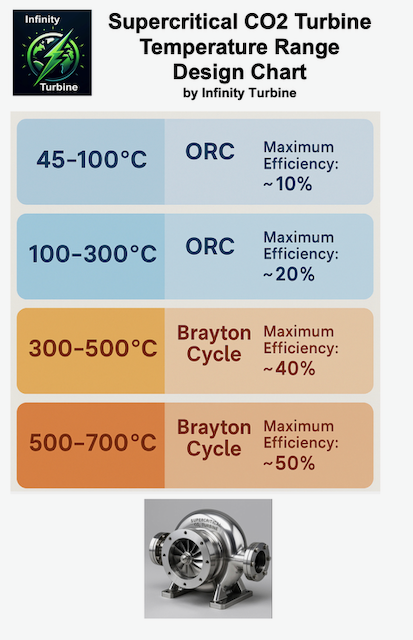

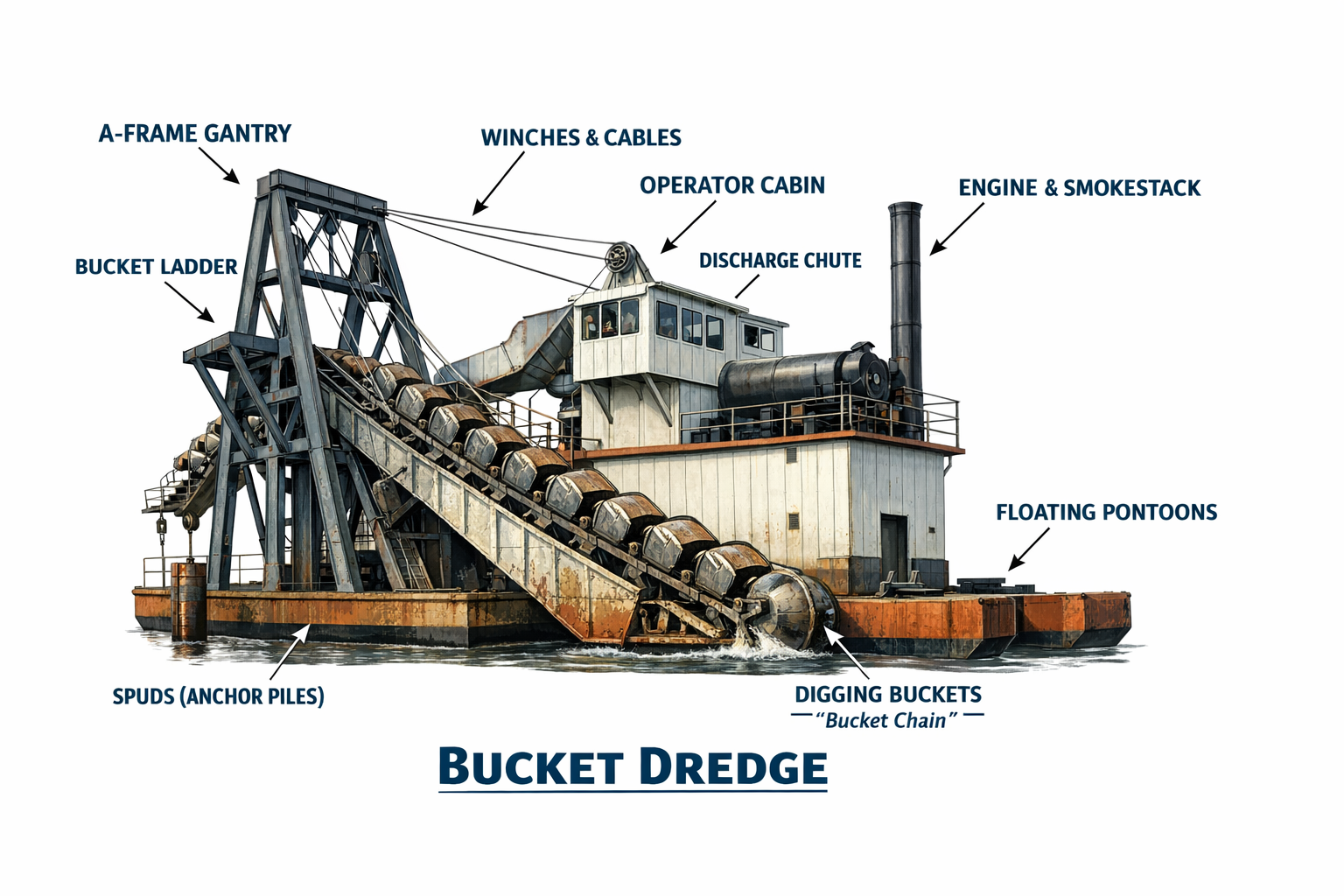

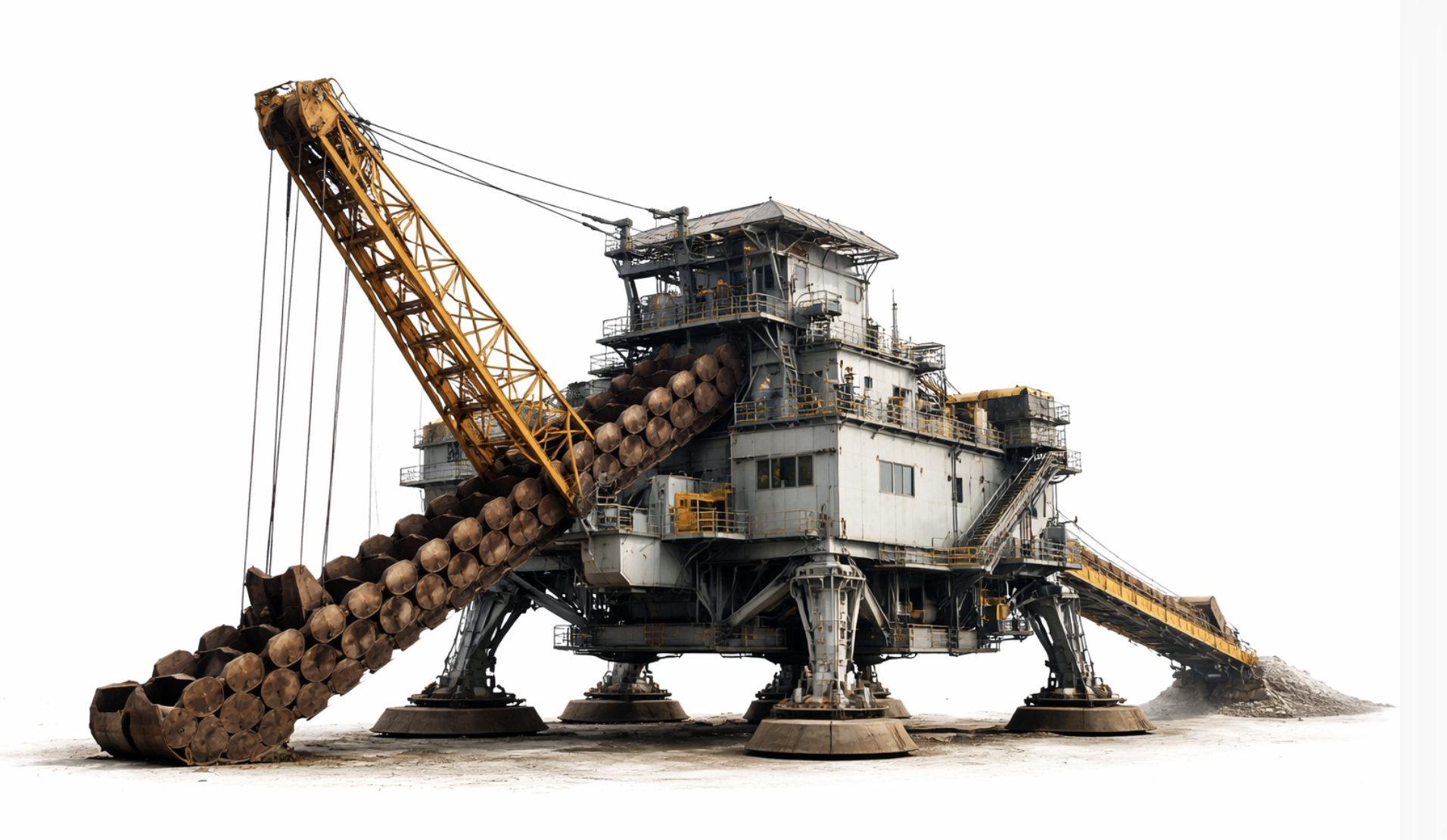

Gold and Silver Recovery Technologies Infinity Turbine is expanding its advanced engineering platform into the recovery of gold and silver through next-generation precious metals technologies. Building on deep expertise in fluid dynamics and energy systems, Infinity Turbine is developing high-performance disc pumps for modern wash plants, advanced cyclone separation systems for efficient material classification, and supercritical CO2 extraction processes designed to recover valuable metals from electronic waste without toxic chemicals. Together, these technologies position Infinity Turbine at the intersection of mining, recycling, and clean industrial innovation, delivering scalable solutions for a more efficient and environmentally responsible precious metals supply chain.Recovery rates of bucket dredges vs shaker wash plants for gold mining operations. |

|

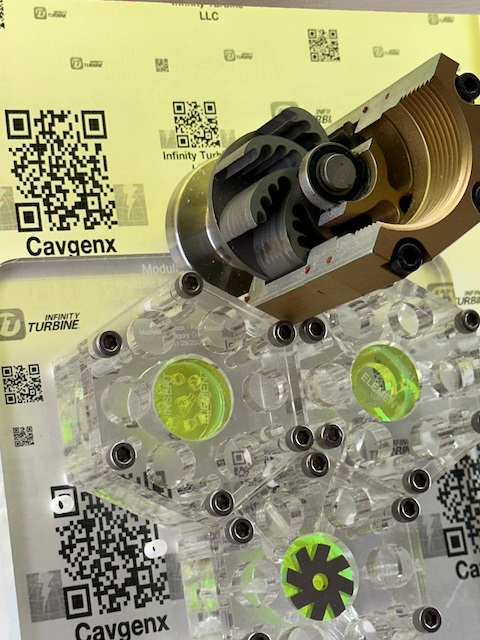

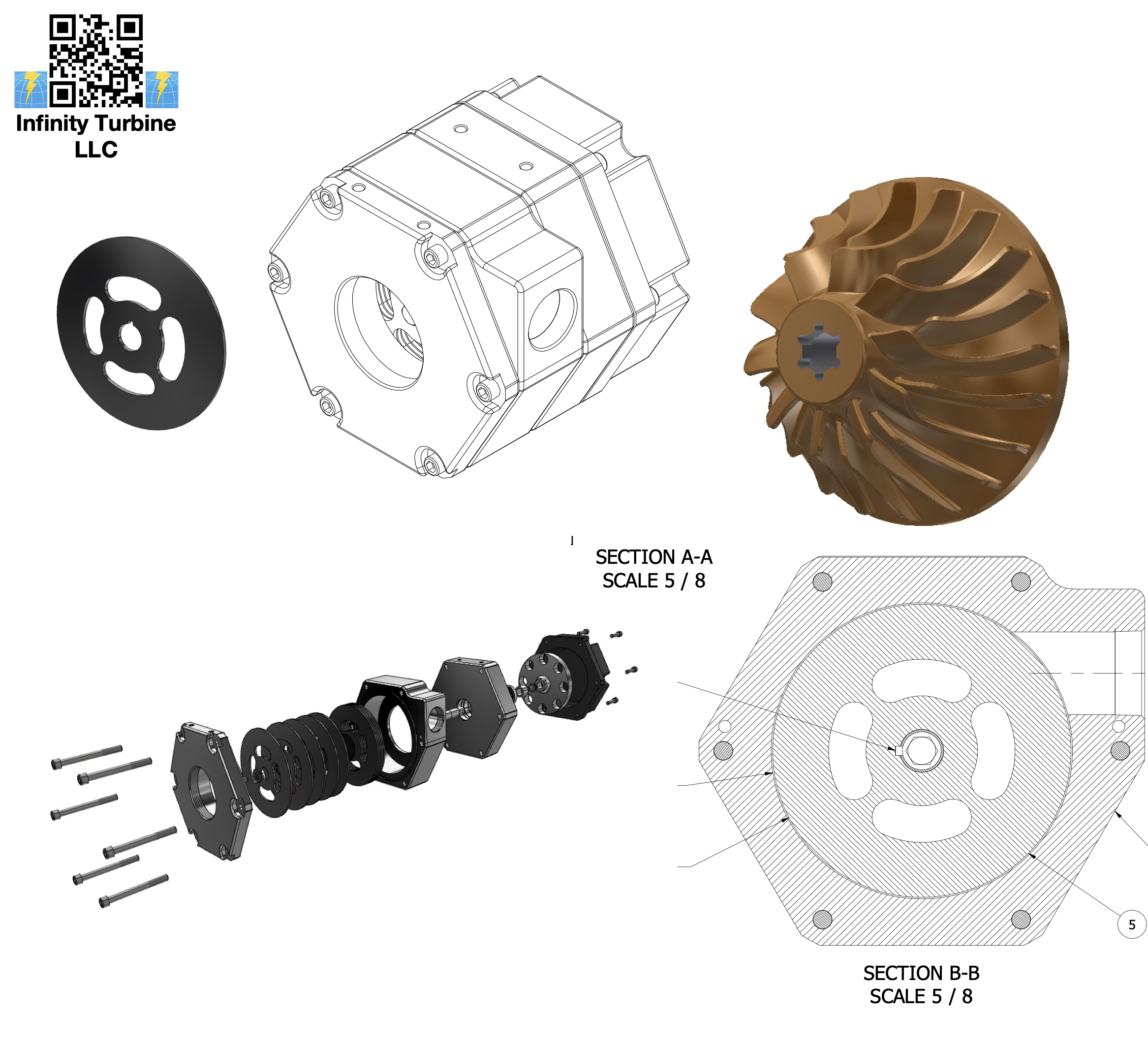

Modular Block Configuration for Heat Pump or Tesla Turbine |

Introducing the IT Mini Experimenters Kit featuring Tesla Turbine and Tesla Pump Discs to Unleash your inner experimenter and explore the fascinating world of energy with this compact and engaging kit Infinity has always emphasized the value of starting with small prototypes and gradually scaling up to address any potential issues. In line with this philosophy, we proudly present the Modular Block Experimenters Kit, a stepping stone for entrepreneurs to validate their developments and seamlessly progress from concept to commercialized products.This comprehensive kit equips you with a range of Tesla pump and turbine discs, carefully crafted from steel through precision stamping. These discs can be conveniently stacked on a common shaft, allowing for a multitude of experimental possibilities.IT Mini Turbine ORC Expander Experimenters Kit Telsa Experimenters Kit for Disc Pumping Liquid and Turbine Applications |

|

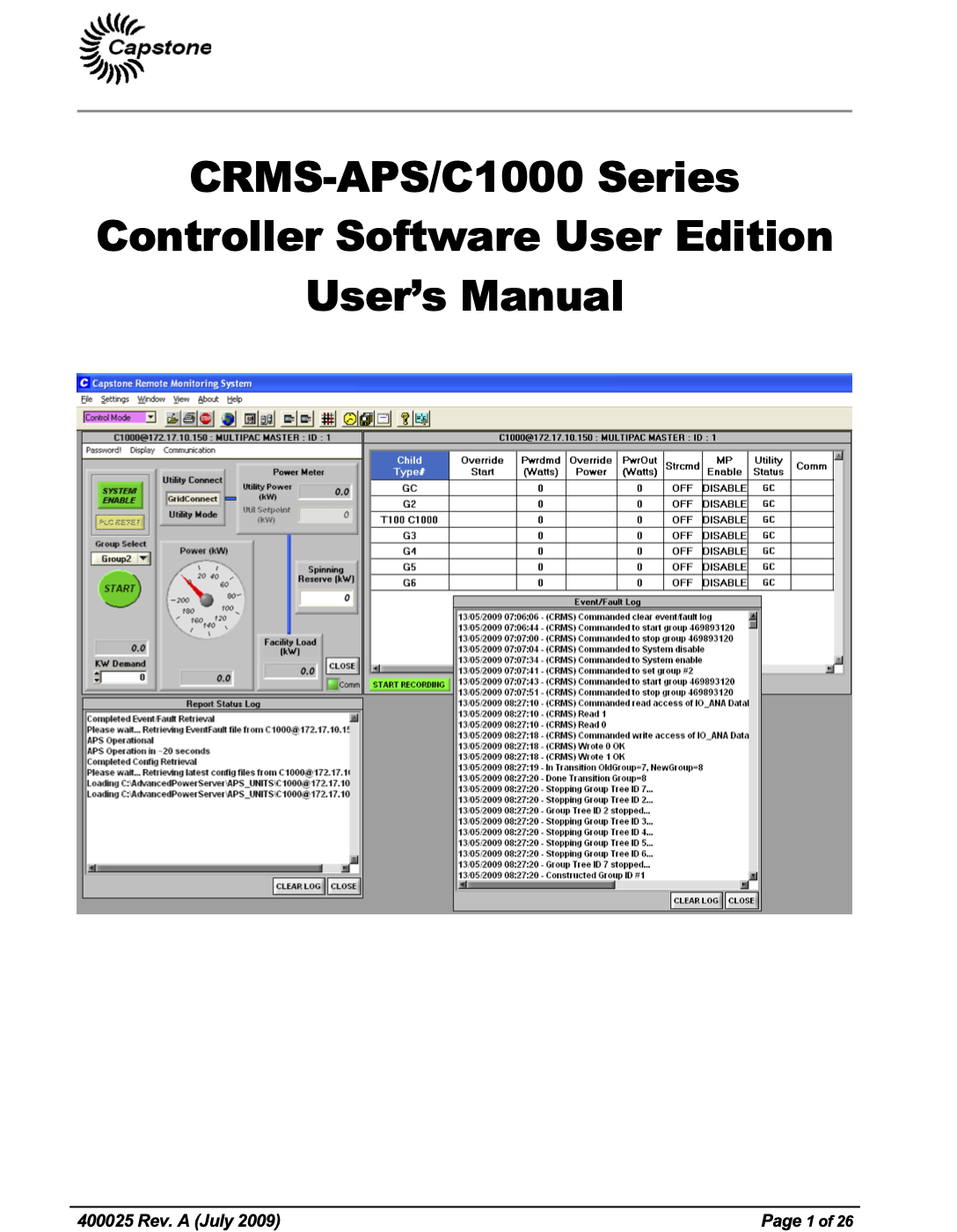

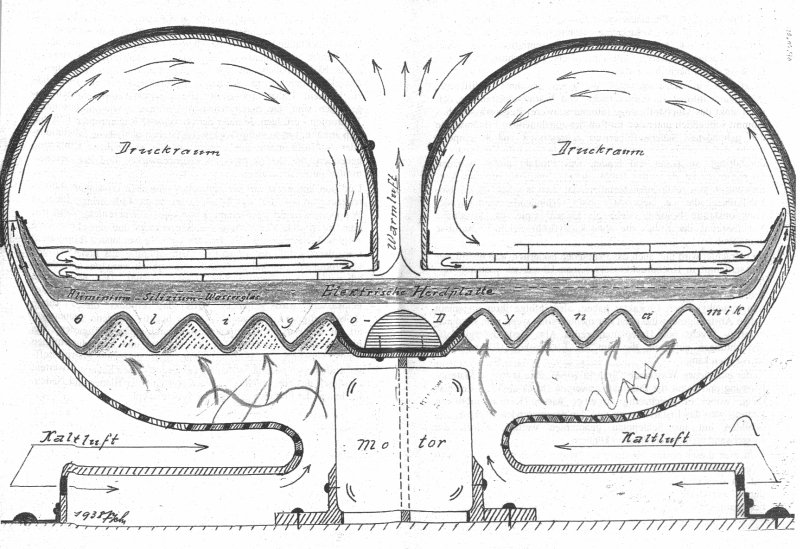

Microturbine OEM App by Global Energy OEM parts for Capstone Turbine C30, C60, C65, C200, C600 (3 x C200), C800 (4 x C200), C1000 (5 x C200).The app for basic part descriptions is free, and a detailed supplier contact list is available for a fee.The savings on buying direct from the OEM is huge, when compared to buying from Capstone or its dealer network.With over 14,000 microturbines manufactured since 2001, there is a need for parts. |

|

|

|

|

|

|

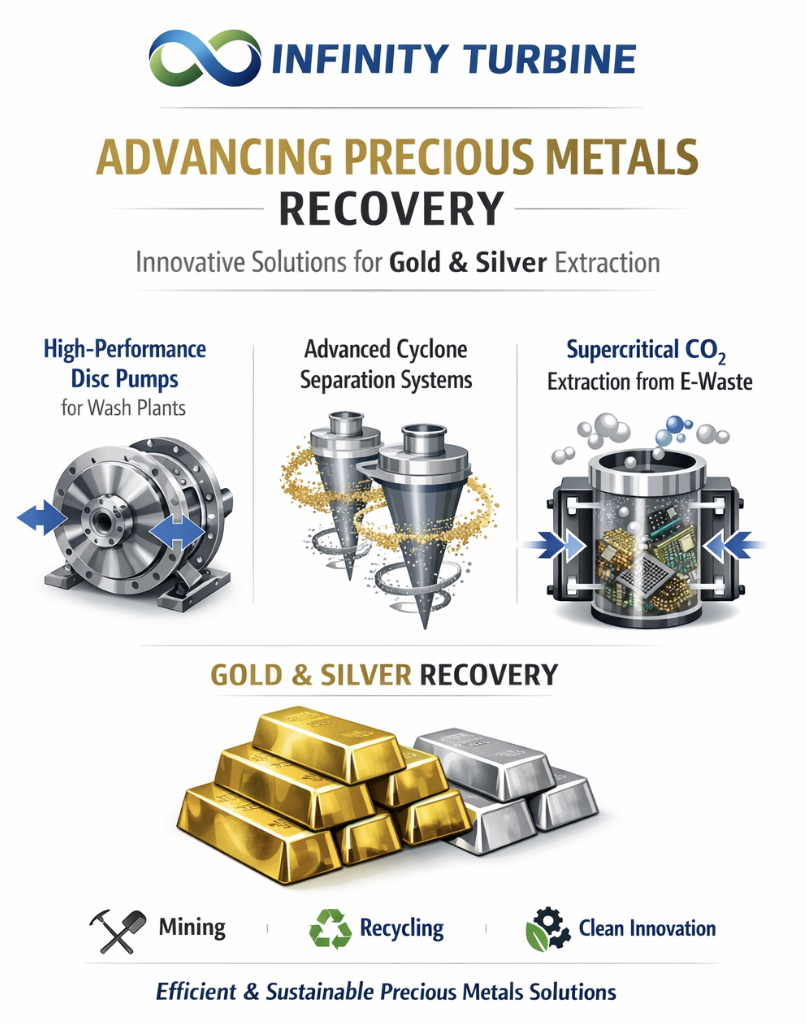

10 MW Supercritical CO2 Turbine Generator Power Block for AI Data Centers Infinity Turbine LLC introduces a 10 MW supercritical CO2 turbine generator power block for AI data centers. This closed-loop system provides efficient, scalable, and versatile power for backup, primary generation, or charging grid-scale batteries.• Use to charge the new Tesla MegaBlock• Most large gas turbine generators have a 24 month wait time• Use for AI Data Center primary power and charging grid-scale batteries• Use a variety of heat sources including natural gas, hydrogen, concentrated solar, and more• Integrally Geared Multi Stage Compressor• Use with smaller nuclear reactors is known as Small Modular Reactors (SMRs) and, in even smaller forms, Microreactors10 MW Supercritical CO2 Turbine Generator Power Block for AI Data Centers |

|

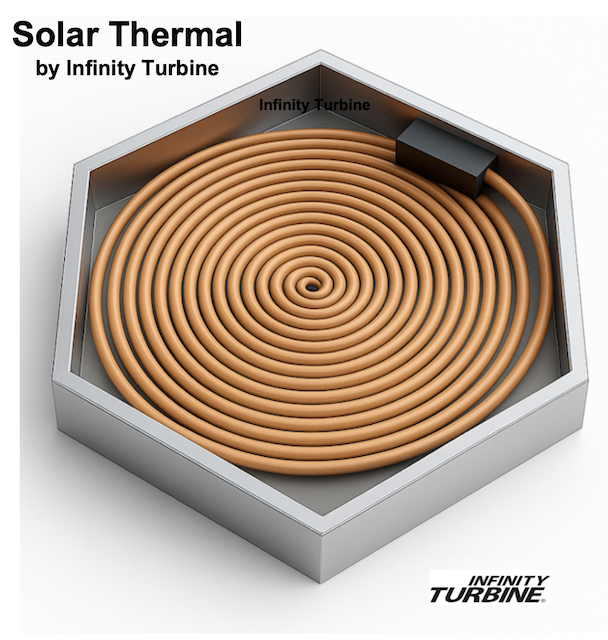

Infinity Solar Thermal Collectors |

Solar Thermal Back in 2008 Infinity designed helical solar collectors, which now have updated in 2025, including: • supercritical CO2 working fluid• laser etched Fresnel lens (allow higher temperatures) option• vacuum sealed collector option• graphene coated sand as the solar heat absorber option• sand-salt thermal storage as part of collector optionCollectors are hexagonal or rectangular for modular manufacturing, shipping, and deployment. |

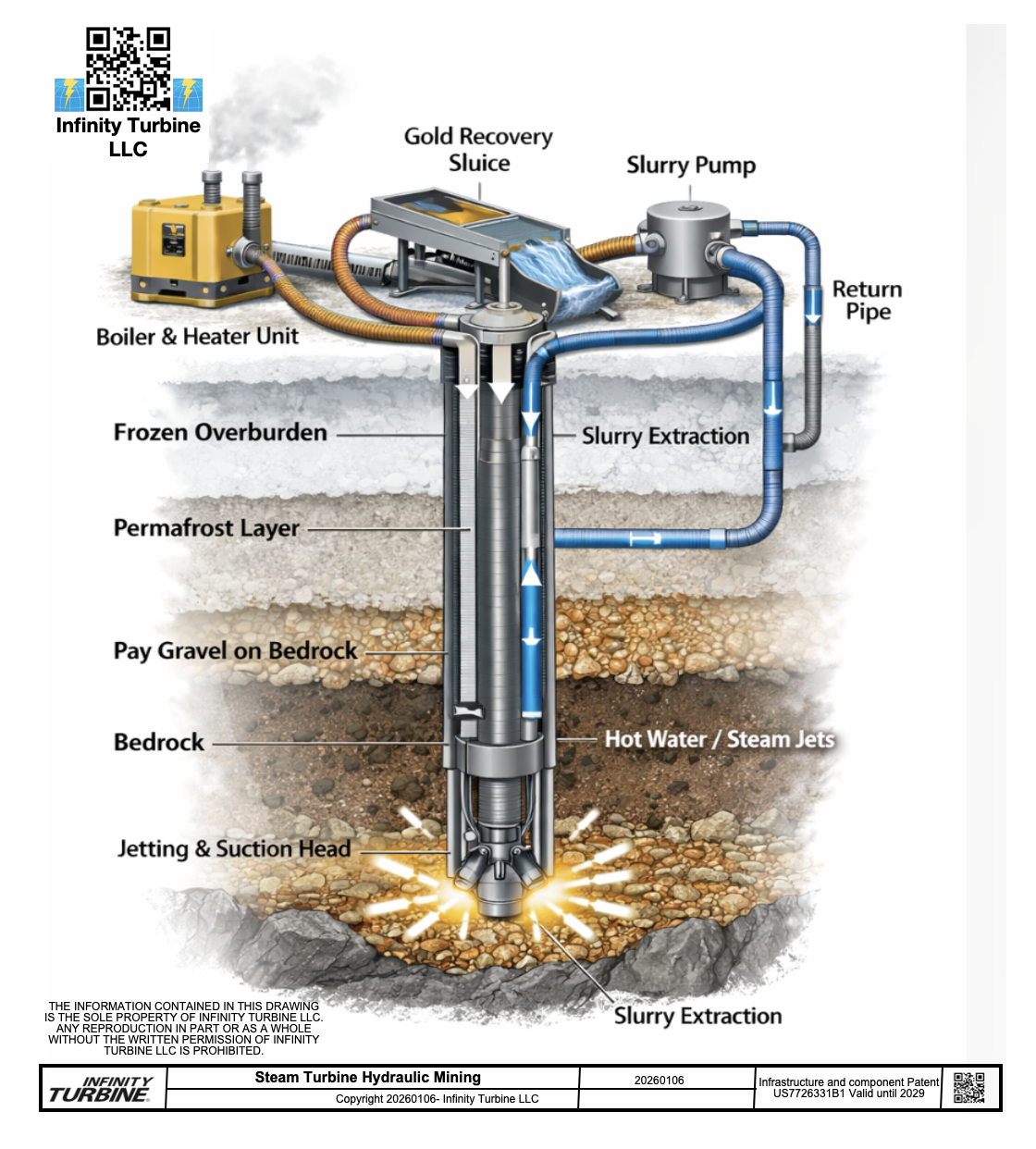

In-situ Recovery of Gold Deposits |

Winter Placer Gold Mining Using Borehole Hydraulic Jetting in Permafrost Placer gold mining in Alaska and the Yukon is traditionally limited to short summer seasons due to frozen ground and permafrost. This article examines a novel winter mining concept that uses drilled wells, hot water hydraulic jets, and closed loop slurry circulation to recover gold directly from bedrock while leaving frozen overburden in place.Winter Placer Gold Mining Using Borehole Hydraulic Jetting in Permafrost |

|

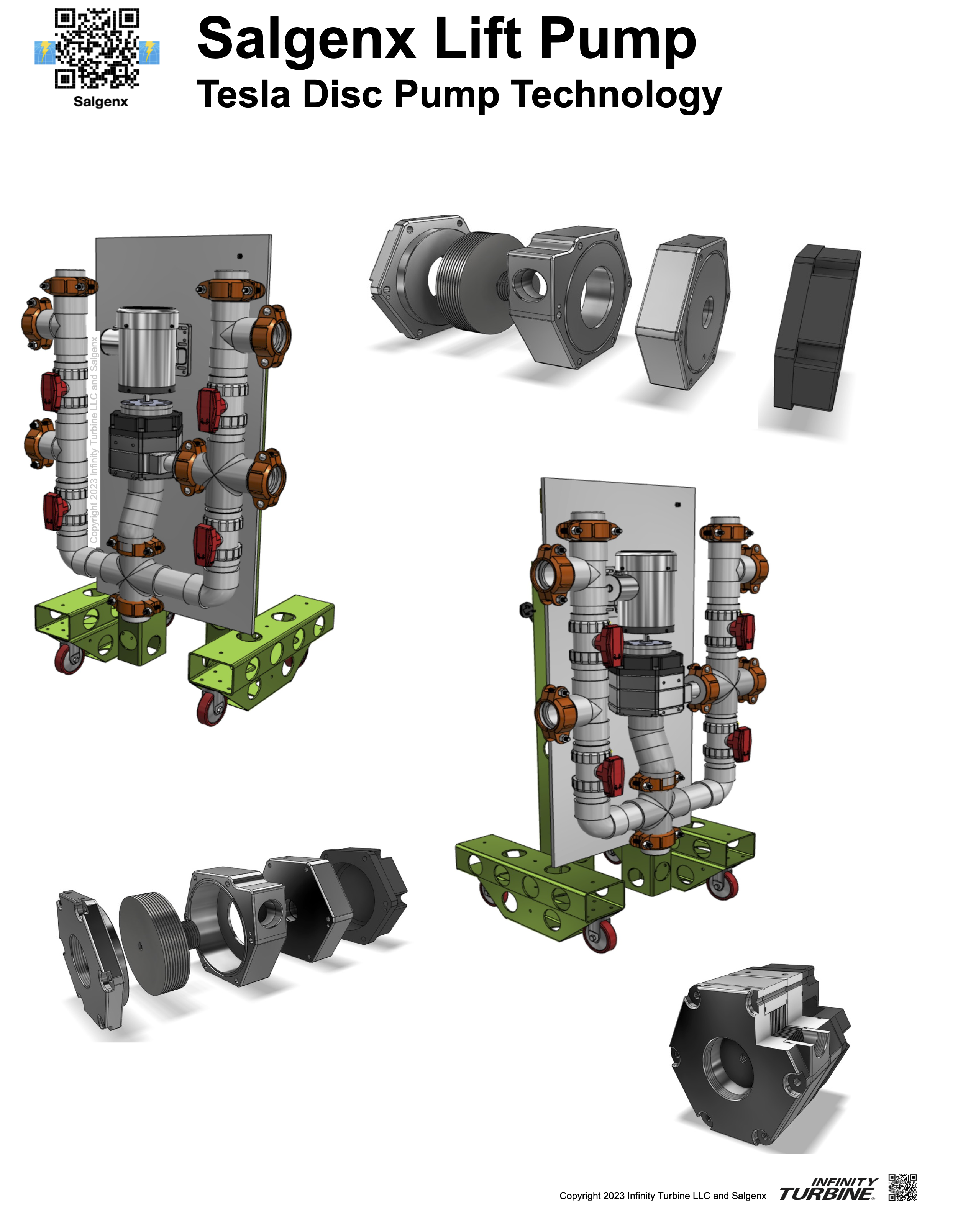

Sand Salt Battery with Supercritical CO2 Hydraulic Power Pack for 16 mm BTU of Energy Storage and 1,500 tons Chiller Cooling or 840 kW of Grid Scale Power in one 40 Foot ISO Shipping Container Advanced sand-salt battery to store thermal energy to be released using CO2 working fluid for hydraulic power to drive generators, pumps, RO desalination, presses, lifts, and more. Charge with solar PV, solar thermal, off-peak grid power, or waste heat. Discover how a standard 40-foot shipping container filled with sand and salt can be transformed into an efficient thermal energy storage unit using a multi-layered thermal oil pipe layout. This setup offers over 16 million BTU of energy capacity with fast charge and discharge performance through 2-inch steel heat exchanger pipes.Sand Salt Battery with Supercritical CO2 Hydraulic Power Pack Converting Hydraulic Pumps into Supercritical CO2 Expanders for Energy Recovery |

|

|

|

Tubercles for ORC Turbine Efficiency: Biomimicry Improves Energy Recovery Can a humpback whale's flipper help your turbine run more efficiently? Discover how tubercle-inspired designs are showing promise for boosting the performance of ORC turbines by reducing drag and turbulence.Tubercles for ORC Turbine Efficiency: Biomimicry Improves Energy Recovery |

Some of the many innovations from Infinity Turbine including a solid 3D print of a counter rotating turbine in one part and a cavitating compressor |

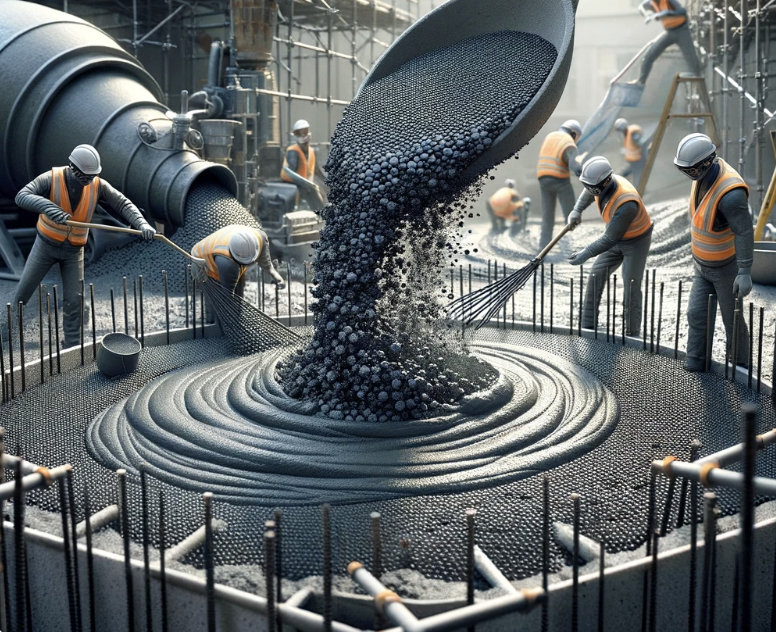

Wood Heat can be used to fire this heat treating kiln for high strength concrete |

Graphene Coated Sand Batch Kiln by Infinity Turbine for Aggregate to make Concrete A modular container mounted kiln for heat treating sand with a coating of graphene for use in the construction industry when used for aggregate and cement to make concrete.Uses: Non-structural concrete for ornamental, siding, containers, troughs, thermal or sound insulation works, fillings, small walls or fences, insulating sub-floors, construction of ditches, sidewalks, and other similar civil works.Aggregate: Sand, Perlite, vermiculite, and more.Ingredients: Aggregate (sand or other materials), activated carbon, and a inexpensive precursor (proprietary - but commonly available).Heat Sources: Wood waste, sawdust, gas, electricity, and hydrogen.Batch Process: This process is for making batch quantities. A continuous kiln process is under development and will be available for licensing at a later date.Time: The processing time to heat treat and coat the aggregate is a matter of hours. Rate at which kiln heats to starting temperature is a big factor.Samples and basic recipe: $10,000. Amount can be deducted if a Licensing Package is purchased below.Licensing Package: Modular container mounted kiln design and plans, heating source plans, graphene batch formula and recipes. Please email for pricing.Note: It is your responsibility to check for codes specific to your state, region or country to determine where and in what applications this can be used according to codes and zoning.More information will be available soon.Email: Graphene Coated Sand Kiln Plans for use as Aggregate for Concrete |

Infinity Turbine is currently developing 1070 nm LED arrays for transcranial photobiomodulation for brain diseases |

1070 nm LED Array for Light Therapy by Infinity Turbine for Neurophotonics Infinity Turbine is currently developing 1070 nm LED arrays for transcranial photobiomodulation for brain diseases.Brain diseases account for 30% of all known diseases. Pharmacological treatments are often limited by the blood-brain barrier, which restricts drug delivery to the central nervous system (CNS). Transcranial photobiomodulation (tPBM) is an emerging technology that shows promise for treating brain diseases due to its effectiveness, non-invasiveness, and affordability. tPBM has been extensively used in pre-clinical experiments and clinical trials for conditions such as stroke and Alzheimer’s disease. The brain, a vital component of the CNS, is responsible for life activities such as thinking, emotion, and memory. Brain regions are anatomically interconnected, demonstrating both specialization and collaboration, making the brain one of the most complex and advanced systems in nature. However, the brain is highly susceptible to various disorders, including cerebrovascular diseases, neurodegenerative diseases, and brain inflammation. Photobiomodulation, which uses low-power light in the visible and near-infrared spectra to trigger biological responses in cells and tissues, has been considered a potential therapeutic strategy for Alzheimer’s disease (AD). Additionally, 1070-nm light pulsed at 10 Hz can reduce perivascular microglia and promote angiogenesis, enhancing Aβ clearance. Our study confirms the crucial roles of microglia and cerebral vessels in using 1070-nm light for treatment. |

|

Concentrated Solar Fails when Compared to Solar PV for Payback Concentrated solar power was once hailed as the crown jewel of renewable energy — a system that could store the sun’s heat and deliver electricity long after sunset. Yet, as solar PV prices plunged, CSP’s promise dimmed. This upcoming technical report, The Limits of Concentrated Solar: When Heat Becomes Power, and When It Fails,dives deep into the physics, economics, and geography that determine CSP’s success or failure.Discover where concentrated solar still outperforms photovoltaics and where it fails due to cost, climate, efficiency, or complexity. A must-read for engineers, energy planners, and investors seeking clarity on the future of solar thermal energy.Investors Guide Technical Report - Read Before you Invest in Concentrated Solar |

|

Compressed air energy storage (CAES) Compressed air energy storage (CAES) is an intriguing method for storing energy, especially in contexts where renewable energy sources, like solar and wind, generate power intermittently. This storage system plays a pivotal role in balancing energy supply and demand, showcasing a notable capacity for large-scale applications.Note: Our ORC turbines are tested on air, so they are good candidates for compressed air storage. |

|

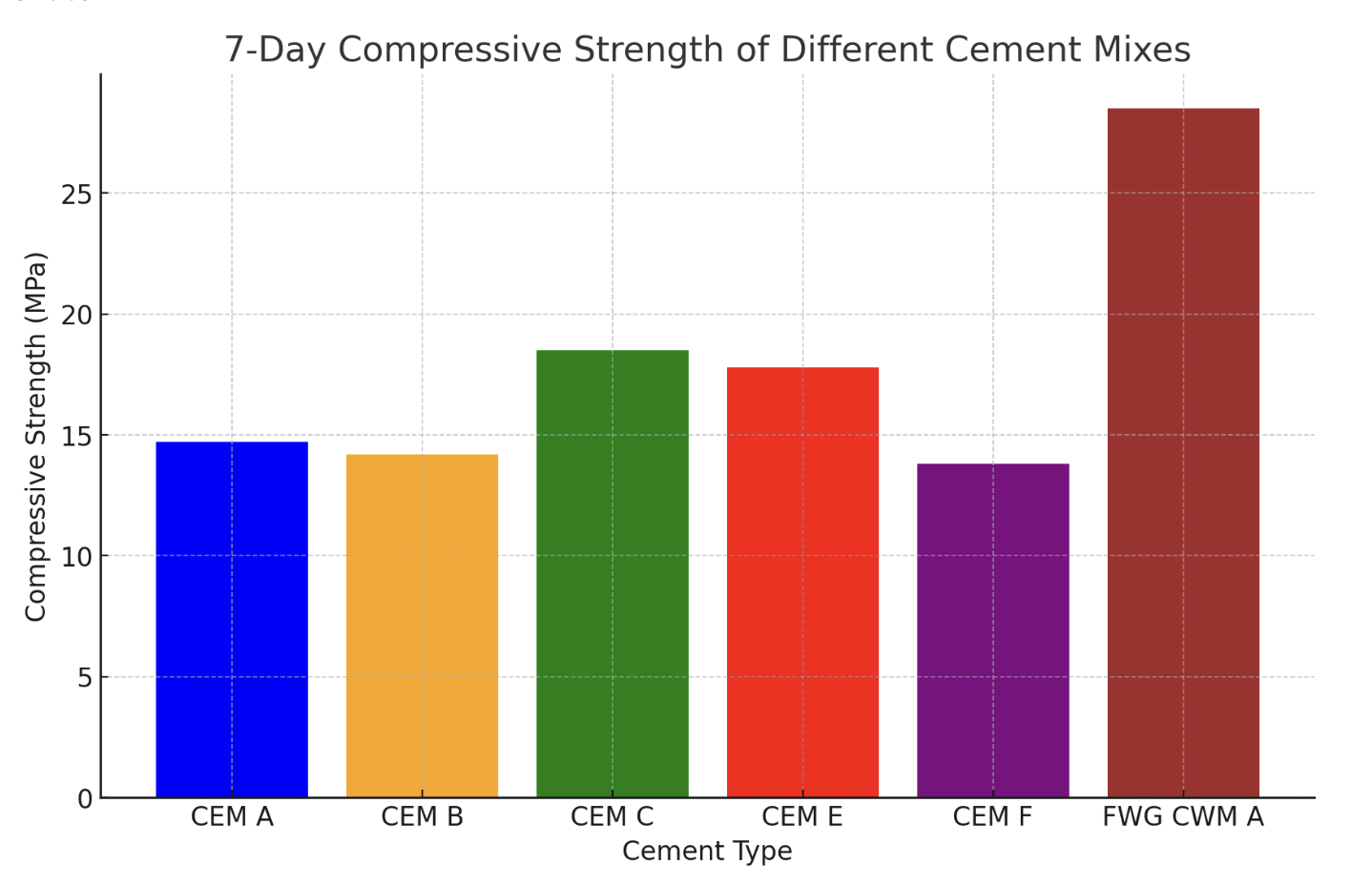

Making Graphene Oxide Using Inexpensive Manufacturing Methods of Sugar and Sand in Kiln Here's a graph displaying the 7-day compressive strength of different cement mixes. Each bar represents a unique cement type, including the Graphene Oxide Coated Sand Concrete (FWG CWM A), showing its compressive strength in Megapascals (MPa). As you can see, the Graphene Oxide Coated Sand Concrete exhibits a significantly higher compressive strength compared to the other cement types.Making Graphene Oxide Using Inexpensive Manufacturing Methods of Sugar and Sand in Kiln |

|

|

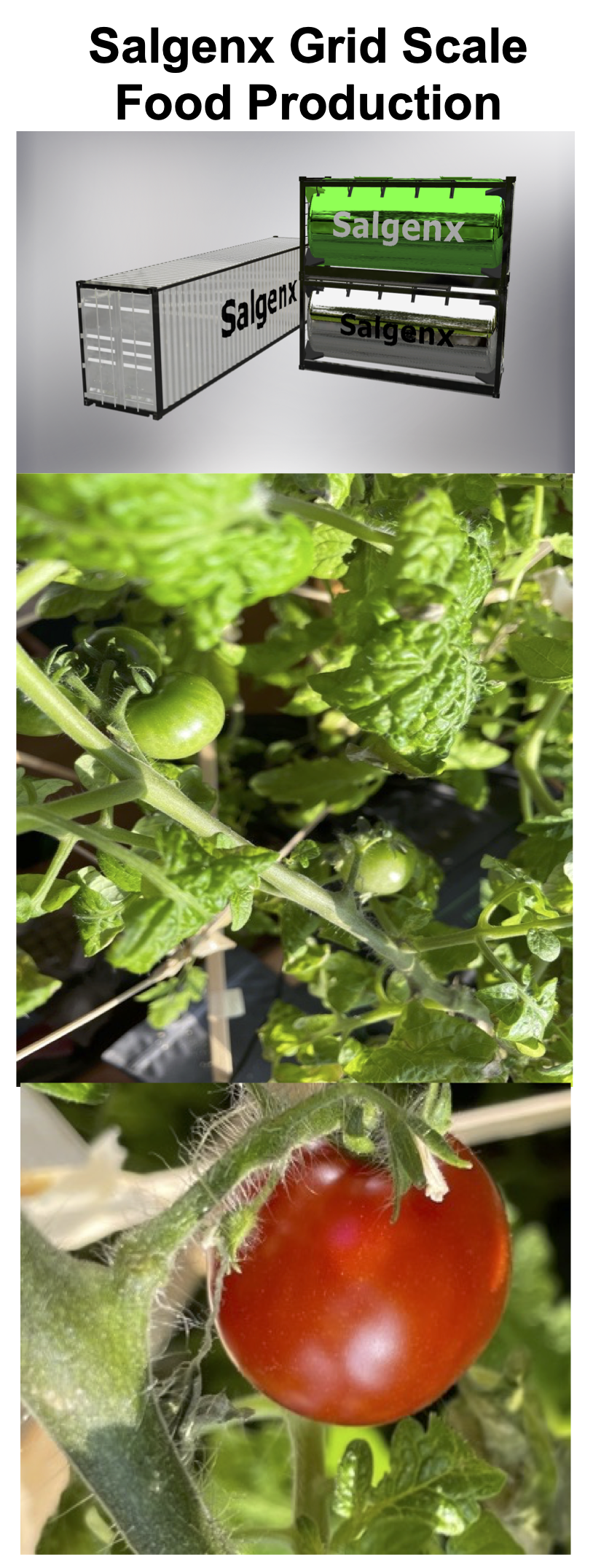

Revolutionizing Agriculture: The Salgenx Food Production Scale Battery System The vegetable production module process is designed to optimize the cultivation of various vegetables using advanced vertical fogponics systems within the controlled environment of hi-cube shipping containers. This innovative approach leverages the precision and efficiency of fogponics, a method that uses nutrient-rich fog to hydrate and feed plants, ensuring optimal growth conditions without the use of soil. The integration of solar photovoltaic (PV) power for lighting and fog generation makes the process sustainable and energy-efficient.Each module, encapsulated in a hi-cube shipping container, is meticulously configured to maximize space utilization and light distribution, ensuring that crops such as tomatoes, leafy greens, peppers, and microgreens thrive. The system's design facilitates year-round production, irrespective of external climate conditions, by maintaining ideal temperature, humidity, and light levels. The process begins with the selection of crops based on their profitability, energy requirements, and compatibility with the fogponics system. Containers are then outfitted with LED lighting, fogponic irrigation systems, and solar PV panels to create a self-sustaining environment. Crop production is closely monitored and managed, focusing on optimizing yield and ensuring high-quality produce.Finally, the Salgenx saltwater battery provides PV energy storage to power the LED lighting and pumps, while simultaneously desalinating seawater during charging.The vegetable production module process represents a fusion of agricultural innovation and environmental stewardship, offering a scalable solution for urban farming and the production of fresh, locally sourced vegetables.Grid Scale Food Production Using Shipping Containers and the Salgenx Saltwater Battery |

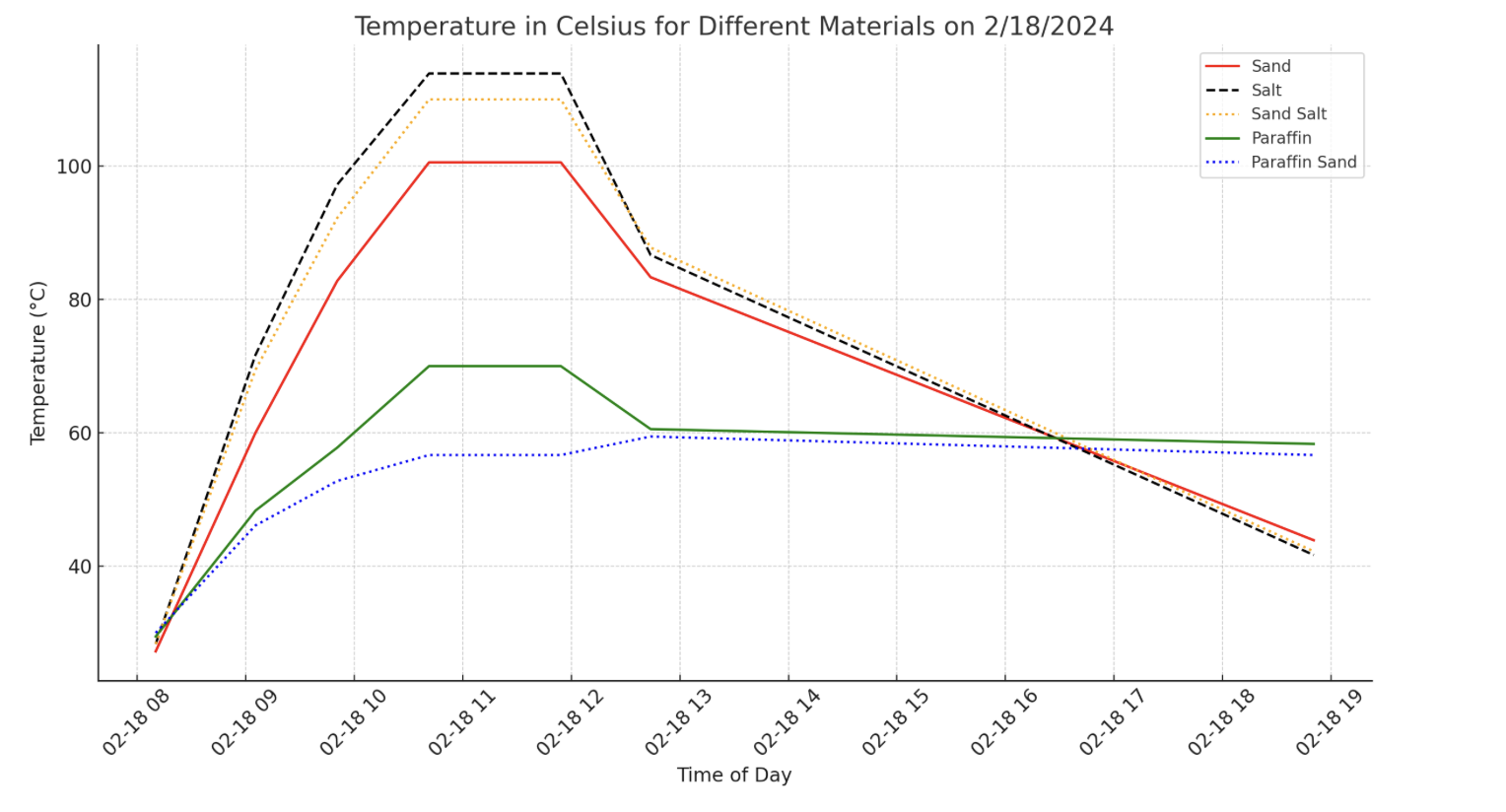

Actual testing of sand, salt, paraffin, sand and salt, sand and paraffin using solar vacuum tube with starting high temperature and end temperature for graphing illustration to show energy densities for small scale TES systems |

Thermal Energy Storage by Comparing Thermal Energy Density and Capacity of Sand Salt and Paraffin Wax From the chart and the values, we can observe that combinations involving paraffin wax generally show higher thermal energy density storage capacities, with the Salt and Wax combination exhibiting the highest capacity among the ones calculated. This is primarily due to the inclusion of paraffin wax's significant latent heat contribution, which enhances the overall energy storage potential. Paraffin wax itself also shows a high capacity due to its phase change properties, despite its lower density compared to the other materials. |

|

|

Infinity Turbine LLC Introduces Revolutionary Data Center Cooling Solution Using Trompe Water Compression and Vortex Tube Technology Infinity Turbine LLC, a leader in sustainable energy and waste heat recovery, is proud to announce an innovative cooling system that combines Trompe water compression technology with modern vortex tube cooling to revolutionize data center cooling. With the rapid growth of data centers and rising energy costs, traditional cooling methods have become unsustainable. Infinity Turbine's new solution, designed for high-performance GPUs like NVIDIA's A100 series, uses naturally compressed air and precise cooling to manage the immense heat generated, reducing energy consumption. The system's core is the Trompe water compressor, an ancient, low-maintenance air compression technology that uses gravity and water without external energy inputs, adapted for modern applications in data centers. |

|

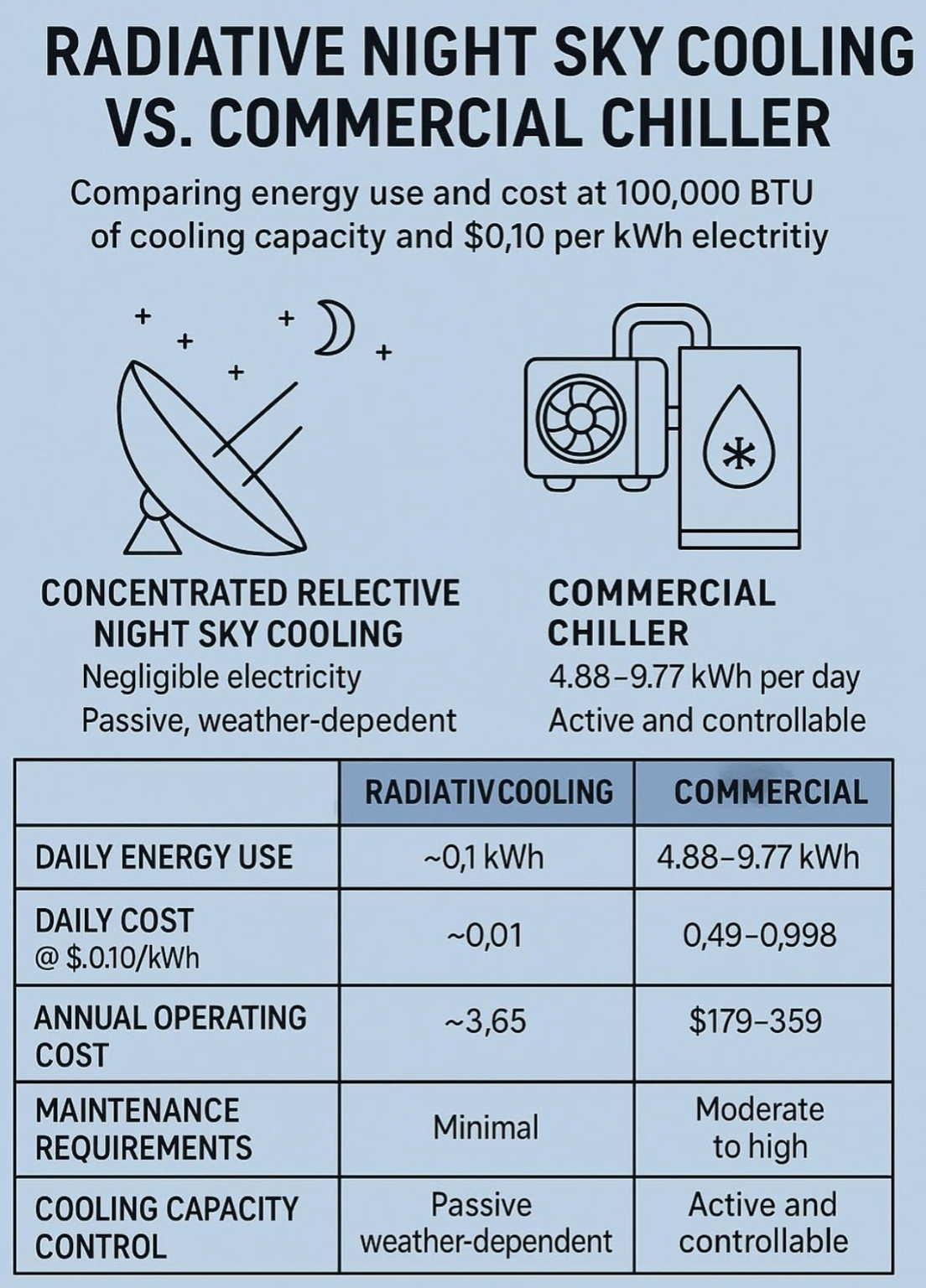

Radiative Night Sky Cooling vs. Commercial Chiller Is cooling your building with the night sky more efficient than a commercial chiller? This comparison examines both technologies by the numbers—energy, efficiency, and operating cost. |

|

Bucket Chain Excavator Gold Placer Mining Using a Dragline Excavator Washplant Which Uses 3 People to Run |

The potential of supercritical CO2 in a AI Data Center |

400025A CRMS APS User Edition UM2009 and CRMS Maintenance Software |

Capstone Remote Monitoring Software (CRMS) V4.25 and CRMS 551 and CRMS APS for C1000 V220 The Capstone Remote Monitoring Software allows users and maintenance to query the Capstone engine via a serial port interface. CRMS Engine Software has been confirmed working as of 15 April 2024 on a Windows computer. |

Capstone App |

Capstone APP Global Microturbine and Infinity Turbine are building a Capstone Turbine App which will provide supplier direct sourcing, to have huge amounts of mark-ups so you can buy parts directly from the manufacturer. |

Flying Device Lift Turbine |

Meet the visionary genius of Viktor Schauberger Discover the remarkable Viktor Schauberger, a devoted student of nature and a true connoisseur of water flows. Endowed with the gift of patient observation and a deep reverence for the outdoors, Schauberger's pioneering work revolutionized the field of flow control and the science of water.His profound fascination with mountain streams and their integral role in the natural environment sparked numerous innovations and inventions. Recognizing the fundamental similarities between water and air, albeit with different densities, Schauberger devised ingenious lift turbines and crafts.Well ahead of his time, Schauberger was among the first scientists to recognize the multi-dimensional nature and intricate structure of water. His understanding of water's surface tension and boundary layer mechanisms, which predates 1900, was truly revolutionary. Notably, Nikola Tesla also shared this realization with his disc turbine during a similar period.During the early stages of his career, Schauberger focused on finding efficient ways to transport and sort sawn timber using water and displacement. At a time before the advent of helicopter lifts, trucks, roads, and aerial cable lift lines, the transportation of timber from mountainous regions posed significant challenges.Viktor Schauberger's invaluable contributions continue to inspire and influence advancements in the understanding and utilization of water, leaving an enduring legacy in the realms of hydrodynamics and ecological engineering.Viktor Schauberger Most Interesting Discoveries and Innovation |

|

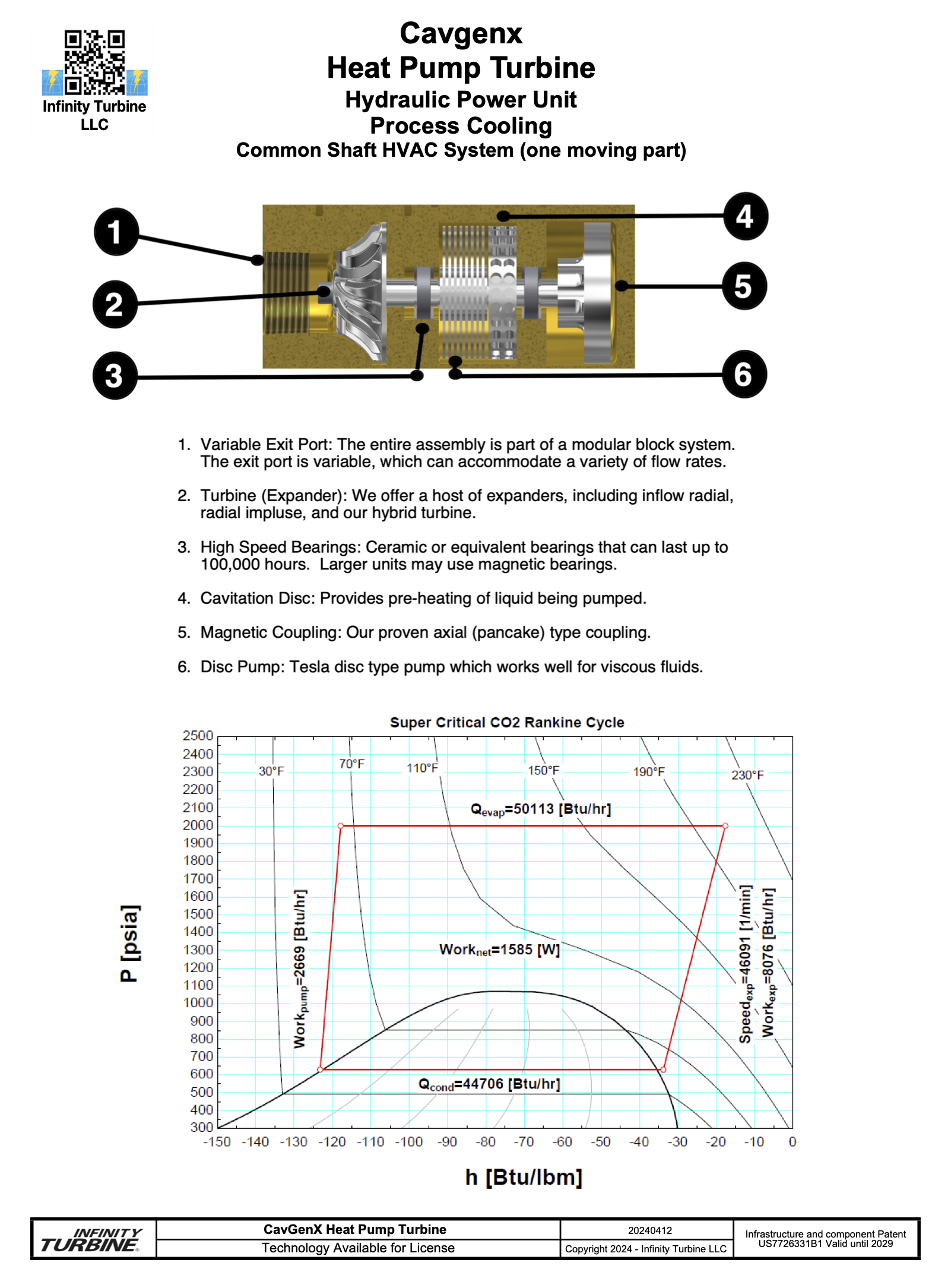

Transform Low Grade 31 C Data Center Waste Heat into Power and Cooling using Revolutionary Supercritical sCO2 Jet Turbine Technology CavGenX. The heat pump turbine. • Process cooling• Hydraulic pumpSupercritical CO2 Brayton Combined Cycle with up to 20 COP for data center cooling, and optional electric or hydraulic direct drive options. CO2 compressor pump common shaft driven from turbine with one moving part. This remarkable turbine is the next step in gas and liquid turbines for HVAC, data center waste heat to energy, closed-loop quiet power production, vehicle HVAC, commercial chiller conversions, and more ...Supercritical CO2 Waste Heat to Power Cart Mounted System from 2013 Photos |

10 MW Supercritical CO2 Turbine Generator Power Block for AI Data Centers |

|

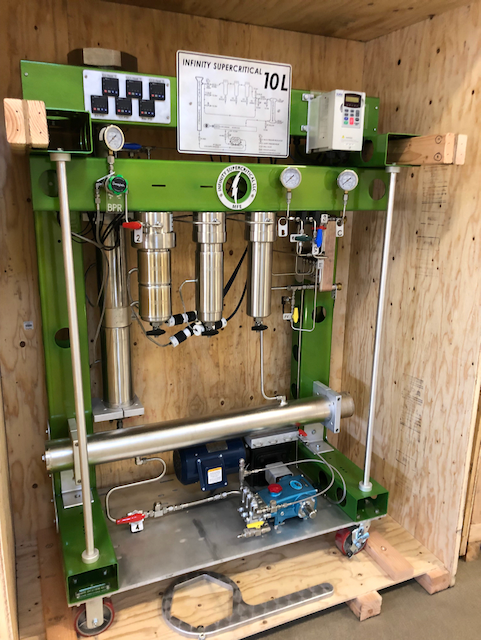

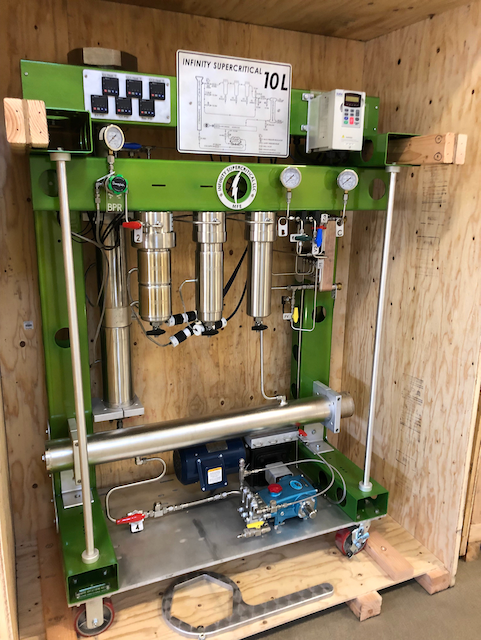

Extract Gold from Electronic Waste Using Supercritical CO2 Extraction System Extracting plant, algae, gold, or other components is a Organic Rankine Cycle. Liquid CO2 is pumped to pressure, simultaneously heated to gas in the extraction vessel, then expanded (a cooling process) which releases the entrained extracted materials into a collection vessel. The CO2 gas is then condensed (cooled) into a liquid and the process is repeated. A liquid pump is used to cycle the CO2 (uses 1/10 the energy as a gas vapor pump).Technology of Supercritical CO2 Botanical Extraction by Infinity TurbineIt is the same cycle which is used to make power, except that the turbine and generator is replaced by the extraction vessel, where materials are held with components that are extracted. The biggest difference between a power vs. extraction transcritical CO2 cycle is the mechanism doing the work (i.e. a turbine generator or a extraction vessel holding material for extraction) and the flow rates. A turbine generator uses a great deal more CO2 flow compared to a extraction process.Infinity built over 100 of these extraction machines between 2015 and 2020. We are now offering the plans and licensing for these systems. Build Licensing 10L Supercritical CO2 Extraction SystemParts to Convert Cat 310 Pump to CO2 for Supercritical SystemsSupercritical CO2 Parts PlansSupercritical CO2 Extraction for Plant Oil and Gold from E-wastes Plans Build Licensing Supercritical CO2 Heat Pump Organic Rankine System Supercritical CO2 Organic Rankine Cycle Heat Pump Experimenter Platform

|

|

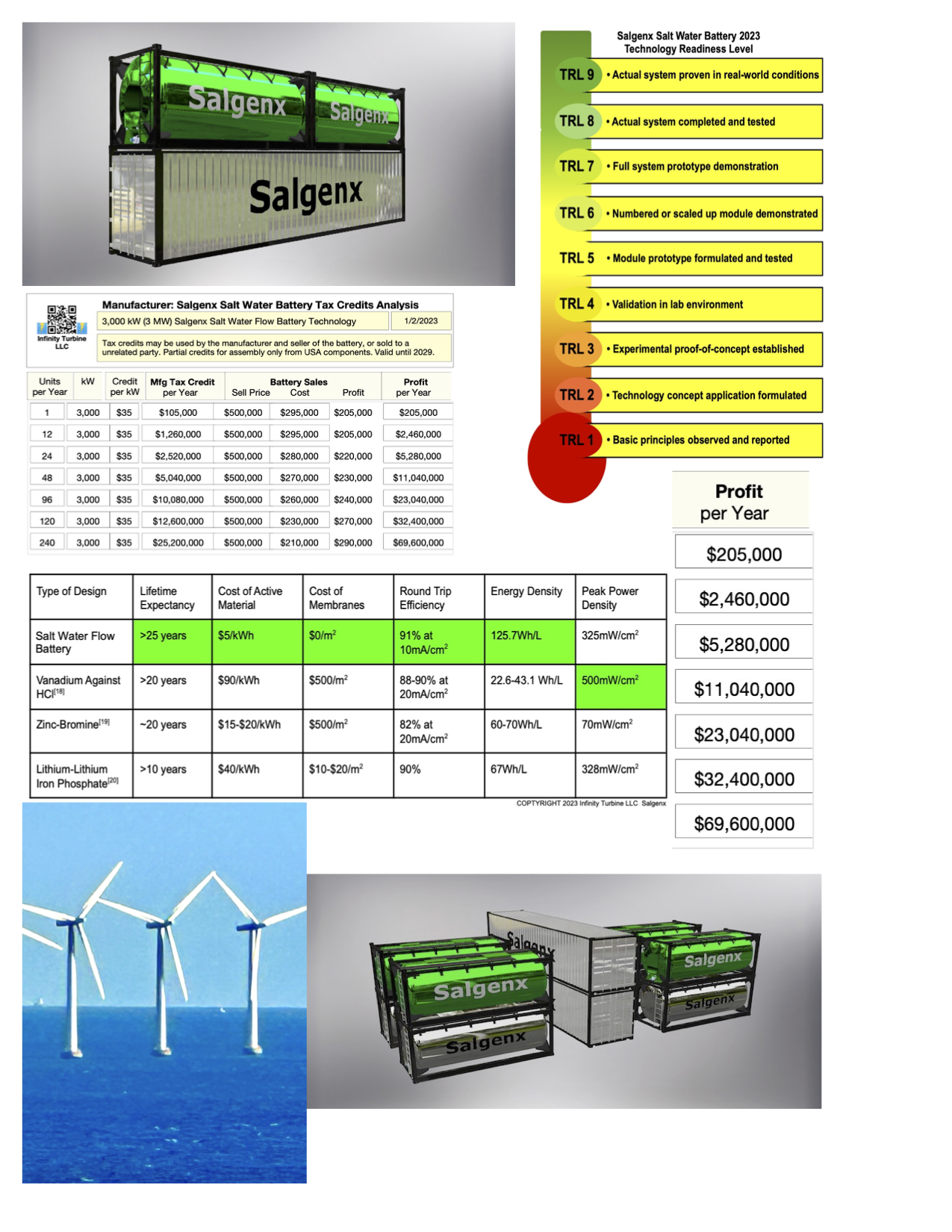

Salgenx Flow Battery Technology Report Salgenx, a renowned provider of innovative energy solutions, has recently unveiled its highly anticipated Salt Water Redox Flow Battery Technology Report. Find out how this technology has been around for 100 years.See why the US Military spent $7 million to verify the technology.Find out why the Pacific Northwest Laboratory did experiments to prove the technology.This comprehensive report takes a deep dive into the dynamics of grid-scale flow batteries, shedding light on crucial aspects such as economics, efficiency, and deployment strategies. With insights derived from extensive research and engineering expertise, the report offers valuable recommendations for optimizing financial viability, enhancing energy conversion efficiency, and successful deployment. This groundbreaking resource is expected to revolutionize the understanding and adoption of grid-scale flow batteries, driving advancements in energy storage and accelerating the transition to a sustainable future. Learn how to build a demo cell that you can test and use.The Salt Water Redox Flow Battery Technology Report is now available for purchase on the Salgenx website, positioning it as an essential read for industry professionals, investors, and stakeholders seeking reliable, efficient, and eco-friendly energy storage solutions.Please email for pricing. |

|

Energy storage and simultaneous desalination with Salgenx technology A breakthrough in desalination technology has been announced today with the unveiling of a new system that uses a saltwater flow battery (BESS) cycle to produce clean drinking water from seawater. This innovative solution has been developed to create a sustainable and cost-effective way of storing energy while simultaneously producing fresh water.The desalination system operates by using a saltwater flow battery cycle without the need for a membrane. The system can use a renewable energy source, such as solar power or large wind turbine, to charge the battery, making it both environmentally friendly and cost-effective. |

Energy Strategy Technology Guide and Handbook |

Energy Strategy Technology Guide and Handbook: Complete guide to energy savings from ORC, thermal storage, heat pumps, grid rate arbitrage, and more.Discover the power of sustainable energy systems with our comprehensive guide on Organic Rankine Cycle, Thermal Storage, Heat Pump, and Energy Arbitrage. Learn how these technologies work, their benefits, and their role in maximizing energy efficiency. Explore the potential for renewable energy and energy storage, and stay ahead of the curve in the evolving landscape of sustainable solutions. Read now for a deep dive into these key components of a greener future. For business and residential use. |

Supercritical CO2 Transcritical Developers Cart for Miniature sCO2 Turbines |

Supercritical CO2 Transcritical Developers Cart Supercritical carbon dioxide is gaining attention as a high-efficiency working fluid for turbines, compressors, and next-generation energy systems. For researchers and engineers developing miniature expanders, a small-scale test system is invaluable. A cart-mounted design offers safety, mobility, and modularity for laboratory settings.This cart-mounted supercritical CO₂ test system enables engineers to test miniature expanders, validate designs, and accelerate innovation in turbine technology. Compact, mobile, and instrumented for precision, this type of system makes supercritical CO₂ research practical and accessible in a laboratory environment.

|

Supercritical CO₂ test cart to explore advanced cooling technologies for AI data center chipsets and server racks, including ejector cooling, cascade systems, Joule Thomson effect cooling, and chiller-style configurations, for small-scale experimentation before large-scale deployment. |

Supercritical CO2 Test Cart for AI Data Center Chip Cooling Development The rapid growth of artificial intelligence workloads has pushed data centers to the limits of existing cooling technologies. High-performance GPUs and server racks generate massive amounts of heat that must be dissipated efficiently and reliably. Supercritical carbon dioxide is emerging as a promising fluid for next-generation cooling. A cart-mounted experimental test system provides a safe and modular platform for evaluating small-scale concepts before scaling up to production-ready designs.Advantages of a Supercritical CO₂ Test Cart• Safe Small-Scale Testing: Engineers can trial miniature systems at manageable pressures and flow rates before investing in large prototypes.• Flexibility: The cart allows quick reconfiguration to test ejector setups one day, and Joule Thomson expansion the next.• Instrumentation: Precise pressure, temperature, and flow measurements make it possible to map performance curves and validate thermal models.• Scalability: Data collected from small test sections informs designs for full-scale data center rack systems.As AI accelerators and GPUs continue to push thermal boundaries, traditional water and air cooling are reaching their limits. Supercritical CO₂ offers unique opportunities for compact, efficient, and versatile cooling technologies. A laboratory-scale test cart provides a vital stepping stone, enabling experimentation with ejectors, cascades, Joule Thomson systems, and chiller-like designs in a controlled environment. By refining these concepts at small scale, engineers can accelerate the development of practical cooling solutions for tomorrow’s data centers.Please contact Infinity Turbine for pricing and availability.

|

|

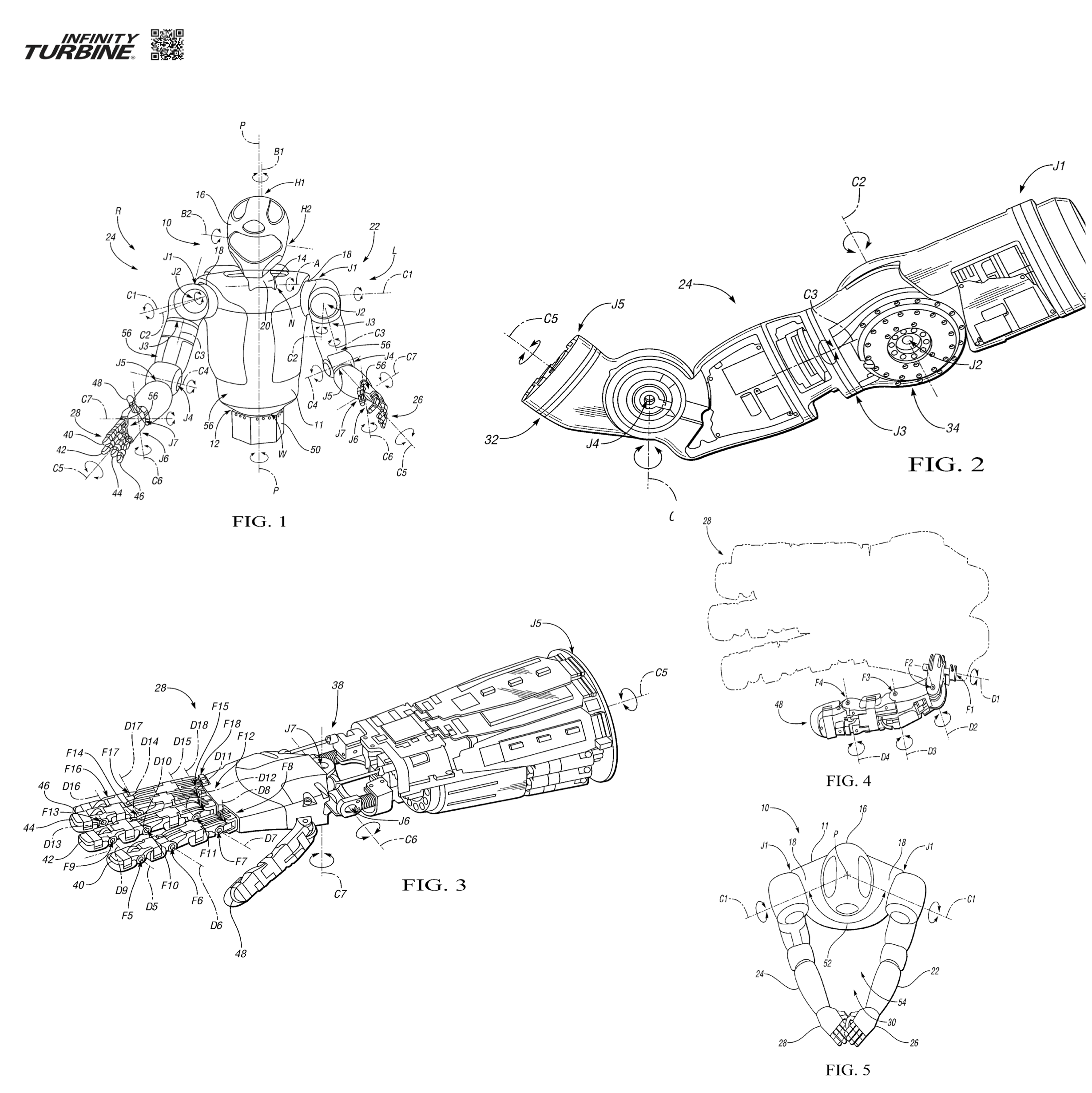

The Micro Robots are Coming Developing microrobots with multiple applications including air movement, liquid flow, heat (sink) flow, heat pipe, conveyor, lifting, sound attenuation, and more.Microbots can be arranged to act as a group (ant farm) or as individuals. Using RFID, these miniature robots can perform inventory tasks on a micro scale.Liquid-microrobot monomer (LRM) can pass through narrow channels via elongation and achieve scaling via splitting and coalescence. LRMs can also reassemble into various kinds of functional liquid-robot aggregates, such as microsticks, micropies, microtrains, microkayaks, and microrollingpins. Multi-terrain surfaces and perform various complex tasks. Dynamic self-assembly and group behavior of a multiple LRM system. These ferrofluid droplet robots provide novel solutions for some potential applications, such as untethered micromanipulation and targeted cargo delivery.Pioneering the Future of Autonomous Technology and Humanoid Robots with Telsa AI and Robotics |

|

Tesla Optimus Robot Technology Guide Coming soon...The Tesla Optimus robot is a game changer for factories due to its exceptional capabilities and the numerous benefits it brings to the manufacturing industry. • GM had the first robot in 1961 in the automotive industry and was created in the 1950s by George Devol called the Unimate• GM and NASA had a Humanoid Robot Patent in 2013 (US8511964)• Leonardo di Vinci designed a mechanical knight and lion in 1495• The term Robot was coined in Prague in 1920 by Josef Čapek in the Czech-language play R.U.R. (Rossumovi Univerzální Roboti)Are you ready for the robot revolution ?Pioneering the Future of Autonomous Technology and Humanoid Robots with Telsa AI and Robotics |

Uniting Engineering and Technology Experts in Palo Alto for Tesla Bot Development |

|

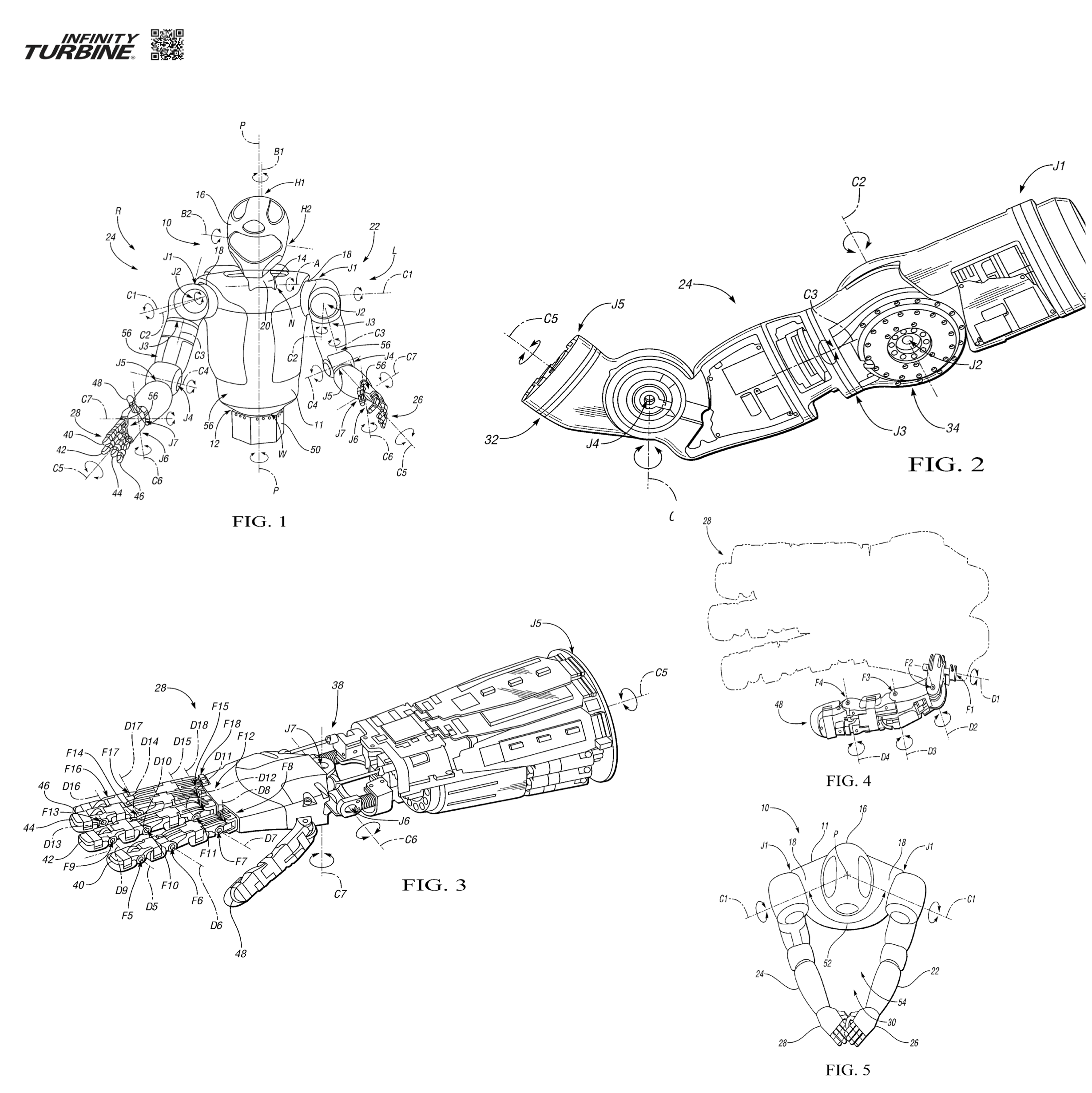

Salgenx Lift Pump System featuring Tesla disc pump technology for viscous fluids |

Salgenx Lift Pump System Featuring Tesla Disc Pump The Salgenx Lift Pump System is design to pump saltwater and viscous fluids.For the saltwater flow battery application, it has piping and fixtures which are electrolyte material compliant to resist corrosion from environmental conditions from saltwater. |

Converting Gas Turbine to sCO2 |

|

|

|

|

|

|

|

|

|

Scalloped Tesla Disc Turbines with Supercritical CO2: A New Approach to Drag Reduction and Efficiency Could a simple scallop pattern make Tesla disc turbines more efficient? By combining supercritical CO2 and bio-inspired blade design, a new frontier in turbine optimization is taking shape. |

|

Why Rotating Disc Arrays Produce Massive Thrust Compared to Traditional Paddle Wheels A 240-disc rotating array powered by a 10 HP motor produces hundreds of thousands of pounds of thrust—far exceeding that of traditional paddle wheels. Why is it so much more powerful? Here's the fluid dynamics explanation.Why Rotating Disc Arrays Produce Massive Thrust Compared to Traditional Paddle Wheels |

|

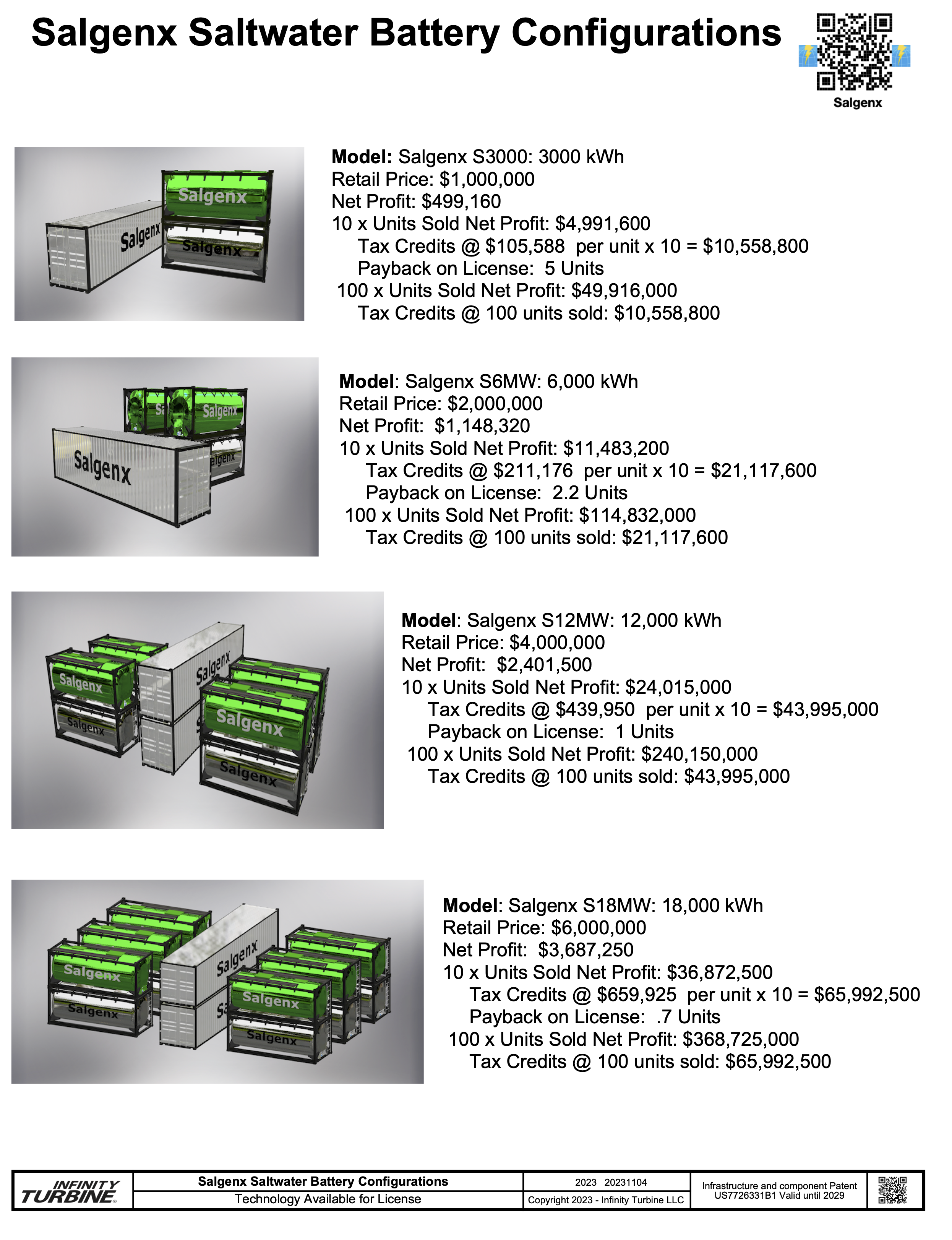

3,000 kWh Grid Scale Saltwater Battery using Shipping Containers. We build the Technology. You Build the Product and Access $105,000 Tax Credits for each Battery. The Salgenx sodium flow battery is unique with simultaneous processing functions.• Store grid-scale power • Store thermal energy (including cogeneration)• Perform selectable revenue processes according to highest revenue on-demand (AI tunable logic may select from charging to thermal storage, and more) including making cement, graphene, and more...• Build for less than $300,000 for a 3-6 MWh System with a $105,000 USA tax credit• Use pre-made (new or used) shipping containers for the battery saltwater and electrolyte storage• The only fabrication are the flow pumps and electrolyzers which you may purchase pre-made to assemble at your location• Customer list of $1.2 billion in orders• License to manufacture starting at $2.5 million• Buy 500 units and own part of the company (see Press Release link for more information and disclosures)The 6 hour flow battery charge rate can be discharged at any time and the stored energy can be held almost indefinitely.$35/kWh USA Battery Tax Credit (paid directly from IRS or may be sold to unreleated party) amounts to $150,000 per 3,000 kWh battery. That is about half of the production cost.The Company That Controls Battery Technology Controls the World - Salgenx the Saltwater Battery |

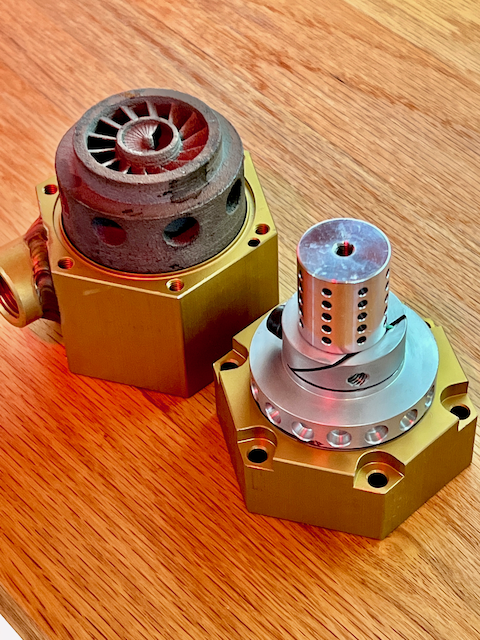

CavGenX. Heat pump turbine with one part compressor and turbine. |

CavGenX The Cavgenx is a heat pump turbine with the main objective to provide hydraulic pressure. That pressure can be used to drive things, like wheels, gears, machines, and even lift devices, like drones.What makes the Cavgenx turbine unique is that its compressor is a combination of a cavitation device and magnetic induction driven on a common shaft from the turbine. A true turboshaft engine. But in this case it is closed-loop, and uses Earth friendly working fluid like closed-loop CO2.In true a Organic Rankine Cycle, this closed-loop process takes a liquid through phase changes to generate heating, cooling, and hydraulic pressure. Liquid is spun into vapor, pressurized by heating, then evaporated and condensed back to liquid to repeat the process. Cooling is the byproduct of the cycle. |

|

Why Salt Water may be the Future of Batteries There’s no shortage of solutions to the world’s need for renewable energy storage, but there is a shortage of accessible and cheap resources to use for those solutions. Lithium and vanadium aren't limitless, so what about regular, run-of-the-mill salt? Redox flow batteries, or RFBs, can exploit the abundance of elements like sodium and iron. One U.S. company already has salt water batteries ready to go, with at least two others developing iron flow variations built to effectively run on rust. They promise to last longer and be far cheaper than the competition. So, what happens if we go with the flow? |

Gasification of wood waste can produce bio char and other products used in battery cathodes |

Unlock the potential of wood waste through the process of gasification yielding high-quality carbon suitable for battery cathodes Gasification is a thermochemical procedure that transforms organic materials, including wood waste, into a valuable gas mixture called syngas. This process involves heating the wood waste in the presence of a controlled amount of oxygen or air, leading to the generation of volatile compounds, bio-oil, and solid residue. These byproducts can undergo additional refining to produce hard carbon or graphite, which find application in battery cathodes.

|

|

Development of a Closed Loop Micro Satellite Plasma Ion Propulsion System Based on a Cavgenx Heat Pump Turbine The following descriptions follow through development of a space propulsion system based on the Cavgenx Heat Pump Turbine concept.Electrical power is needed to start the process and as a topping off heat additive when needed.The turbine would power the cavitation compressor as well as supply shaft horsepower to spin induction magnetic heating.The high COP of the liquid cavitation compressor (already shown by NASA - see link below) is used in concert with a induction heating system to power the cycle. Note that cavitating a liquid by use of a spinning disc was invented more than 100 years ago. The spacecraft skin would be used as a condenser heat sink for the closed-loop CO2 Organic Rankine Cycle system.

|

|

Thermal Sand and Salt Battery A Revolutionary Approach to Desalination and Energy Storage by Harnessing the Power of Sand and SaltThis novel approach ingeniously combines sand, salt, and renewable energy sources to create a thermal battery system capable of both desalinating water and storing energy.Sand and Salt Battery for Thermal Energy Storage Wax Motor and Energy Storage Device

|

|

Saltwater Flow Battery and Materials Manufacturing Module Salgenx: The saltwater flow battery . Grid-Scale Battery Capable of Also Functioning as a Materials Manufacturing Facility:• Grid-scale power storage• Thermal energy storage• Desalinate seawater • Harvest and refine lithium from brine • Exfoliate graphite into graphene by intercalating Na• Selectable revenue processes according to highest revenue on-demand (AI tunable logic)• Massive manufacturing tax credits.

|

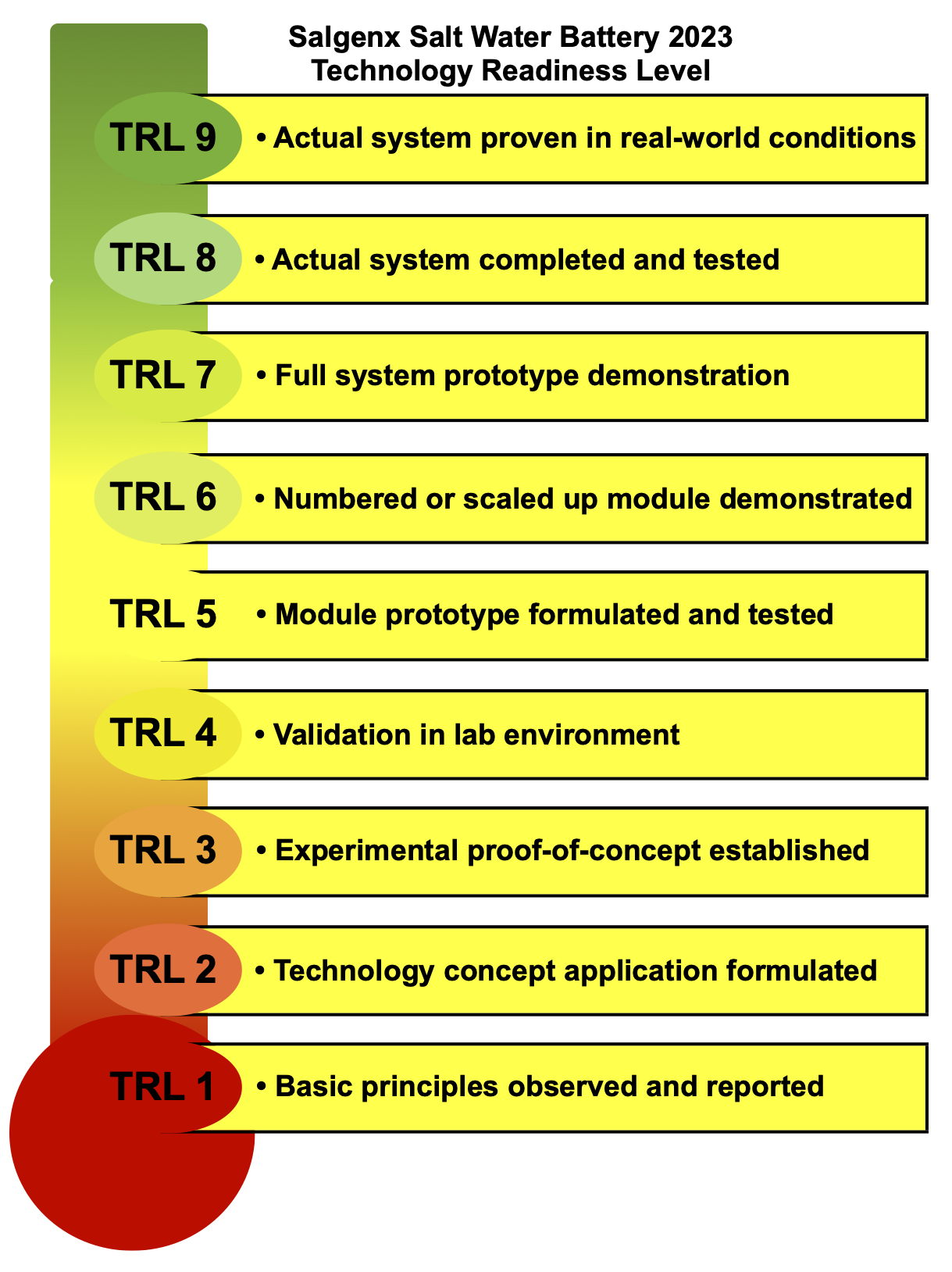

TRL or Technology Readiness Level for the Salt Water Battery |

TRL Technology Readiness Level for Salgenx Saltwater Battery Technology As of March 2023, Salgenx is at TRL (graph developed by NASA to indicate readiness level of technology) somewhere above 3.The goal of technology licensing is to work with licensee to formulate TRL 5 and TRL 6 according to system model configuration (power and volts desired for customer application). The licensee is responsible for TRL 7 through TRL 9, where it then becomes a MRL (manufacturing readiness level). |

|

Summary of Tesla Megapack Lathrop Production Facility as of November 2023 In a November 16, 2023 interview on the Randy Kirk YouTube channel, Bradford Ferguson provided an update on Tesla's Megapack manufacturing. He visited Lathrop, California, and observed the production rate of Megapacks. In March 2023, he counted about 10 Megapacks produced per day. On a recent visit, he noted an increase to 27 per day, but estimated the actual rate to be around 18-19, occasionally dropping to 10 per day. The production capacity is believed to be 27 units per day, equating to 4 GW hours.Ferguson identified the primary production limitations as the availability of batteries and power electronics, specifically silicon carbide. Power electronics are crucial for converting DC to AC power and include devices like gallium nitride FETs and power diodes. The cost of batteries in each Megapack is around $300,000, with the total price of a 3 MWh Megapack being approximately $1.9 million.The interview concluded that with the resolution of battery and power electronics supply chain issues, Tesla could adopt a rapid expansion model for Megapack factories worldwide, potentially producing between 10,000 to 20,000 units annually. At full capacity (27 units per day), the output could reach 9,855 Megapacks (30 GWh) annually, yielding $18.725 billion in revenue and $9.362 billion in net profit. |

Infinity Turbine Disc Pump which can be run Reverse as Turbine including Radial Impeller Option |

New: Infinity Tesla Disc Pump and Turbine with Radial Impeller Option Infinity is now offering its experimental Tesla disc pump and turbine package. It also includes a radial pump/turbine impeller. This is experimental. The 6 inch (152.4 mm) diameter disc pack can be swapped out for any type Tesla disc for optimizing pump according to liquid viscosity. Pump discs are mounted on a keyed common shaft to a magnetic coupler which allows a outside pump motor (with magnetic coupler) or external generator. Prototype pump discs or impellers can be 3D printed for this type of Modular Block assembly housing. Typical blocks are machined from aluminum (for pumping or expander operations) or HDPE for just pumping.The pump housing is good for pressures lower than 300 PSI and less than 100 C. If higher pressures are desired, then a high strength material magnetic coupler block needs to be designed and manufactured (something like carbon fiber).Please email for pricing.

|

Conducting experiments with flow battery electrodes to explore a novel method for graphene production. |

Unleash the power of Salgenx Saltwater flow battery to create graphene In the ongoing development of the Salgenx flow battery, electrochemistry plays a pivotal role in the process of producing graphene from exfoliated graphite. Notably, there are significant similarities in utilizing sodium (Na) for the purpose of graphene exfoliation from graphite.Na is harvested during the Salgenx Flow Battery charging process.Electro-Exfoliation of Graphite to Graphene in an Aqueous Solution of Inorganic Salt Exfoliated Graphene Production Using Electrochemistry for Simultaneous Energy Storage |

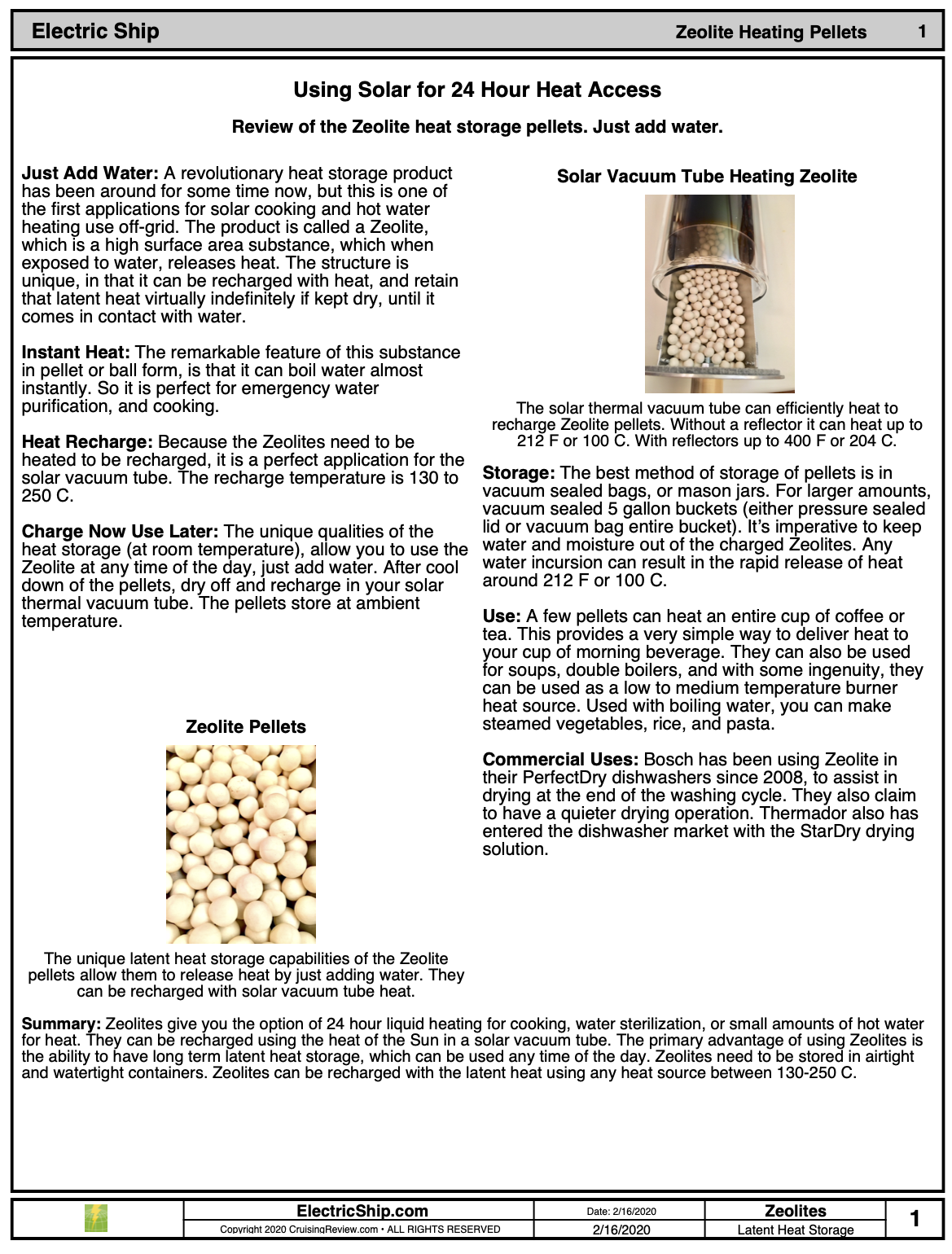

zeolite heat storage and retrieval |

Using Solar for 24 Hour Heat Access. Just add water. Zeolites give you the option of 24 hour liquid heating for cooking, water sterilization, or small amounts of hot water for heat. They can be recharged using the heat of the Sun in a solar vacuum tube. The primary advantage of using Zeolites is the ability to have long term latent heat storage, which can be used any time of the day. Zeolites need to be stored in airtight and watertight containers. Zeolites can be recharged with the latent heat using any heat source between 130-250 C.

|

New Drone under Development by Infinity with Unlimited Loiter Time for Defensive, Observation, and Power Grid Compromise |

Zmeia — the Snake Drone for Persistent Reach A new class of unmanned platform, Zmeia reimagines aerial presence with a long, flexible airframe that unfurls like a living vine across the sky. Designed for extended missions that demand reach, endurance, and discrete observation, Zmeia combines graceful motion with sophisticated sensors to silently extend situational awareness where traditional platforms cannot.Lightweight and serpentine, Zmeia excels at filling gaps — threading through urban corridors, tracing river valleys, or stationing along borders and coastlines to provide continuous, low-profile coverage. Its unique form factor enables prolonged airborne persistence and smooth, adaptive flight paths that keep sensors trained on key areas without drawing attention. Field deployed with on-site generated hydrogen.Zmeia is built for responsible deployment: configurable mission profiles, layered safety controls, and data governance that prioritize lawful, ethical surveillance and respect for privacy. Whether supporting humanitarian search operations, environmental monitoring, or secure perimeter awareness, Zmeia is about seeing more with less footprint — thoughtfully and safely. |

|

|

Performance Comparison of Graphene-Coated Enhanced Sand vs. Sand-Salt Thermal Batteries Can coating sand with graphene transform how thermal energy is stored and released? This article compares traditional sand-salt batteries with graphene-enhanced systems to determine which offers better thermal performance.Infinity Turbine is developing sand and sand-salt enhanced thermal storage batteries.Graphene-Coated Sand vs. Sand-Salt Thermal Batteries: A Performance Comparison |

|

| CONTACT TEL: +1-608-238-6001 (Chicago Time Zone USA) Email: greg@infinityturbine.com | AMP | PDF |