PDF Publication Title:

Text from PDF Page: 048

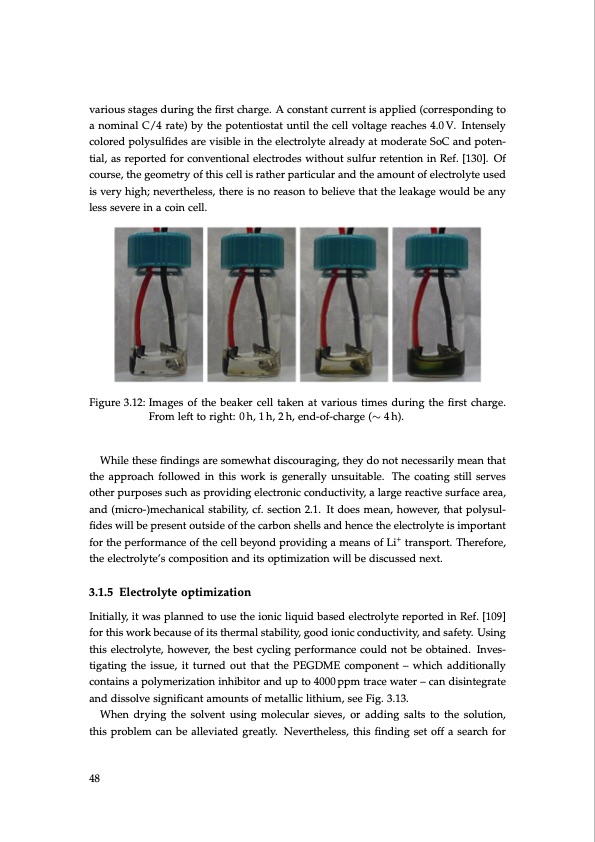

various stages during the first charge. A constant current is applied (corresponding to a nominal C/4 rate) by the potentiostat until the cell voltage reaches 4.0 V. Intensely colored polysulfides are visible in the electrolyte already at moderate SoC and poten- tial, as reported for conventional electrodes without sulfur retention in Ref. [130]. Of course, the geometry of this cell is rather particular and the amount of electrolyte used is very high; nevertheless, there is no reason to believe that the leakage would be any less severe in a coin cell. Figure 3.12: Images of the beaker cell taken at various times during the first charge. From left to right: 0 h, 1 h, 2 h, end-of-charge (∼ 4 h). While these findings are somewhat discouraging, they do not necessarily mean that the approach followed in this work is generally unsuitable. The coating still serves other purposes such as providing electronic conductivity, a large reactive surface area, and (micro-)mechanical stability, cf. section 2.1. It does mean, however, that polysul- fides will be present outside of the carbon shells and hence the electrolyte is important for the performance of the cell beyond providing a means of Li+ transport. Therefore, the electrolyte’s composition and its optimization will be discussed next. 3.1.5 Electrolyte optimization Initially, it was planned to use the ionic liquid based electrolyte reported in Ref. [109] for this work because of its thermal stability, good ionic conductivity, and safety. Using this electrolyte, however, the best cycling performance could not be obtained. Inves- tigating the issue, it turned out that the PEGDME component – which additionally contains a polymerization inhibitor and up to 4000 ppm trace water – can disintegrate and dissolve significant amounts of metallic lithium, see Fig. 3.13. When drying the solvent using molecular sieves, or adding salts to the solution, this problem can be alleviated greatly. Nevertheless, this finding set off a search for 48PDF Image | Lithium-Sulfur Battery: Design, Characterization, and Physically-based Modeling

PDF Search Title:

Lithium-Sulfur Battery: Design, Characterization, and Physically-based ModelingOriginal File Name Searched:

Dissertation_David_N._Fronczek_The_Lithium_Sulfur_Battery.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |