PDF Publication Title:

Text from PDF Page: 007

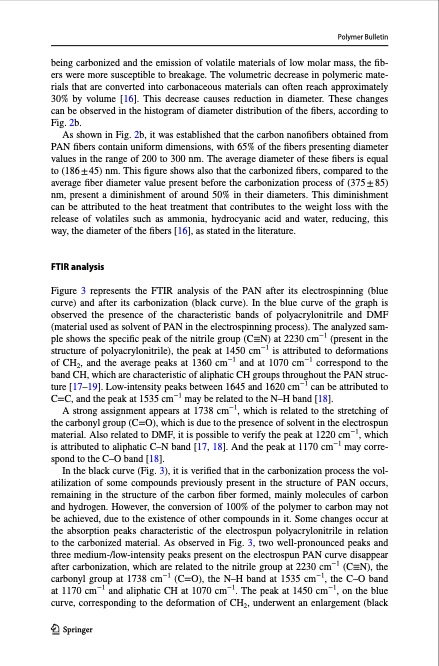

being carbonized and the emission of volatile materials of low molar mass, the fib- ers were more susceptible to breakage. The volumetric decrease in polymeric mate- rials that are converted into carbonaceous materials can often reach approximately 30% by volume [16]. This decrease causes reduction in diameter. These changes can be observed in the histogram of diameter distribution of the fibers, according to Fig. 2b. As shown in Fig. 2b, it was established that the carbon nanofibers obtained from PAN fibers contain uniform dimensions, with 65% of the fibers presenting diameter values in the range of 200 to 300 nm. The average diameter of these fibers is equal to (186 ± 45) nm. This figure shows also that the carbonized fibers, compared to the average fiber diameter value present before the carbonization process of (375±85) nm, present a diminishment of around 50% in their diameters. This diminishment can be attributed to the heat treatment that contributes to the weight loss with the release of volatiles such as ammonia, hydrocyanic acid and water, reducing, this way, the diameter of the fibers [16], as stated in the literature. FTIR analysis Figure 3 represents the FTIR analysis of the PAN after its electrospinning (blue curve) and after its carbonization (black curve). In the blue curve of the graph is observed the presence of the characteristic bands of polyacrylonitrile and DMF (material used as solvent of PAN in the electrospinning process). The analyzed sam- ple shows the specific peak of the nitrile group (C≡N) at 2230 cm−1 (present in the structure of polyacrylonitrile), the peak at 1450 cm−1 is attributed to deformations of CH2, and the average peaks at 1360 cm−1 and at 1070 cm−1 correspond to the band CH, which are characteristic of aliphatic CH groups throughout the PAN struc- ture [17–19]. Low-intensity peaks between 1645 and 1620 cm−1 can be attributed to C=C, and the peak at 1535 cm−1 may be related to the N–H band [18]. A strong assignment appears at 1738 cm−1, which is related to the stretching of the carbonyl group (C=O), which is due to the presence of solvent in the electrospun material. Also related to DMF, it is possible to verify the peak at 1220 cm−1, which is attributed to aliphatic C–N band [17, 18]. And the peak at 1170 cm−1 may corre- spond to the C–O band [18]. In the black curve (Fig. 3), it is verified that in the carbonization process the vol- atilization of some compounds previously present in the structure of PAN occurs, remaining in the structure of the carbon fiber formed, mainly molecules of carbon and hydrogen. However, the conversion of 100% of the polymer to carbon may not be achieved, due to the existence of other compounds in it. Some changes occur at the absorption peaks characteristic of the electrospun polyacrylonitrile in relation to the carbonized material. As observed in Fig. 3, two well-pronounced peaks and three medium-/low-intensity peaks present on the electrospun PAN curve disappear after carbonization, which are related to the nitrile group at 2230 cm−1 (C≡N), the carbonyl group at 1738 cm−1 (C=O), the N–H band at 1535 cm−1, the C–O band at 1170 cm−1 and aliphatic CH at 1070 cm−1. The peak at 1450 cm−1, on the blue curve, corresponding to the deformation of CH2, underwent an enlargement (black 13 Polymer BulletinPDF Image | Carbon nanofibers obtained from electrospinning process

PDF Search Title:

Carbon nanofibers obtained from electrospinning processOriginal File Name Searched:

Artigoelectrospinnigprocess2019.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |