PDF Publication Title:

Text from PDF Page: 105

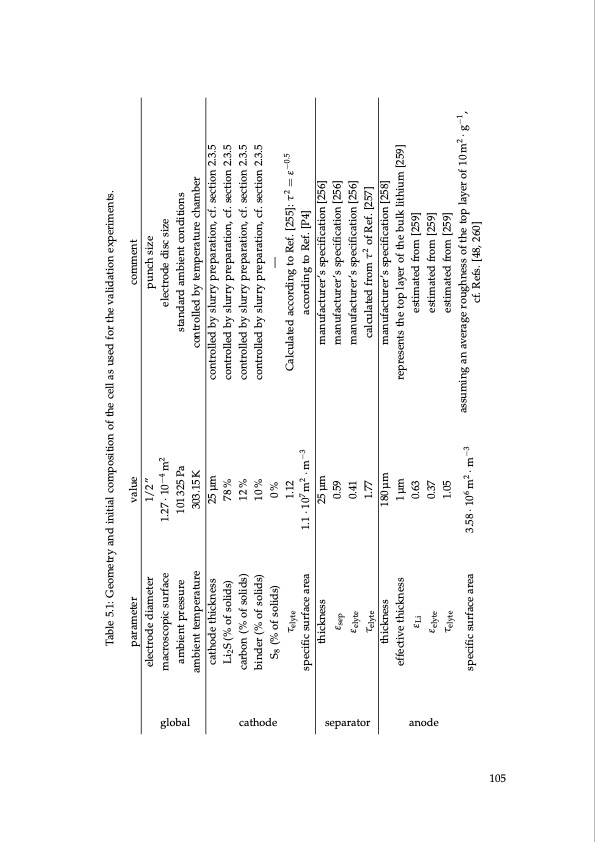

global cathode separator anode 105 Table 5.1: Geometry and initial composition of the cell as used for the validation experiments. parameter value comment electrode diameter macroscopic surface ambient pressure ambient temperature cathode thickness Li2 S (% of solids) carbon (% of solids) binder (% of solids) S8 (% of solids) 1/2 ” 1.27 · 10−4 m2 101 325 Pa 303.15 K 25 μm 78 % 12 % 10 % 0 % punch size τelyte 1.12 Calculated according to Ref. [255]: τ2 = ε−0.5 specific surface area thickness εsep εelyte 1.1 · 107 m2 · m−3 25 μm 0.59 0.41 1.77 180 μm 1 μm 0.63 0.37 1.05 according to Ref. [P4] τelyte thickness effective thickness εLi εelyte τelyte calculated from τ2 of Ref. [257] specific surface area 3.58 · 106 m2 · m−3 assuming an average roughness of the top layer of 10 m2 · g−1, cf. Refs. [48, 260] electrode disc size standard ambient conditions controlled by temperature chamber controlled by slurry preparation, cf. section 2.3.5 controlled by slurry preparation, cf. section 2.3.5 controlled by slurry preparation, cf. section 2.3.5 controlled by slurry preparation, cf. section 2.3.5 — manufacturer’s specification [256] manufacturer’s specification [256] manufacturer’s specification [256] manufacturer’s specification [258] represents the top layer of the bulk lithium [259] estimated from [259] estimated from [259] estimated from [259]PDF Image | Lithium-Sulfur Battery: Design, Characterization, and Physically-based Modeling

PDF Search Title:

Lithium-Sulfur Battery: Design, Characterization, and Physically-based ModelingOriginal File Name Searched:

Dissertation_David_N._Fronczek_The_Lithium_Sulfur_Battery.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |