|

|

|

Infinity Turbine Patented Modular Block

|

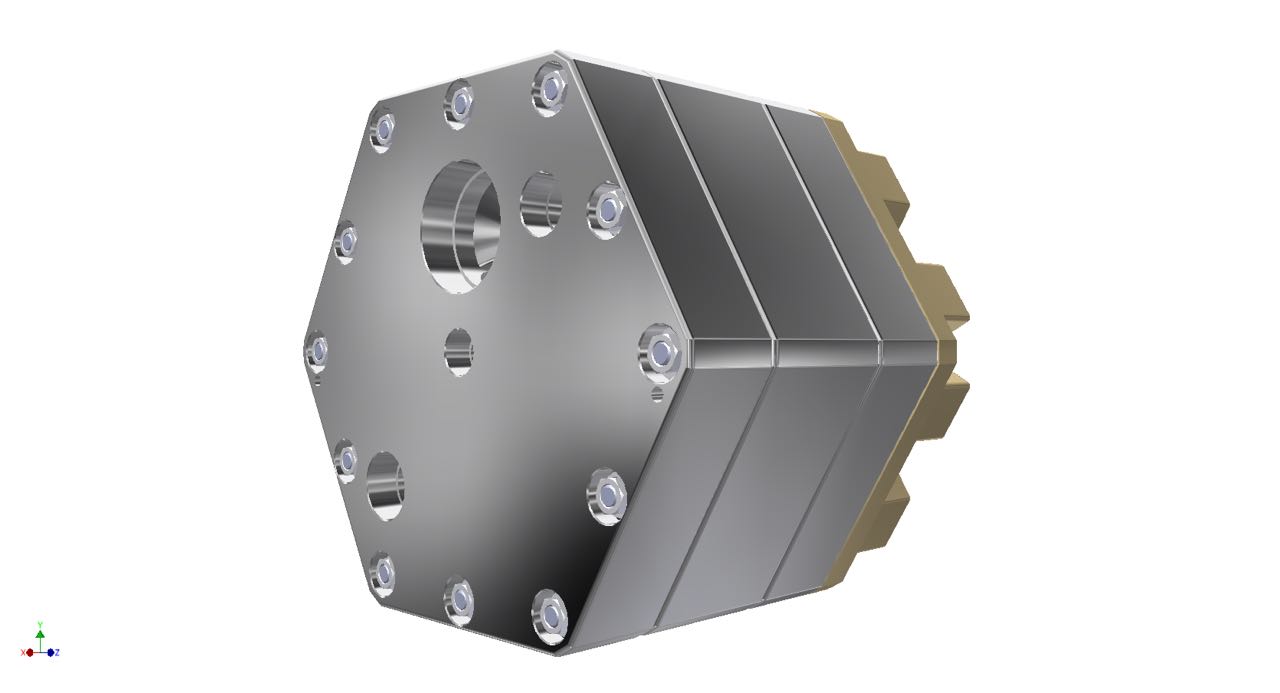

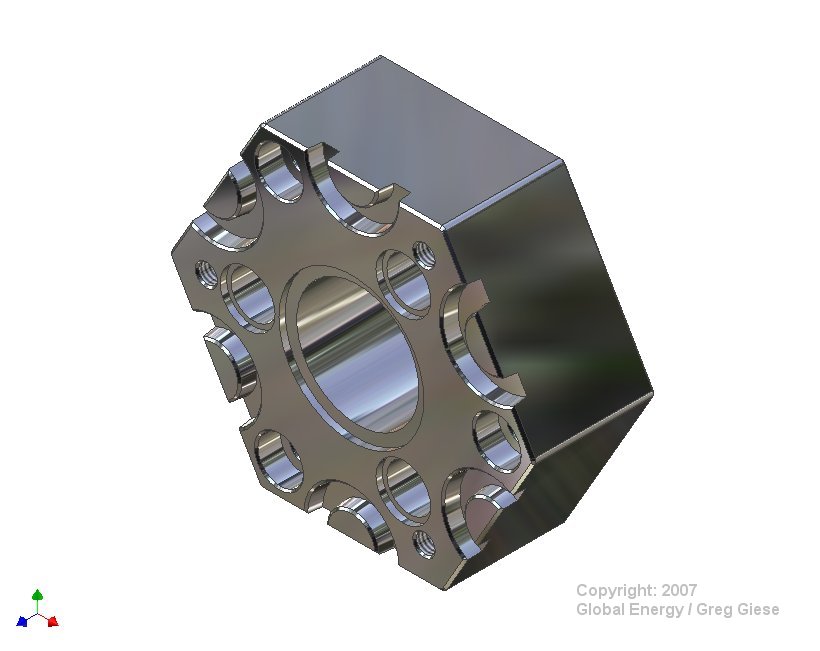

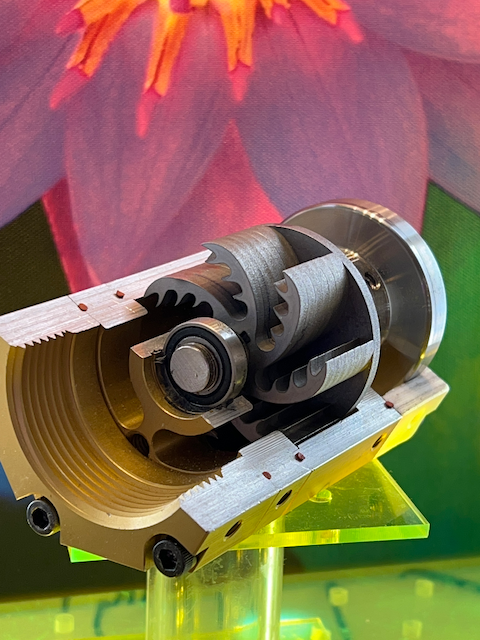

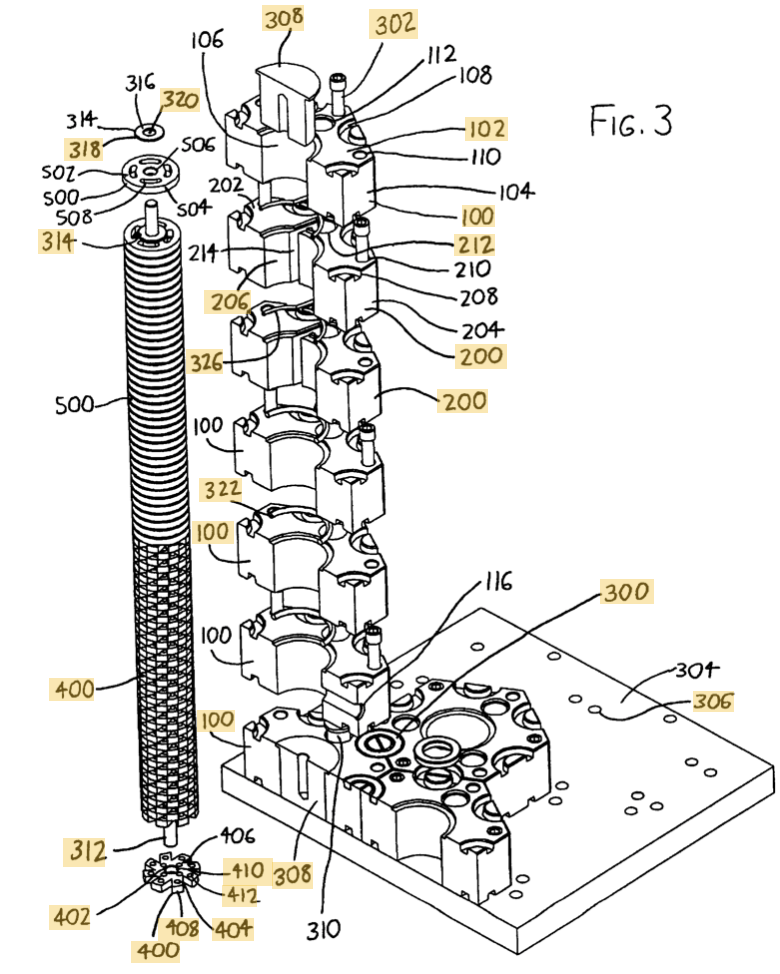

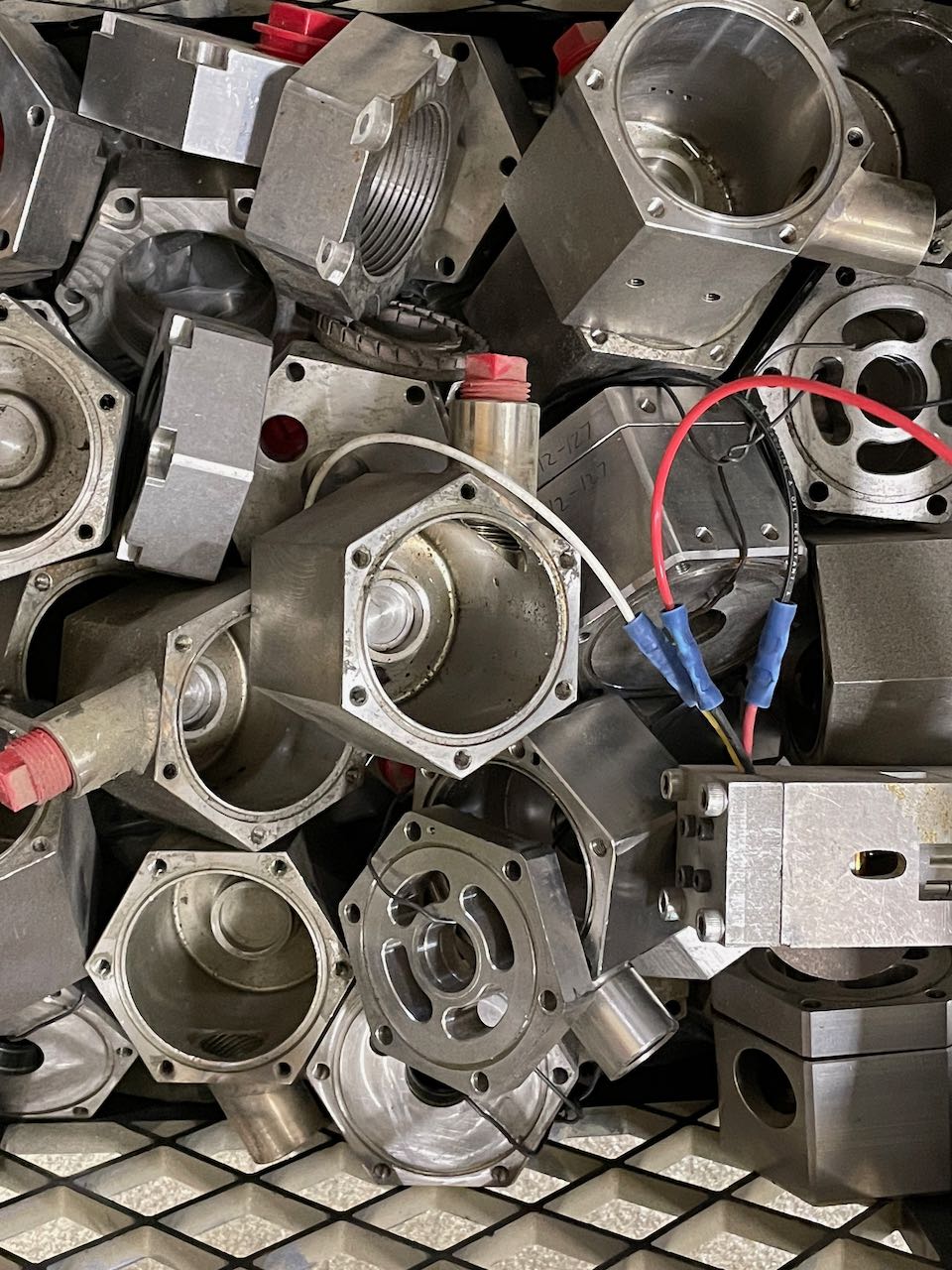

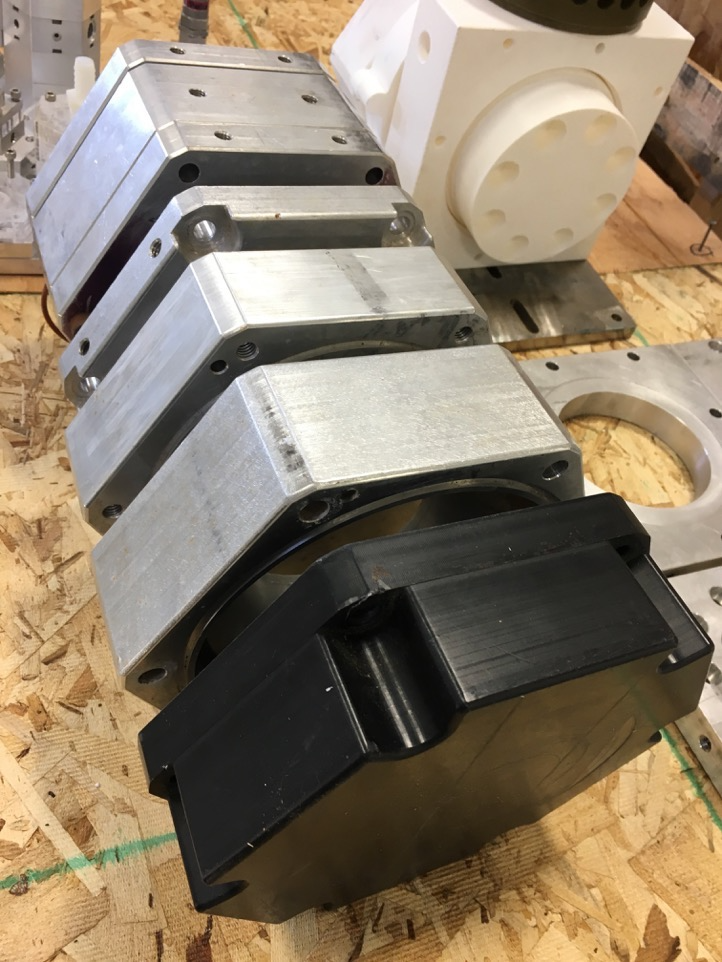

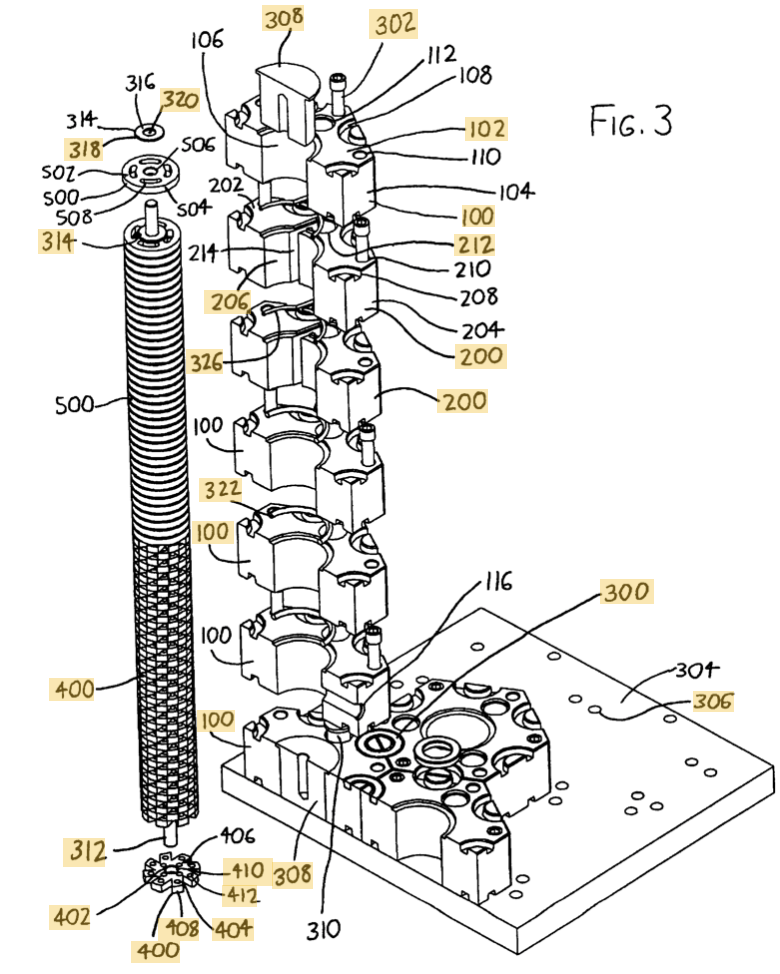

Modular fluid handling device II (Components of the Gas Leverage Turbine)

A modular fluid handling device includes at least one block having opposing block faces shaped as tessellating regular polygons, and a series of block sides therebetween. Each block includes a central bore and fluid passages extending between the block faces, and possibly ducts extending between the bore and the fluid passages. The blocks may be rapidly horizontally and/or vertically affixed with their bores and/or fluid passages in communication to form a fluid handling device having the desired configuration (e.g., with the bores and fluid passages forming a desired process flow path, fluid circuit, or the like). Star wheels and/or rotor discs can be provided within the block bores for purposes of pumping fluids flowing within the bores, and/or for purposes of deriving power from fluid flow within the bores.FIELD OF THE INVENTIONThis document concerns an invention relating generally to devices for processing and sampling of gases and liquids, and more specifically to devices allowing rapid construction of fluid reactors, distillers, extractors, homogenizers, filtration/separation devices, process models (e.g., devices for modeling engine cycles, refrigeration cycles, etc.), and other devices for handling fluids.BACKGROUND OF THE INVENTIONFluid handling devices including fermenters, distillers, filtration tanks, evaporators, etc. (or combinations of these components) are exceedingly common in industry and in research labs. Researchers and engineers also often need to experiment with models for common thermodynamic cycles, e.g., refrigeration cycles (vapor compression cycle, Einstein cycle, etc.) and power cycles (Otto cycle, Diesel cycle, Brayton cycle, Rankine cycle, etc.). While it is often desirable to generate prototypes or small-scale versions of such devices, they are usually time-consuming, difficult, and expensive to construct. One approach commonly used in laboratories is to connect glassware vessels (e.g., flasks, towers, heat exchangers, etc.) with rubber tubing so that the vessels form some desired fluid process model. Even apart from the significant time and expense required for their construction, these are quite fragile, are unsuitable for pressurized processes, and are also usually unsuitable for processes involving extreme temperatures or corrosive materials owing to the weakness of the tubing. In some cases, more durable fluid handling devices can be formed from metal vessels connected with (for example) brazed copper tubing, but these involve even greater time, cost, and fabrication burdens.A prior patent (U.S. Pat. No. 7,146,999 to Giese et al., which is incorporated by reference herein) describes a modular fluid handling system wherein modular blocks bear passageways for carrying fluids, and wherein inserts having different functionality—e.g., valve inserts, filter inserts, turbine inserts, pump inserts, heating/cooling inserts, sensor inserts, flow routing/diverting inserts, etc.—can be inserted into selected blocks. The blocks, with or without inserts, can be affixed together to construct a durable fluid handling device. This document relates to improvements and additions to the modular fluid handling system described in U.S. Pat. No. 7,146,999 to Giese et al.

|