Silver Nanoparticle production using SDR

Silver Nanoparticle Production $14 per gram from botanical sources

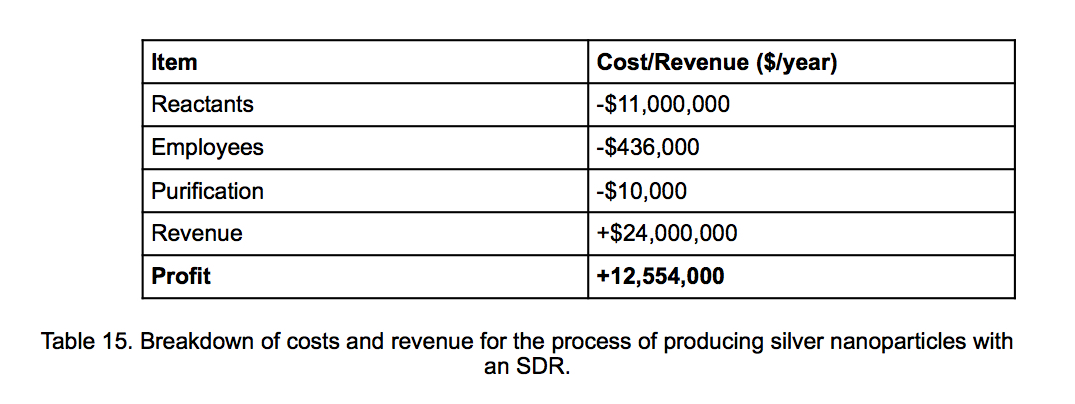

Spinning Disc Reactor for Nanoparticle Production to make $24 million per yearFor the full review, please download our pdf: 20190425-infinity-supercritical-sdr-nanoparticle-review (see link below).Spinning Disc Reactors, or SDRs, are a very new type of processing unit that has had new applications discovered every year.A big field of interest as of lately has been process intensification which is a design approach that focuses on smaller, cleaner, safer, and more energy efficient processes. One design that has received considerable attention as of late has been the spinning disc reactor (SDR). Its basic design includes one or more liquid streams being flowed onto a quickly rotating disc.The centrifugal acceleration from the rotation creates a very thin liquid film which significantly heightens the mass transfer and micro-mixing ability of the liquid streams. It also is a continuous feed reactor which can be applied to many processes that have relied on large volume and high residence time designs like batch or continuously stirred tank reactors (CSTR).While the SDR can be used for many different processes, it excels greatly in a specific few. These include processes that rely on precipitation and uniformly mixed reactants. These traits allow for SDRs to be used in the bottom-up production of nanoparticles, where particles are created through nucleations and subsequently crystal growth. This is where batch reactors and CSTRs aren’t as easily applied due to their high volumes and lack of sufficient mixing ability. “Top-down” processing where bulk material is ground down into nanoparticles is typically avoided when trying to achieve nanoparticles of a certain size and narrow size distribution due to the lack of control over the process.In 2010, the global market for quantum dots was low, sitting at $67 million [27]. It was projected to have an amazing 59.3% compound annual growth rate, which was mostly realized and by 2016 it has become a $610 million global market (with the estimated CAGR it was predicted to reach $670 million by 2015) [28]. The current growth rate is estimated at 41.3% now for 2016 to 2021, predicting the global market to reach $3.4 billion by 2021 [28].Both silver and titanium dioxide nanoparticles have a realized and open market to enter with predicted growth and new applications coming out consistently. The cost to produce the materials is rather low and the production ability seems high enough, especially with silver, that a company could actively pursue using an SDR to produce the nanoparticles with success. Since the proof of concept and idea is already detailed, there would be a low cost of entry into these markets as well. The revenue from such could be used to support R and D into quantum dots or pharmaceutical nanoparticles.Strategy: (prices updated on 5 January 2021)Silver Nano Particles Production at $14.25/gram Sell Price ($285/20/ml):[Note: these are 2017 figures. For 2021 double the figures below.] If silver nanoparticles of 99% purity or higher can be produced anywhere in the range of 10 nm – 40 nm, they can be sold at a wholesale price of $3+ a gram ($6/gram in 2021). To undercut the market to allow for entry I assumed a price of $2 a gram ($4/gram in 2021). This comes out to be about $24 million a year in revenue for 2017 ($48 million in 2021). As seen in Table 15, this comes out to about $12 million a year in profit for 2017 ($24 million a year for 2021). Referencing Section 2.21, a producer with the production rate would have a 1.56 percent market share of the global market. Infinity Turbine: SDR Technology Review for Nanoparticle Production