PDF Publication Title:

Text from PDF Page: 008

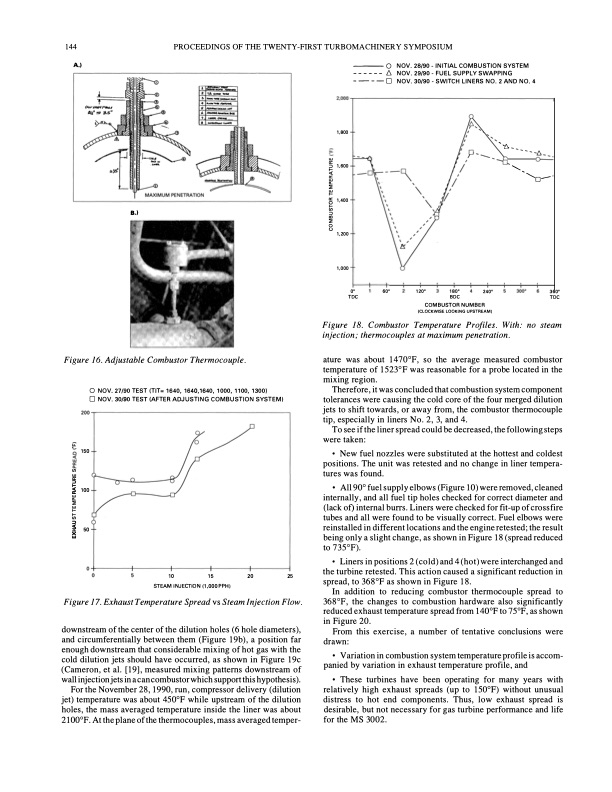

144 A.) PROCEEDINGS OF THE TWENTY-FIRST TURBOMACHINERY SYMPOSIUM -- 0 NOV. 28/90- INITIAL COMBUSTION SYSTEM ------ !: NOV. 29/90- FUEL SUPPLY SWAPPING -- -- 0 NOV. 30/90- SWITCH LINERS NO. 2 AND NO. 4 ---------- 360' TDC B.) t;::>., tw a::: 2,000 1,800 1,600 1,400 1,200 1,000 TDC ' y, _ _ _ _ _ _/:; '-.., \(a:w.. ::!! w... � 'o- ::!! 0u Figure 16. Adjustable Combustor Thermocouple. Figure 18. Combustor Temperature Profiles. With: no steam injection; thermocouples at maximum penetration. ature was about 1470°F, so the average measured combustor temperature of 1523°F was reasonable for a probe located in the mixing region. Therefore, it was concluded that combustion system component tolerances were causing the cold core of the four merged dilution jets to shift towards, or away from, the combustor thermocouple tip, especially in liners No. 2, 3, and 4. To see if the liner spread could be decreased, the following steps were taken: • New fuel nozzles were substituted at the hottest and coldest positions. The unit was retested and no change in liner tempera tures was found. • All 90° fuel supply elbows (Figure 10) were removed, cleaned internally, and all fuel tip holes checked for correct diameter and (lack of) internal burrs. Liners were checked for fit-up of crossfire tubes and all were found to be visually correct. Fuel elbows were reinstalled in different locations and the engine retested; the result being only a slight change, as shown in Figure 18 (spread reduced to 735°F). • Liners in positions 2 (cold) and 4 (hot) were interchanged and the turbine retested. This action caused a significant reduction in spread, to 368°F as shown in Figure 18. In addition to reducing combustor thermocouple spread to 368°F, the changes to combustion hardware also significantly reduced exhaust temperature spread from 140°F to 75°F, as shown in Figure 20. From this exercise, a number of tentative conclusions were drawn: • Variation in combustion system temperature profile is accom panied by variation in exhaust temperature profile, and • These turbines have been operating for many years with relatively high exhaust spreads (up to 150°F) without unusual distress to hot end components. Thus, low exhaust spread is desirable, but not necessary for gas turbine performance and life for the MS 3002. 0 NOV. 27/90 TEST (TIT= 1640, 1640,1640, 1000, 1100, 1300) 0 NOV. 30/90 TEST (AFTER ADJUSTING COMBUSTION SYSTEM) t;� Figure 17. Exhaust Temperature Spread vs Steam injection Flow. downstream of the center of the dilution holes (6 hole diameters), and circumferentially between them (Figure 19b), a position far enough downstream that considerable mixing of hot gas with the cold dilution jets should have occurred, as shown in Figure 19c (Cameron, et al. [19], measured mixing pattems downstream of wall injection jets in a can combustor which support this hypothesis). For the November 28, 1990, run, compressor delivery (dilution jet) temperature was about 450°F while upstream of the dilution holes, the mass averaged temperature inside the liner was about 2100°F. At the plane of the thermocouples, mass averaged temper- 0' 60' 120' 180' 240' BDC COMBUSTOR NUMBER (CLOCKWISE LOOKING UPSTREAM} iL - 150 Il�l !:! � 100 w.. ::!! � 50 10 15 20 25 STEAM INJECTION ( 1,000 PPHJPDF Image | STEAM INJECTION SYSTEM ON AN EARLY FRAME 3 GAS TURBINE IN A COMBINED CYCLE PIPELINE COMPRESSOR STATION

PDF Search Title:

STEAM INJECTION SYSTEM ON AN EARLY FRAME 3 GAS TURBINE IN A COMBINED CYCLE PIPELINE COMPRESSOR STATIONOriginal File Name Searched:

T21137-150.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |