PDF Publication Title:

Text from PDF Page: 005

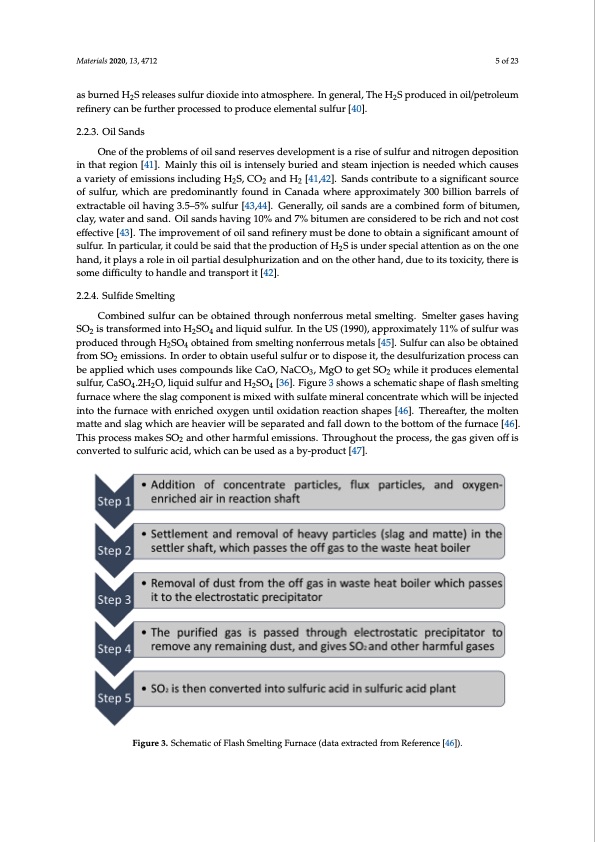

Materials 2020, 13, 4712 5 of 23 as burned H2S releases sulfur dioxide into atmosphere. In general, The H2S produced in oil/petroleum refinery can be further processed to produce elemental sulfur [40]. 2.2.3. Oil Sands One of the problems of oil sand reserves development is a rise of sulfur and nitrogen deposition in that region [41]. Mainly this oil is intensely buried and steam injection is needed which causes a variety of emissions including H2S, CO2 and H2 [41,42]. Sands contribute to a significant source of sulfur, which are predominantly found in Canada where approximately 300 billion barrels of extractable oil having 3.5–5% sulfur [43,44]. Generally, oil sands are a combined form of bitumen, clay, water and sand. Oil sands having 10% and 7% bitumen are considered to be rich and not cost effective [43]. The improvement of oil sand refinery must be done to obtain a significant amount of sulfur. In particular, it could be said that the production of H2S is under special attention as on the one hand, it plays a role in oil partial desulphurization and on the other hand, due to its toxicity, there is some difficulty to handle and transport it [42]. 2.2.4. Sulfide Smelting Combined sulfur can be obtained through nonferrous metal smelting. Smelter gases having SO2 is transformed into H2SO4 and liquid sulfur. In the US (1990), approximately 11% of sulfur was produced through H2SO4 obtained from smelting nonferrous metals [45]. Sulfur can also be obtained from SO2 emissions. In order to obtain useful sulfur or to dispose it, the desulfurization process can be applied which uses compounds like CaO, NaCO3, MgO to get SO2 while it produces elemental sulfur, CaSO4.2H2O, liquid sulfur and H2SO4 [36]. Figure 3 shows a schematic shape of flash smelting furnace where the slag component is mixed with sulfate mineral concentrate which will be injected into the furnace with enriched oxygen until oxidation reaction shapes [46]. Thereafter, the molten matte and slag which are heavier will be separated and fall down to the bottom of the furnace [46]. This process makes SO2 and other harmful emissions. Throughout the process, the gas given off is converted to sulfuric acid, which can be used as a by-product [47]. Figure 3. Schematic of Flash Smelting Furnace (data extracted from Reference [46]).PDF Image | Critical Review on the Properties and Applications of Sulfur-Based Concrete

PDF Search Title:

Critical Review on the Properties and Applications of Sulfur-Based ConcreteOriginal File Name Searched:

materials-13-04712.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |