PDF Publication Title:

Text from PDF Page: 067

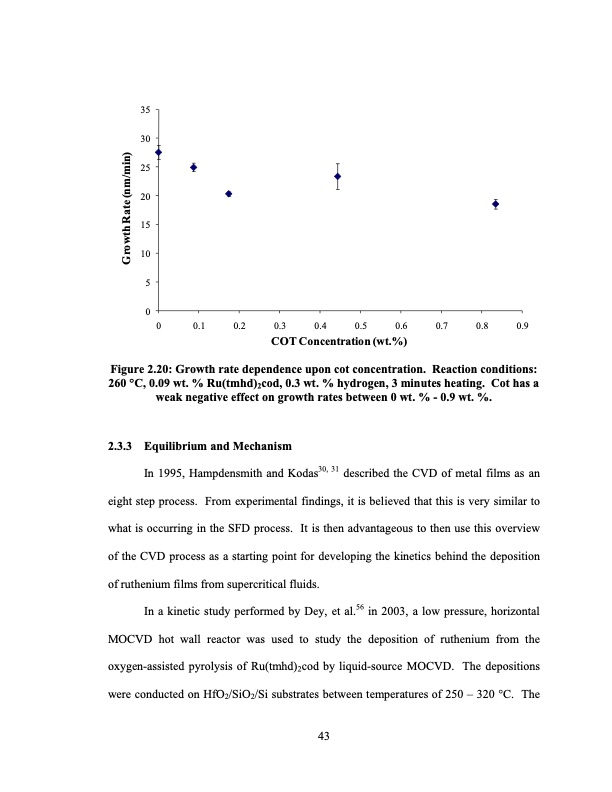

35 30 25 20 15 10 5 0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 COT Concentration (wt.%) Figure 2.20: Growth rate dependence upon cot concentration. Reaction conditions: 260 °C, 0.09 wt. % Ru(tmhd)2cod, 0.3 wt. % hydrogen, 3 minutes heating. Cot has a weak negative effect on growth rates between 0 wt. % - 0.9 wt. %. 2.3.3 Equilibrium and Mechanism In 1995, Hampdensmith and Kodas30, 31 described the CVD of metal films as an eight step process. From experimental findings, it is believed that this is very similar to what is occurring in the SFD process. It is then advantageous to then use this overview of the CVD process as a starting point for developing the kinetics behind the deposition of ruthenium films from supercritical fluids. In a kinetic study performed by Dey, et al.56 in 2003, a low pressure, horizontal MOCVD hot wall reactor was used to study the deposition of ruthenium from the oxygen-assisted pyrolysis of Ru(tmhd)2cod by liquid-source MOCVD. The depositions were conducted on HfO2/SiO2/Si substrates between temperatures of 250 – 320 °C. The 43 Growth Rate (nm/min)PDF Image | Supercritical Fluid Deposition Of Thin Metal Films

PDF Search Title:

Supercritical Fluid Deposition Of Thin Metal FilmsOriginal File Name Searched:

Supercritical-Fluid-Deposition-Of-Thin-Metal-Films-Kinetics-Mec.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |