PDF Publication Title:

Text from PDF Page: 016

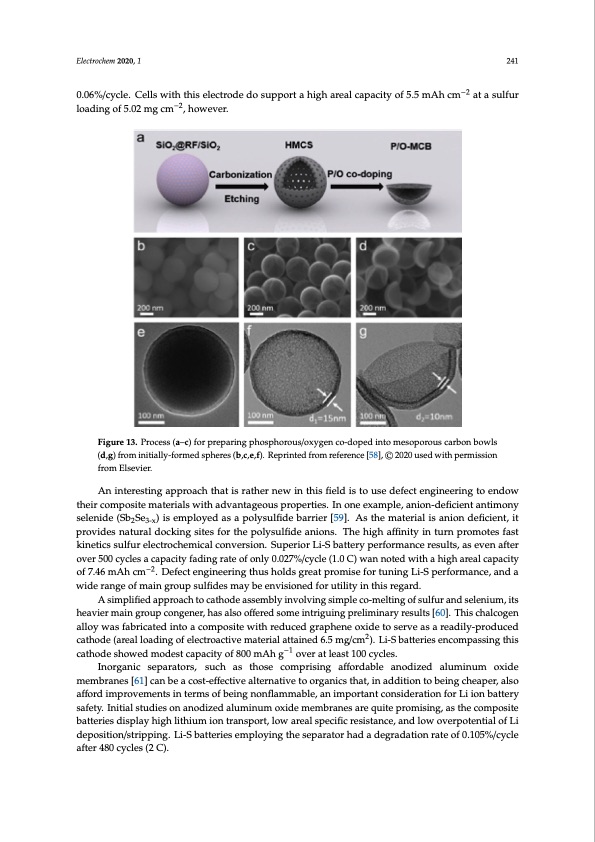

Electrochem 2020, 1 241 0.06%/cycle. Cells with this electrode do support a high areal capacity of 5.5 mAh cm−2 at a sulfur loading of 5.02 mg cm−2, however. Electrochem 2020, 2, FOR PEER REVIEW 17 Figure 13. Process (a–c) for preparing phosphorous/oxygen co-doped into mesoporous carbon bowls Figure 13. Process (a–c) for preparing phosphorous/oxygen co-doped into mesoporous carbon bowls (d,g) from initially-formed spheres (b,c,e,f). Reprinted from reference [58], © 2020 used with (d,g) from initially-formed spheres (b,c,e,f). Reprinted from reference [58], © 2020 used with permission permission from Elsevier. from Elsevier. An interesting approach that is rather new in this ffiield is to use defect engineering to endow their composite materials with advantageous properties. In one example, anion-deffiicient antimony selenide (Sb2Se3-x))isiseempploloyyeeddaassa pollysullffiide barriier [59]. Asstthe matteriiall is anion deffiicient, it 2 3-x provides natural docking sites for the polysulfifide anions. The high afffifinity in turn promotes fast kinetics sulfur electrochemical conversion. Superriiorr Lii--S battery performance results,, as even after over 500 cycles a capacity fading rate of only 0.027%/cycle (1.0 C) wan noted with a high areal capacity −2 of7.46mAhcm ..DeffeccttengiineerriingtthussholldssgreattpromisefortuningLi-Sperformance,anda wide range of main group sulfifides may be enviisiioned for uttiilliitty iin tthiis regarrd.. A simplififiedapprroacchttooccaaththooddeeaassesmembblylyinivnovlovlivnigngsismimplpelceoc-om-melteilntginogfosfuslfulrfuarnadnsdelseenlieunmiu,mits, ihtesahveiearvmiearinmgarionugprcoounpgecnoenrg, ehnaesra,lshoasoffaelsreodosfofemredinstroimgueinigntprirgeuliimnginaprryelriemsuinltasr[y60r]e.sTuhltis c[6h0a]l.coTgheins cahllaolycowgaens falbloryicawteads fianbtoricaacteodmipnotosiatecwomithporseidteucweidthgreadpuhceende gorxaidpehetnoeseorxvideeastoasreravdeilays-parroedaudcileyd- 22 pcartohdoudced(arceatlhloaddein(garoefaelleloctardoiancgtivoefmealetecrtiraolaacttiavienemda6t.e5rmiagl/camttai)n.eLdi-S6b.5attmergi/ecsmen)c.oLmi-pSasbsianttgerthieis −1 −1 ecantchoomdpeasshsoinwgetdhmisocadtehsotdcaepsahcoiwtyeodfm80o0dmesAthcagpaciotvyeorfa8t0l0eamstA10h0gcycolvese.ratleast100cycles. Inorganic separators, such as those comprising affffordable anodized aluminum oxide membranes [61] can be a cost-effffective alternative to organics that, in addition to being cheaper, also afffford improvements in terms of being nonflflammable, an important consideration for Li ion battery safety. Initial studies on anodized aluminum oxide membranes are quite promising, as the composite batteries display high lithium ion transport, low areal speciffiic resistance, and low overpotential of Li deposition/stripping. Lii-S batteriies emplloyiing the separator had a degradation rate of 0.105%/cycle after 480 cycles (2 C). One rather novel approach to growing a cathode material was to grow carbon fibers from the vapor phase to penetrate sulfur crystals [92]. A reasonable areal mass loading and capacity (3.4–4.4 mAh cm−2) were achieved with this cathode. Between 93–97% of capacity is retained at low current densities (0.2–0.5 C) Concerning the stability of the capacity, 90% of the initial 920 mA h g−1 capacity is retained after 200 cycles (0.1 C), with a reported coulombic efficiency of 100%.PDF Image | Lithium-Sulfur Batteries: Advances and Trends

PDF Search Title:

Lithium-Sulfur Batteries: Advances and TrendsOriginal File Name Searched:

electrochem-01-00016.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |