PDF Publication Title:

Text from PDF Page: 046

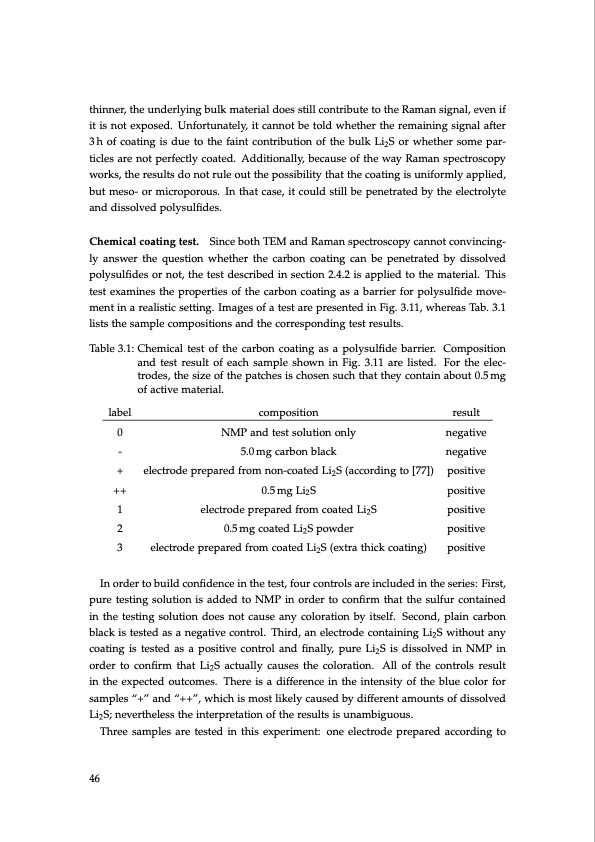

thinner, the underlying bulk material does still contribute to the Raman signal, even if it is not exposed. Unfortunately, it cannot be told whether the remaining signal after 3h of coating is due to the faint contribution of the bulk Li2S or whether some par- ticles are not perfectly coated. Additionally, because of the way Raman spectroscopy works, the results do not rule out the possibility that the coating is uniformly applied, but meso- or microporous. In that case, it could still be penetrated by the electrolyte and dissolved polysulfides. Chemical coating test. Since both TEM and Raman spectroscopy cannot convincing- ly answer the question whether the carbon coating can be penetrated by dissolved polysulfides or not, the test described in section 2.4.2 is applied to the material. This test examines the properties of the carbon coating as a barrier for polysulfide move- ment in a realistic setting. Images of a test are presented in Fig. 3.11, whereas Tab. 3.1 lists the sample compositions and the corresponding test results. Table 3.1: Chemical test of the carbon coating as a polysulfide barrier. Composition and test result of each sample shown in Fig. 3.11 are listed. For the elec- trodes, the size of the patches is chosen such that they contain about 0.5 mg of active material. label 0 - + ++ 1 2 3 composition NMP and test solution only 5.0 mg carbon black electrode prepared from non-coated Li2S (according to [77]) 0.5mg Li2S electrode prepared from coated Li2S 0.5 mg coated Li2S powder electrode prepared from coated Li2S (extra thick coating) result negative negative positive positive positive positive positive In order to build confidence in the test, four controls are included in the series: First, pure testing solution is added to NMP in order to confirm that the sulfur contained in the testing solution does not cause any coloration by itself. Second, plain carbon black is tested as a negative control. Third, an electrode containing Li2S without any coating is tested as a positive control and finally, pure Li2S is dissolved in NMP in order to confirm that Li2S actually causes the coloration. All of the controls result in the expected outcomes. There is a difference in the intensity of the blue color for samples “+” and “++”, which is most likely caused by different amounts of dissolved Li2S; nevertheless the interpretation of the results is unambiguous. Three samples are tested in this experiment: one electrode prepared according to 46PDF Image | Lithium-Sulfur Battery: Design, Characterization, and Physically-based Modeling

PDF Search Title:

Lithium-Sulfur Battery: Design, Characterization, and Physically-based ModelingOriginal File Name Searched:

Dissertation_David_N._Fronczek_The_Lithium_Sulfur_Battery.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |