PDF Publication Title:

Text from PDF Page: 013

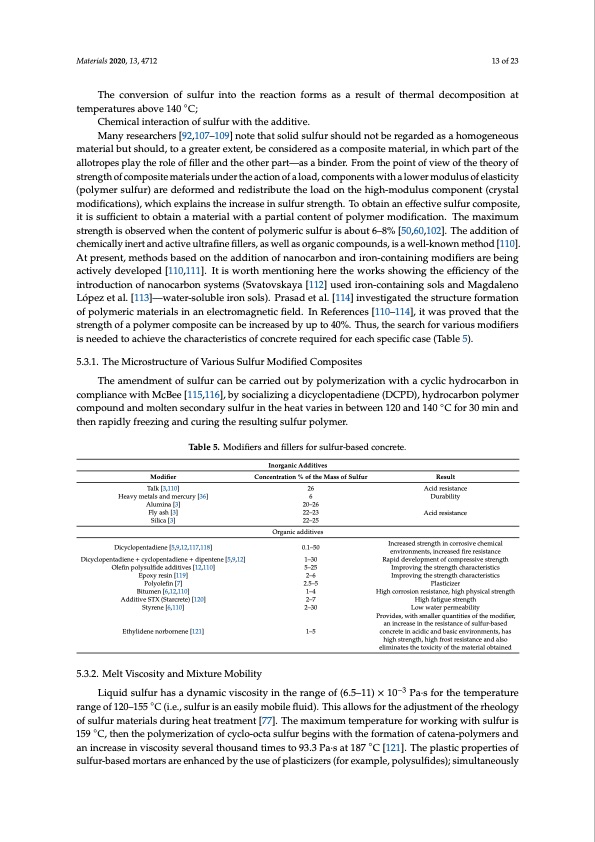

Materials 2020, 13, 4712 13 of 23 The conversion of sulfur into the reaction forms as a result of thermal decomposition at temperatures above 140 ◦C; Chemical interaction of sulfur with the additive. Many researchers [92,107–109] note that solid sulfur should not be regarded as a homogeneous material but should, to a greater extent, be considered as a composite material, in which part of the allotropes play the role of filler and the other part—as a binder. From the point of view of the theory of strength of composite materials under the action of a load, components with a lower modulus of elasticity (polymer sulfur) are deformed and redistribute the load on the high-modulus component (crystal modifications), which explains the increase in sulfur strength. To obtain an effective sulfur composite, it is sufficient to obtain a material with a partial content of polymer modification. The maximum strength is observed when the content of polymeric sulfur is about 6–8% [50,60,102]. The addition of chemically inert and active ultrafine fillers, as well as organic compounds, is a well-known method [110]. At present, methods based on the addition of nanocarbon and iron-containing modifiers are being actively developed [110,111]. It is worth mentioning here the works showing the efficiency of the introduction of nanocarbon systems (Svatovskaya [112] used iron-containing sols and Magdaleno López et al. [113]—water-soluble iron sols). Prasad et al. [114] investigated the structure formation of polymeric materials in an electromagnetic field. In References [110–114], it was proved that the strength of a polymer composite can be increased by up to 40%. Thus, the search for various modifiers is needed to achieve the characteristics of concrete required for each specific case (Table 5). 5.3.1. The Microstructure of Various Sulfur Modified Composites The amendment of sulfur can be carried out by polymerization with a cyclic hydrocarbon in compliance with McBee [115,116], by socializing a dicyclopentadiene (DCPD), hydrocarbon polymer compound and molten secondary sulfur in the heat varies in between 120 and 140 ◦C for 30 min and then rapidly freezing and curing the resulting sulfur polymer. Modifier Talk [3,110] Heavy metals and mercury [36] Alumina [3] Fly ash [3] Silica [3] Dicyclopentadiene [5,9,12,117,118] Dicyclopentadiene + cyclopentadiene + dipentene [5,9,12] Olefin polysulfide additives [12,110] Epoxy resin [119] Polyolefin [7] Bitumen [6,12,110] Additive STX (Starcrete) [120] Styrene [6,110] Ethylidene norbornene [121] 5.3.2. Melt Viscosity and Mixture Mobility Result Acid resistance Durability Acid resistance Increased strength in corrosive chemical environments, increased fire resistance Rapid development of compressive strength Improving the strength characteristics Improving the strength characteristics Plasticizer High corrosion resistance, high physical strength High fatigue strength Low water permeability Provides, with smaller quantities of the modifier, an increase in the resistance of sulfur-based concrete in acidic and basic environments, has high strength, high frost resistance and also eliminates the toxicity of the material obtained Table 5. Modifiers and fillers for sulfur-based concrete. Inorganic Additives Concentration % of the Mass of Sulfur 26 6 20–26 22–23 22–25 Organic additives 0.1–50 1–30 5–25 2–6 2.5–5 1–4 2–7 2–30 1–5 Liquid sulfur has a dynamic viscosity in the range of (6.5–11) × 10−3 Pa·s for the temperature range of 120–155 ◦C (i.e., sulfur is an easily mobile fluid). This allows for the adjustment of the rheology of sulfur materials during heat treatment [77]. The maximum temperature for working with sulfur is 159 ◦C, then the polymerization of cyclo-octa sulfur begins with the formation of catena-polymers and an increase in viscosity several thousand times to 93.3 Pa·s at 187 ◦C [121]. The plastic properties of sulfur-based mortars are enhanced by the use of plasticizers (for example, polysulfides); simultaneouslyPDF Image | Critical Review on the Properties and Applications of Sulfur-Based Concrete

PDF Search Title:

Critical Review on the Properties and Applications of Sulfur-Based ConcreteOriginal File Name Searched:

materials-13-04712.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |