PDF Publication Title:

Text from PDF Page: 011

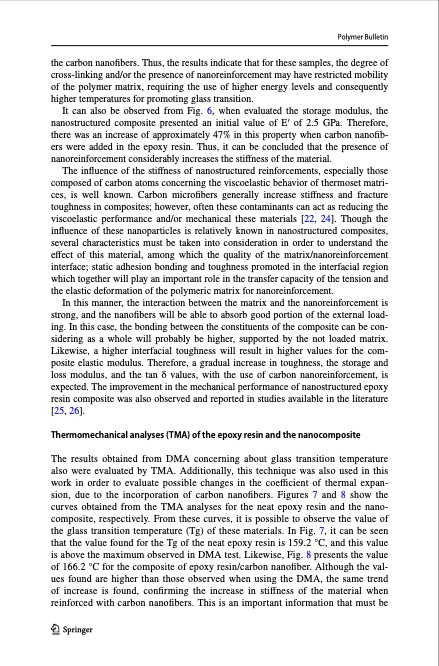

the carbon nanofibers. Thus, the results indicate that for these samples, the degree of cross-linking and/or the presence of nanoreinforcement may have restricted mobility of the polymer matrix, requiring the use of higher energy levels and consequently higher temperatures for promoting glass transition. It can also be observed from Fig. 6, when evaluated the storage modulus, the nanostructured composite presented an initial value of E′ of 2.5 GPa. Therefore, there was an increase of approximately 47% in this property when carbon nanofib- ers were added in the epoxy resin. Thus, it can be concluded that the presence of nanoreinforcement considerably increases the stiffness of the material. The influence of the stiffness of nanostructured reinforcements, especially those composed of carbon atoms concerning the viscoelastic behavior of thermoset matri- ces, is well known. Carbon microfibers generally increase stiffness and fracture toughness in composites; however, often these contaminants can act as reducing the viscoelastic performance and/or mechanical these materials [22, 24]. Though the influence of these nanoparticles is relatively known in nanostructured composites, several characteristics must be taken into consideration in order to understand the effect of this material, among which the quality of the matrix/nanoreinforcement interface; static adhesion bonding and toughness promoted in the interfacial region which together will play an important role in the transfer capacity of the tension and the elastic deformation of the polymeric matrix for nanoreinforcement. In this manner, the interaction between the matrix and the nanoreinforcement is strong, and the nanofibers will be able to absorb good portion of the external load- ing. In this case, the bonding between the constituents of the composite can be con- sidering as a whole will probably be higher, supported by the not loaded matrix. Likewise, a higher interfacial toughness will result in higher values for the com- posite elastic modulus. Therefore, a gradual increase in toughness, the storage and loss modulus, and the tan δ values, with the use of carbon nanoreinforcement, is expected. The improvement in the mechanical performance of nanostructured epoxy resin composite was also observed and reported in studies available in the literature [25, 26]. Thermomechanical analyses (TMA) of the epoxy resin and the nanocomposite The results obtained from DMA concerning about glass transition temperature also were evaluated by TMA. Additionally, this technique was also used in this work in order to evaluate possible changes in the coefficient of thermal expan- sion, due to the incorporation of carbon nanofibers. Figures 7 and 8 show the curves obtained from the TMA analyses for the neat epoxy resin and the nano- composite, respectively. From these curves, it is possible to observe the value of the glass transition temperature (Tg) of these materials. In Fig. 7, it can be seen that the value found for the Tg of the neat epoxy resin is 159.2 °C, and this value is above the maximum observed in DMA test. Likewise, Fig. 8 presents the value of 166.2 °C for the composite of epoxy resin/carbon nanofiber. Although the val- ues found are higher than those observed when using the DMA, the same trend of increase is found, confirming the increase in stiffness of the material when reinforced with carbon nanofibers. This is an important information that must be 13 Polymer BulletinPDF Image | Carbon nanofibers obtained from electrospinning process

PDF Search Title:

Carbon nanofibers obtained from electrospinning processOriginal File Name Searched:

Artigoelectrospinnigprocess2019.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |