PDF Publication Title:

Text from PDF Page: 049

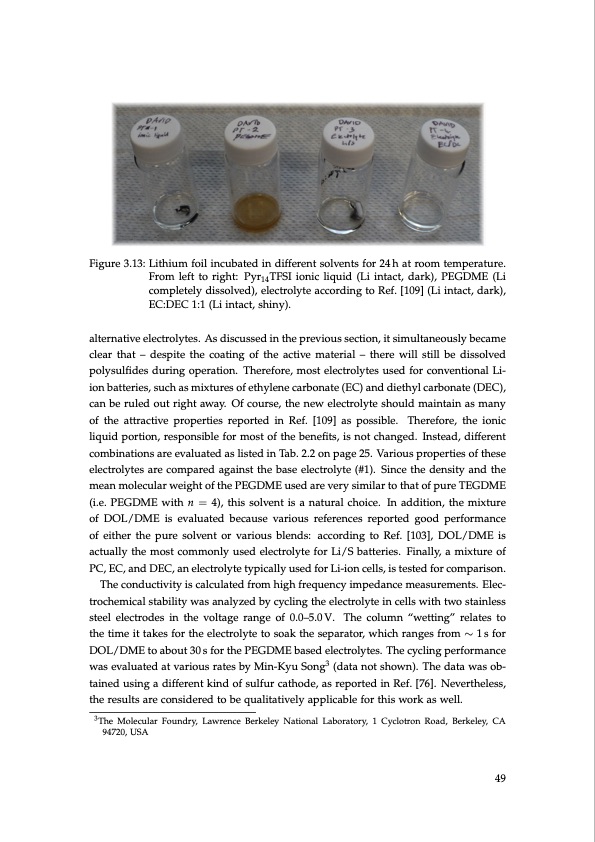

Figure 3.13: Lithium foil incubated in different solvents for 24 h at room temperature. From left to right: Pyr14TFSI ionic liquid (Li intact, dark), PEGDME (Li completely dissolved), electrolyte according to Ref. [109] (Li intact, dark), EC:DEC 1:1 (Li intact, shiny). alternative electrolytes. As discussed in the previous section, it simultaneously became clear that – despite the coating of the active material – there will still be dissolved polysulfides during operation. Therefore, most electrolytes used for conventional Li- ion batteries, such as mixtures of ethylene carbonate (EC) and diethyl carbonate (DEC), can be ruled out right away. Of course, the new electrolyte should maintain as many of the attractive properties reported in Ref. [109] as possible. Therefore, the ionic liquid portion, responsible for most of the benefits, is not changed. Instead, different combinations are evaluated as listed in Tab. 2.2 on page 25. Various properties of these electrolytes are compared against the base electrolyte (#1). Since the density and the mean molecular weight of the PEGDME used are very similar to that of pure TEGDME (i.e. PEGDME with n = 4), this solvent is a natural choice. In addition, the mixture of DOL/DME is evaluated because various references reported good performance of either the pure solvent or various blends: according to Ref. [103], DOL/DME is actually the most commonly used electrolyte for Li/S batteries. Finally, a mixture of PC, EC, and DEC, an electrolyte typically used for Li-ion cells, is tested for comparison. The conductivity is calculated from high frequency impedance measurements. Elec- trochemical stability was analyzed by cycling the electrolyte in cells with two stainless steel electrodes in the voltage range of 0.0–5.0V. The column “wetting” relates to the time it takes for the electrolyte to soak the separator, which ranges from ∼ 1 s for DOL/DME to about 30 s for the PEGDME based electrolytes. The cycling performance was evaluated at various rates by Min-Kyu Song3 (data not shown). The data was ob- tained using a different kind of sulfur cathode, as reported in Ref. [76]. Nevertheless, the results are considered to be qualitatively applicable for this work as well. 3The Molecular Foundry, Lawrence Berkeley National Laboratory, 1 Cyclotron Road, Berkeley, CA 94720, USA 49PDF Image | Lithium-Sulfur Battery: Design, Characterization, and Physically-based Modeling

PDF Search Title:

Lithium-Sulfur Battery: Design, Characterization, and Physically-based ModelingOriginal File Name Searched:

Dissertation_David_N._Fronczek_The_Lithium_Sulfur_Battery.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |