PDF Publication Title:

Text from PDF Page: 088

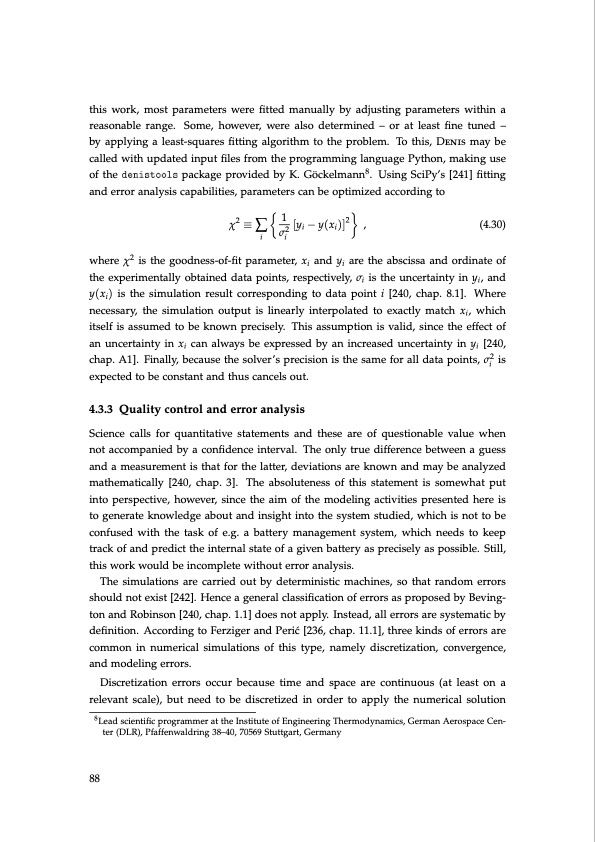

this work, most parameters were fitted manually by adjusting parameters within a reasonable range. Some, however, were also determined – or at least fine tuned – by applying a least-squares fitting algorithm to the problem. To this, Denis may be called with updated input files from the programming language Python, making use of the denistools package provided by K. Göckelmann8. Using SciPy’s [241] fitting and error analysis capabilities, parameters can be optimized according to 2 1 2 χ ≡∑i σi2[yi−y(xi)] , (4.30) where χ2 is the goodness-of-fit parameter, xi and yi are the abscissa and ordinate of the experimentally obtained data points, respectively, σi is the uncertainty in yi, and y(xi) is the simulation result corresponding to data point i [240, chap. 8.1]. Where necessary, the simulation output is linearly interpolated to exactly match xi, which itself is assumed to be known precisely. This assumption is valid, since the effect of an uncertainty in xi can always be expressed by an increased uncertainty in yi [240, chap. A1]. Finally, because the solver’s precision is the same for all data points, σi2 is expected to be constant and thus cancels out. 4.3.3 Quality control and error analysis Science calls for quantitative statements and these are of questionable value when not accompanied by a confidence interval. The only true difference between a guess and a measurement is that for the latter, deviations are known and may be analyzed mathematically [240, chap. 3]. The absoluteness of this statement is somewhat put into perspective, however, since the aim of the modeling activities presented here is to generate knowledge about and insight into the system studied, which is not to be confused with the task of e.g. a battery management system, which needs to keep track of and predict the internal state of a given battery as precisely as possible. Still, this work would be incomplete without error analysis. The simulations are carried out by deterministic machines, so that random errors should not exist [242]. Hence a general classification of errors as proposed by Beving- ton and Robinson [240, chap. 1.1] does not apply. Instead, all errors are systematic by definition. According to Ferziger and Peric ́ [236, chap. 11.1], three kinds of errors are common in numerical simulations of this type, namely discretization, convergence, and modeling errors. Discretization errors occur because time and space are continuous (at least on a relevant scale), but need to be discretized in order to apply the numerical solution 8Lead scientific programmer at the Institute of Engineering Thermodynamics, German Aerospace Cen- ter (DLR), Pfaffenwaldring 38–40, 70569 Stuttgart, Germany 88PDF Image | Lithium-Sulfur Battery: Design, Characterization, and Physically-based Modeling

PDF Search Title:

Lithium-Sulfur Battery: Design, Characterization, and Physically-based ModelingOriginal File Name Searched:

Dissertation_David_N._Fronczek_The_Lithium_Sulfur_Battery.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |