PDF Publication Title:

Text from PDF Page: 007

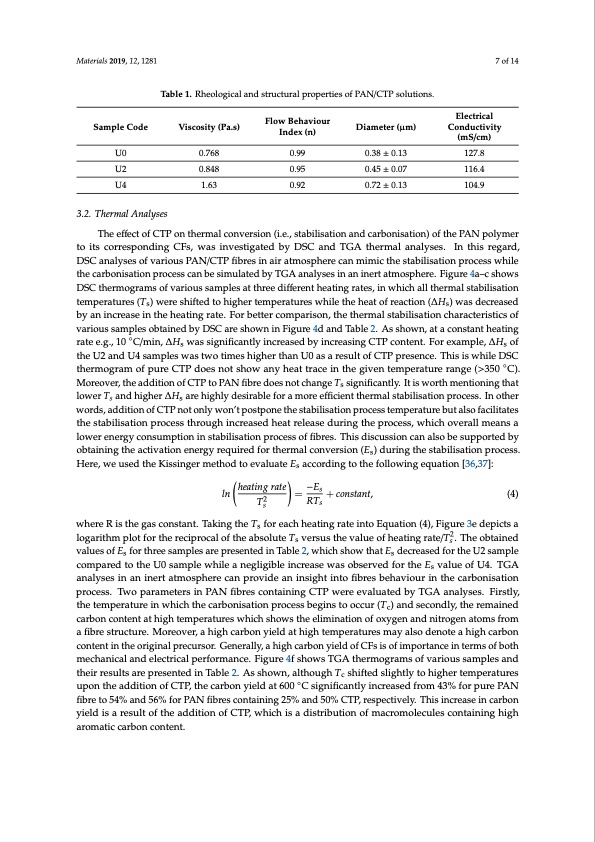

Materials 2019, 12, 1281 7 of 14 Table 1. Rheological and structural properties of PAN/CTP solutions. Sample Code U0 U2 U4 3.2. Thermal Analyses Viscosity (Pa.s) 0.768 0.848 1.63 Flow Behaviour Index (n) 0.99 0.95 0.92 Diameter (μm) 0.38 ± 0.13 0.45 ± 0.07 0.72 ± 0.13 Electrical Conductivity (mS/cm) 127.8 116.4 104.9 The effect of CTP on thermal conversion (i.e., stabilisation and carbonisation) of the PAN polymer to its corresponding CFs, was investigated by DSC and TGA thermal analyses. In this regard, DSC analyses of various PAN/CTP fibres in air atmosphere can mimic the stabilisation process while the carbonisation process can be simulated by TGA analyses in an inert atmosphere. Figure 4a–c shows DSC thermograms of various samples at three different heating rates, in which all thermal stabilisation temperatures (Ts) were shifted to higher temperatures while the heat of reaction (∆Hs) was decreased by an increase in the heating rate. For better comparison, the thermal stabilisation characteristics of various samples obtained by DSC are shown in Figure 4d and Table 2. As shown, at a constant heating rate e.g., 10 ◦C/min, ∆Hs was significantly increased by increasing CTP content. For example, ∆Hs of the U2 and U4 samples was two times higher than U0 as a result of CTP presence. This is while DSC thermogram of pure CTP does not show any heat trace in the given temperature range (>350 ◦C). Moreover, the addition of CTP to PAN fibre does not change Ts significantly. It is worth mentioning that lower Ts and higher ∆Hs are highly desirable for a more efficient thermal stabilisation process. In other words, addition of CTP not only won’t postpone the stabilisation process temperature but also facilitates the stabilisation process through increased heat release during the process, which overall means a lower energy consumption in stabilisation process of fibres. This discussion can also be supported by obtaining the activation energy required for thermal conversion (Es) during the stabilisation process. Here, we used the Kissinger method to evaluate Es according to the following equation [36,37]: heating rate −Es ln 2 =RT +constant, (4) Ts s where R is the gas constant. Taking the Ts for each heating rate into Equation (4), Figure 3e depicts a logarithm plot for the reciprocal of the absolute Ts versus the value of heating rate/Ts2. The obtained values of Es for three samples are presented in Table 2, which show that Es decreased for the U2 sample compared to the U0 sample while a negligible increase was observed for the Es value of U4. TGA analyses in an inert atmosphere can provide an insight into fibres behaviour in the carbonisation process. Two parameters in PAN fibres containing CTP were evaluated by TGA analyses. Firstly, the temperature in which the carbonisation process begins to occur (Tc) and secondly, the remained carbon content at high temperatures which shows the elimination of oxygen and nitrogen atoms from a fibre structure. Moreover, a high carbon yield at high temperatures may also denote a high carbon content in the original precursor. Generally, a high carbon yield of CFs is of importance in terms of both mechanical and electrical performance. Figure 4f shows TGA thermograms of various samples and their results are presented in Table 2. As shown, although Tc shifted slightly to higher temperatures upon the addition of CTP, the carbon yield at 600 ◦C significantly increased from 43% for pure PAN fibre to 54% and 56% for PAN fibres containing 25% and 50% CTP, respectively. This increase in carbon yield is a result of the addition of CTP, which is a distribution of macromolecules containing high aromatic carbon content.PDF Image | Low-Cost Carbon Fibre Derived from Sustainable Coal Tar Pitch and Polyacrylonitrile

PDF Search Title:

Low-Cost Carbon Fibre Derived from Sustainable Coal Tar Pitch and PolyacrylonitrileOriginal File Name Searched:

6e63fb65b81e089e97ddfbe19bee7d22311e.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |