PDF Publication Title:

Text from PDF Page: 010

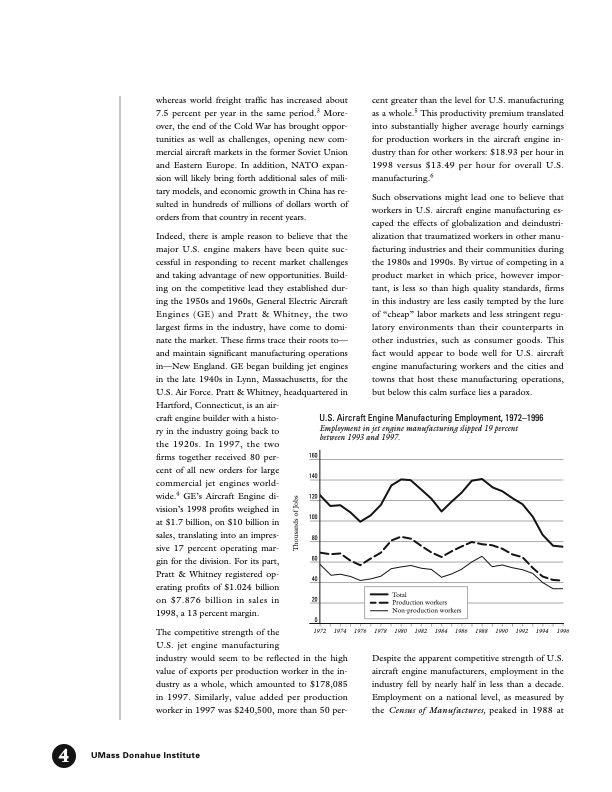

whereas world freight traffic has increased about 7.5 percent per year in the same period.3 More- over, the end of the Cold War has brought oppor- tunities as well as challenges, opening new com- mercial aircraft markets in the former Soviet Union and Eastern Europe. In addition, NATO expan- sion will likely bring forth additional sales of mili- tary models, and economic growth in China has re- sulted in hundreds of millions of dollars worth of orders from that country in recent years. Indeed, there is ample reason to believe that the major U.S. engine makers have been quite suc- cessful in responding to recent market challenges and taking advantage of new opportunities. Build- ing on the competitive lead they established dur- ing the 1950s and 1960s, General Electric Aircraft Engines (GE) and Pratt & Whitney, the two largest firms in the industry, have come to domi- nate the market. These firms trace their roots to— and maintain significant manufacturing operations in—New England. GE began building jet engines in the late 1940s in Lynn, Massachusetts, for the U.S. Air Force. Pratt & Whitney, headquartered in Hartford, Connecticut, is an air- craft engine builder with a histo- ry in the industry going back to the 1920s. In 1997, the two firms together received 80 per- cent of all new orders for large commercial jet engines world- wide.4 GE’s Aircraft Engine di- vision’s 1998 profits weighed in at $1.7 billion, on $10 billion in sales, translating into an impres- sive 17 percent operating mar- gin for the division. For its part, Pratt & Whitney registered op- erating profits of $1.024 billion on $7.876 billion in sales in 1998, a 13 percent margin. The competitive strength of the U.S. jet engine manufacturing industry would seem to be reflected in the high value of exports per production worker in the in- dustry as a whole, which amounted to $178,085 in 1997. Similarly, value added per production worker in 1997 was $240,500, more than 50 per- cent greater than the level for U.S. manufacturing as a whole.5 This productivity premium translated into substantially higher average hourly earnings for production workers in the aircraft engine in- dustry than for other workers: $18.93 per hour in 1998 versus $13.49 per hour for overall U.S. manufacturing.6 Such observations might lead one to believe that workers in U.S. aircraft engine manufacturing es- caped the effects of globalization and deindustri- alization that traumatized workers in other manu- facturing industries and their communities during the 1980s and 1990s. By virtue of competing in a product market in which price, however impor- tant, is less so than high quality standards, firms in this industry are less easily tempted by the lure of “cheap” labor markets and less stringent regu- latory environments than their counterparts in other industries, such as consumer goods. This fact would appear to bode well for U.S. aircraft engine manufacturing workers and the cities and towns that host these manufacturing operations, but below this calm surface lies a paradox. U.S. Aircraft Engine Manufacturing Employment, 1972–1996 Employment in jet engine manufacturing slipped 19 percent between 1993 and 1997. 160 140 120 100 80 60 40 20 0 1972 1974 1976 1978 1980 1982 1984 1986 1988 1990 1992 1994 1996 Total Production workers Non-production workers 4 UMass Donahue Institute Despite the apparent competitive strength of U.S. aircraft engine manufacturers, employment in the industry fell by nearly half in less than a decade. Employment on a national level, as measured by the Census of Manufactures, peaked in 1988 at Thousands of JobsPDF Image | JET ENGINE MANUFACTURING IN NEW ENGLAND

PDF Search Title:

JET ENGINE MANUFACTURING IN NEW ENGLANDOriginal File Name Searched:

jetengine01.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |