PDF Publication Title:

Text from PDF Page: 030

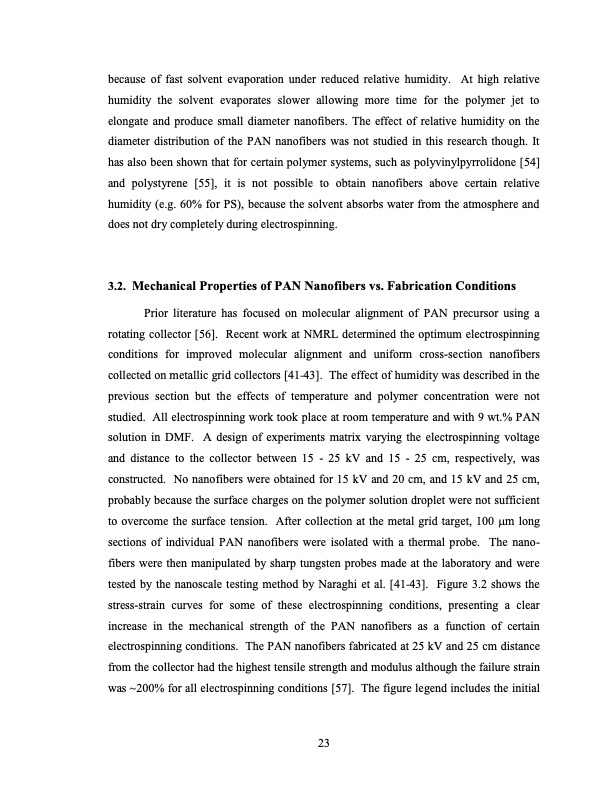

because of fast solvent evaporation under reduced relative humidity. At high relative humidity the solvent evaporates slower allowing more time for the polymer jet to elongate and produce small diameter nanofibers. The effect of relative humidity on the diameter distribution of the PAN nanofibers was not studied in this research though. It has also been shown that for certain polymer systems, such as polyvinylpyrrolidone [54] and polystyrene [55], it is not possible to obtain nanofibers above certain relative humidity (e.g. 60% for PS), because the solvent absorbs water from the atmosphere and does not dry completely during electrospinning. 3.2. Mechanical Properties of PAN Nanofibers vs. Fabrication Conditions Prior literature has focused on molecular alignment of PAN precursor using a rotating collector [56]. Recent work at NMRL determined the optimum electrospinning conditions for improved molecular alignment and uniform cross-section nanofibers collected on metallic grid collectors [41-43]. The effect of humidity was described in the previous section but the effects of temperature and polymer concentration were not studied. All electrospinning work took place at room temperature and with 9 wt.% PAN solution in DMF. A design of experiments matrix varying the electrospinning voltage and distance to the collector between 15 - 25 kV and 15 - 25 cm, respectively, was constructed. No nanofibers were obtained for 15 kV and 20 cm, and 15 kV and 25 cm, probably because the surface charges on the polymer solution droplet were not sufficient to overcome the surface tension. After collection at the metal grid target, 100 m long sections of individual PAN nanofibers were isolated with a thermal probe. The nano- fibers were then manipulated by sharp tungsten probes made at the laboratory and were tested by the nanoscale testing method by Naraghi et al. [41-43]. Figure 3.2 shows the stress-strain curves for some of these electrospinning conditions, presenting a clear increase in the mechanical strength of the PAN nanofibers as a function of certain electrospinning conditions. The PAN nanofibers fabricated at 25 kV and 25 cm distance from the collector had the highest tensile strength and modulus although the failure strain was ~200% for all electrospinning conditions [57]. The figure legend includes the initial 23PDF Image | HIGH STRENGTH CARBON NANOFIBERS DERIVED FROM ELECTROSPUN POLYACRYLONITRILE

PDF Search Title:

HIGH STRENGTH CARBON NANOFIBERS DERIVED FROM ELECTROSPUN POLYACRYLONITRILEOriginal File Name Searched:

4835609.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |