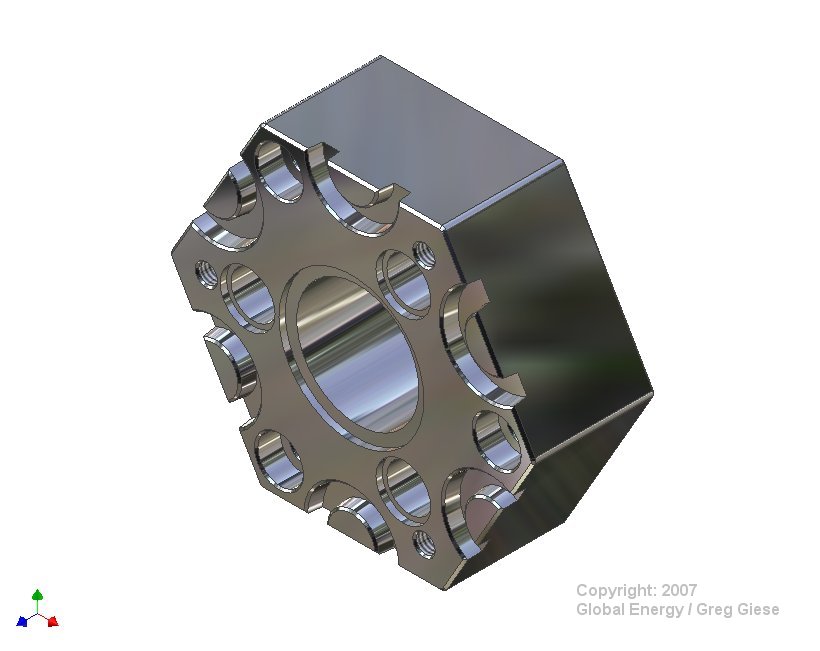

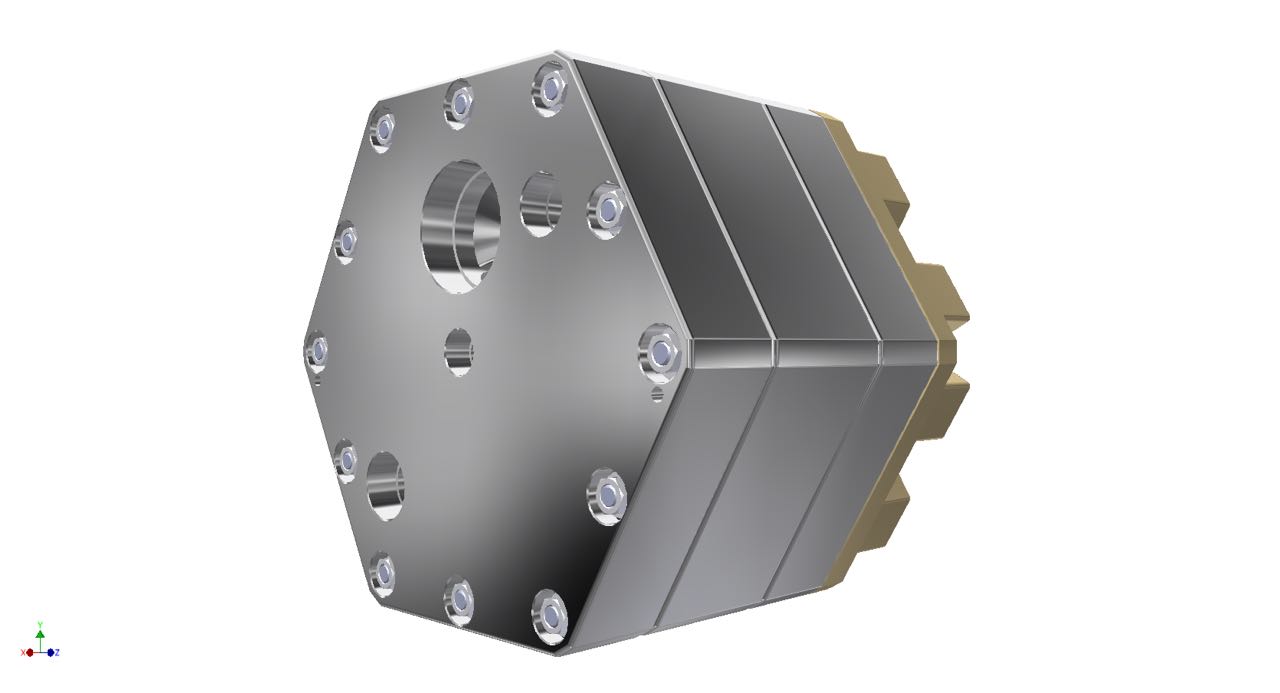

Example of Modular Block Turbine Housing

Modular Block

The modular fluid handling device has a central bore with fluid passages that extend between block faces, both horizontally and vertically. The blocks can be stacked horizontally, vertically, or both. Rotating elements can be configured in any of the passages for the purpose of pumping, extraction, or power production. Purpose: The functionality of the blocks is to perform rapid prototyping by deploying modular construction of systems using bolts.Standard Blocks: 3 inch size with 10/32 inch fasteners. 1 inch center bore and 1/4 and 1/2 inch horizontal bores.Larger Blocks: 6 inch size with 3/8 inch fasteners. 3 inch center bore and 1/4, 3/8, and 1/2 inch horizontal bores.Patents (I and II) cover all sizes and most applications. Modular Block Patent