PDF Publication Title:

Text from PDF Page: 017

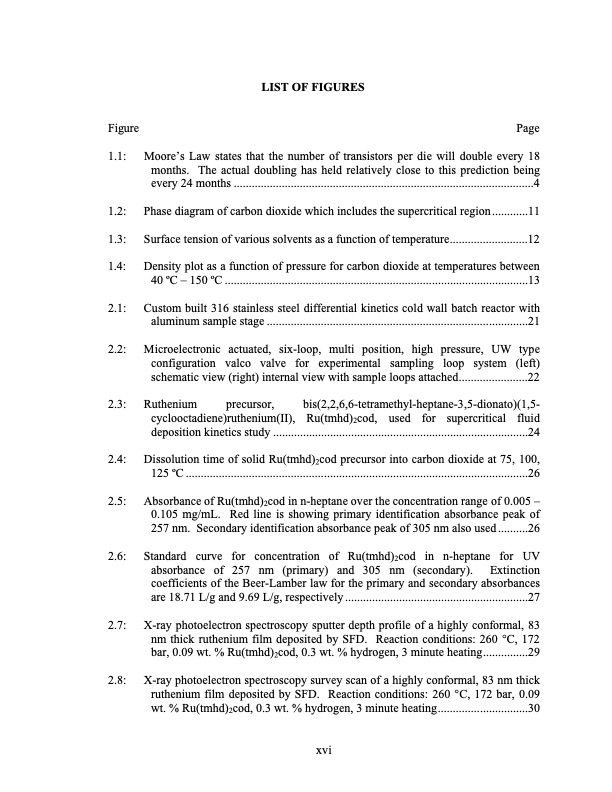

LIST OF FIGURES Figure Page 1.1: Moore’s Law states that the number of transistors per die will double every 18 months. The actual doubling has held relatively close to this prediction being every 24 months ....................................................................................................4 1.2: Phase diagram of carbon dioxide which includes the supercritical region............11 1.3: Surface tension of various solvents as a function of temperature..........................12 1.4: Density plot as a function of pressure for carbon dioxide at temperatures between 40 oC – 150 oC .....................................................................................................13 2.1: Custom built 316 stainless steel differential kinetics cold wall batch reactor with aluminum sample stage .......................................................................................21 2.2: Microelectronic actuated, six-loop, multi position, high pressure, UW type configuration valco valve for experimental sampling loop system (left) schematic view (right) internal view with sample loops attached.......................22 2.3: Ruthenium precursor, bis(2,2,6,6-tetramethyl-heptane-3,5-dionato)(1,5- cyclooctadiene)ruthenium(II), Ru(tmhd)2cod, used for supercritical fluid deposition kinetics study .....................................................................................24 2.4: Dissolution time of solid Ru(tmhd)2cod precursor into carbon dioxide at 75, 100, 125 oC ..................................................................................................................26 2.5: Absorbance of Ru(tmhd)2cod in n-heptane over the concentration range of 0.005 – 0.105 mg/mL. Red line is showing primary identification absorbance peak of 257 nm. Secondary identification absorbance peak of 305 nm also used ..........26 2.6: Standard curve for concentration of Ru(tmhd)2cod in n-heptane for UV absorbance of 257 nm (primary) and 305 nm (secondary). Extinction coefficients of the Beer-Lamber law for the primary and secondary absorbances are 18.71 L/g and 9.69 L/g, respectively .............................................................27 2.7: X-ray photoelectron spectroscopy sputter depth profile of a highly conformal, 83 nm thick ruthenium film deposited by SFD. Reaction conditions: 260 °C, 172 bar, 0.09 wt. % Ru(tmhd)2cod, 0.3 wt. % hydrogen, 3 minute heating...............29 2.8: X-ray photoelectron spectroscopy survey scan of a highly conformal, 83 nm thick ruthenium film deposited by SFD. Reaction conditions: 260 °C, 172 bar, 0.09 wt. % Ru(tmhd)2cod, 0.3 wt. % hydrogen, 3 minute heating..............................30 xviPDF Image | Supercritical Fluid Deposition Of Thin Metal Films

PDF Search Title:

Supercritical Fluid Deposition Of Thin Metal FilmsOriginal File Name Searched:

Supercritical-Fluid-Deposition-Of-Thin-Metal-Films-Kinetics-Mec.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |