PDF Publication Title:

Text from PDF Page: 009

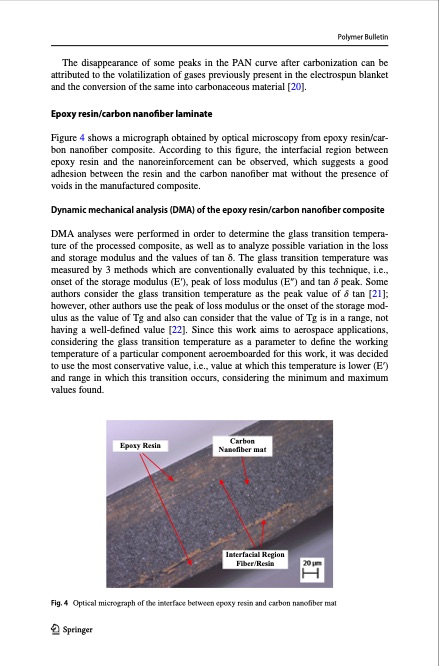

The disappearance of some peaks in the PAN curve after carbonization can be attributed to the volatilization of gases previously present in the electrospun blanket and the conversion of the same into carbonaceous material [20]. Epoxy resin/carbon nanofiber laminate Figure 4 shows a micrograph obtained by optical microscopy from epoxy resin/car- bon nanofiber composite. According to this figure, the interfacial region between epoxy resin and the nanoreinforcement can be observed, which suggests a good adhesion between the resin and the carbon nanofiber mat without the presence of voids in the manufactured composite. Dynamic mechanical analysis (DMA) of the epoxy resin/carbon nanofiber composite DMA analyses were performed in order to determine the glass transition tempera- ture of the processed composite, as well as to analyze possible variation in the loss and storage modulus and the values of tan δ. The glass transition temperature was measured by 3 methods which are conventionally evaluated by this technique, i.e., onset of the storage modulus (E′), peak of loss modulus (E′′) and tan δ peak. Some authors consider the glass transition temperature as the peak value of δ tan [21]; however, other authors use the peak of loss modulus or the onset of the storage mod- ulus as the value of Tg and also can consider that the value of Tg is in a range, not having a well-defined value [22]. Since this work aims to aerospace applications, considering the glass transition temperature as a parameter to define the working temperature of a particular component aeroemboarded for this work, it was decided to use the most conservative value, i.e., value at which this temperature is lower (E′) and range in which this transition occurs, considering the minimum and maximum values found. Fig. 4 Optical micrograph of the interface between epoxy resin and carbon nanofiber mat 13 Polymer Bulletin Epoxy Resin Carbon Nanofiber mat Interfacial Region Fiber/ResinPDF Image | Carbon nanofibers obtained from electrospinning process

PDF Search Title:

Carbon nanofibers obtained from electrospinning processOriginal File Name Searched:

Artigoelectrospinnigprocess2019.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |