PDF Publication Title:

Text from PDF Page: 022

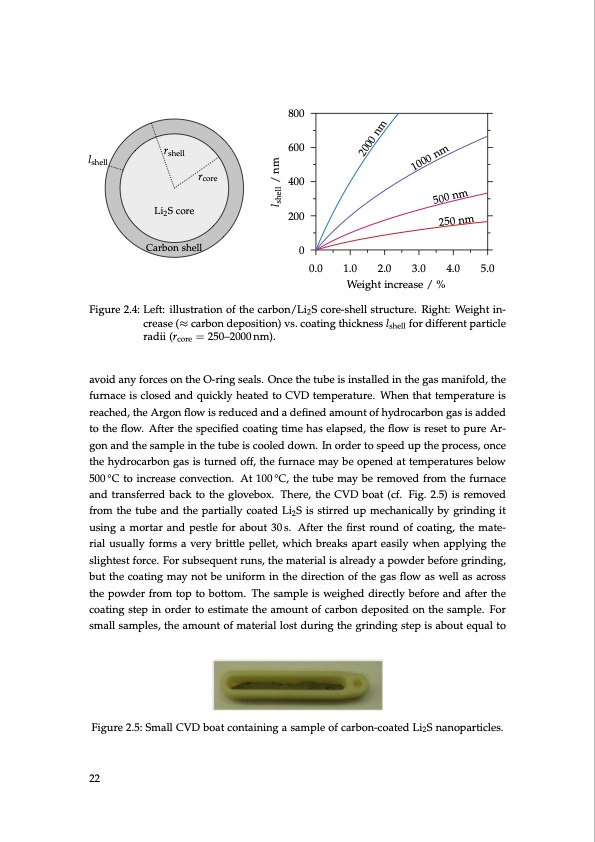

lshell rshell rcore Li2S core Carbon shell 800 600 400 200 0 Figure 2.4: Left: illustration of the carbon/Li2S core-shell structure. Right: Weight in- crease (≈ carbon deposition) vs. coating thickness lshell for different particle radii (rcore = 250–2000 nm). avoid any forces on the O-ring seals. Once the tube is installed in the gas manifold, the furnace is closed and quickly heated to CVD temperature. When that temperature is reached, the Argon flow is reduced and a defined amount of hydrocarbon gas is added to the flow. After the specified coating time has elapsed, the flow is reset to pure Ar- gon and the sample in the tube is cooled down. In order to speed up the process, once the hydrocarbon gas is turned off, the furnace may be opened at temperatures below 500 °C to increase convection. At 100 °C, the tube may be removed from the furnace and transferred back to the glovebox. There, the CVD boat (cf. Fig. 2.5) is removed from the tube and the partially coated Li2S is stirred up mechanically by grinding it using a mortar and pestle for about 30 s. After the first round of coating, the mate- rial usually forms a very brittle pellet, which breaks apart easily when applying the slightest force. For subsequent runs, the material is already a powder before grinding, but the coating may not be uniform in the direction of the gas flow as well as across the powder from top to bottom. The sample is weighed directly before and after the coating step in order to estimate the amount of carbon deposited on the sample. For small samples, the amount of material lost during the grinding step is about equal to Figure 2.5: Small CVD boat containing a sample of carbon-coated Li2S nanoparticles. 22 0.0 1.0 Weight increase / % 2.0 3.0 4.0 5.0 2000 nm lshell / nm 1000 nm 500 nm 250 nmPDF Image | Lithium-Sulfur Battery: Design, Characterization, and Physically-based Modeling

PDF Search Title:

Lithium-Sulfur Battery: Design, Characterization, and Physically-based ModelingOriginal File Name Searched:

Dissertation_David_N._Fronczek_The_Lithium_Sulfur_Battery.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |