PDF Publication Title:

Text from PDF Page: 014

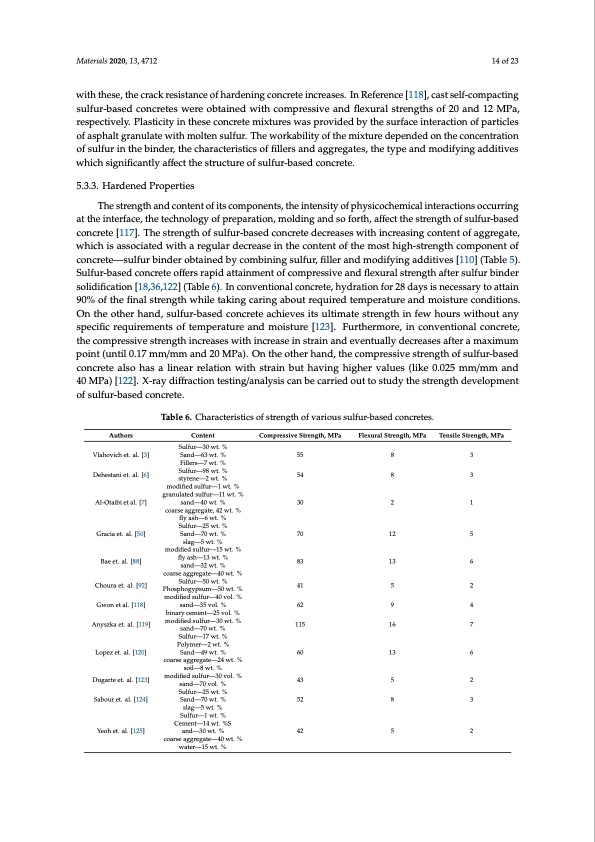

Materials 2020, 13, 4712 14 of 23 with these, the crack resistance of hardening concrete increases. In Reference [118], cast self-compacting sulfur-based concretes were obtained with compressive and flexural strengths of 20 and 12 MPa, respectively. Plasticity in these concrete mixtures was provided by the surface interaction of particles of asphalt granulate with molten sulfur. The workability of the mixture depended on the concentration of sulfur in the binder, the characteristics of fillers and aggregates, the type and modifying additives which significantly affect the structure of sulfur-based concrete. 5.3.3. Hardened Properties The strength and content of its components, the intensity of physicochemical interactions occurring at the interface, the technology of preparation, molding and so forth, affect the strength of sulfur-based concrete [117]. The strength of sulfur-based concrete decreases with increasing content of aggregate, which is associated with a regular decrease in the content of the most high-strength component of concrete—sulfur binder obtained by combining sulfur, filler and modifying additives [110] (Table 5). Sulfur-based concrete offers rapid attainment of compressive and flexural strength after sulfur binder solidification [18,36,122] (Table 6). In conventional concrete, hydration for 28 days is necessary to attain 90% of the final strength while taking caring about required temperature and moisture conditions. On the other hand, sulfur-based concrete achieves its ultimate strength in few hours without any specific requirements of temperature and moisture [123]. Furthermore, in conventional concrete, the compressive strength increases with increase in strain and eventually decreases after a maximum point (until 0.17 mm/mm and 20 MPa). On the other hand, the compressive strength of sulfur-based concrete also has a linear relation with strain but having higher values (like 0.025 mm/mm and 40 MPa) [122]. X-ray diffraction testing/analysis can be carried out to study the strength development of sulfur-based concrete. Authors Vlahovich et. al. [3] Dehestani et. al. [6] Al-Otaibi et al. [7] Gracia et. al. [50] Bae et. al. [88] Choura et. al. [92] Gwon et al. [118] Anyszka et. al. [119] Lopez et. al. [120] Dugarte et. al. [123] Sabour et. al. [124] Yeoh et. al. [125] Content Sulfur—30 wt. % Sand—63 wt. % Fillers—7 wt. % Sulfur—98 wt. % styrene—2 wt. % modified sulfur—1 wt. % granulated sulfur—11 wt. % sand—40 wt. % coarse aggregate, 42 wt. % fly ash—6 wt. % Sulfur—25 wt. % Sand—70 wt. % slag—5 wt. % modified sulfur—15 wt. % fly ash—13 wt. % sand—32 wt. % coarse aggregate—40 wt. % Sulfur—50 wt. % Phosphogypsum—50 wt. % modified sulfur—40 vol. % sand—35 vol. % binary cement—25 vol. % Compressive Strength, MPa Flexural Strength, MPa 558 548 302 70 12 83 13 415 629 Tensile Strength, MPa 3 3 1 5 6 2 4 7 6 2 3 2 Table 6. Characteristics of strength of various sulfur-based concretes. modified sulfur—30 wt. % 115 16 sand—70 wt. % Sulfur—17 wt. % Polymer—2 wt. % Sand—49 wt. % coarse aggregate—24 wt. % soil—8 wt. % modified sulfur—30 vol. % sand—70 vol. % Sulfur—25 wt. % Sand—70 wt. % slag—5 wt. % Sulfur—1 wt. % Cement—14 wt. %S and—30 wt. % coarse aggregate—40 wt. % water—15 wt. % 60 13 435 528 425PDF Image | Critical Review on the Properties and Applications of Sulfur-Based Concrete

PDF Search Title:

Critical Review on the Properties and Applications of Sulfur-Based ConcreteOriginal File Name Searched:

materials-13-04712.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |