PDF Publication Title:

Text from PDF Page: 012

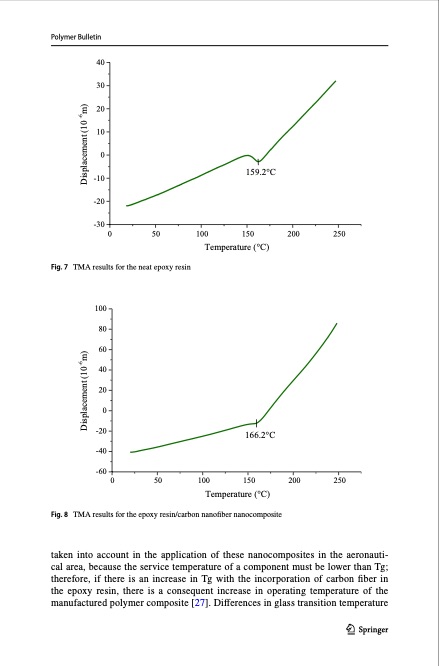

Polymer Bulletin Fig. 7 TMA results for the neat epoxy resin Fig. 8 TMA results for the epoxy resin/carbon nanofiber nanocomposite 40 30 20 10 0 -10 -20 -30 159.2°C 100 80 60 40 20 0 -20 -40 -60 166.2°C 0 50 100 150 200 250 Temperature (°C) Displacement (10-6m) Displacement (10 -6m) 0 50 100 150 200 250 Temperature (°C) taken into account in the application of these nanocomposites in the aeronauti- cal area, because the service temperature of a component must be lower than Tg; therefore, if there is an increase in Tg with the incorporation of carbon fiber in the epoxy resin, there is a consequent increase in operating temperature of the manufactured polymer composite [27]. Differences in glass transition temperature 13PDF Image | Carbon nanofibers obtained from electrospinning process

PDF Search Title:

Carbon nanofibers obtained from electrospinning processOriginal File Name Searched:

Artigoelectrospinnigprocess2019.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |