PDF Publication Title:

Text from PDF Page: 021

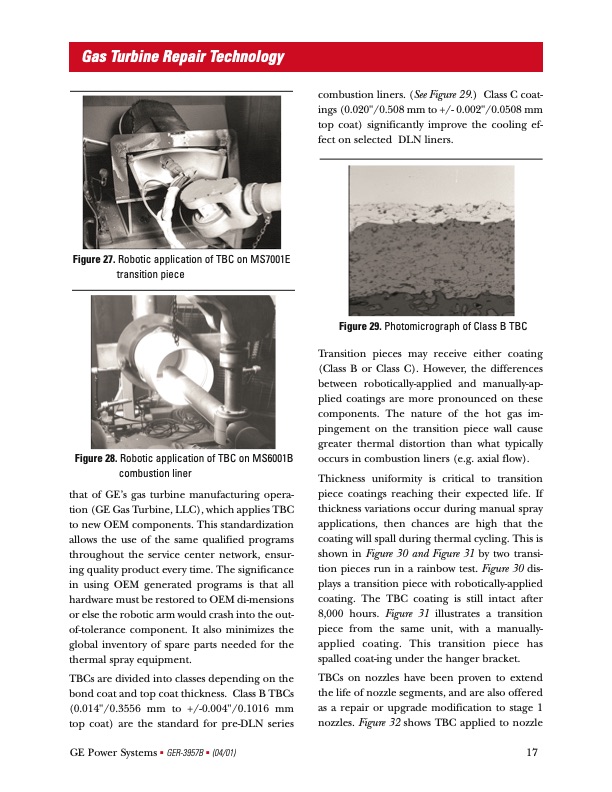

Gas Turbine Repair Technology Figure 27. Robotic application of TBC on MS7001E transition piece Figure 28. Robotic application of TBC on MS6001B combustion liner Figure 29. Photomicrograph of Class B TBC that of GE’s gas turbine manufacturing opera- tion (GE Gas Turbine, LLC), which applies TBC to new OEM components. This standardization allows the use of the same qualified programs throughout the service center network, ensur- ing quality product every time. The significance in using OEM generated programs is that all hardware must be restored to OEM di-mensions or else the robotic arm would crash into the out- of-tolerance component. It also minimizes the global inventory of spare parts needed for the thermal spray equipment. TBCs are divided into classes depending on the bond coat and top coat thickness. Class B TBCs (0.014"/0.3556 mm to +/-0.004"/0.1016 mm top coat) are the standard for pre-DLN series combustion liners. (See Figure 29.) Class C coat- ings (0.020"/0.508 mm to +/- 0.002"/0.0508 mm top coat) significantly improve the cooling ef- fect on selected DLN liners. Transition pieces may receive either coating (Class B or Class C). However, the differences between robotically-applied and manually-ap- plied coatings are more pronounced on these components. The nature of the hot gas im- pingement on the transition piece wall cause greater thermal distortion than what typically occurs in combustion liners (e.g. axial flow). Thickness uniformity is critical to transition piece coatings reaching their expected life. If thickness variations occur during manual spray applications, then chances are high that the coating will spall during thermal cycling. This is shown in Figure 30 and Figure 31 by two transi- tion pieces run in a rainbow test. Figure 30 dis- plays a transition piece with robotically-applied coating. The TBC coating is still intact after 8,000 hours. Figure 31 illustrates a transition piece from the same unit, with a manually- applied coating. This transition piece has spalled coat-ing under the hanger bracket. TBCs on nozzles have been proven to extend the life of nozzle segments, and are also offered as a repair or upgrade modification to stage 1 nozzles. Figure 32 shows TBC applied to nozzle GE Power Systems ■ GER-3957B ■ (04/01) 17PDF Image | Gas Turbine Repair Technology GE

PDF Search Title:

Gas Turbine Repair Technology GEOriginal File Name Searched:

ger-3957b-gas-turbine-repair-technology.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |