PDF Publication Title:

Text from PDF Page: 008

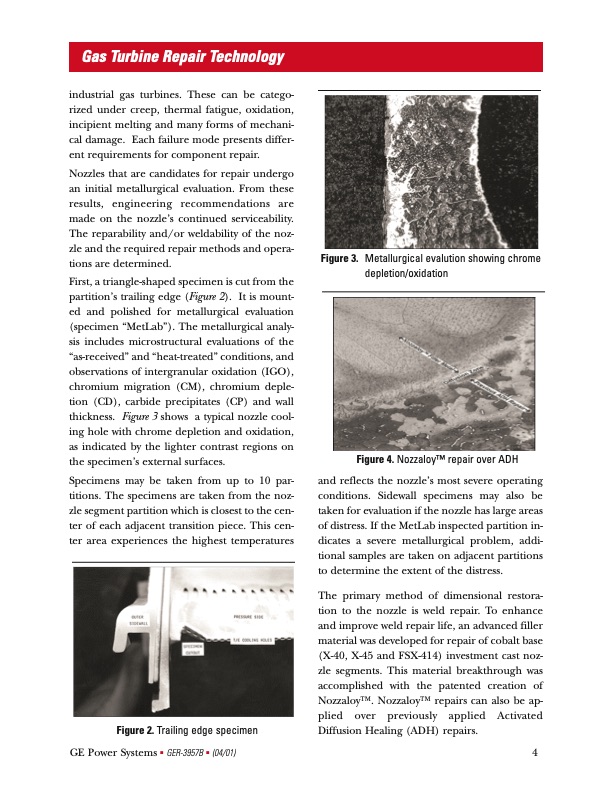

Gas Turbine Repair Technology industrial gas turbines. These can be catego- rized under creep, thermal fatigue, oxidation, incipient melting and many forms of mechani- cal damage. Each failure mode presents differ- ent requirements for component repair. Nozzles that are candidates for repair undergo an initial metallurgical evaluation. From these results, engineering recommendations are made on the nozzle’s continued serviceability. The reparability and/or weldability of the noz- zle and the required repair methods and opera- tions are determined. First, a triangle-shaped specimen is cut from the partition’s trailing edge (Figure 2). It is mount- ed and polished for metallurgical evaluation (specimen “MetLab”). The metallurgical analy- sis includes microstructural evaluations of the “as-received” and “heat-treated” conditions, and observations of intergranular oxidation (IGO), chromium migration (CM), chromium deple- tion (CD), carbide precipitates (CP) and wall thickness. Figure 3 shows a typical nozzle cool- ing hole with chrome depletion and oxidation, as indicated by the lighter contrast regions on the specimen’s external surfaces. Specimens may be taken from up to 10 par- titions. The specimens are taken from the noz- zle segment partition which is closest to the cen- ter of each adjacent transition piece. This cen- ter area experiences the highest temperatures and reflects the nozzle’s most severe operating conditions. Sidewall specimens may also be taken for evaluation if the nozzle has large areas of distress. If the MetLab inspected partition in- dicates a severe metallurgical problem, addi- tional samples are taken on adjacent partitions to determine the extent of the distress. The primary method of dimensional restora- tion to the nozzle is weld repair. To enhance and improve weld repair life, an advanced filler material was developed for repair of cobalt base (X-40, X-45 and FSX-414) investment cast noz- zle segments. This material breakthrough was accomplished with the patented creation of NozzaloyTM. NozzaloyTM repairs can also be ap- plied over previously applied Activated Diffusion Healing (ADH) repairs. Figure3. Metallurgicalevalutionshowingchrome depletion/oxidation Figure 4. NozzaloyTM repair over ADH Figure 2. Trailing edge specimen GE Power Systems ■ GER-3957B ■ (04/01) 4PDF Image | Gas Turbine Repair Technology GE

PDF Search Title:

Gas Turbine Repair Technology GEOriginal File Name Searched:

ger-3957b-gas-turbine-repair-technology.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |