PDF Publication Title:

Text from PDF Page: 005

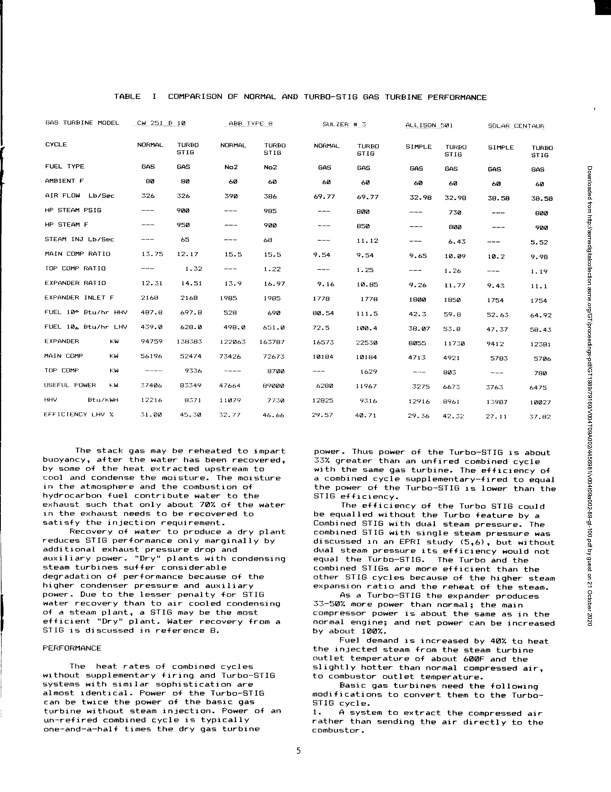

GAS TURBINE MODEL CYCLE FUEL TYPE AMBIENT F AIR FLOW Lb/Sec HP STEAM PSIG HP STEAM F STEAM INJ Lb/Sec MAIN COMP RATIO TOP COMP RATIO EXPANDER RATIO EXPANDER INLET F FUEL 10a Btu/hr HHV FUEL 10a Btu/hr LHV 439.0 EXPANDER KW MAIN COMP KW TOP COMP KW USEFUL POWER KW HHV Btu/KWH EFFICIENCY LHV 7. CW 251 8 10 ABB TYPE 8 SULZER 3 3 TURBO STIG ALLISON 501 SOLAR CENTAUR SIMPLE TURBO STIG NORMAL TURBO STIG STIG GAS 80 326 --- --- --- GAS 80 326 900 950 65 12.17 1.32 GAS 60 60 60 13.75 --- 1.26 --- 9.43 11.1 NORMAL TURBO No2 No2 GAS 60 60 390 386 69.77 --- 985 --- 900 --- --- 68 --- 15.5 15.5 9.54 --- 1.22 --- 13.9 16.97 69.77 32.98 800 --- 850 --- 800 11.12 --- 6.43 9.54 9.65 10.09 1.25 --- 10.85 9.26 11.77 NORMAL SIMPLE TURBO STIG --- 38.58 800 --- 900 --- 5.52 10.2 9.98 GAS GAS 60 60 60 32.98 38.58 730 --- GAS GAS U TABLE I COMPARISON OF NORMAL AND TURBO - S T I G GAS TURBINE PERFORMANCE 12.31 2168 487.8 14.51 2168 697.8 628.0 498.0 651.0 72.5 94759 56196 ---- 37406 12216 31.00 138-183 52474 9336 83349 8371 45.30 122063 73426 ---- 47664 11079 32.77 163787 72673 8700 89000 77-,0 46.66 16573 10184 --- 6280 12825 29.57 1629 --- 780 The stack gas may be reheated to impart buoyancy, after the water has been recovered, by some of the heat extracted upstream to cool and condense the moisture. The moisture in the atmosphere and the combustion of hydrocarbon fuel contribute water to the exhaust such that only about 707. of the water in the exhaust needs to be recovered to satisfy the injection requirement. Recovery of water to produce a dry plant reduces STIG performance only marginally by additional exhaust pressure drop and auxiliary power. "Dry" plants with condensing steam turbines suffer considerable degradation of performance because of the higher condenser pressure and auxiliary power. Due to the lesser penalty for S T I G water recovery than to air cooled condensing ofasteamplant,a STIG maybethemost efficient "Dry" plant. Water recovery from a S T I G is discussed in reference 8. PERFORMANCE The heat rates of combined cycles without supplementary firing and Turbo-STIG systems with similar sophistication are almost identical. Power of the Turbo-STIG can be twice the power of the basic gas turbine without steam injection. Power of an un-refired combined cycle is typically one-and-a-half times the dry gas turbine power. Thus power of the Turbo-STIG is about =37 greater than an unfired combined cycle with the same gas turbine. The efficiency of a combined cycle supplementary-fired to equal the power of the Turbo- S T I G is lower than the STIGefficiency. The efficiency of the Turbo S T I G could be equalled without the Turbo feature by a Combined S T I G with dual steam pressure. The combined STIG with single steam pressure was discussed in an EPRI study ( ,6), but without dual steam pressure its efficiency would not equal the Turbo- S T I G . The Turbo and the combined S T I G s are more efficient than the other S T I G cycles because of the higher steam expansion ratio and the reheat of the steam. As a Turbo - S T I G the expander produces 33-50r more power than normal; the main compressor power is about the same as in the normal engine; and net power can be increased by about 100'1.. Fuel demand is increased by 40% to heat the injected steam from the steam turbine outlet temperature of about 60OF and the slightly hotter than normal compressed air, to combustor outlet temperature. Basic gas turbines need the following modifications to convert them to the Turbo- STIG cycle. 1. A system to extract the compressed air rather than sending the air directly to the combustor. 9.16 1985 1985 1778 1778 1800 1850 111.5 42.3 59.8 528 690 80.54 1754 1754 52.63 64.92 5783 5706 803 --- 6673 3763 6475 5 100.4 38.07 22530 8055 11730 10184 4713 4921 11967 9316 12916 40.71 29.36 32275 53.8 47.37 9412 12381 8961 13987 42.32 27.11 77.82 1.19 58.43 10027 Downloaded from http://asmedigitalcollection.asme.org/GT/proceedings-pdf/GT1989/79160/V004T09A002/4456981/v004t09a002-89-gt-100.pdf by guest on 21 October 2020PDF Image | The Turbocharged Steam Injected Gas Turbine Cycle

PDF Search Title:

The Turbocharged Steam Injected Gas Turbine CycleOriginal File Name Searched:

v004t09a002-89-gt-100.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |