PDF Publication Title:

Text from PDF Page: 028

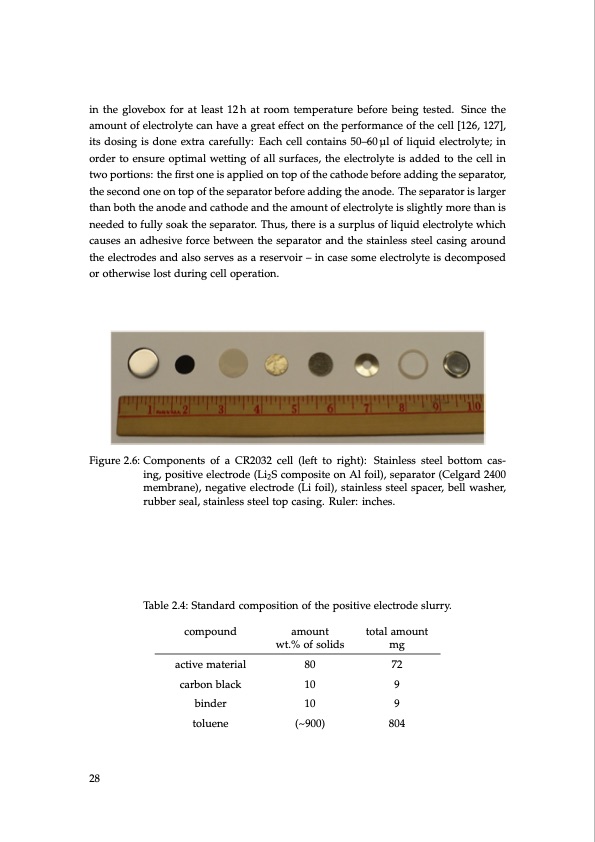

in the glovebox for at least 12 h at room temperature before being tested. Since the amount of electrolyte can have a great effect on the performance of the cell [126, 127], its dosing is done extra carefully: Each cell contains 50–60 μl of liquid electrolyte; in order to ensure optimal wetting of all surfaces, the electrolyte is added to the cell in two portions: the first one is applied on top of the cathode before adding the separator, the second one on top of the separator before adding the anode. The separator is larger than both the anode and cathode and the amount of electrolyte is slightly more than is needed to fully soak the separator. Thus, there is a surplus of liquid electrolyte which causes an adhesive force between the separator and the stainless steel casing around the electrodes and also serves as a reservoir – in case some electrolyte is decomposed or otherwise lost during cell operation. Figure 2.6: Components of a CR2032 cell (left to right): Stainless steel bottom cas- ing, positive electrode (Li2S composite on Al foil), separator (Celgard 2400 membrane), negative electrode (Li foil), stainless steel spacer, bell washer, rubber seal, stainless steel top casing. Ruler: inches. Table 2.4: Standard composition of the positive electrode slurry. compound active material carbon black binder toluene amount wt.% of solids 80 10 10 (~900) total amount mg 72 9 9 804 28PDF Image | Lithium-Sulfur Battery: Design, Characterization, and Physically-based Modeling

PDF Search Title:

Lithium-Sulfur Battery: Design, Characterization, and Physically-based ModelingOriginal File Name Searched:

Dissertation_David_N._Fronczek_The_Lithium_Sulfur_Battery.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |