PDF Publication Title:

Text from PDF Page: 083

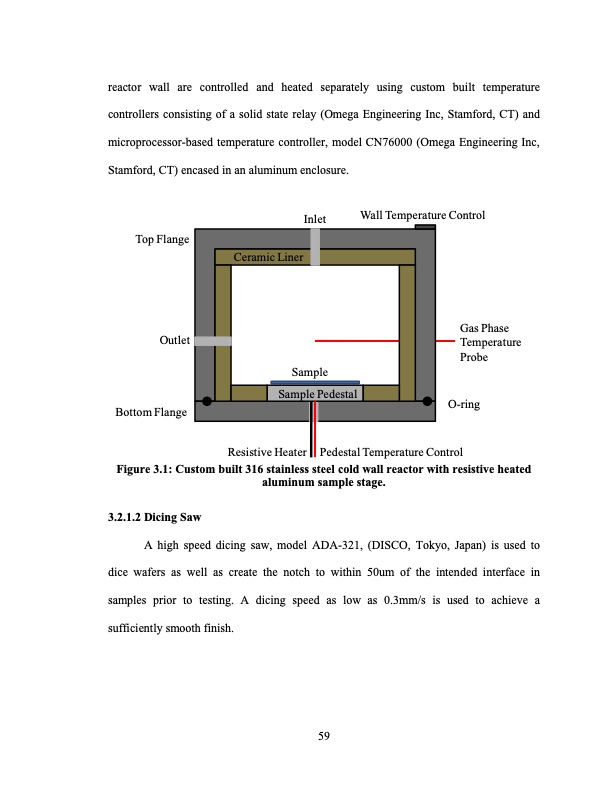

reactor wall are controlled and heated separately using custom built temperature controllers consisting of a solid state relay (Omega Engineering Inc, Stamford, CT) and microprocessor-based temperature controller, model CN76000 (Omega Engineering Inc, Stamford, CT) encased in an aluminum enclosure. Inlet Wall Temperature Control Gas Phase Temperature Probe O-ring Pedestal Temperature Control Ceramic Liner Sample Sample Pedestal Top Flange Outlet Bottom Flange Resistive Heater Figure 3.1: Custom built 316 stainless steel cold wall reactor with resistive heated aluminum sample stage. 3.2.1.2 Dicing Saw A high speed dicing saw, model ADA-321, (DISCO, Tokyo, Japan) is used to dice wafers as well as create the notch to within 50um of the intended interface in samples prior to testing. A dicing speed as low as 0.3mm/s is used to achieve a sufficiently smooth finish. 59PDF Image | Supercritical Fluid Deposition Of Thin Metal Films

PDF Search Title:

Supercritical Fluid Deposition Of Thin Metal FilmsOriginal File Name Searched:

Supercritical-Fluid-Deposition-Of-Thin-Metal-Films-Kinetics-Mec.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |