PDF Publication Title:

Text from PDF Page: 013

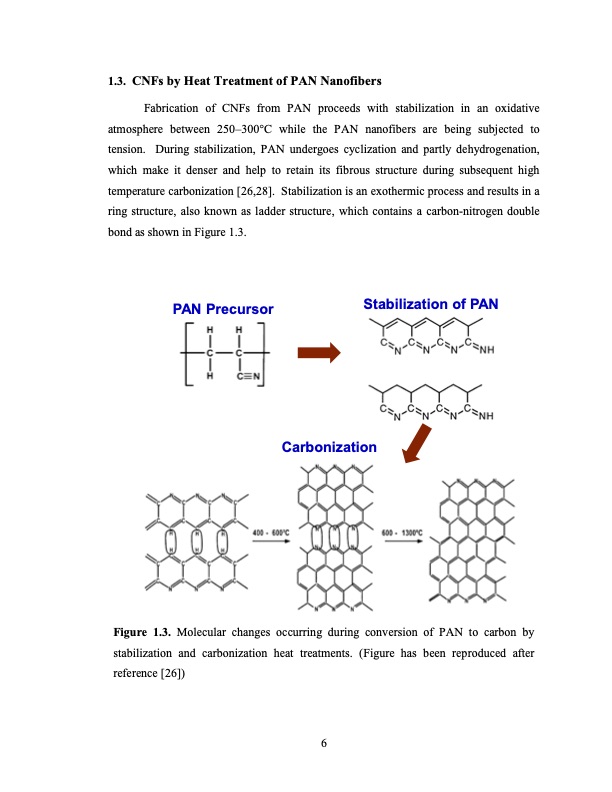

1.3. CNFs by Heat Treatment of PAN Nanofibers Fabrication of CNFs from PAN proceeds with stabilization in an oxidative atmosphere between 250–300°C while the PAN nanofibers are being subjected to tension. During stabilization, PAN undergoes cyclization and partly dehydrogenation, which make it denser and help to retain its fibrous structure during subsequent high temperature carbonization [26,28]. Stabilization is an exothermic process and results in a ring structure, also known as ladder structure, which contains a carbon-nitrogen double bond as shown in Figure 1.3. PAN Precursor Stabilization of PAN Carbonization Figure 1.3. Molecular changes occurring during conversion of PAN to carbon by stabilization and carbonization heat treatments. (Figure has been reproduced after reference [26]) 6PDF Image | HIGH STRENGTH CARBON NANOFIBERS DERIVED FROM ELECTROSPUN POLYACRYLONITRILE

PDF Search Title:

HIGH STRENGTH CARBON NANOFIBERS DERIVED FROM ELECTROSPUN POLYACRYLONITRILEOriginal File Name Searched:

4835609.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |