PDF Publication Title:

Text from PDF Page: 016

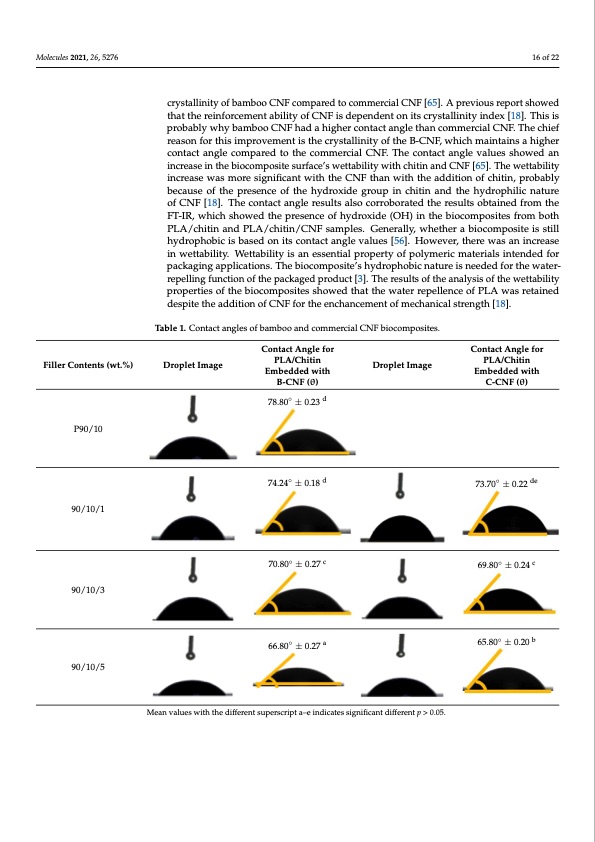

2..7.2.T.T7h.eeTWheetWttaebtiitlliaitbtyilPiPtryropPpererortptiiesrstoioeffsBoafmBbaomobaonodaCnCodomCmomeerrmcciiearllcCiaNl FCF-N-RFeei-inRnffeoirnrccfeeodrcPeLdLAP/L/CAh/iitCtiinhnitin Bionanocomposites The bamboo CNF was isolated with combined alkaline digestion, chlorine-free pulp- e o ) e s x s d e h n y d Molecules 2021, 26, 5276 6B6i.o3n°anaoncdom6p5o.s5i°tesfor 5% loading of bamboo CNF (B-CNF) and commercial 1C6 Nof F22(C-CNF 66.3° and 65.5° for 5% loading of bamboo CNF (B-CNF) and commercial CNF (C-CNF). 66.3° and 65.5° for 5% loading of bamboo CNF (B-CNF) and commercial CNF (C-CNF). Filler Filler CoFniiltlelFenirrtlsle(rwt.%) Table 1d.eCsopnitaectthaeCnagodlPendsLtitoaAifoc/btnCaAhomfinbtCiognNoleFanfdorctohmemenercchialnCceNmFebnitoocofmpeocshiatensi.cal strenPgLthAC/[oC18nh]t.iaticnt Angle for Contact Angle for Contact Angle for Filler Contact Angle for Contact Angle for Contents Droplet Image ConCnttoacncttaAcntngAgllnegffloerrfor Droplet Image ConCnttoacncttaAcntngAgllnegffloerrfor Bionanocomposites Molecules2021,26,xFORPEERREBVBIiEoWnanocomposites 17 of 23 BiionBnaianonocaconomomcpoomossipitteoesites The wettability properties of the bionanocomposite were evaluated using contact an The wettability properties of the bionanocomposite were evaluated using contact an- The wettability properties of the bionanocomposite were evaluated using contact an- TheTwhwetwttaebtitilaliitbtyilpiptryropreorrpttiiersstoioeffstthohfetbhbieionbnaiaonoacnomcpopmosspiitoteswiwterwreerveaelluvuatlteuedadtueusdsiinungsgicncogncttaoacncttacnt--an- gle analysis. The results of the contact angle analysis, shown in Table 1, showed that th gle analysis. The results of the contact angle analysis, shown in Table 1, showed that the gle analysis. The results of the contact angle analysis, shown in Table 1, showed that the gllegalnenallynysasilisys..sTish.eTrhressuruelltstssuolotfsf ttohfetchcoencttaoacncttacntgallenegalnenallynysasilisys,,sishsh,oswhnonwiinTinabTlleaeb1l,e, ss1h,oswheoedwd tethdathtthahtethe values were lower than 90°. The contact angle values ranged from 78.8° for PLA/chitin t va2l.u7.eTshwe Werettlaobwilietyr Pthroapner9ti0e°s.oTf Bhaemcboonotancdt CaonmgmleervcaialluCeNs rFa-RneginefdorfcreodmPL7A8/.C8h°itfionr PLA/chitin to Molecules 2021, 26, x FOR PEEvRvaRlEluVeIeEsWwere lower than 90°. The contact angle values ranged from 78.8° for17PLoLfA23/chitin to valluvueaeslsuweserwreelloroewleoerwrtthehrantnh9a90n0°°.9.T0T°h.eTchcoencttaoacncttacntgallenegvlaealluvueaeslsurreasnrgaendgfefrrdomfmro7m8..878°8°f.f8o°rrfPoLrLAP/L/cAhi/itctiihnittoion to 66..363°6°a.a3n°dan65d5..56°5°f.f5o°rrf5o5%r 5llo%oadldoiinandgionofgfboafmbbabomoobCoCoNCFN((BF--C(CBN-CF)N)aFn)dancodomcmomermrcieiarllcCiCaNlNCFN((CF--C(CN-CF)N)..F). The contact angle was reduced with increased CNF loadings from 1 to 5%. The lowes The coTnhteawcteattnagbilleitywparsoprerdtuiecseodf twheitbhioinacnroecaosmedpoCsiNteFwleoraedeivnaglusaftreodmusi1ngtoco5n%ta.cTt ahne- lowest The contact angle was reduced with increased CNF loadings from 1 to 5%. The lowest T T h h e e T c h c o e o n n c t t a o a c n c t t t a a a c n n t g g a l l e n e g w wl e a a s ws r a r e e s d d r u u e c c d e e u d d c we w d i i t t h wh i i t i n n h c c r i r e n e a c a s r s e e e d a d s Ce C d N N CF F N l l o o F a a d l d o i i n a n d g g s i s n f g f r r s o o mf m r o 1 1 m t t o o 1 5 5 t %o % . 5 . T %T h h . e e T l h l o o e w w l e o e s ws t t e s t cgolnetancatlyasnigs.leThwearsesoubltsaionfethdeacto5n%tacCt aNnFglleoandailnygsi.sT, sheowbanminboToab-CleN1,Fs-hreoiwnefodrtcheadt tbhieocompo conta2c.t7.aTnhgelWeewttabsiliotybtParionperdtieastof5B%amCboNoFanldoCaodminmger.cTiahl CeNbFa-mRebinofor-cCedNPFL-Ar/eCihniftoinrced biocompo- contact angle was obtained at 5% CNF loading. The bamboo-CNF-reinforced biocompo- concttaoacncttacntgallenegwleaswsoabsbttaoaibinteaedidnaeatdt5a%t 5C%NCFNlloFadldoiinandg.i.nTgh.eTbhbaeambbabomoob--CoCoN-CF-N-rreFeii-nrfefoirnrcfceoedrdcbebidiocbcoiomcpopmo--po- svitaelsuBehisoanwdaneaorceoglmorepwoasetiretertshcaonn9t0a°c.tTahnegcloenthacatnanthgelecvoamlumeserracnigaeldCfNroFmb7i8o.c8o°mfopr oPsLiAte/sc,hpitirnobtoably du sites had a greater contact angle than the commercial CNF biocomposites, probably due sites had a greater contact angle than the commercial CNF biocomposites, probably due crysstsiaitltelesissnithihetaysadhoafadbgararmeagabtrtoeroartcCceorNnctFtaoacncottamacnptgalrlenegdtthlhetaontnhctoathmnemtchcoeoemrmcmiomamleCrmrcNieiaFrllcC[iC6aN5lN]CF.FNAbiFipocrbceoiovomicopopumosspiriteotepssoi,,trpeptsrrs,ohpborawoblelyadybdluyuedue 66.3° and 65.5° for 5% loading of bamboo CNF (B-CNF) and commercial CNF (C-CNF). to the higher crystallinity of bamboo CNF compared to commercial CNF [65]. A previou to the higThheerwcreyttsatbaililtiynpitryopoefrtbieasmofbtohoe bCioNnFancoocmomppaorseitde wtoerceoemvamlueartceidaul sCinNgFco[n6t5a]c.t Aan-previous to the higher crystallinity of bamboo CNF compared to commercial CNF [65]. A previous thatttotohteththoerethihnieigfgohreiecgrrehcmcerryeyscnstrtayalasllbitinanililitltiynoiotfyfbCoafNmbFbabomiosobdCoCeoNpCFeFnNcdoFoemncpotpmaoarnrpedaidtrstetodcrctyosmtcamomlmleienrmrcictieiyarllciCniCadNleCFxFN[616F585][].6.A5AT]h.pAirsreipvsirioeouvusisous The contact angle was reduced with increased CNF loadings from 1 to 5%. The lowest repogrltesahnoalwyseids. tThaetrtehsuelrtseionf ftohrecceomnteancttanbgileitaynoalfyCsiNs, sFhioswdneipneTnadbelen1t,osnhoitwsecdrythsattalthlienity inde report showed that the reinforcement ability of CNF is dependent on its crystallinity index report showed that the reinforcement ability of CNF is dependent on its crystallinity index probrreaepbproloyerrptcwtososhnhrhtotyoaswchbteoaeadmwdntgebthlhdoeaotwthtCtahahseNteotrFhrbetihainriafnefdoeirndracfceoaehmtrmic5ge%ehnmnetCtreaNncbotFiilanlilitbotyayailcdoiotifyfnaCgnoN.NfgTClFhFeNeiitsshbFdaiemnespdbceoenopmd-eCemenNndettFero-cnrnietaioinlttsnfCsociNrtrcsyeFscd.strtTaybalhisloliteincanocilitlmhtiynipeinotfny-dienxdex values were lower than 90°. The contact angle values ranged from 78.8° for PLA/chitin to [18]. This is probably why bamboo CNF had a higher contact angle than commercial CNF [18]. This is probably why bamboo CNF had a higher contact angle than commercial CNF. [18]. This is probably why bamboo CNF had a higher contact angle than commercial CNF. reas[o[1n8][]f.1.oT8Trsh]ih.tiheiTss6ihis6ishsi.is3apmp°dirrsaopaonpbrbdgorarobv6eb5laely.atym5eb°wrwelfycohnhorytwyn5ibt%hsbaaycatmlthmobaeababndomcgoirnoloybegCosCtothoNfaNalbCFnlFaiNhnmthaiFbatedyodhcoaoaoaCmdfhNitmaighgFheheh(reiBecBgri-rha-CcCcleoNoCrNnFnNct)FtaoaFa,cncnwtbtdaihaocncnicotcgogmahlmlenmempgtteholhraeascaintanheltcsacCo,oniNpnmcrsFomomab(mCeaehr-bmrCcilcgyiNeiahardFllce)uCirC.aeNl CF.N. F. The chief reason for this improvement is the crystallinity of the B-CNF, which maintain The chief reason for this improvement is the crystallinity of the B-CNF, which maintains ThtoetchcThehiheifcgorhnetarascotrnynasnftfgoaolrerlitntwhiatiys orimemfdbpuacrmeodbvoewomitCheNnintFtcicrseoatmhshepedacrCreyNydsFtoalolclaoidnmintmtygyseorfcfrioatmhl eCe1NBt-Fo-C[5N6N%5F.]F.,T,Awhwephrlioiecwvhieomsmut saintains contTahcheteTachchnheigiecelfhef rirceofasmrsoeopansaforfoenrdrfttohthroiisstthihimimespicmrrompvremomvernmcntitaeiilnsstCtthihNseFtchc.rreyTyschstrteayalslclitoinanilitltiyayncoiotfyfattonhfegetlBehB-e-CvCBaNl-uCFe,N,swFsh,hiwiochwhimecmdhaimaintataiinintsasins a higher contact angle compared to the commercial CNF. The contact angle values showe a higher contact angle compared to the commercial CNF. The contact angle values showed a hrheipgohchroetnrsthaccotwnatenadgcltehawantagtshleoebcrcteoaimimnfepodracaretemd5d%etnoCttaNhbFeillcicotoyamdoifmnmCgeN. rTFchieaslbdCaemNpNebFno.odT-eChnhNeteoFcn-orenintistntafccocrtrytcasaetndaglgbllilineoicvtoyamlilnupdeoes-xshowed incraeaahsieaigihneiegtrrhceornbncittoaoacncottmacnptgoallesneigctceoloemsmcuporpfmarrcpedad’rstetowodteththtoeteatcbhcoiemlmictmoymwermrictciheiarlclcChiCaiNtNliCnF.Na.TnFhdh.eTCchcoNoenFcttao[a6cnct5ta]a.cnTtgahllenegvwvlaellutvuteaeslbsusislehihstoyoswheoedwd ed an increase in the biocomposite surface’s wettability with chitin and CNF [65]. The wetta a n i n c s i r t e e a s s h e a d i n a t g h r e e a b t i e o r c c o o mn t a p c o t s a i n t g e l e s u t h r a f a n c t e h ’ e s c w o m e t m t a e b r c i l i a i t l y C w N F i t h b i o c h c o i mt i n p o a s n i t d e s , C p N r o F b a [ b 6 l 5 y ] . d T u h e e w e t t a - an[1i8n]c.cTrehaiseisipnrtothbeabliyiowcohmy bpaomsibteoeosuCurNfaFchea’sdwa hetitgtahbeirilcitoynwtwacithancghlietitnhancdomCNmNeFrc[6i6a5l]C. TNThFe.e wetta- incraeanansiaeincwcrirenaeascasrsmeaioinsnreetthihnseitgbhbnieioioficbcociomamcnpoptmowsspiittotehessistutuherrefsfauaCcreNfe’a’ssFcwewt’hsetawttnaebtwitilaliitbttyhyilwitwthyiietthwhacidcthdiitictitihninoiatnainodafCnCcdNhNiCFtFiNn[[6,6F5p][].r6.oT5Tbh]h.aeTbwhwlyetwttae--tta- bilitytoitnhcerheiagsherwcraysstmalloinreitysiogfnbiafmicbaonotCwNitFhcothmepCarNedFtothcoamnmweirtchiatlhCeNaFd[d65it]i.oAnporefvcihouitsin, proba biTlihtye cinhcierferaesaesownafsormthoirseimsigpnroifviecmanetnwt isitthethceryCstNalFlinthitaynofwthitehBt-hCeNaFd,dwithiiocnh mofacinhtiatins, proba- becausebbiolilftiyttyhinieinccrpcrereaeasseseenwcaeassosmfmotohrrereshsisgiygndnirfiiofcixcaciandntetwgirtiohthutphtheeienCCNcNhFFiFtihtnhaananwdwitiththtehtheheyaadaddrdoditpiithoionilniocoffnfccahchtiutitrnien, ,pprrorobbaa-- biilliittyiincrreassewassmorressiigniiffiicanttwiitthttheCNFtthanwiitthttheaddiittiionoffchiittiin,,prroba-- report showed that the reinforcement ability of CNF is dependent on its crystallinity index balyhibghecear ucosnetaocft tahneglperceosmenpcaereodftoththeehcyodmrmoxeridciealgCrNouF.pTihne cohnitianctandglethvealhuyesdsrhoopwheildic natur bly because of the presence of the hydroxide group in chitin and the hydrophilic nature of CNF b[1ly8]b. eTcahauesceoonftathcteapnrgeslsenrcecesuolftsthaelshoycdororxoibdoeragtreodupthienrcehsiuitilintnsaonbdtatihnedhyfdrdoromophthhileic nature bllybleyecbaueucssaeuosfef ttohfetphprerepsserenenscenocfef ttohfethyeydhrryodxiridodexeigdgrerogurpouiinpcihnhiitctiihnitaindantthdethyeydhrryodprhoiiplliichcinlniacattunurareteure [18]. This is probably why bamboo CNF had a higher contact angle than commercial CNF. oafnCinNcFre[a1s8e]i.nTthebcioncotamcptoasnitgelesurrefsaucelt’swalestotacboilritryobwoitrhatcehdititnhaenrdesCuNltFs[o6b5]t.aTinhedwfertotam- theFT of CNF [18]. The contact angle results also corroborated the results obtained from the FT- FT-IR, wohfiCchNFsFh[o1w8]e.dThteheecopnrteascetnacnegolefrheysudulrltosxaildlseo(cOorHro)bionortahtedbtihoeceormespuoltsitoebstafrinonemedbfrotmh theFT- offCoNfNCFN[[1T1F8h][]e.1.Tc8Th]hi.eTf chrcoeoeansctotaoancnctftoarcnthgailsleneigrmrelepssruruoelvltstsesumalatlelsnsotoailcscsotrhrcerocbrbrroyosrrtbatolteleridnaditeythdeoeftrhrtehesesuruBellt-stCssuNolotbFbs,ttaowaibinhntieacedhidnmfefrrdaoimnfmrtaotithmnhesetFhFTeT--FT- bility increase was more significant with the CNF than with the addition of chitin, proba- IR, which showed the presence of hydroxide (OH) in the biocomposites from bot IR, which showed the presence of hydroxide (OH) in the biocomposites from both PLA/chIiRti,nwanhdicgchPeLrsAchoo/nwtcaheceitdtaintg/hleCecNopmFrepsaeaernmendcpetoleotoshf.e hchGoymednmreoerxrxacilidalyele,C(wN(OFhH.eTt)heieincronaththabecitobabcniogmclceopvmaolpsuioeotsesisithieseoswstfefirdlolom both IIR,,IwRw,hiwichicsshoswheoedwdetthdhethperrepsserenenscenocoeff hohyfydhrryodxiridodexeid((OeOH(O))Hiin) tithnhethbeiiocbcoiomcpopmosspiitotessitfefrsromfmrobmbotthbhoth bly because of the presence of the hydroxide group in chitin and the hydrophilic nature PLA/chitin and PLA/chitin/CNF samples. Generally, whether a biocomposite is still hy PLA/chitin and PLA/chitin/CNF samples. Generally, whether a biocomposite is still hy- hydrophPoLbAic/acinhsinbticianrseeasdnedoinnPthLietAsb/icohcnoitmtianpc/otCsaiNtneFgsulserafavmcaepl’uslewese.t[Gt5aeb6eni]nl.ietyrHawlolliywyth,ecwvhehihtrie,ntthahnedrrCeaNwbFiao[sc6co5oa]m.nTpihnoecswriteteattsiaise- still hy- PLAP/L/coAhfi/iCtctiiNhniFtain[n1d8da]nP.PTdLhAPe/Lc/coAhni/itctaiihncnti//tCaCinNg/CFlFeNsrsaeFasmuslpaptsmlleaspsl.s.loeGsce.eonGrereoerrabnaloelrlrya,t,lewlwdyh,hthewetethrerstrhuaeltrbsbioaiobcbctoaioimncepopdmofssrpioitotemesiitstshesestitFsiilTlsl-thilyl--hy- drophobic is based on its contact angle values [56]. However, there was an increase i drophbiolibtyicinicsrebaasseewdasomnoirtesscigonitfiaccatntawnigthlethveaCluNeFsth[5a6n]w. Hithotwheavdedr,ititohneorefcwhitains,apnroibnac-rease in in wettadbrioloiptyh.oWbicectitsabialisteydisonanitesscsoentaiaaclt parnogplervtyaluoufesp[o[5l6y6]m. HeHroicwmevaetrer,ritahlesrienwtweanasdeadn fionrcrease in drrodprhoIoRopb,bhiicwocbhiisiscbhbiasasshbedoadwsoeoedndnoiitthnssecictoposnrnecttsaoaecncnttcaeacntogfallenehgyvldaearlluovuxeaeisldsue[e[5s(6O][].5H.H6H)]o.oinwHwetoehvwverrb,v,ietothrch,oermtrehepewowrseaiatswessansfnroiainmncrirbeneoacatsrsheaisine in wettbalbyiblietcya.uWseeotftathbeilpitryesiesncaenoefstshenhtyiadlropxriodpeegrtoyupofinpcohliytimnaenridctmheahteyrdiraolpshiinlitcenadtuerdeforpack wettability. Wettability is an essential property of polymeric materials intended for pack- packaginwgPeLtattApapb/bcilihlilicitayiynt.ioWaWnedest.ttPtTaLbhbAiel/icbthyioiticisnoa/amCnNpeFossseieatnemt’isipalhlepysp.drGorpoepnpeerhrtoaylbloyifcf, pwpnoahltleyutmhmreerirsaicnbmeioeacadotemdrpiafolsritietnhtitesenswtdialeltdehryf-o- r pack- wetwttaebtitilaliitbtyil..iWtWy.eWtttaebtitilaliitbtyiliistsyains eaesnssensnsttieianlltpiparrlopreorrpttyerotfyfpofllypymomleyermriicemrmicatmterariitaellrssiaiinlnstteindtdendfefodrrfpoarcpka--ck- of CNF [18]. The contact angle results also corroborated the results obtained from the FT- aging applications. The biocomposite’s hydrophobic nature is needed for the water-repel aging applications. The biocomposite’s hydrophobic nature is needed for the water-repel- repellingagfduirnogcpthaiopnbpilcolicfcisathtbieoaosnpesad.cTkohanhgeietbsdiocopocrnotmadcupt coatsns[ig3tele]e.’sTvhahylyeuderrseos[pup5h6lht]oso. bHoifcotwnhaetvtauenr,eaetliyhsesnirseeoewdfdaeteshdeafnworientchtraebawisleiattytiener-repel- agiinangianapgppIpaRllpi,icpawalttihicioioacnhtsiso.s.nThTosh.weTebhbdieiotchbcoeiompcporpemosoesspniitcotes’’sisothefh’yshdydhrdryorodopxrhiodopebhi(icoOcbnHniac)ttuniunraretetuhiisresenbieisoencdoemedpfeofosdrirtftetohshreftrwhwomeatwteberaor--trhrerp-rell-p- el- ling function of the packaged product [3]. The results of the analysis of the wettabilit ling function of the packaged product [3]. The results of the analysis of the wettability propertileinsnwgoetftuauthbnieclitbiyoi.onWcoefmfttatphboeielsitpipytaeicskasanhgoewsdsepndrtriotahdl aputrcotph[e3r]tw.yTaohtfheperorleyesmpueltrtlsisecnomcfeatheorefiaPalsnLnaiaAnlytyewsniadsseodrfeftothareiepnawewcdke-ttability lliinglinffugnfcuPttinLiocAnt/icohnfifttitonhfeaentphdpaeaPcpLkAacg/gckeheadidgtipnepd/rCroNpdrFuocscdattum[[3cp3t]l].e.[sT3T. ]hGh. eTnrhrersasulrulelylts,tssuwolohtfsfetthohefertahanebnaiaoallycnyosasmilisyspsoisfsfitetohfiesetswhwtieleltwthtayaeb-btitilaliitbtyility properties of the biocomposites showed that the water repellence of PLA was retaine praogpinegrtaiepsploicfatihoensb. iTohceobmiopcosmitpeossisthe’oswhyedrothpahtobthicenwatuarterisrneepeedlelednfcoer tohfe PwLaAterw-reapselr-etained despite tphreopapdederdrtotipteihsoonoboifoctftihsCebNabsFieodfcoornmthiptesoecsonitntcethsascastsnhaconoewgwmledvnattltuhoheafastm[t5eh6ce]e.hHwawnoaiwtcearvlersrrete,rptehenelglrletnhwc[eae1s8oa]f.nPinLcAreawseaisnretained properties of the biocomposites showed that the water repellence of PLA was retained prropreorrpttiiersstioeofsf ttohfetbhbieiocbcoiomcpopmosspiitotessitseshsoswheoedwd tethdhathttahtetwhweatwterartrrerprellplenlclcenocofef PoLfLAPLwAasws raresttarieinteaedidned dliensgpiftuentchtieonadodf itthioe npaocfkCagNeFd fporrodthuecte[n3c].hTahnecermesuenltts of mthecahnaanlyicsaisl ostfrtehnegwthet[t1a8b]i.lity despiwtetthabeilaitdyd. WitieottnaboiflitCyNisFanfoersstehnetiaelnpcrhopanerctyemofepnotlyomf emrieccmhatneriicaalsl isnttrendgetdhfo[1r 8p]a.ck- despite the addition of CNF for the enchancement of mechanical strength [18]. dessdpeiitsteptiththetahadedaiidttiidonintiofnfCoNfNCFNffoFrrfttohretehenecehnacnhcaenmcenmntteonfftmofecmcheacnhiicacanallicssattrlresntgrgettnhg[[t1h8][].1. 8]. properties of the biocomposites showed that the water repellence of PLA was retained Table 1. Contact angginlegsaopfpbliacmatiboonos.aTnhdecboiomcmomerpcoisailteC’sNhFydbirocpohmobpiocsniatetus.re is needed for the water-repel- Tabdles1pl.iiCntgeontfhutaencattdiaodnigtoiloefsnthoeff bpCaNmckFbaofgoerdatnhpderoecdnoucmchtma[n3ec]r.ecmTiahleenCtrNeosFfumbltiseocochof amtnhpeicoaslnitsaetlryse.snisgothf t[h1e8]w. ettability Table 1. Contact angles of bamboo and commercial CNF biocomposites. Table 1. Contact angles of bamboo and commercial CNF biocomposites. Filler TabTlleaeb1.l.eC1o.nCttaoacncttancntgallenessgoloeffsboafmbbaomoobaonodacncodmcmommerrmcciiaearllcCiaNl FCFNbiiFoccboimomcpopomossipitteoes.i.tes. propertiesCoofntthaectbAioncogmlepfosritesshowedthatthewaterrepellencCeonftPaLctAAwnagslereftoarined Droplet Image PLEAm/bCehdidtiend Ewmithbedded Droplet Image EmbPeLdAde/Cd hwiittihn Embedded Droplet Image PLA/Chitin Embedded Droplet Image PLA/Chitin Embedded ConteFnitlslser DropletImage PLACAo/CnthaictinAnnEgmlebfeodrded DropletImage CoPnPLtLaAct/ACnhgitlieinfoErmbedded Contents ConCnttoenttsesnts DrroDprlloetpt IlIemt aIagmgeage PLAP/L/CAh/iCittihinitEinmEbmedbdeeded DrroDprlloetpt IlIemt aIagmgeage PLAP/L/CAh/iCittihinitEinmEbmedbdeeded C-CNF (θ) (wt.%) B-CNF (θ) with B-CNF (θ) with C-CNF (θ) (wt.%) with B-CNF (θ) with C-CNF (θ) (wtC.%on)tents Droplet Image Droplet Image PLAw/CiththitBiBn-CEmNbFe(d(θd)ed wiittwhiBth--CBN-CFN((θF))(θ) Droplet Image Droplet Image PLA/ChitwiwniEthmCbe-CdCdNeFdF (θ) wiittwhiCth--CN-CFN((θF))(θ) ((wtt(..%w%t)).%) (wt.%) Table 1. Contact angles of bamboo and commercial CNF biocomposites. Filler Contents Contact Angle for Contact Angle for P90/10 (wt.%) P90/P190/10 with B-CNF (θ) P90/10 P90P//1910/10 78.80° ± 0.23 d P90/10 P90/10 ◦dd 7w8i.78t8h0.8B±0-C°0N±.2F03.(2θ3)d 78.80° ± 0.23 d with C-CNF (θ) 78.80° ± 0dd.23d 78.P.878L080A°.°8/±C±0h0°0.i±.2t2i3n03.E2m3 bedded PLA/Chitin Embedded with C-CNF (θ) 78.80° ± 0.23 d 74.24° ± 0.18d 74.2◦4° ± 0.18d d de 73.70° ± 0.22de 73.70° ± 0.22 de 7474.424.2.4.24°±°±±0.0.01.d1d.8.8188dd 74..24°°±0..18 d 73.70°d±e 0dd.e.e22de 737.7370.373◦.0.7±°030±°0.°70.±2±0.20°02.d±.2e202.22 90/10/1 74.24° ± 0.18 d 73.70° ± 0.22 de cc 69.80° ±690.2840° ± 0.24c 69.80° ± 0.24 c 90/10/1 90/10900/1/10/1 90/1910/10/1 90/10/1 90/10/3 90/10/3 90/10/3 90/1910/3130/3 Molecules 2021, 26, x FOR PEER REVIEW MoleMcuollescu2l0e2s12,02261,,x2F6,OxRFPOEREPREREERVRIEWVIEW 18 of 23 Molecules 2021, 26, x FOR PEER REVIEW 90/190//510/5 9900//190/510/5 18 o1f82o3f 23 18 of 23 c 770.08.08°0±° 0±.207.27c 70.80° ± 0.27 c 69.80° ± 0cc.24c 69..868090°.°8±00°0.±.2404.24 90/10/3 90/10/3 70.8◦0° ± 0cc.2c7c 70..8780.°8.°80±00°0±.±.2707.2.277 c c 69.80° ± 0.24 c 70.80° ± 0.27 69.80 ◦ ± 0.24 c a 66.8◦0° ± 0.a2a7a a 65.80° ± 0.b20 b 65.860◦5°.8±6050°.82±00°b.±20.20 b 666.6860.6.8°.08±°0±0°±.±20.7.2027.727 65.80 ± 0.20 Mean values with the different superscript a–e indicates significant different p > 0.05. Mean values with the different superscript a–e indicates significant different p > 0.05. MeaMnevaanluveasluweisthwtihthe tdhieffedrieffnetresuntpseurspcerripsctraip–et ain–edicnadteicsastiegsnsiifgicnainfitcadniftfedrieffnetrepn>t 0p.0>50. .05. Mean values with the different superscript a–e indicates significant different p > 0.05. 3. Materials and Methods 3. Materials and Methods 3. M3.aMteraitaelrsialnsdanMdeMtheotdhsods 3.1. Materials 3.1. Materials 3.1.3M.1.atMeraiatelsrials The PLA was obtained from Sigma Aldrich, Pasir Pan-jang Rd, Singapore. The prop- The PLA was obtained from Sigma Aldrich, Pasir Pan-jang Rd, Singapore. The prop- eTrthieTsPhoLfeAtPhLewAparsawcoatbisctaolibngtreadidneferdPoLmfAroS4mi0g4mS3iDagmAwaledrAeril5cd3hr,MicPhPa,asPi(rtaePsniasrnilP-ejasntr-gejanRnggdth,R)Sdain,dgSai1np.2go4arp(es.opTreehc.iefTicphreopr-op- erties of the practical grade PLA 4043D were 53 MPa (tensile strength) and 1.24 (specific gravity). The chitin’s practical grade (90% deacetylated) was purchased from Biobasic, ertierstioefstohfetphreapctriaccatlicgarlagdreaPdLeAPL4A04430D43wDerwee5r3eM53PMa (Ptaen(steilnessilteresntrgetnhg) tahn)dan1.d241.(2s4pe(scpifeicific gMraavlaitys)i.a.TThheecChNitiFnw’sapsrparcetpicaareldgrfraodmeb(9a0m%bodoe,acnedtyalactoemdm)ewrcaisalpCuNrcFhwasaesdobfrtoaimnedBiobasic, gragvritayv)i.tyT)h. eTchheitcihni’tsinp’rsapctriaccatlicgarlagdread(9e0%(90d%eadcetaycleattyelda)tewd)aswpaus rpchuarcshedasefrdomfroBmioBbaiosbica,sic, from the cellulose lab, Canada, as a standard reference to verify the viability of the isola- Malaysia. The CNF was prepared from bamboo, and a commercial CNF was obtained MaMlayaslaiay.sTiah.eTCheNCFNwFaswparsepraerpedarefrdomfrobmambbaomob,oaon,danadcoamcmomermciearlciCaNl CFNwFaswoabstaoibnteadined tion technique. from the cellulose lab, Canada, as a standard reference to verify the viability of the isola- fromfrotmhe tcheellcuelloluselolsaeb,laCba,nCaadnaa, daas,astansdtanrdaredferreefnercentcoevteorivfeyritfhye tvhieabvilaitbyiliotfytohfe tihseolias-ola- tion technique. t i o n t i t o e n c h t e n c i hq un i e q . u e . 3.2. The Isolation and Characterisation of Cellulose Nanofibrillated Fibre from BambooPDF Image | Supercritical Carbon Dioxide Isolation of Cellulose Nanofibre

PDF Search Title:

Supercritical Carbon Dioxide Isolation of Cellulose NanofibreOriginal File Name Searched:

molecules-26-05276-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |