PDF Publication Title:

Text from PDF Page: 050

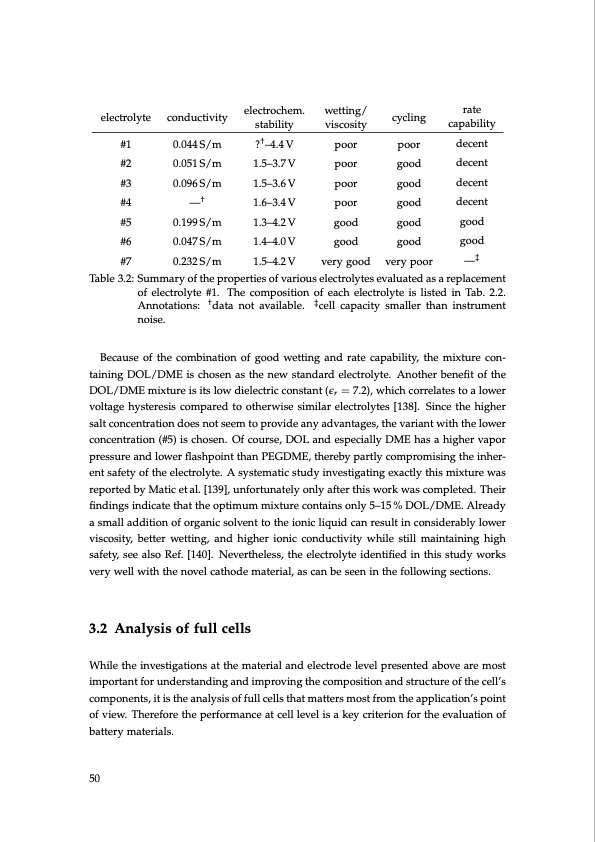

electrolyte conductivity electrochem. wetting/ cycling stability viscosity ?†–4.4V poor poor rate capability decent decent decent decent good good —‡ #1 0.044 S/m #2 0.051 S/m #3 0.096 S/m #4 —† #5 0.199 S/m #6 0.047 S/m #7 0.232 S/m 1.5–3.7 V 1.5–3.6 V 1.6–3.4 V 1.3–4.2 V 1.4–4.0 V 1.5–4.2 V poor poor poor good good very good good good good good good very poor Table 3.2: Summary of the properties of various electrolytes evaluated as a replacement of electrolyte #1. The composition of each electrolyte is listed in Tab. 2.2. Annotations: † data not available. ‡ cell capacity smaller than instrument noise. Because of the combination of good wetting and rate capability, the mixture con- taining DOL/DME is chosen as the new standard electrolyte. Another benefit of the DOL/DME mixture is its low dielectric constant (εr = 7.2), which correlates to a lower voltage hysteresis compared to otherwise similar electrolytes [138]. Since the higher salt concentration does not seem to provide any advantages, the variant with the lower concentration (#5) is chosen. Of course, DOL and especially DME has a higher vapor pressure and lower flashpoint than PEGDME, thereby partly compromising the inher- ent safety of the electrolyte. A systematic study investigating exactly this mixture was reported by Matic et al. [139], unfortunately only after this work was completed. Their findings indicate that the optimum mixture contains only 5–15 % DOL/DME. Already a small addition of organic solvent to the ionic liquid can result in considerably lower viscosity, better wetting, and higher ionic conductivity while still maintaining high safety, see also Ref. [140]. Nevertheless, the electrolyte identified in this study works very well with the novel cathode material, as can be seen in the following sections. 3.2 Analysis of full cells While the investigations at the material and electrode level presented above are most important for understanding and improving the composition and structure of the cell’s components, it is the analysis of full cells that matters most from the application’s point of view. Therefore the performance at cell level is a key criterion for the evaluation of battery materials. 50PDF Image | Lithium-Sulfur Battery: Design, Characterization, and Physically-based Modeling

PDF Search Title:

Lithium-Sulfur Battery: Design, Characterization, and Physically-based ModelingOriginal File Name Searched:

Dissertation_David_N._Fronczek_The_Lithium_Sulfur_Battery.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |