PDF Publication Title:

Text from PDF Page: 055

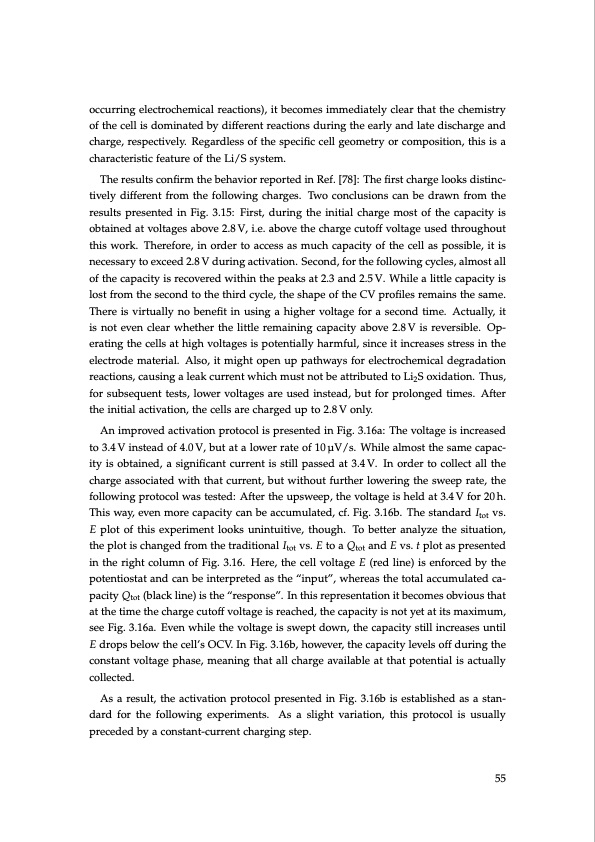

occurring electrochemical reactions), it becomes immediately clear that the chemistry of the cell is dominated by different reactions during the early and late discharge and charge, respectively. Regardless of the specific cell geometry or composition, this is a characteristic feature of the Li/S system. The results confirm the behavior reported in Ref. [78]: The first charge looks distinc- tively different from the following charges. Two conclusions can be drawn from the results presented in Fig. 3.15: First, during the initial charge most of the capacity is obtained at voltages above 2.8 V, i.e. above the charge cutoff voltage used throughout this work. Therefore, in order to access as much capacity of the cell as possible, it is necessary to exceed 2.8 V during activation. Second, for the following cycles, almost all of the capacity is recovered within the peaks at 2.3 and 2.5 V. While a little capacity is lost from the second to the third cycle, the shape of the CV profiles remains the same. There is virtually no benefit in using a higher voltage for a second time. Actually, it is not even clear whether the little remaining capacity above 2.8 V is reversible. Op- erating the cells at high voltages is potentially harmful, since it increases stress in the electrode material. Also, it might open up pathways for electrochemical degradation reactions, causing a leak current which must not be attributed to Li2S oxidation. Thus, for subsequent tests, lower voltages are used instead, but for prolonged times. After the initial activation, the cells are charged up to 2.8 V only. An improved activation protocol is presented in Fig. 3.16a: The voltage is increased to 3.4 V instead of 4.0 V, but at a lower rate of 10 μV/s. While almost the same capac- ity is obtained, a significant current is still passed at 3.4 V. In order to collect all the charge associated with that current, but without further lowering the sweep rate, the following protocol was tested: After the upsweep, the voltage is held at 3.4 V for 20 h. This way, even more capacity can be accumulated, cf. Fig. 3.16b. The standard Itot vs. E plot of this experiment looks unintuitive, though. To better analyze the situation, the plot is changed from the traditional Itot vs. E to a Qtot and E vs. t plot as presented in the right column of Fig. 3.16. Here, the cell voltage E (red line) is enforced by the potentiostat and can be interpreted as the “input”, whereas the total accumulated ca- pacity Qtot (black line) is the “response”. In this representation it becomes obvious that at the time the charge cutoff voltage is reached, the capacity is not yet at its maximum, see Fig. 3.16a. Even while the voltage is swept down, the capacity still increases until E drops below the cell’s OCV. In Fig. 3.16b, however, the capacity levels off during the constant voltage phase, meaning that all charge available at that potential is actually collected. As a result, the activation protocol presented in Fig. 3.16b is established as a stan- dard for the following experiments. As a slight variation, this protocol is usually preceded by a constant-current charging step. 55PDF Image | Lithium-Sulfur Battery: Design, Characterization, and Physically-based Modeling

PDF Search Title:

Lithium-Sulfur Battery: Design, Characterization, and Physically-based ModelingOriginal File Name Searched:

Dissertation_David_N._Fronczek_The_Lithium_Sulfur_Battery.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |