PDF Publication Title:

Text from PDF Page: 115

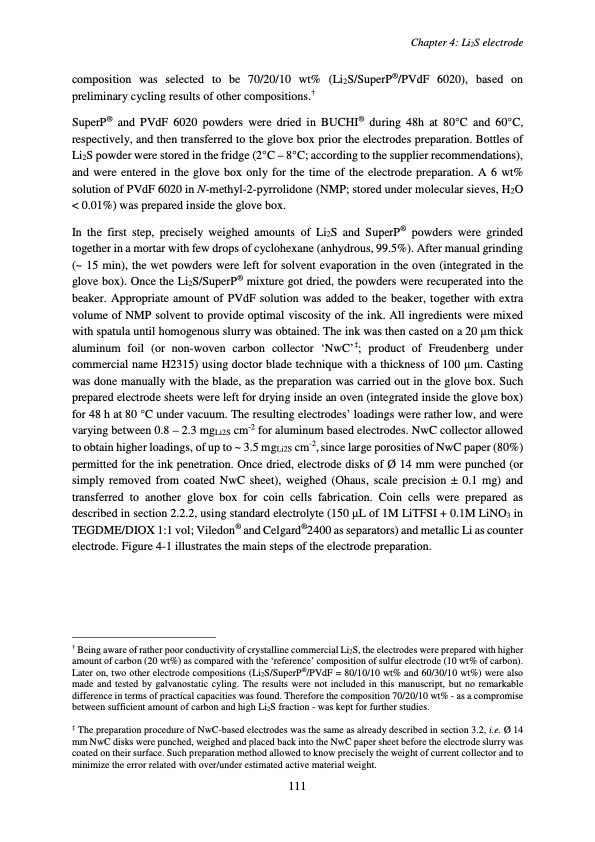

composition was selected to be 70/20/10 wt% (Li2S/SuperP®/PVdF 6020), based on preliminary cycling results of other compositions.† SuperP® and PVdF 6020 powders were dried in BUCHI® during 48h at 80°C and 60°C, respectively, and then transferred to the glove box prior the electrodes preparation. Bottles of Li2S powder were stored in the fridge (2°C – 8°C; according to the supplier recommendations), and were entered in the glove box only for the time of the electrode preparation. A 6 wt% solution of PVdF 6020 in N-methyl-2-pyrrolidone (NMP; stored under molecular sieves, H2O < 0.01%) was prepared inside the glove box. In the first step, precisely weighed amounts of Li2S and SuperP® powders were grinded together in a mortar with few drops of cyclohexane (anhydrous, 99.5%). After manual grinding (~ 15 min), the wet powders were left for solvent evaporation in the oven (integrated in the glove box). Once the Li2S/SuperP® mixture got dried, the powders were recuperated into the beaker. Appropriate amount of PVdF solution was added to the beaker, together with extra volume of NMP solvent to provide optimal viscosity of the ink. All ingredients were mixed with spatula until homogenous slurry was obtained. The ink was then casted on a 20 μm thick aluminum foil (or non-woven carbon collector ‘NwC’‡; product of Freudenberg under commercial name H2315) using doctor blade technique with a thickness of 100 μm. Casting was done manually with the blade, as the preparation was carried out in the glove box. Such prepared electrode sheets were left for drying inside an oven (integrated inside the glove box) for 48 h at 80 °C under vacuum. The resulting electrodes’ loadings were rather low, and were varying between 0.8 – 2.3 mgLi2S cm-2 for aluminum based electrodes. NwC collector allowed to obtain higher loadings, of up to ~ 3.5 mgLi2S cm-2, since large porosities of NwC paper (80%) permitted for the ink penetration. Once dried, electrode disks of Ø 14 mm were punched (or simply removed from coated NwC sheet), weighed (Ohaus, scale precision ± 0.1 mg) and transferred to another glove box for coin cells fabrication. Coin cells were prepared as described in section 2.2.2, using standard electrolyte (150 μL of 1M LiTFSI + 0.1M LiNO3 in TEGDME/DIOX 1:1 vol; Viledon® and Celgard®2400 as separators) and metallic Li as counter electrode. Figure 4-1 illustrates the main steps of the electrode preparation. † Being aware of rather poor conductivity of crystalline commercial Li2S, the electrodes were prepared with higher amount of carbon (20 wt%) as compared with the ‘reference’ composition of sulfur electrode (10 wt% of carbon). Later on, two other electrode compositions (Li2S/SuperP®/PVdF = 80/10/10 wt% and 60/30/10 wt%) were also made and tested by galvanostatic cyling. The results were not included in this manuscript, but no remarkable difference in terms of practical capacities was found. Therefore the composition 70/20/10 wt% - as a compromise between sufficient amount of carbon and high Li2S fraction - was kept for further studies. ‡ The preparation procedure of NwC-based electrodes was the same as already described in section 3.2, i.e. Ø 14 mm NwC disks were punched, weighed and placed back into the NwC paper sheet before the electrode slurry was coated on their surface. Such preparation method allowed to know precisely the weight of current collector and to minimize the error related with over/under estimated active material weight. Chapter 4: Li2S electrode 111PDF Image | Accumulateur Lithium Soufre

PDF Search Title:

Accumulateur Lithium SoufreOriginal File Name Searched:

WALUS_2015_archivage.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |