PDF Publication Title:

Text from PDF Page: 116

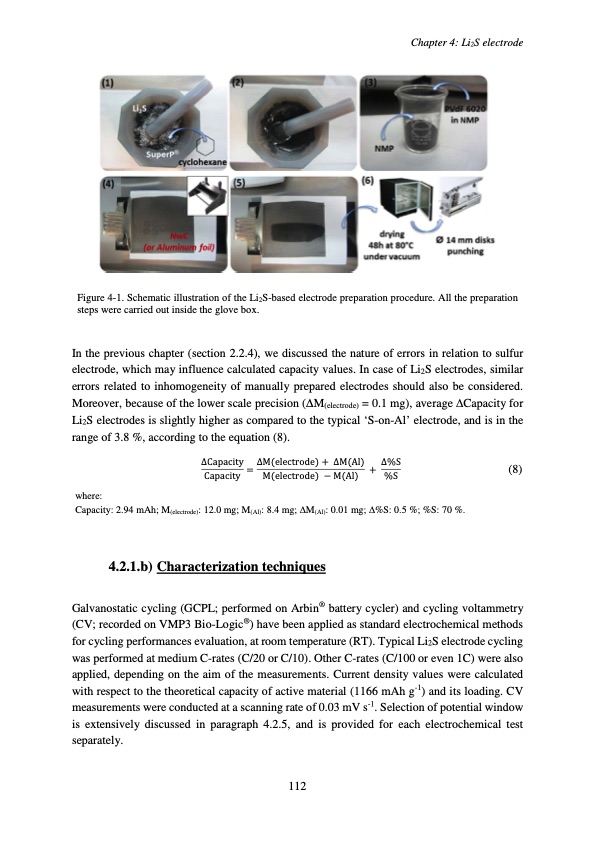

Chapter 4: Li2S electrode Figure 4-1. Schematic illustration of the Li2S-based electrode preparation procedure. All the preparation steps were carried out inside the glove box. In the previous chapter (section 2.2.4), we discussed the nature of errors in relation to sulfur electrode, which may influence calculated capacity values. In case of Li2S electrodes, similar errors related to inhomogeneity of manually prepared electrodes should also be considered. Moreover, because of the lower scale precision (∆M(electrode) = 0.1 mg), average ∆Capacity for Li2S electrodes is slightly higher as compared to the typical ‘S-on-Al’ electrode, and is in the range of 3.8 %, according to the equation (8). ∆Capacity = ∆M(electrode) + ∆M(Al) + ∆%S (8) Capacity M(electrode) − M(Al) %S where: Capacity: 2.94 mAh; M(electrode): 12.0 mg; M(Al): 8.4 mg; ∆M(Al): 0.01 mg; ∆%S: 0.5 %; %S: 70 %. 4.2.1.b) Characterization techniques Galvanostatic cycling (GCPL; performed on Arbin® battery cycler) and cycling voltammetry (CV; recorded on VMP3 Bio-Logic®) have been applied as standard electrochemical methods for cycling performances evaluation, at room temperature (RT). Typical Li2S electrode cycling was performed at medium C-rates (C/20 or C/10). Other C-rates (C/100 or even 1C) were also applied, depending on the aim of the measurements. Current density values were calculated with respect to the theoretical capacity of active material (1166 mAh g-1) and its loading. CV measurements were conducted at a scanning rate of 0.03 mV s-1. Selection of potential window is extensively discussed in paragraph 4.2.5, and is provided for each electrochemical test separately. 112PDF Image | Accumulateur Lithium Soufre

PDF Search Title:

Accumulateur Lithium SoufreOriginal File Name Searched:

WALUS_2015_archivage.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |