PDF Publication Title:

Text from PDF Page: 007

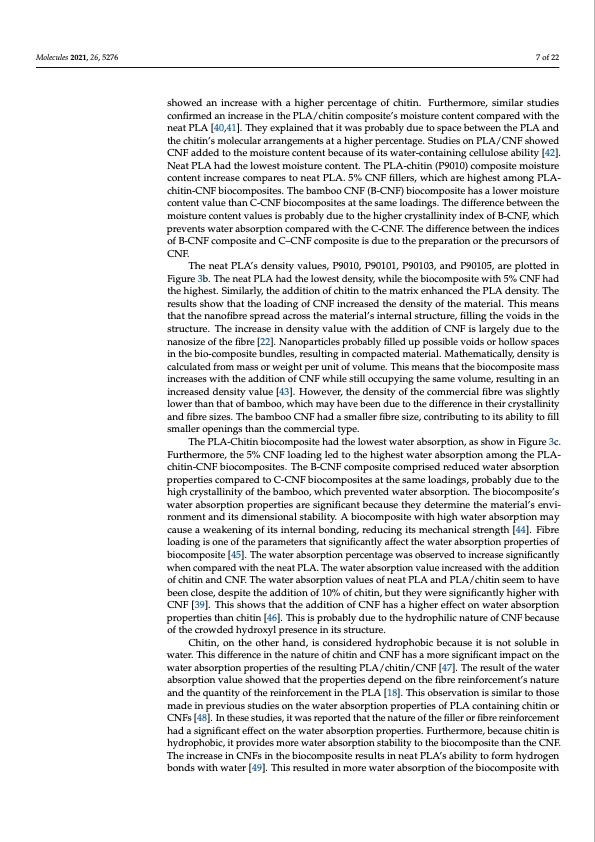

Molecules 2021, 26, 5276 7 of 22 showed an increase with a higher percentage of chitin. Furthermore, similar studies confirmed an increase in the PLA/chitin composite’s moisture content compared with the neat PLA [40,41]. They explained that it was probably due to space between the PLA and the chitin’s molecular arrangements at a higher percentage. Studies on PLA/CNF showed CNF added to the moisture content because of its water-containing cellulose ability [42]. Neat PLA had the lowest moisture content. The PLA-chitin (P9010) composite moisture content increase compares to neat PLA. 5% CNF fillers, which are highest among PLA- chitin-CNF biocomposites. The bamboo CNF (B-CNF) biocomposite has a lower moisture content value than C-CNF biocomposites at the same loadings. The difference between the moisture content values is probably due to the higher crystallinity index of B-CNF, which prevents water absorption compared with the C-CNF. The difference between the indices of B-CNF composite and C–CNF composite is due to the preparation or the precursors of CNF. The neat PLA’s density values, P9010, P90101, P90103, and P90105, are plotted in Figure 3b. The neat PLA had the lowest density, while the biocomposite with 5% CNF had the highest. Similarly, the addition of chitin to the matrix enhanced the PLA density. The results show that the loading of CNF increased the density of the material. This means that the nanofibre spread across the material’s internal structure, filling the voids in the structure. The increase in density value with the addition of CNF is largely due to the nanosize of the fibre [22]. Nanoparticles probably filled up possible voids or hollow spaces in the bio-composite bundles, resulting in compacted material. Mathematically, density is calculated from mass or weight per unit of volume. This means that the biocomposite mass increases with the addition of CNF while still occupying the same volume, resulting in an increased density value [43]. However, the density of the commercial fibre was slightly lower than that of bamboo, which may have been due to the difference in their crystallinity and fibre sizes. The bamboo CNF had a smaller fibre size, contributing to its ability to fill smaller openings than the commercial type. The PLA-Chitin biocomposite had the lowest water absorption, as show in Figure 3c. Furthermore, the 5% CNF loading led to the highest water absorption among the PLA- chitin-CNF biocomposites. The B-CNF composite comprised reduced water absorption properties compared to C-CNF biocomposites at the same loadings, probably due to the high crystallinity of the bamboo, which prevented water absorption. The biocomposite’s water absorption properties are significant because they determine the material’s envi- ronment and its dimensional stability. A biocomposite with high water absorption may cause a weakening of its internal bonding, reducing its mechanical strength [44]. Fibre loading is one of the parameters that significantly affect the water absorption properties of biocomposite [45]. The water absorption percentage was observed to increase significantly when compared with the neat PLA. The water absorption value increased with the addition of chitin and CNF. The water absorption values of neat PLA and PLA/chitin seem to have been close, despite the addition of 10% of chitin, but they were significantly higher with CNF [39]. This shows that the addition of CNF has a higher effect on water absorption properties than chitin [46]. This is probably due to the hydrophilic nature of CNF because of the crowded hydroxyl presence in its structure. Chitin, on the other hand, is considered hydrophobic because it is not soluble in water. This difference in the nature of chitin and CNF has a more significant impact on the water absorption properties of the resulting PLA/chitin/CNF [47]. The result of the water absorption value showed that the properties depend on the fibre reinforcement’s nature and the quantity of the reinforcement in the PLA [18]. This observation is similar to those made in previous studies on the water absorption properties of PLA containing chitin or CNFs [48]. In these studies, it was reported that the nature of the filler or fibre reinforcement had a significant effect on the water absorption properties. Furthermore, because chitin is hydrophobic, it provides more water absorption stability to the biocomposite than the CNF. The increase in CNFs in the biocomposite results in neat PLA’s ability to form hydrogen bonds with water [49]. This resulted in more water absorption of the biocomposite withPDF Image | Supercritical Carbon Dioxide Isolation of Cellulose Nanofibre

PDF Search Title:

Supercritical Carbon Dioxide Isolation of Cellulose NanofibreOriginal File Name Searched:

molecules-26-05276-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |