PDF Publication Title:

Text from PDF Page: 065

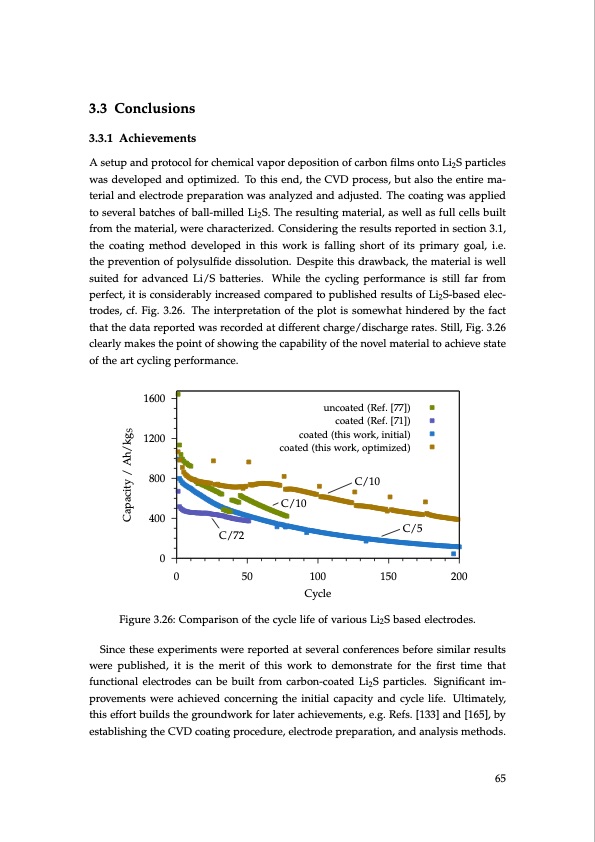

3.3 Conclusions 3.3.1 Achievements A setup and protocol for chemical vapor deposition of carbon films onto Li2S particles was developed and optimized. To this end, the CVD process, but also the entire ma- terial and electrode preparation was analyzed and adjusted. The coating was applied to several batches of ball-milled Li2S. The resulting material, as well as full cells built from the material, were characterized. Considering the results reported in section 3.1, the coating method developed in this work is falling short of its primary goal, i.e. the prevention of polysulfide dissolution. Despite this drawback, the material is well suited for advanced Li/S batteries. While the cycling performance is still far from perfect, it is considerably increased compared to published results of Li2S-based elec- trodes, cf. Fig. 3.26. The interpretation of the plot is somewhat hindered by the fact that the data reported was recorded at different charge/discharge rates. Still, Fig. 3.26 clearly makes the point of showing the capability of the novel material to achieve state of the art cycling performance. 1600 1200 800 400 0 Figure 3.26: Comparison of the cycle life of various Li2S based electrodes. Since these experiments were reported at several conferences before similar results were published, it is the merit of this work to demonstrate for the first time that functional electrodes can be built from carbon-coated Li2S particles. Significant im- provements were achieved concerning the initial capacity and cycle life. Ultimately, this effort builds the groundwork for later achievements, e.g. Refs. [133] and [165], by establishing the CVD coating procedure, electrode preparation, and analysis methods. C/10 C/72 C/5 uncoated (Ref. [77]) coated (Ref. [71]) coated (this work, initial) coated (this work, optimized) C/10 0 50 100 150 200 Cycle 65 Capacity / Ah/kgSPDF Image | Lithium-Sulfur Battery: Design, Characterization, and Physically-based Modeling

PDF Search Title:

Lithium-Sulfur Battery: Design, Characterization, and Physically-based ModelingOriginal File Name Searched:

Dissertation_David_N._Fronczek_The_Lithium_Sulfur_Battery.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |