|

Viktor Schauberger's Repulsine Turbine

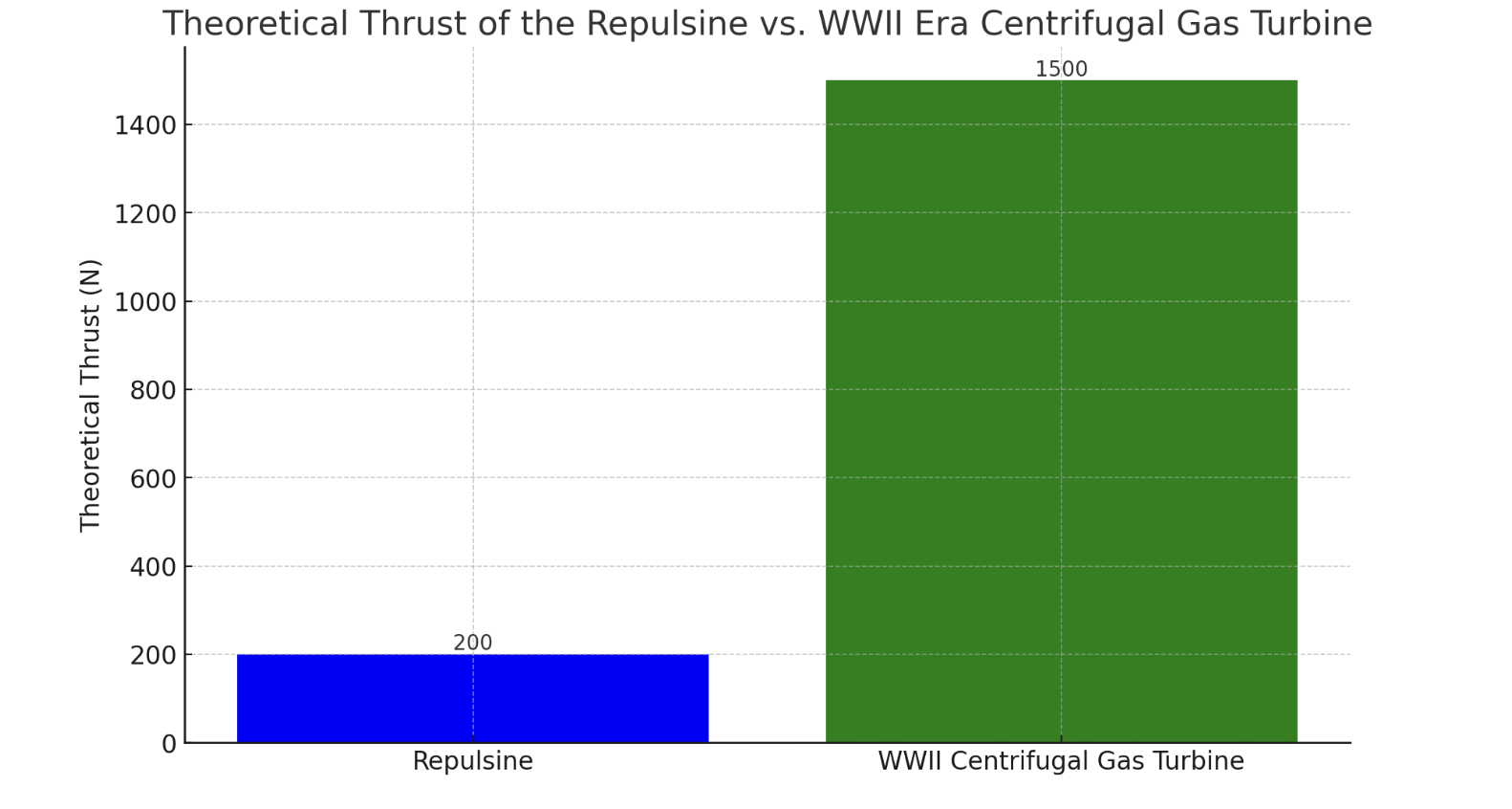

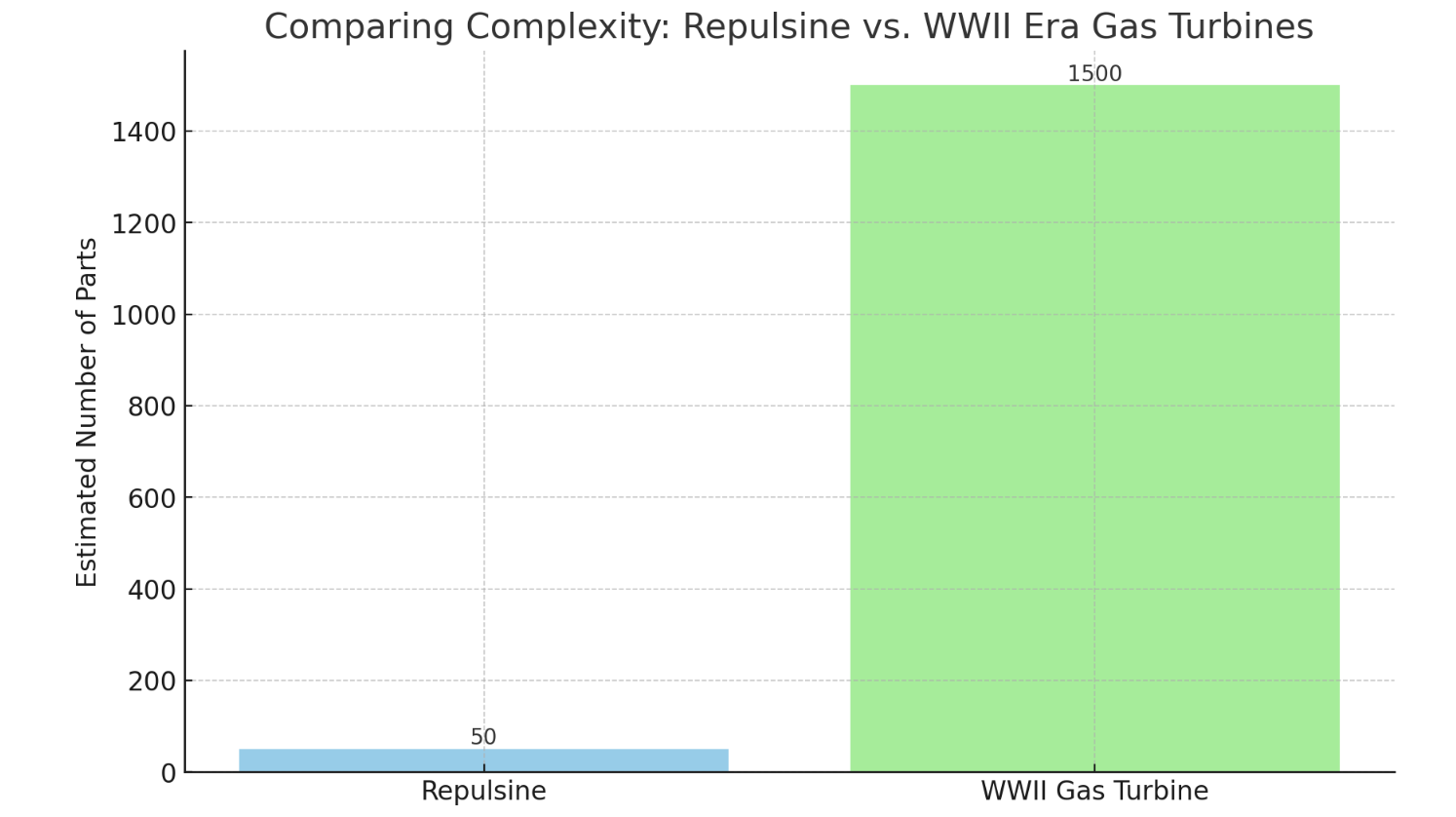

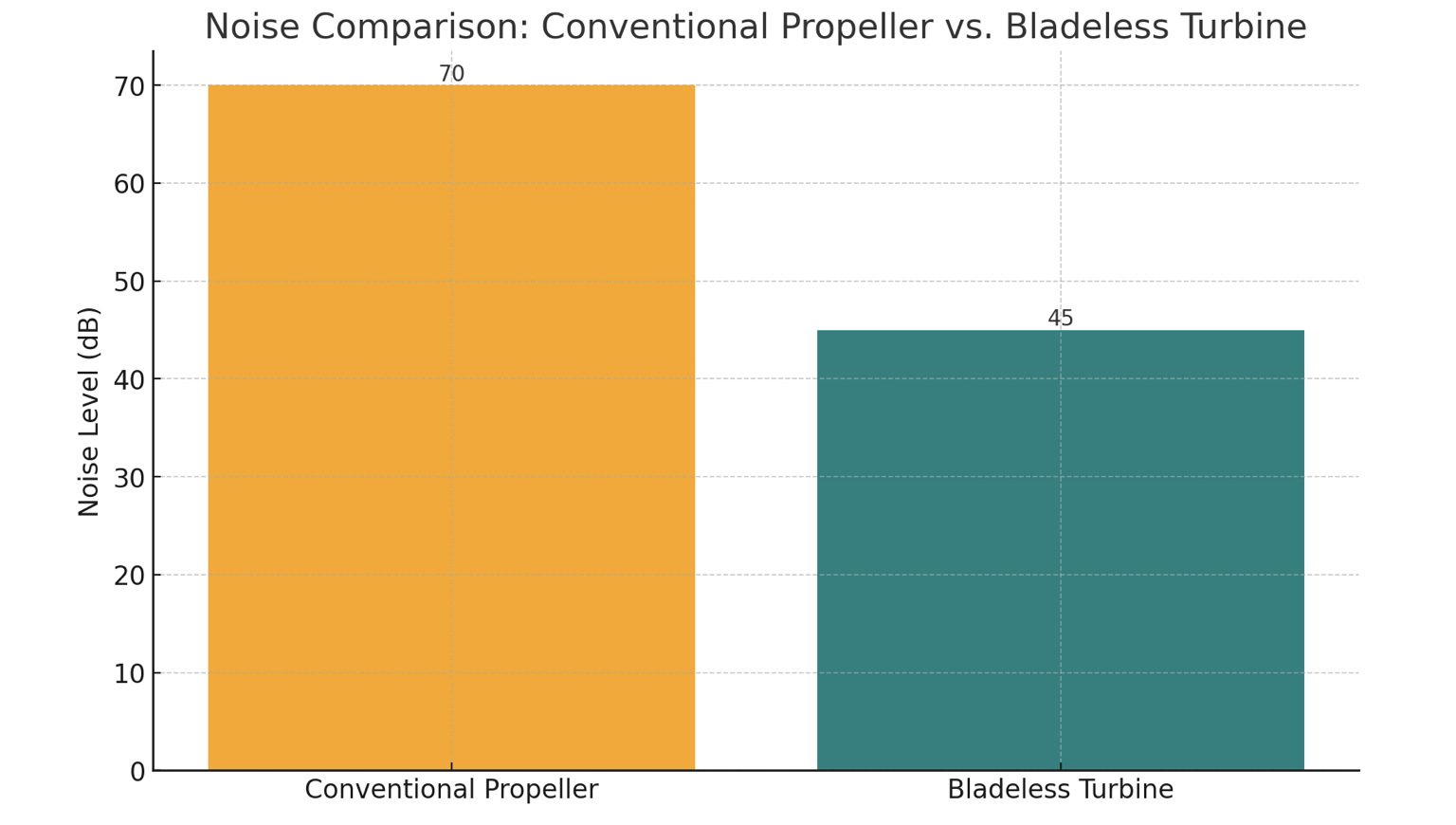

The exploration of innovative technologies and their comparison with conventional counterparts offers a fascinating window into the evolution of engineering and design principles. Among such intriguing subjects is the work of Viktor Schauberger and his Repulsine turbine, a device that starkly contrasts with the conventional turbines used during World War II. This article aims to delve into the characteristics, theoretical foundations, and practical implications of Schauberger's invention, juxtaposing it with the more traditional turbines of the same era, to shed light on their unique features and potential impacts on technology and society.Viktor Schauberger's Repulsine TurbineViktor Schauberger (1885–1958), an Austrian inventor, and naturalist, introduced the concept of the Repulsine turbine in the mid-20th century. Schauberger's work was heavily influenced by his observations of natural processes, particularly the ways in which water flows and vortices form in rivers and streams. The Repulsine, sometimes referred to as the flying saucer turbine due to its unique shape and rumored capabilities of levitation, was designed to harness the power of implosion, a principle fundamentally different from the explosion-based technologies prevalent at the time.Key Features:• Implosion Technology: Unlike conventional turbines that rely on combustion or explosive force, the Repulsine was designed to use implosion, a process where energy is generated inwardly, supposedly offering a more efficient and harmonious way to harness energy.• Vortex Dynamics: The device aimed to mimic the natural motion of water and air in vortices, potentially leading to a more efficient energy transfer and minimal loss of momentum.• Innovative Design: With a distinctive saucer-like shape, the Repulsine was intended to create a self-sustaining vortex that could, theoretically, power itself and even achieve flight.Conventional Turbines of WWIIIn contrast, the conventional turbines of World War II were largely based on combustion technology. These turbines were primarily used for propulsion in aircraft and ships, and for power generation. The technology behind these turbines was well-understood and had been refined over decades of industrial and military applications.Key Features:• Combustion-Based: Relied on the explosive force of burning fuel to generate power, which was then converted into mechanical energy.• High Power Output: Designed to produce a significant amount of power, essential for the heavy machinery and vehicles used during the war.• Efficiency and Reliability: Though less environmentally friendly, these turbines were valued for their efficiency and reliability under the demanding conditions of wartime.Comparison and ImplicationsEfficiency and Environmental Impact: The Repulsine's implosion-based design promised a more efficient and eco-friendly approach, reducing waste and potentially offering a cleaner alternative to combustion. However, its practical efficiency and feasibility remain speculative, as detailed documentation and successful replications of Schauberger's work are scarce.Technological Innovation: Schauberger's turbine represented a radical departure from conventional engineering wisdom, emphasizing the potential of biomimicry and natural systems in technological design. In contrast, WWII turbines were the culmination of incremental improvements in established technologies.Practical Application: While conventional turbines played a crucial role in the Allied and Axis powers' machinery, the Repulsine never saw widespread application or development, remaining a fascinating but largely unexplored footnote in the history of engineering.ConclusionThe comparison between Viktor Schauberger's Repulsine turbine and the conventional turbines of WWII highlights the diversity of thought and innovation that characterized the 20th century. Schauberger's vision, though not fully realized in his lifetime, continues to inspire those seeking sustainable and efficient energy solutions, reminding us of the value of looking to nature for inspiration. Meanwhile, the conventional turbines of WWII demonstrated the peak of industrial-age technology, providing a reliable foundation upon which modern advancements continue to build. Together, these contrasting approaches to turbine design reflect the broad spectrum of human ingenuity and the ongoing quest for technological advancement.

|