PDF Publication Title:

Text from PDF Page: 019

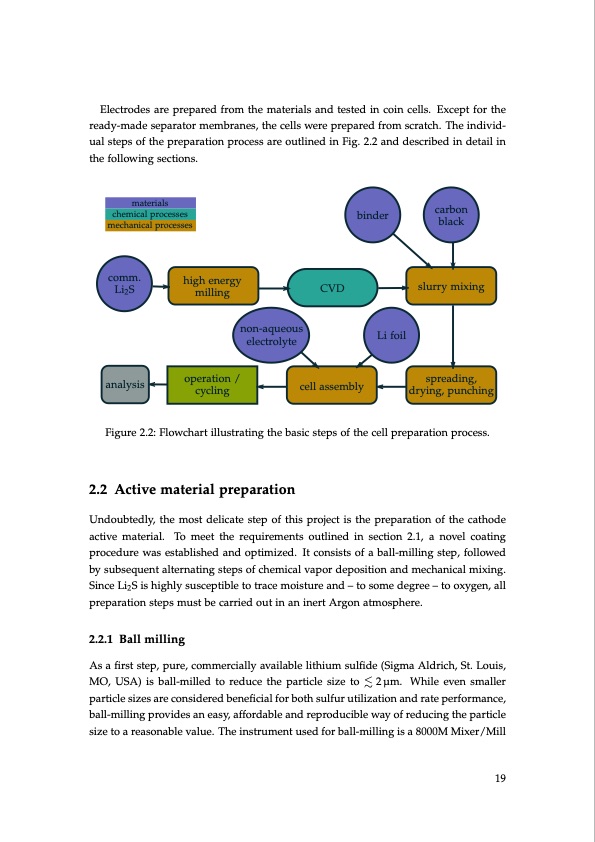

Electrodes are prepared from the materials and tested in coin cells. Except for the ready-made separator membranes, the cells were prepared from scratch. The individ- ual steps of the preparation process are outlined in Fig. 2.2 and described in detail in the following sections. materials chemical processes mechanical processes binder carbon black slurry mixing Li foil comm. Li2 S analysis high energy milling non-aqueous electrolyte CVD operation / cycling Figure 2.2: Flowchart illustrating the basic steps of the cell preparation process. 2.2 Active material preparation Undoubtedly, the most delicate step of this project is the preparation of the cathode active material. To meet the requirements outlined in section 2.1, a novel coating procedure was established and optimized. It consists of a ball-milling step, followed by subsequent alternating steps of chemical vapor deposition and mechanical mixing. Since Li2S is highly susceptible to trace moisture and – to some degree – to oxygen, all preparation steps must be carried out in an inert Argon atmosphere. 2.2.1 Ball milling As a first step, pure, commercially available lithium sulfide (Sigma Aldrich, St. Louis, MO, USA) is ball-milled to reduce the particle size to 2 μm. While even smaller particle sizes are considered beneficial for both sulfur utilization and rate performance, ball-milling provides an easy, affordable and reproducible way of reducing the particle size to a reasonable value. The instrument used for ball-milling is a 8000M Mixer/Mill cell assembly spreading, drying, punching 19PDF Image | Lithium-Sulfur Battery: Design, Characterization, and Physically-based Modeling

PDF Search Title:

Lithium-Sulfur Battery: Design, Characterization, and Physically-based ModelingOriginal File Name Searched:

Dissertation_David_N._Fronczek_The_Lithium_Sulfur_Battery.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |